Combined catalyst and method for producing C5 and C6

A combined catalyst and catalyst technology, applied in the hydrogenation of C6 and C5 fields, can solve the problems of mesopores without structure and reduce interaction, etc., and achieve high yield and high octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

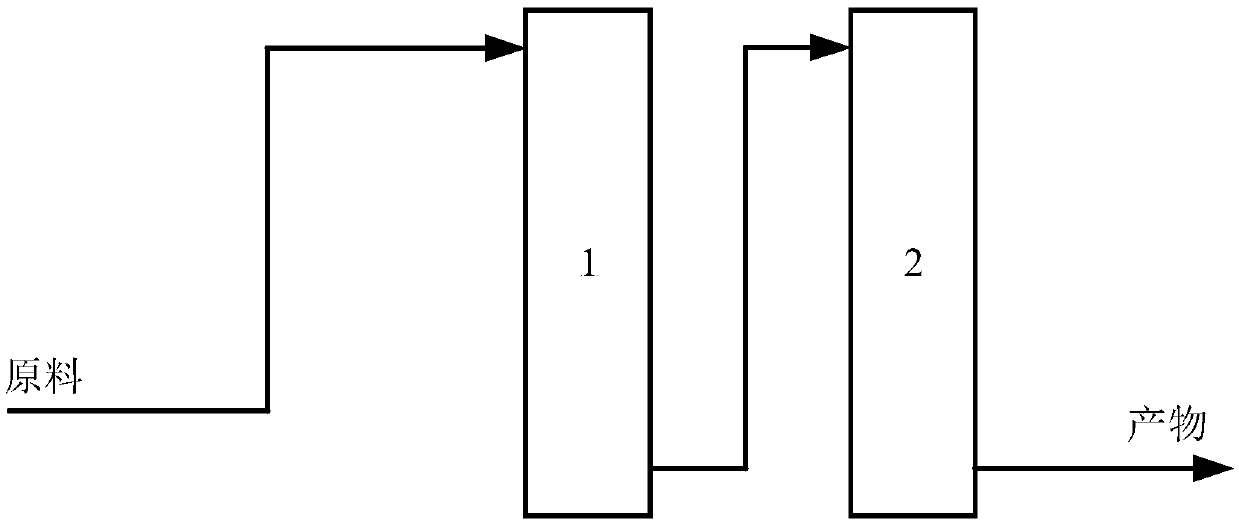

Image

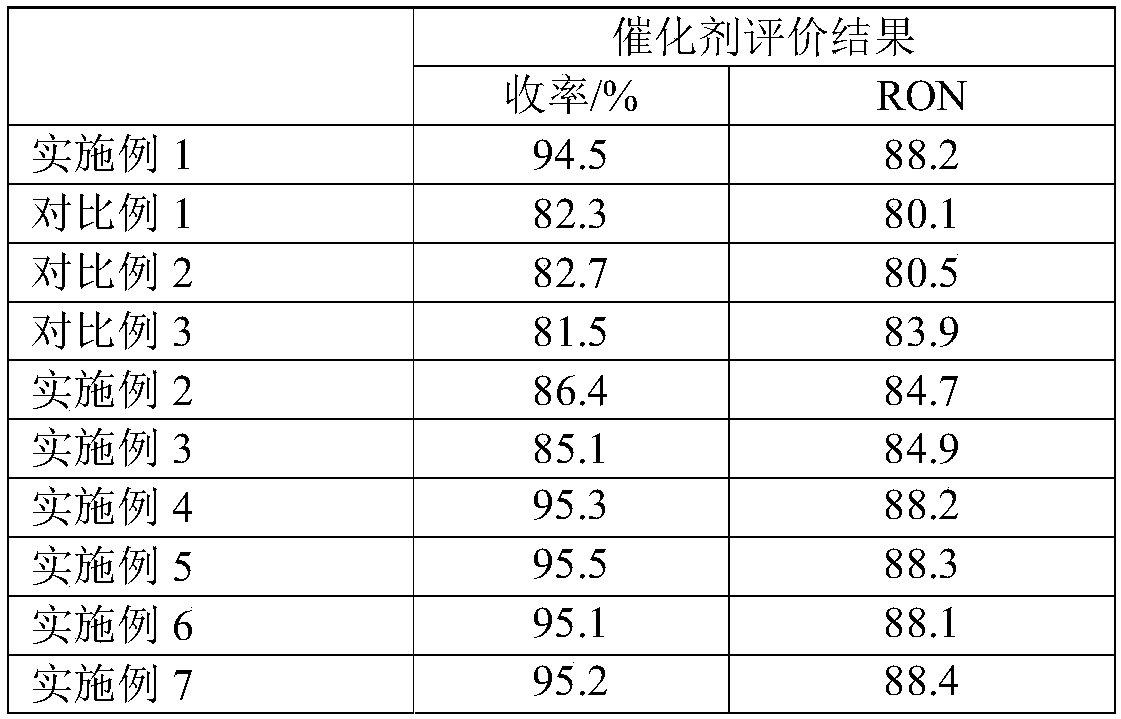

Examples

preparation example Construction

[0063]In the present invention, the mother liquor after crystallization can be prepared according to conventional methods in the art, for example, when the ten-membered ring molecular sieve is ZSM-22 molecular sieve, the preparation method of the mother liquor after crystallization can refer to document O. Muraza et al., Microporous and Mesoporous Materials 206(2015) 136–143. When the ten-membered ring molecular sieve is ZSM-48 molecular sieve, the preparation method of the mother liquor after crystallization can refer to the literature P.Me'riaudeau et al / Journal of Catalysis, 1999 (185), 435-444, or refer to the US patent application US5961951. In one embodiment, the preparation process of the crystallized mother liquor includes: preparing a silicon-containing solution, an aluminum-containing solution, and an alkaline liquid, mixing the above-mentioned liquids to form a gel, and then performing crystallization at a certain temperature.

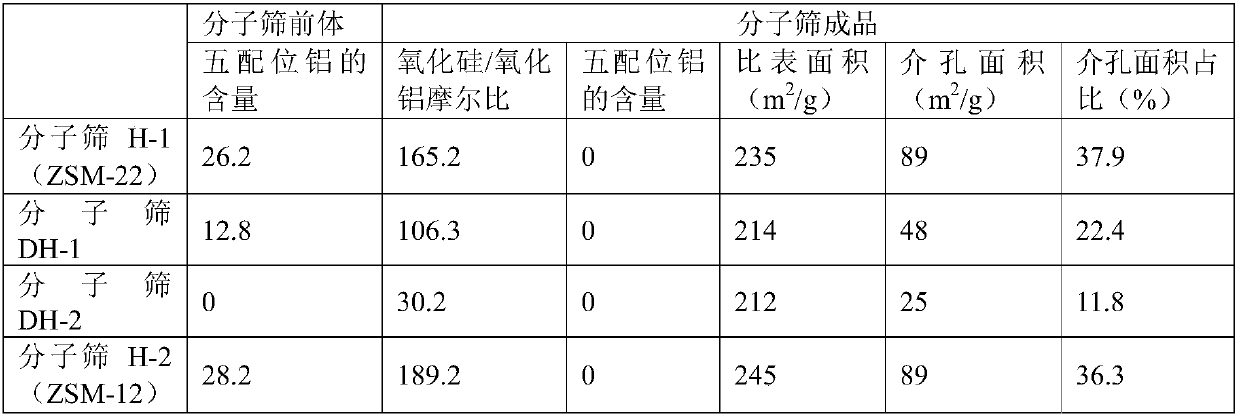

[0064] In the combined catalyst of t...

preparation example 1

[0082] (1) Preparation of mother liquor after crystallization

[0083] Take 36.3 grams of SiO containing 40% by weight 2 silica sol, 1.77 g of analytically pure Al 2 (SO 4 ) 3 18H 2 O, 3.94 grams of analytically pure KOH and 8.44 grams of hexamethylenediamine are ready for use. Hexamethylenediamine was mixed with silica sol, KOH and Al 2 (SO 4 ) 3 18H 2 O and 89.4 grams of deionized water were mixed, and then the two solutions were mixed, stirred for 1 hour, then transferred to a reaction kettle, and crystallized at 160° C. for 72 hours.

[0084] (2) Preparation of filter cake

[0085] Filter the mother liquor after crystallization prepared in the operation (1), and continue suction filtration for 5 minutes when there is no filtrate on the filter cake, and obtain the filter cake F-1, which has a dry basis content of 11.2 % by weight and a silica / alumina molar ratio of 60.

[0086] (3) Preparation of molecular sieve precursor

[0087] The filter cake F-1 was raised ...

preparation example 2

[0097] (1) Preparation of mother liquor after crystallization

[0098]Take 38.5mL containing 40% by weight of SiO 2 Silica sol, 1.48 grams of analytically pure sodium aluminate, and 17.5 mL of tetraethylammonium hydroxide (40% by weight) were used. Mix tetraethylammonium hydroxide, sodium aluminate and 37 grams of deionized water, then add silica sol, stir for 1 hour, then transfer to a reaction kettle, and crystallize at 160°C for 132 hours.

[0099] (2) Preparation of filter cake

[0100] Filter the crystallized mother liquor prepared in step (1), count as there is no filtrate on the filter cake, continue suction filtration for 5 minutes, obtain filter cake F-2, and the dry basis content of the filter cake F-2 is 11.2 % by weight and a silica / alumina molar ratio of 40.6.

[0101] (3) Preparation of molecular sieve precursor

[0102] The filter cake F-2 was raised from room temperature to 450° C. at a heating rate of 25° C. / minute, and kept at a constant temperature for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com