Patents

Literature

35 results about "Rubidium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubidium fluoride (RbF) is the fluoride salt of rubidium. It is a cubic crystal with rock-salt structure. There are several methods for synthesising rubidium fluoride.

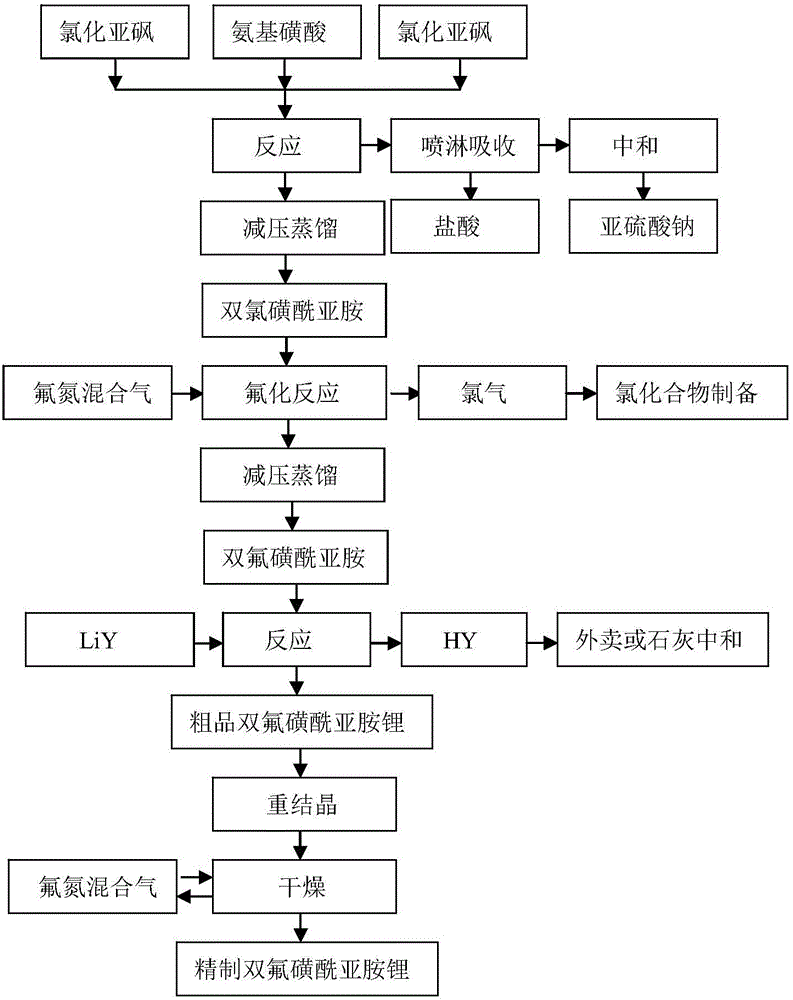

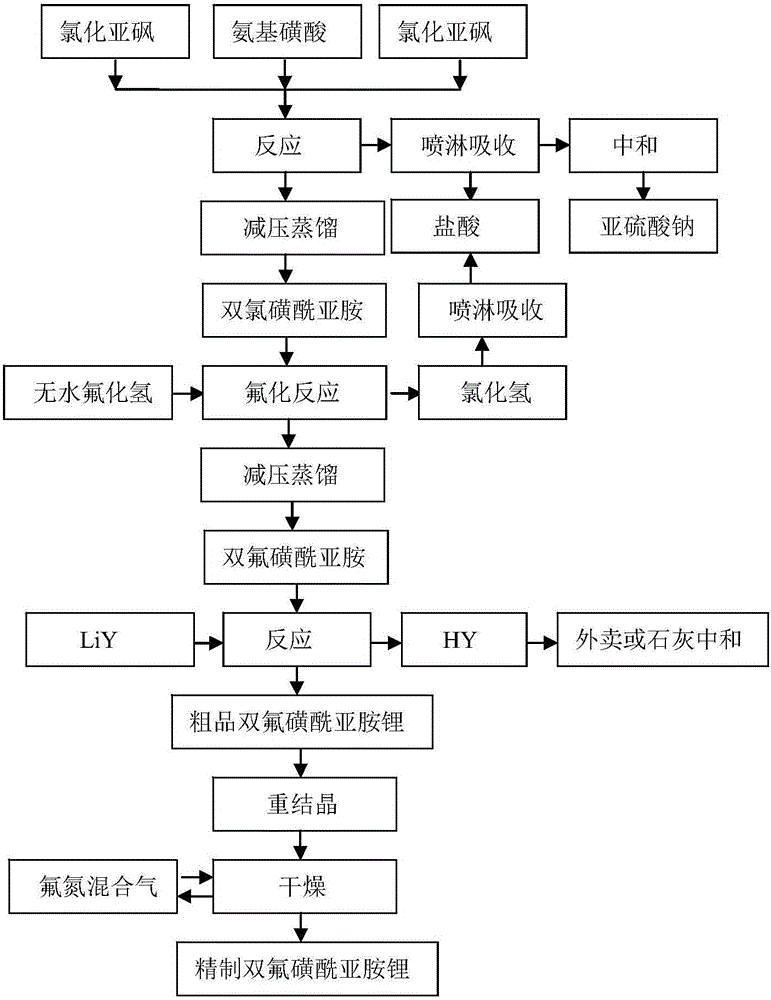

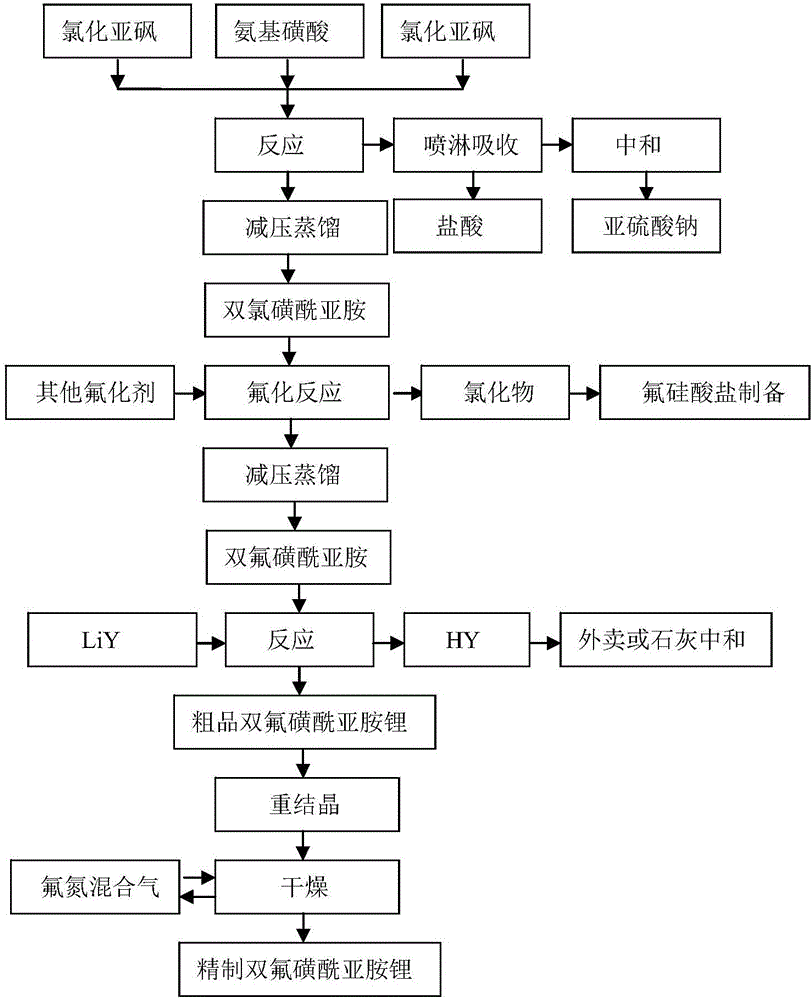

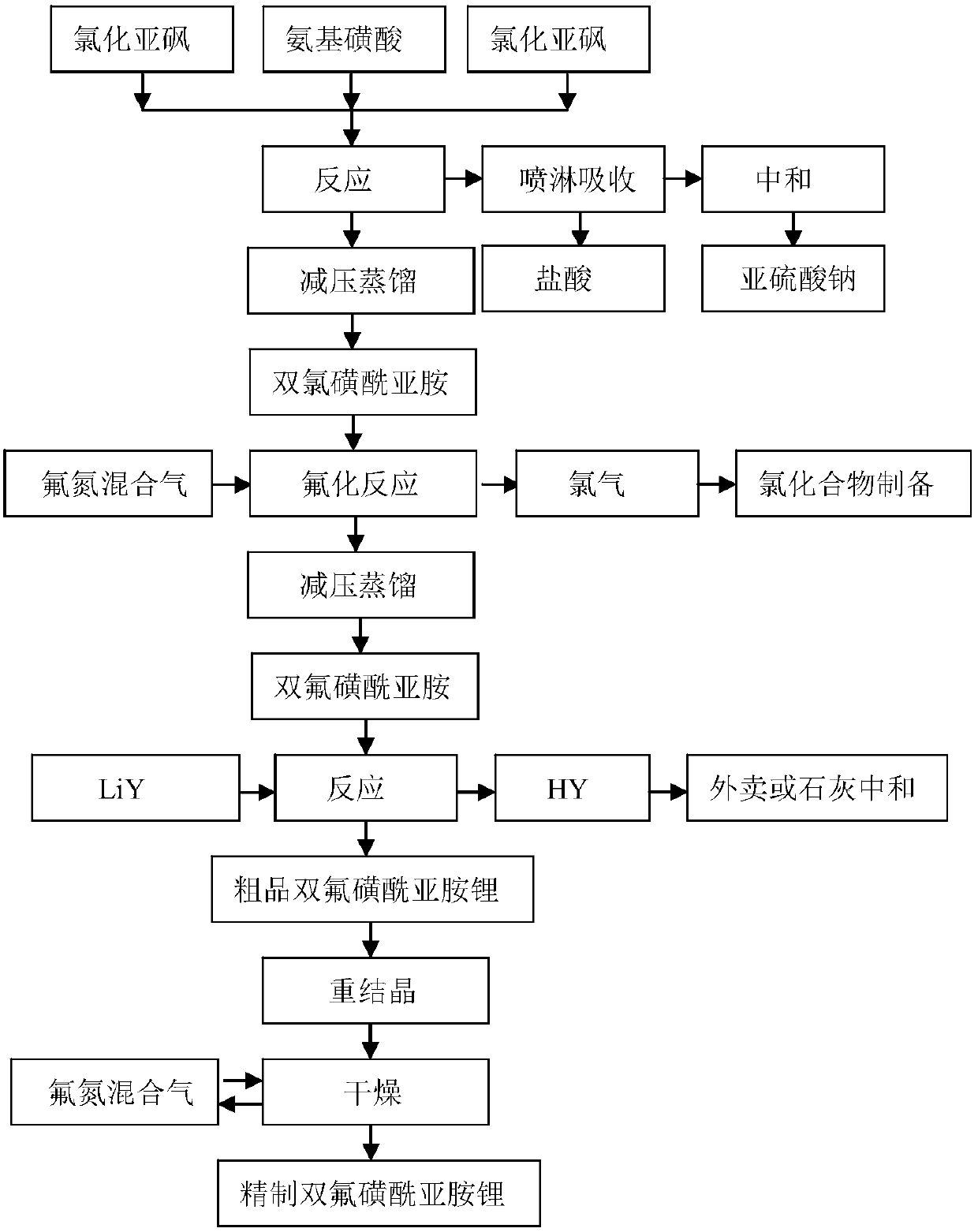

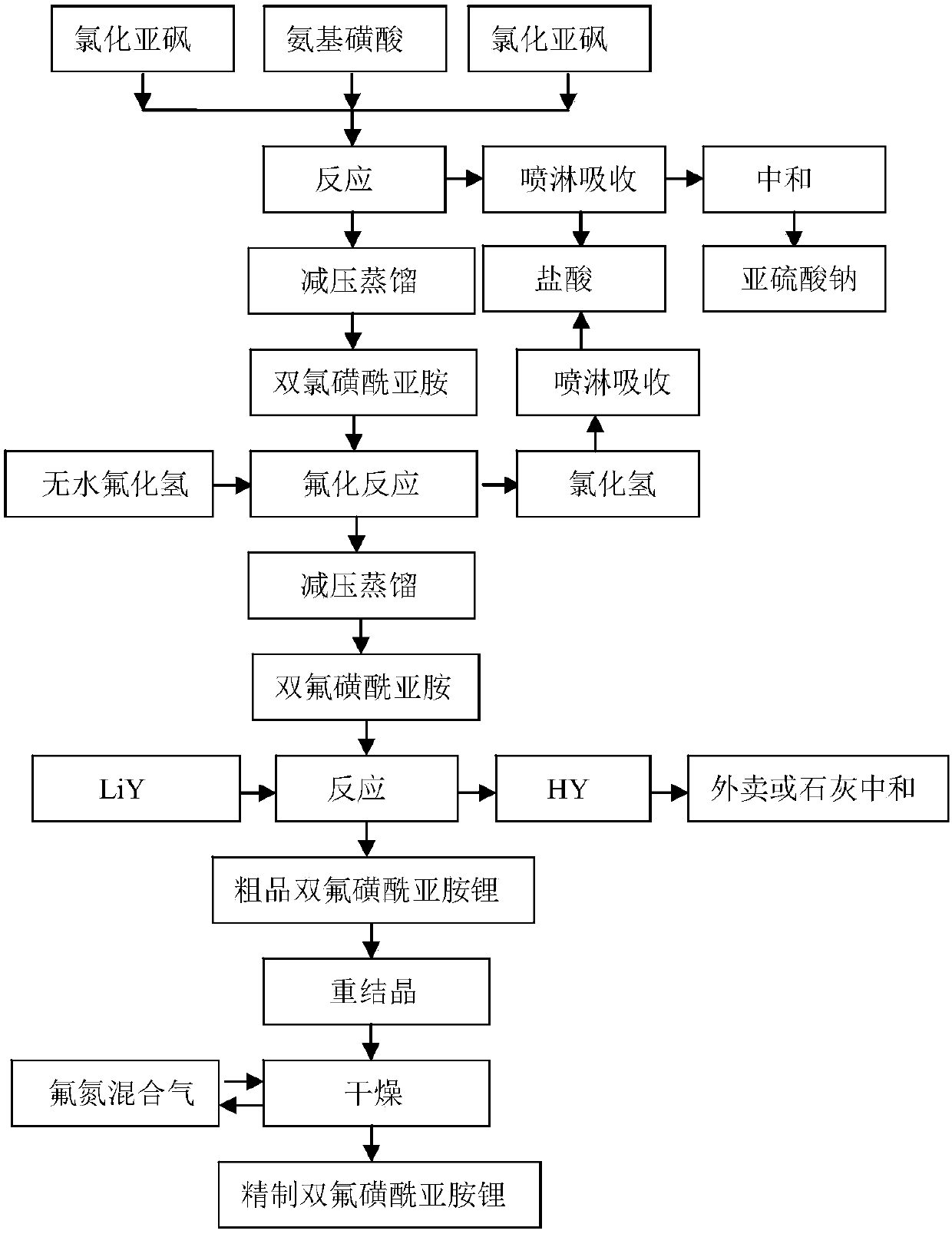

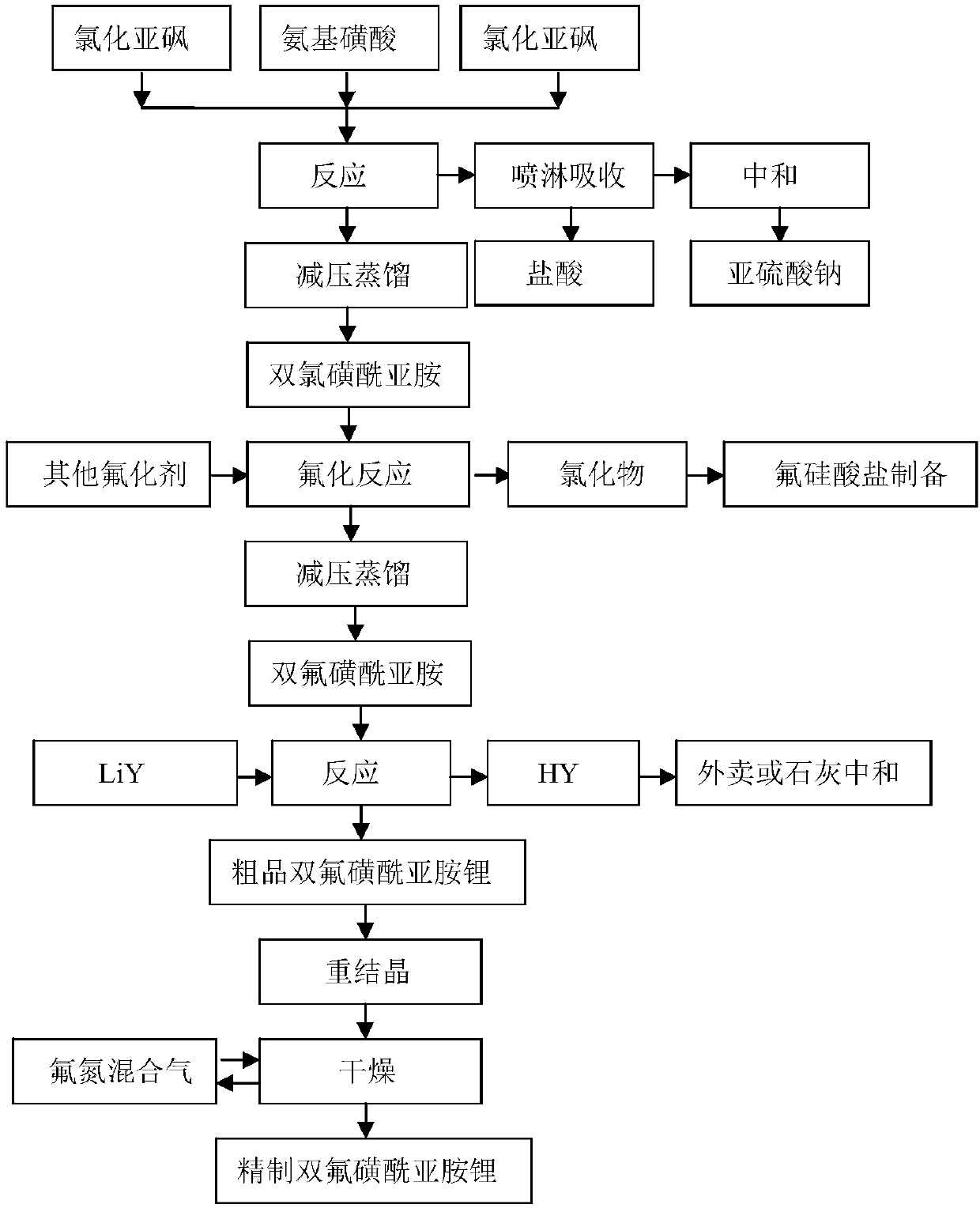

Preparation method of difluoro-sulfonyl imide lithium

The invention discloses a preparation method of difluoro-sulfonyl imide lithium. The preparation method comprises the following steps: 1) under a protective atmosphere, adding a fluorizating agent into difluoro-sulfonyl imide to perform a fluorination reaction so as to obtain a mixture, wherein the fluorizating agent is one of or a combination of fluorine, a fluorine-containing mixed gas, anhydrous hydrogen fluoride, potassium fluoride, antimonic fluoride and rubidium fluoride; 2) performing reduced pressure distillation on the obtained mixture to obtain a di(fluoro-sulfonyl) imide intermediate; and 3) under a protective atmosphere, performing synthetic reaction on the obtained di(fluoro-sulfonyl) imide intermediate and a lithium source, and performing solid-liquid separation to obtain difluoro-sulfonyl imide lithium. According to the preparation method disclosed by the invention, the fluorination reaction does not need a solvent or other auxiliary agent, is less in types of adopted reagents, does not introduce a new impurity, is simple in operation, and is easy to control; the method is less in side reaction, good in fluorination effect and low in fluorination cost; and the purity and the yield of the product namely difluoro-sulfonyl imide lithium obtained by a subsequent synthetic reaction are improved on the whole, and the method has good economic and environmental benefits.

Owner:DO FLUORIDE CHEM CO LTD

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559AImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

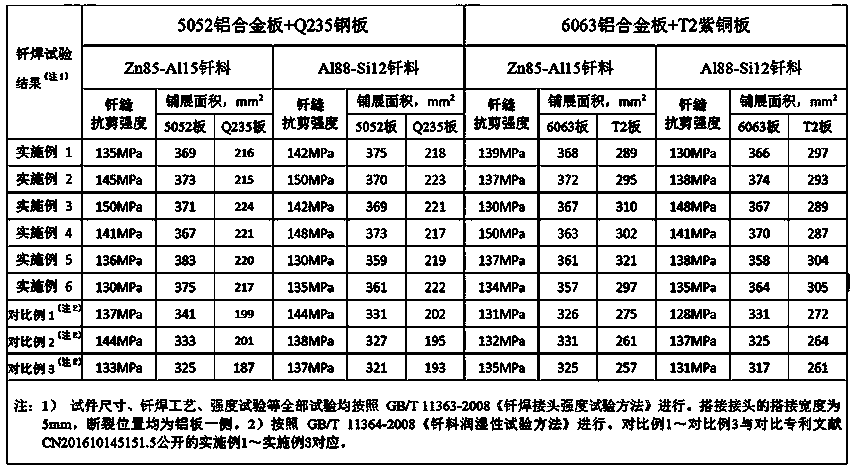

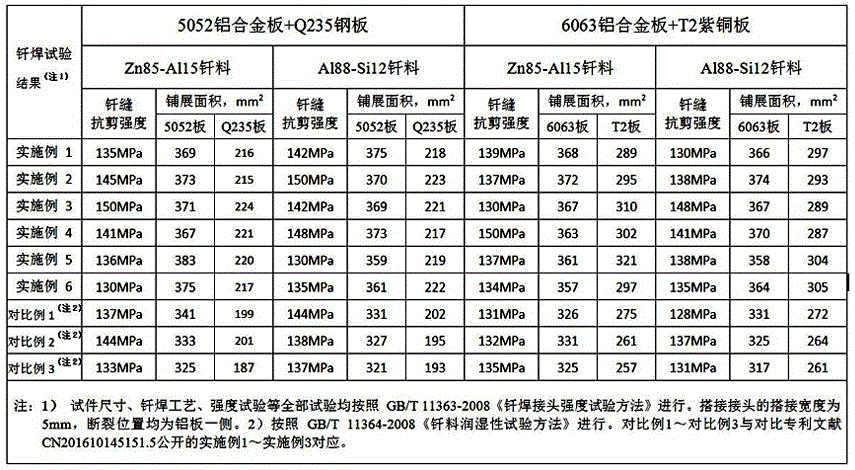

Brazing aluminum steel and cesium and rubidium containing brazing flux thereof

ActiveCN103909359ALow costImprove reliabilityWelding/cutting media/materialsSoldering mediaAluminum fluorideRubidium

The invention relates to brazing aluminum steel and a cesium and rubidium containing brazing flux thereof and belongs to the field of brazing materials in non-metal materials. The brazing flux comprises, by a mole ratio, 0.01 mol to 0.56 mol of rubidium fluoride (RbF), 0.15 mol to 0.58 mol of cesium fluoride (CsF), 0.001 mol to 0.25 mol of aluminum oxide (Al2O3), 0.001 mol to 0.2 mol of potassium fluoride (KF), 0.002 mol to 0.05 mol of gallium fluoride (GaF3), 0.001 mol to 0.025 mol of lithium fluoride (LiF), 0.001 mol to 0.025 mol of boron fluoride (BF3), and the balance aluminum fluoride (AlF3). According to the brazing aluminum steel and a cesium and rubidium containing brazing flux thereof, brazing technical requirements of aluminum to aluminum, aluminum to copper, and aluminum to steel can be simultaneously met, and the high-activity novel soldering flux is achieved.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

Caesium rubidium soldering flux containing gallium oxide

ActiveCN104551450ASatisfy brazing requirementsGood spreadabilityWelding/cutting media/materialsSoldering mediaRubidiumAluminium fluoride

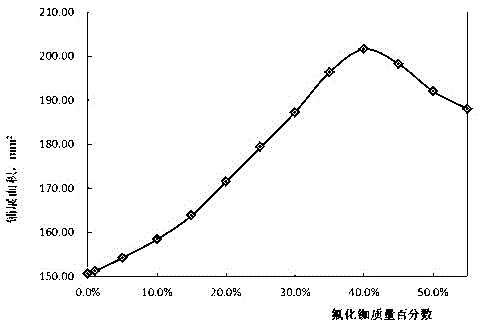

The invention discloses a caesium rubidium soldering flux containing gallium oxide, belonging to the brazing material field of non-metallic materials. The caesium rubidium soldering flux containing gallium oxide is characterized in that the caesium rubidium soldering flux containing gallium oxide comprises the following components in proportion in mole number: 0.12-0.5 mole of rubidium fluoride (RbF), 0.12-0.5 mole of cesium fluoride (CsF), 0.001-0.2 mole of aluminium oxide (Al2O3), 0.001-0.02 mole of potassium fluoride (KF), 0.0001-0.02 mole of gallium oxide (Ga2O3), and 0.159-0.479 mole of aluminium fluoride (AlF3). According to the caesium rubidium soldering flux containing the gallium oxide, the requirement on brazing the aluminium-copper, the aluminium-steel and the aluminium-aluminium can be satisfied simultaneously and the caesium rubidium soldering flux containing gallium oxide has high activity.

Owner:ZHEJIANG YONGWANG WELDING MATERIALS CO LTD

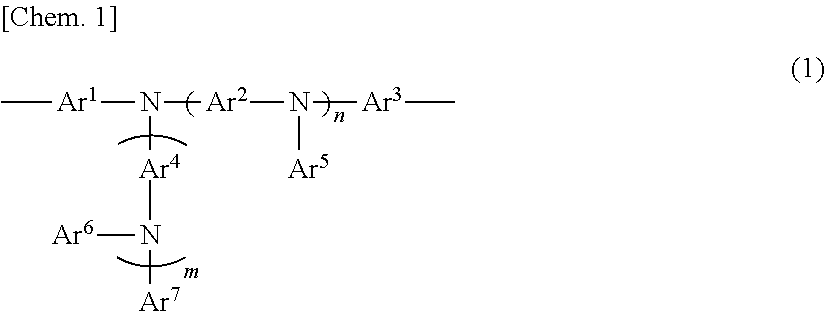

Polymer light emitting element

InactiveUS20130033173A1Increase brightnessReduce the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesAlkaline earth metalLow voltage

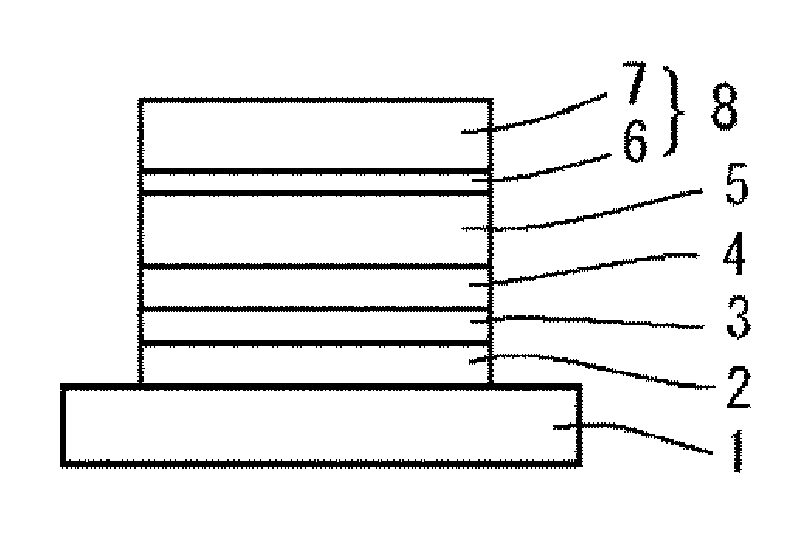

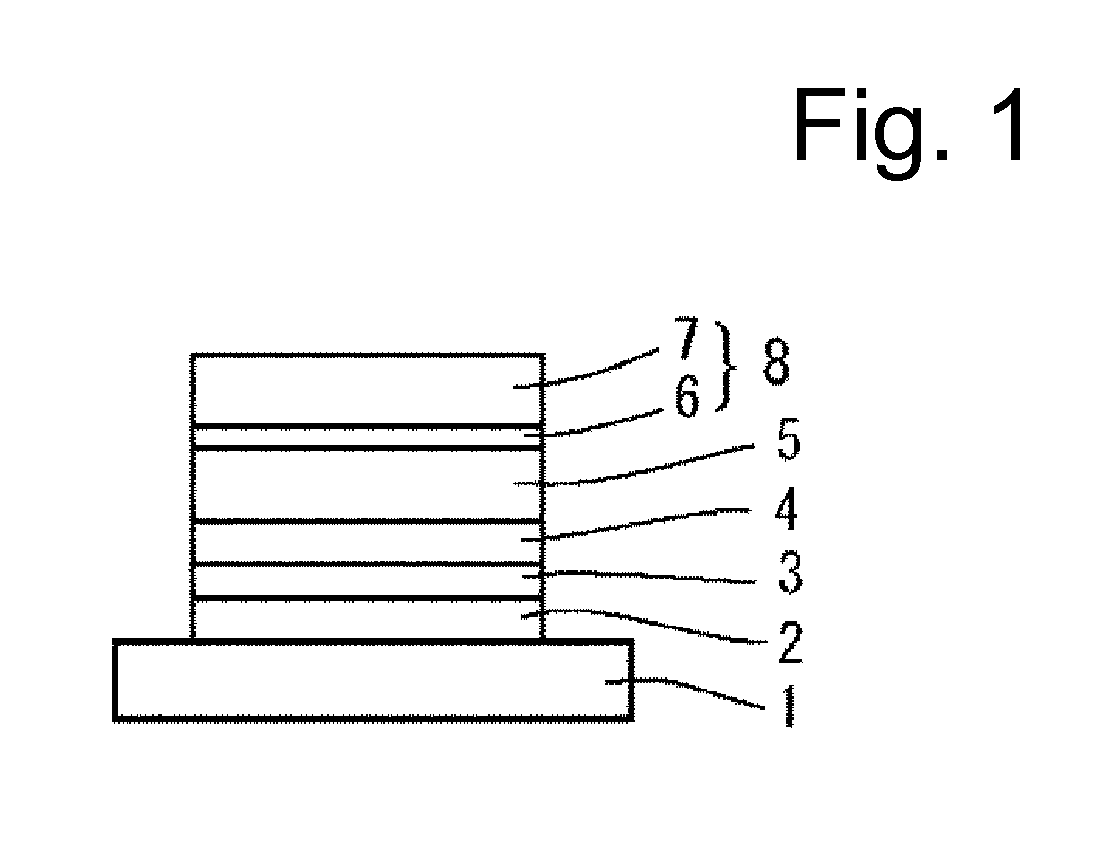

The problem to be solved of the present invention is to improve luminance level of a polymer light-emitting device even when it is driven at a low voltage. Means for solving the problem is a polymer light-emitting device comprising a cathode, an anode, and a functional layer containing a polymer compound and a light-emitting layer containing an organic polymer light-emitting compound arranged between the cathode and the anode, wherein the cathode comprises a first electrode layer and a second electrode layer in this order from the light-emitting layer side, the first electrode layer comprises a first material and a second material, the first material comprises a material which contains one or more compounds selected from the group consisting of sodium fluoride, potassium fluoride, cesium fluoride, rubidium fluoride and a carbonate of an alkaline earth metal, and the second material comprises a substance which has a reduction action on the first material.

Owner:SUMITOMO CHEM CO LTD

A kind of preparation method of lithium bisfluorosulfonyl imide

The invention discloses a preparation method of difluoro-sulfonyl imide lithium. The preparation method comprises the following steps: 1) under a protective atmosphere, adding a fluorizating agent into difluoro-sulfonyl imide to perform a fluorination reaction so as to obtain a mixture, wherein the fluorizating agent is one of or a combination of fluorine, a fluorine-containing mixed gas, anhydrous hydrogen fluoride, potassium fluoride, antimonic fluoride and rubidium fluoride; 2) performing reduced pressure distillation on the obtained mixture to obtain a di(fluoro-sulfonyl) imide intermediate; and 3) under a protective atmosphere, performing synthetic reaction on the obtained di(fluoro-sulfonyl) imide intermediate and a lithium source, and performing solid-liquid separation to obtain difluoro-sulfonyl imide lithium. According to the preparation method disclosed by the invention, the fluorination reaction does not need a solvent or other auxiliary agent, is less in types of adopted reagents, does not introduce a new impurity, is simple in operation, and is easy to control; the method is less in side reaction, good in fluorination effect and low in fluorination cost; and the purity and the yield of the product namely difluoro-sulfonyl imide lithium obtained by a subsequent synthetic reaction are improved on the whole, and the method has good economic and environmental benefits.

Owner:DO FLUORIDE CHEM CO LTD

Brazing flux suitable for brazing aluminium and steel

ActiveCN105643144AHigh activityLow priceWelding/cutting media/materialsWelding/soldering/cutting articlesAluminum fluorideAluminium hydroxide

The invention relates to a brazing flux suitable for brazing aluminium and steel, and belongs to the field of non-metallic brazing materials. The brazing flux comprises the following components in percent by mass: 0.001-0.01 percent of rubidium fluoride, 11.0-45.0 percent of cesium fluoride, 0.01-2.0 percent of aluminium hydroxide, 0.01-5.0 percent of potassium fluoride, 0.01-0.04 percent of zinc fluoride, and the balance of aluminum fluoride. The brazing flux can meet the requirements of aluminium-steel brazing, aluminium-copper brazing and aluminium-aluminium brazing synchronously and is high in activity.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

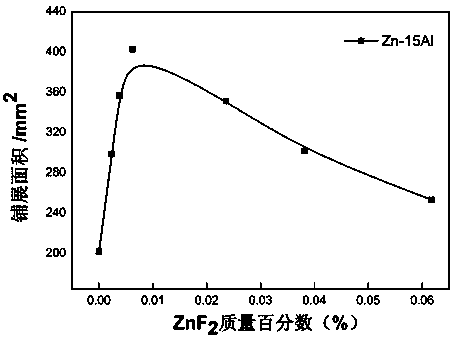

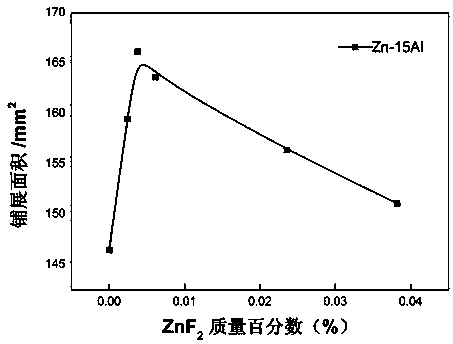

Soldering flux suitable for aluminum steel brazing

ActiveCN105618960AGood spreadabilityHigh activityWelding/cutting media/materialsWelding/soldering/cutting articlesAluminum fluorideMetallic materials

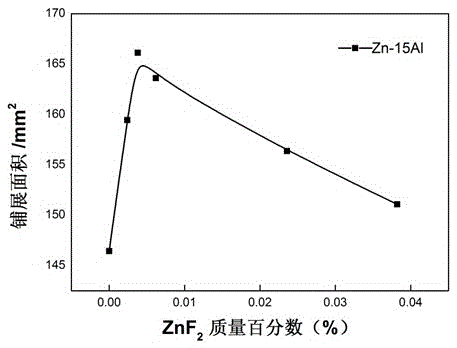

The invention belongs to the field of brazing material of non-metallic material and discloses soldering flux suitable for aluminum steel brazing. The soldering flux is characterized by being composed of, by weight, 0.001-0.01% of rubidium fluoride (RbF), 11.0-45.0% of cesium fluoride (CsF), 0.01-2.0% of aluminum oxide (Al2O3), 0.01-5.0% of potassium fluoride (KF), 0.001-0.04% of zinc fluoride (ZnF2) and the balance aluminum fluoride (AlF3). The soldering flux can meet the brazing requirements of aluminum-steel, aluminum-copper and aluminum-aluminum and is high in activity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cesium and rubidium brazing flux containing zinc tetrafluoroborate hydrate

ActiveCN105618961ASimple preparation processQuality is easy to controlWelding/cutting media/materialsSoldering mediaTetrafluoroborateRubidium

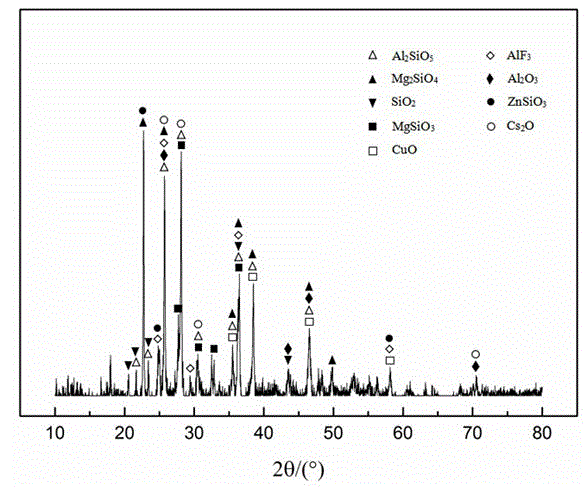

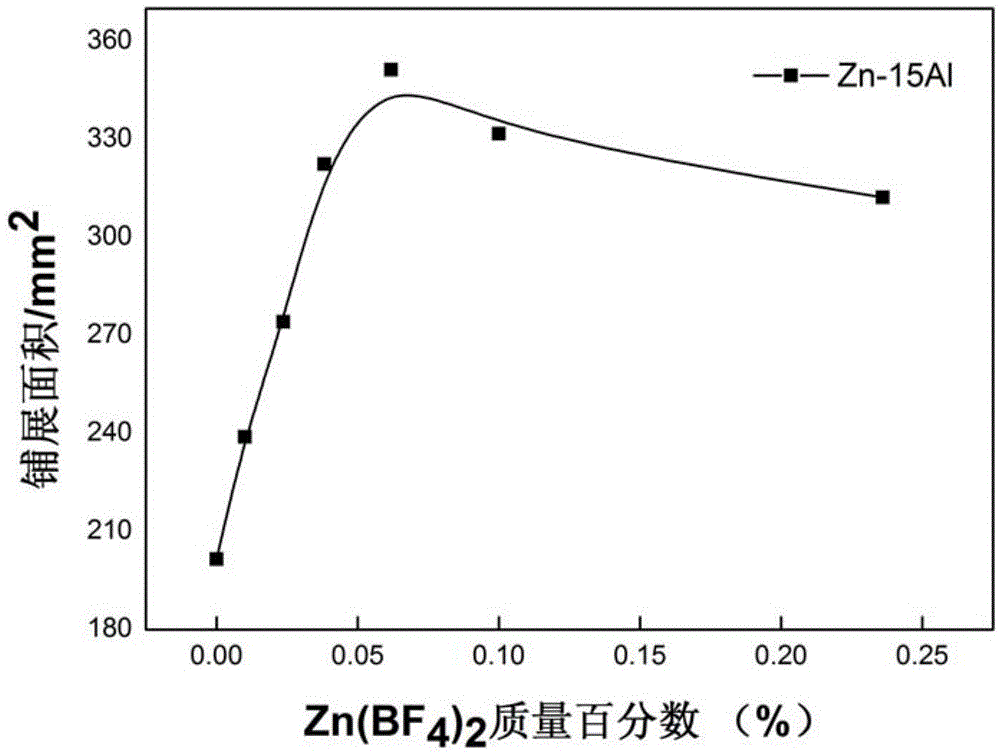

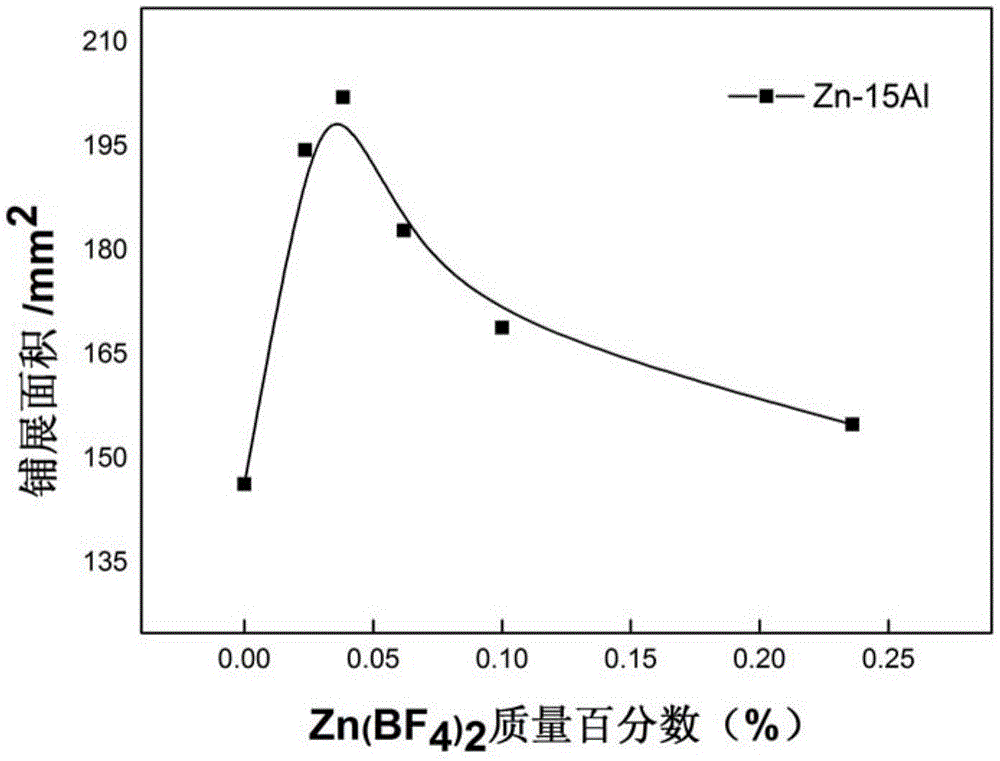

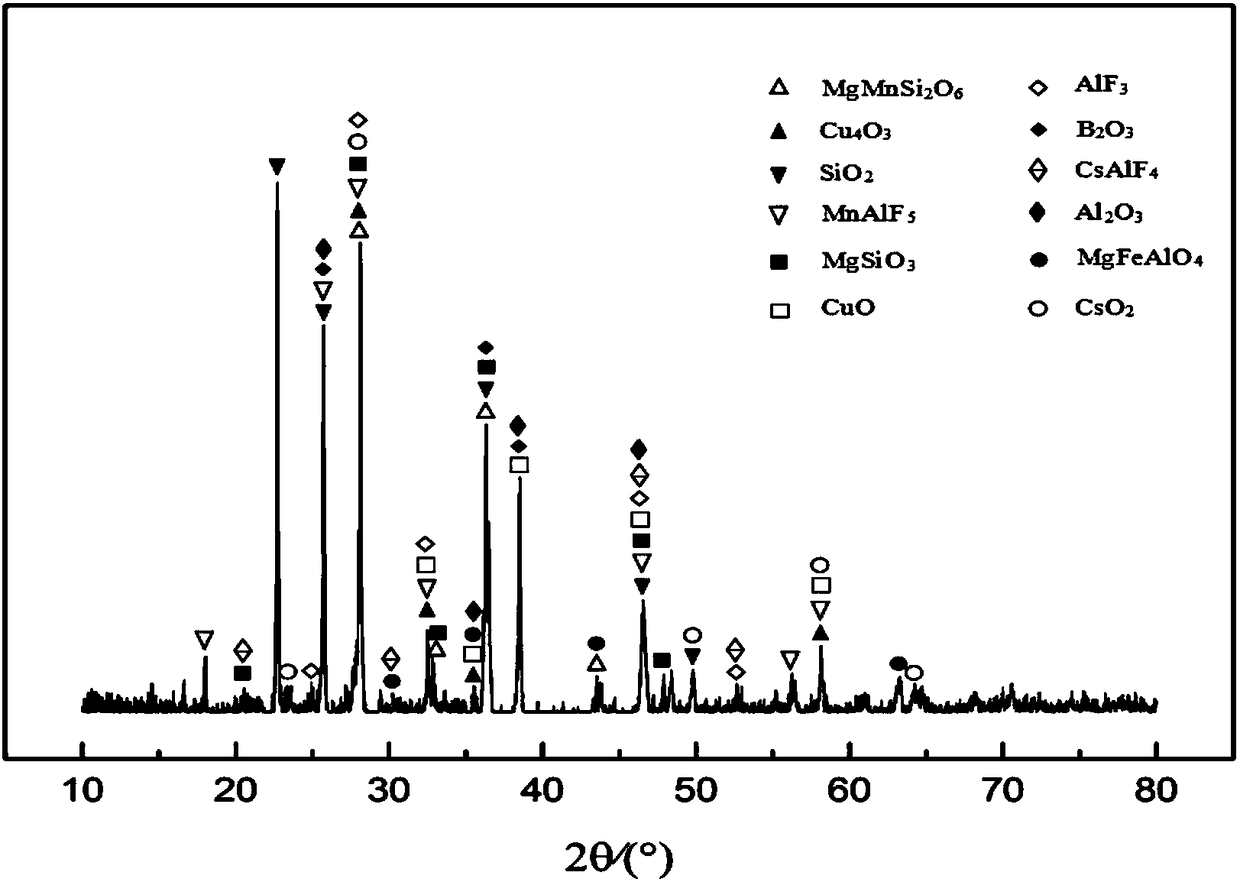

The invention discloses cesium and rubidium brazing flux containing zinc tetrafluoroborate hydrate. The cesium and rubidium brazing flux comprises, by mass percentage, 0.001%-0.01% of rubidium fluoride, 10.0%-50.0% of cesium fluoride, 0.01%-5.0% of aluminum oxide, 0.01%-5.0% of potassium fluoride, 0.001%-0.25% of zinc tetrafluoroborate hydrate and the balance aluminum fluoride. According to the cesium and rubidium brazing flux containing zinc tetrafluoroborate hydrate, zinc tetrafluoroborate hydrate is added, the usage amount of rubidium fluoride is reduced greatly, brazing of the same material of aluminum-aluminum, dissimilar materials of aluminum-cooper, dissimilar materials of aluminum-steel and an alloy material of aluminum-aluminum can be achieved, the material cost is reduced remarkably, and the brazing flux has excellent capacity of removing FeO, Fe2O3, NiO, Cr2O3 and other oxide on the surface of aluminum alloy or steel; and the brazing flux on the base metal has excellent wetting performance, spreading performance and penetrating performance, the brazing seam strength can reach 125 MPa to 145 MPa, and the requirements for low lost, high reliability and environmental-friendly manufacturing of the industries of air conditioners, refrigerator complete machines, refrigeration accessories, rail transit and energy can be met.

Owner:NANJING UNIV OF SCI & TECH

Medium-temperature type anti-corrosion fluoroaluminate soldering flux and preparation method thereof

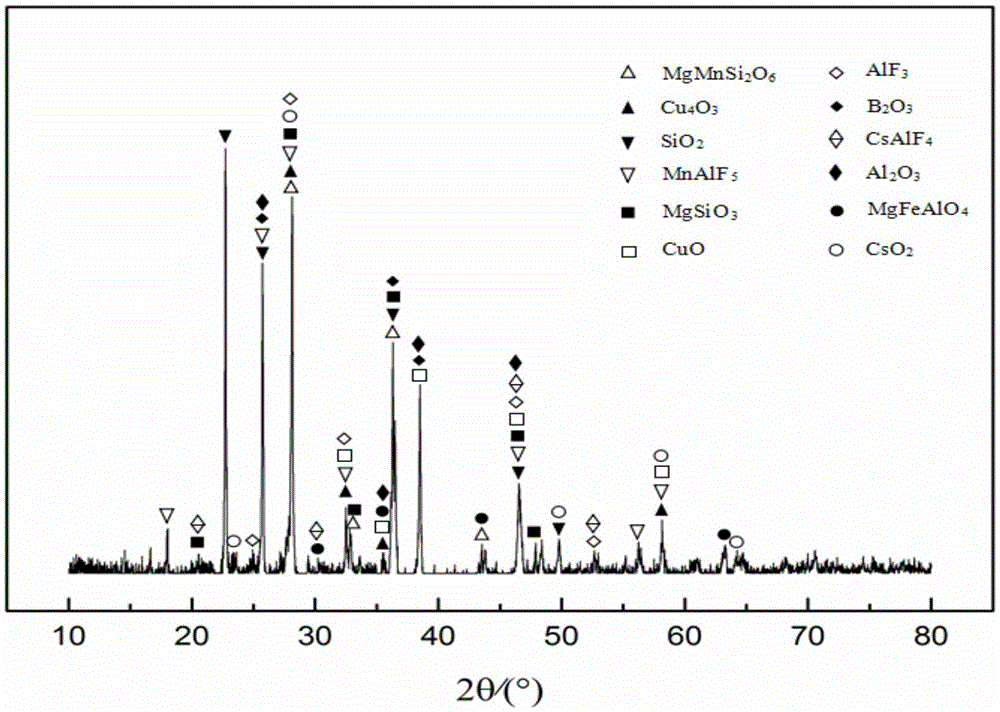

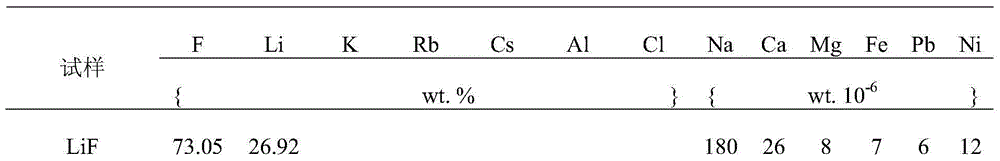

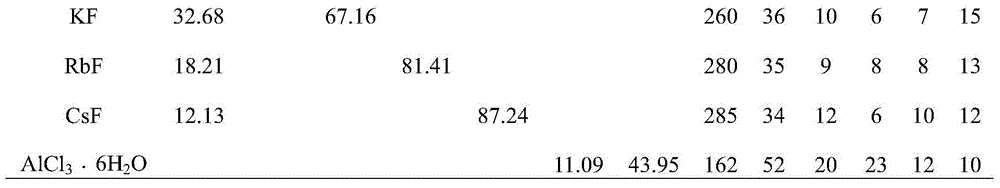

ActiveCN104816107AIncrease moistureImprove ductilityWelding/cutting media/materialsSoldering mediaRubidiumLepidolite

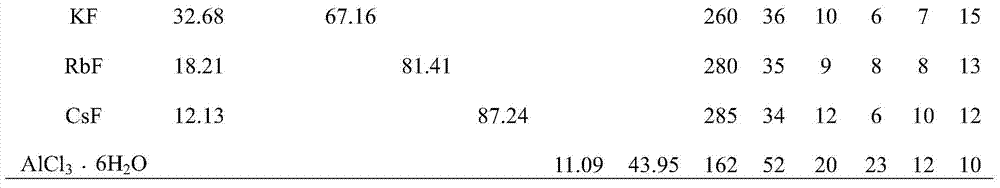

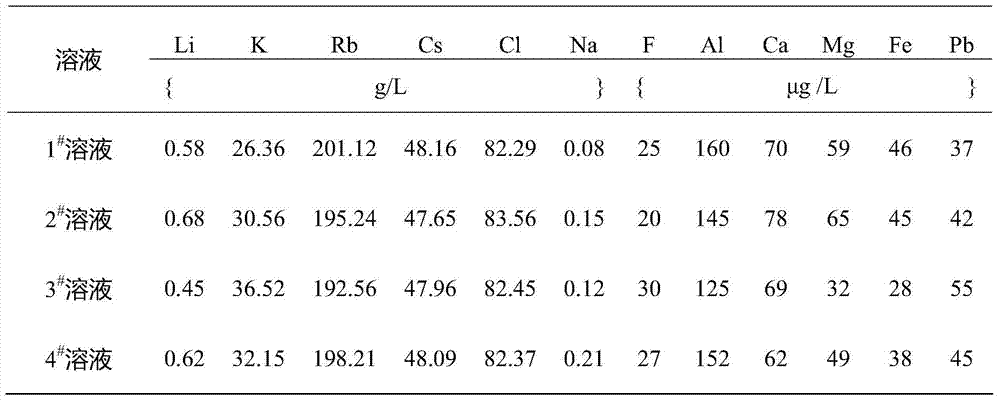

The invention relates to medium-temperature type anti-corrosion fluoroaluminate soldering flux and a preparation method thereof. The soldering flux takes lithium-settling mother liquor obtained by extracting lithium from Jiangxi lepidolite as a base solution; the base solution is subjected to impurity removal to obtain a solution rich in k, Rb and Cs as a raw material solution; one or more of aluminum fluoride, potassium fluoride, rubidium fluoride and cesium fluoride are dosed and added to prepare mixed type soldering flux; the added metal salts can be extracted from the lepidolite. The lepidolite is rich in rubidium and cesium, so that the production cost of the novel soldering flux is greatly reduced, and the Jiangxi lepidolite realizes resource maximum utilization. The medium-temperature type anti-corrosion fluoroaluminate soldering flux is suitable for welding aluminum alloy and high-magnesium alloy, and has special activity on alloy with high magnesium content.

Owner:JIANGXI HZONE LITHIUM TECH

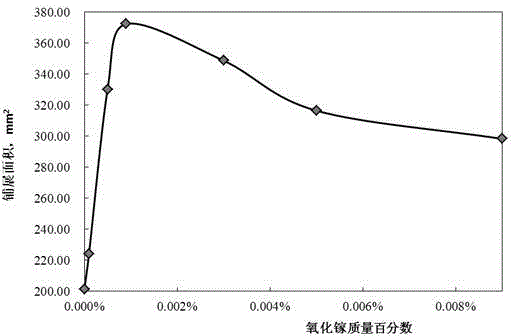

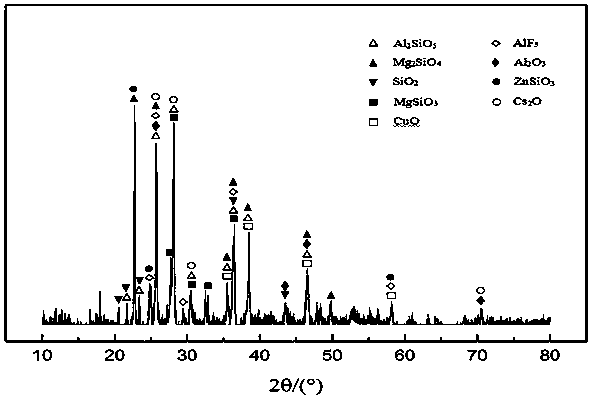

Composite flux suitable for copper-aluminum dissimilar metal brazing

ActiveCN104708232BReduced active temperature rangeHigh activityWelding/cutting media/materialsSoldering mediaPotassiumFiller metal

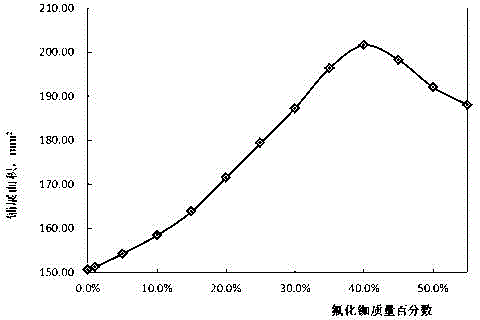

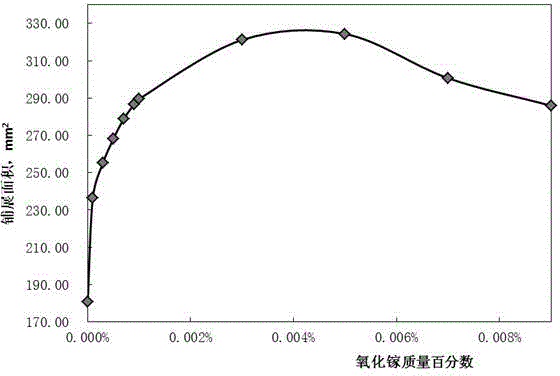

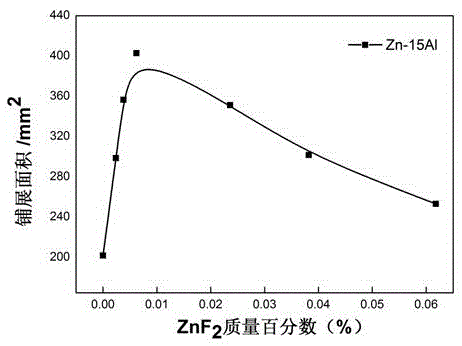

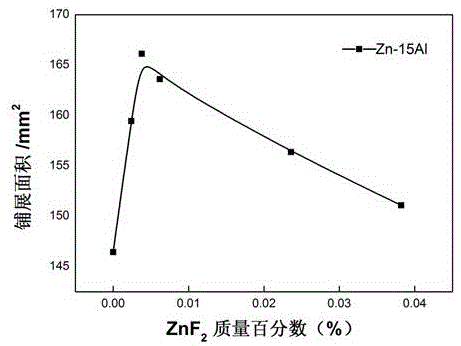

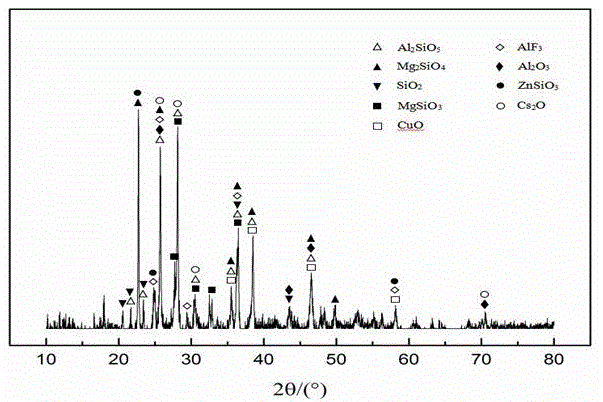

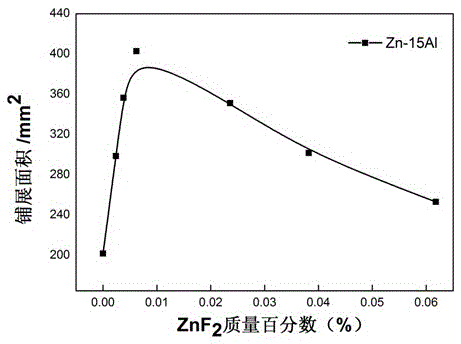

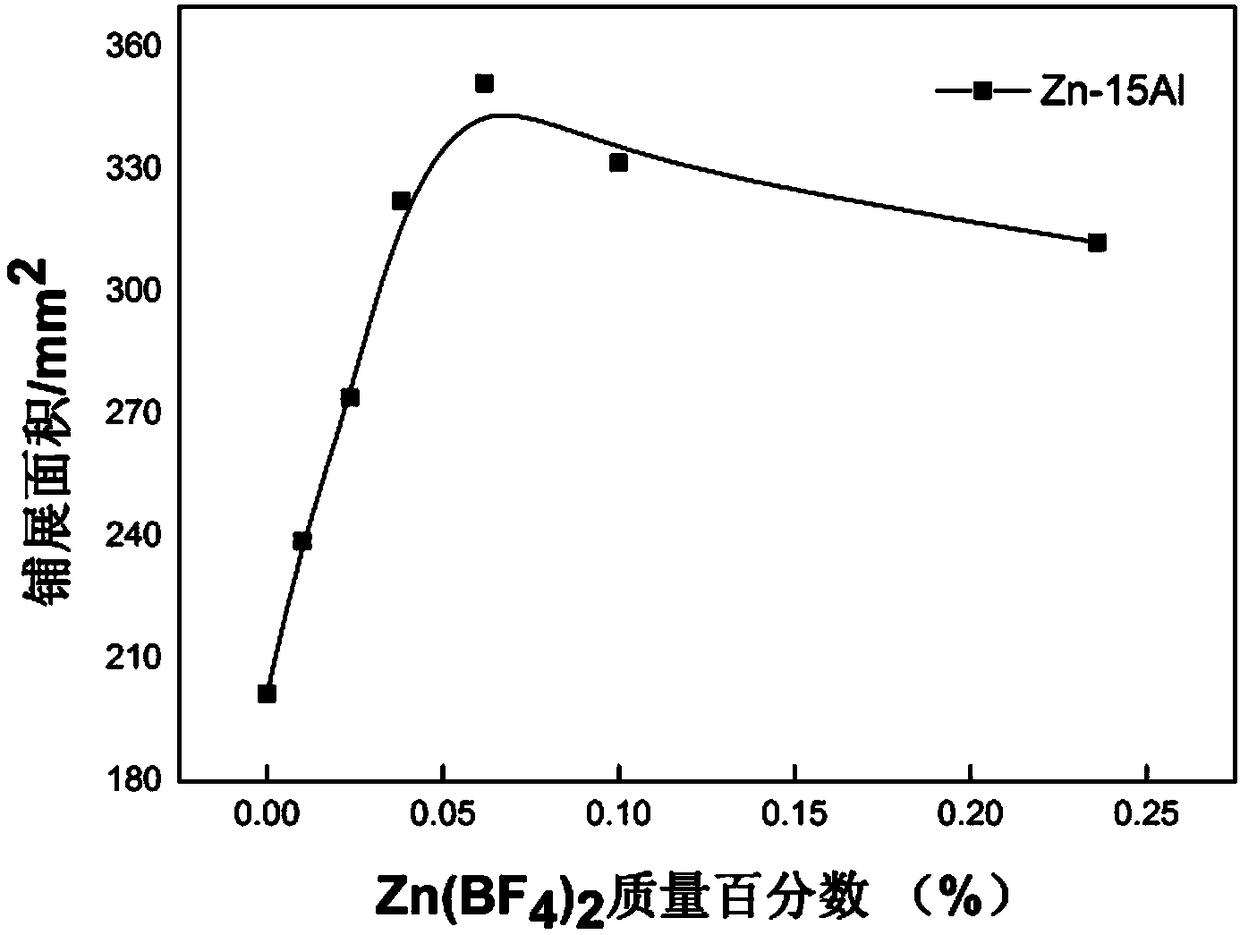

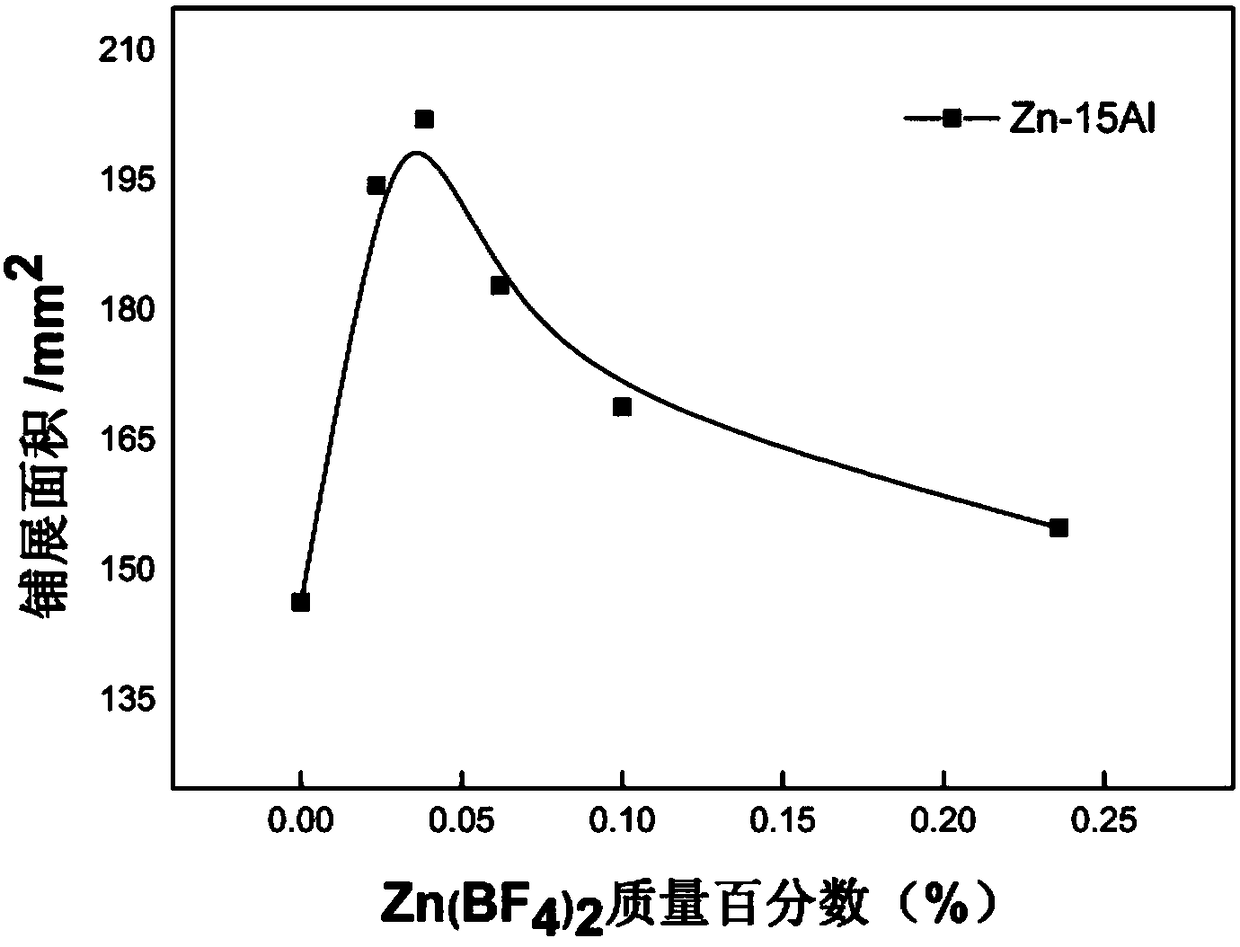

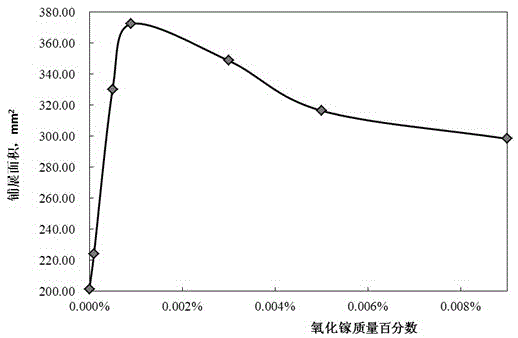

The invention discloses a composite brazing flux suitable for copper and aluminum dissimilar metal brazing. The composite brazing flux comprises 50-55% of cesium fluoride, 30-35% of aluminum fluoride, 3-5% of potassium fluoride, 10-12% of rubidium fluoride, 0.1-1% of potassium fluorogermanate, 0.1-0.5% of zinc difluoro and 0.1-0.5% of potassium fluoborate. The composite brazing flux is formed by preparing seven kinds of fluoride in proportion, and has the advantages of being non-hygroscopic and free of corrosion compared with a traditional chloride brazing flux; compared with a traditional fluoride brazing flux, the composite brazing flux obviously narrows the activity temperature range and further improves the activity; compared with a traditional fluoride brazing flux, the spreading area of ZN-15AL brazing filler metal on an aluminum alloy plate at 500 DEGC is improved by about 40%, and the spreading area of the ZN-15AL brazing filler metal on the aluminum alloy plate at 520 DEG C is improved by about 25%.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

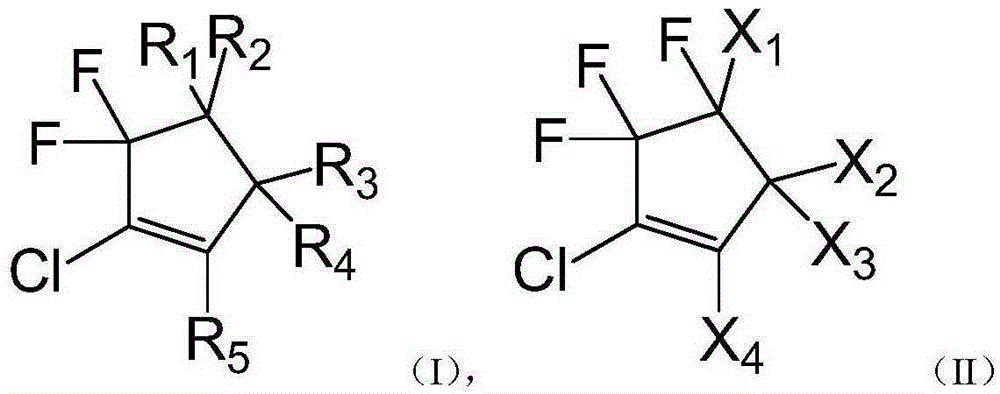

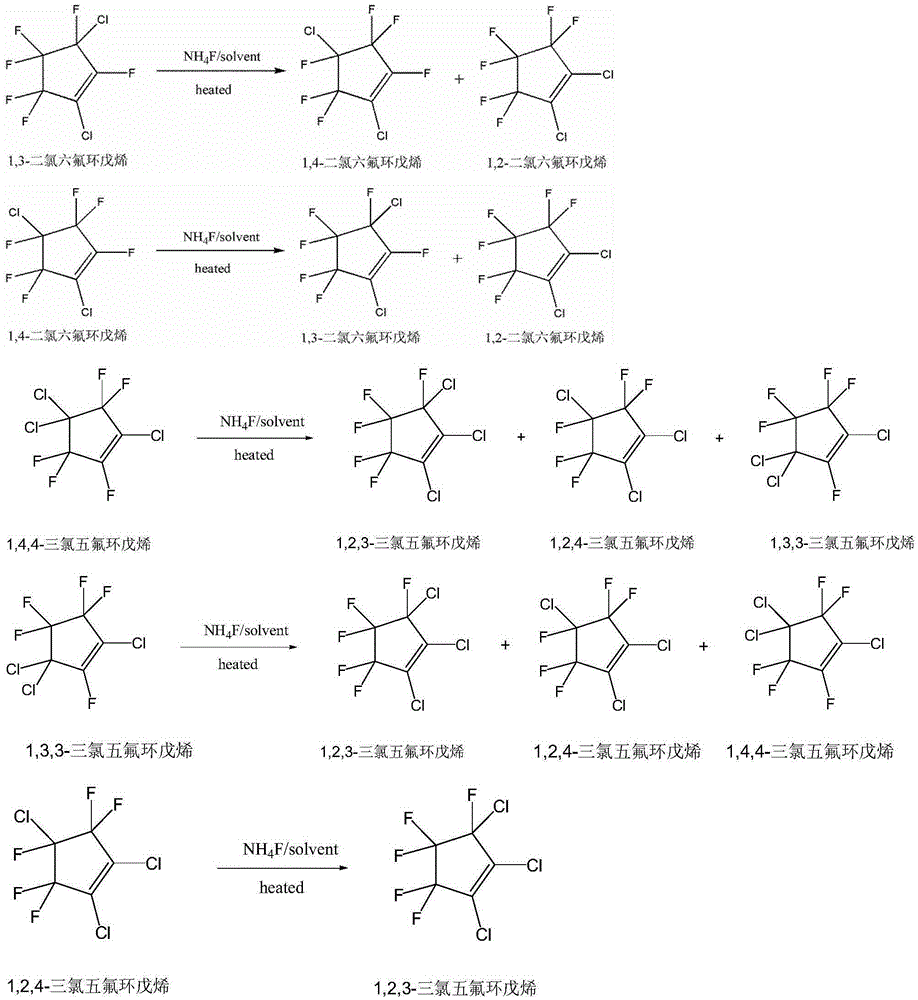

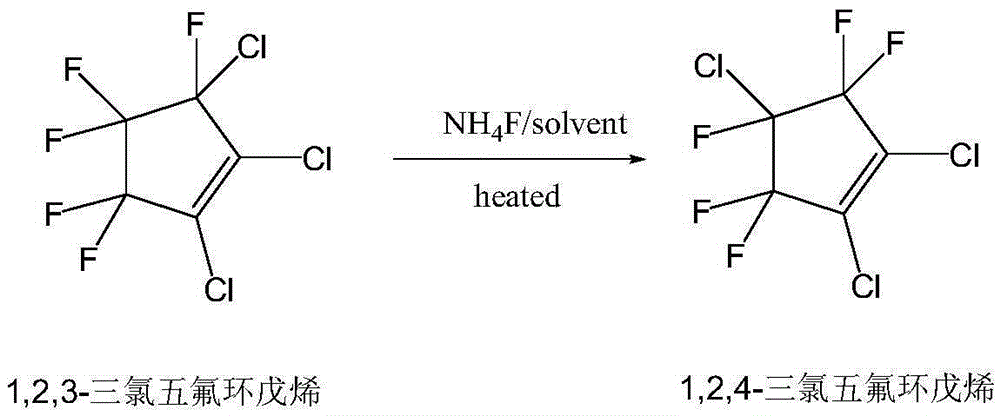

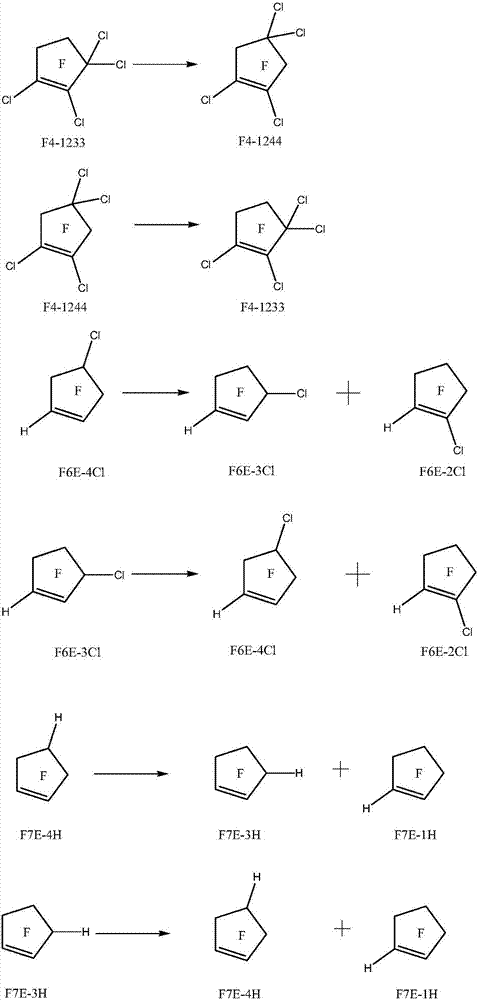

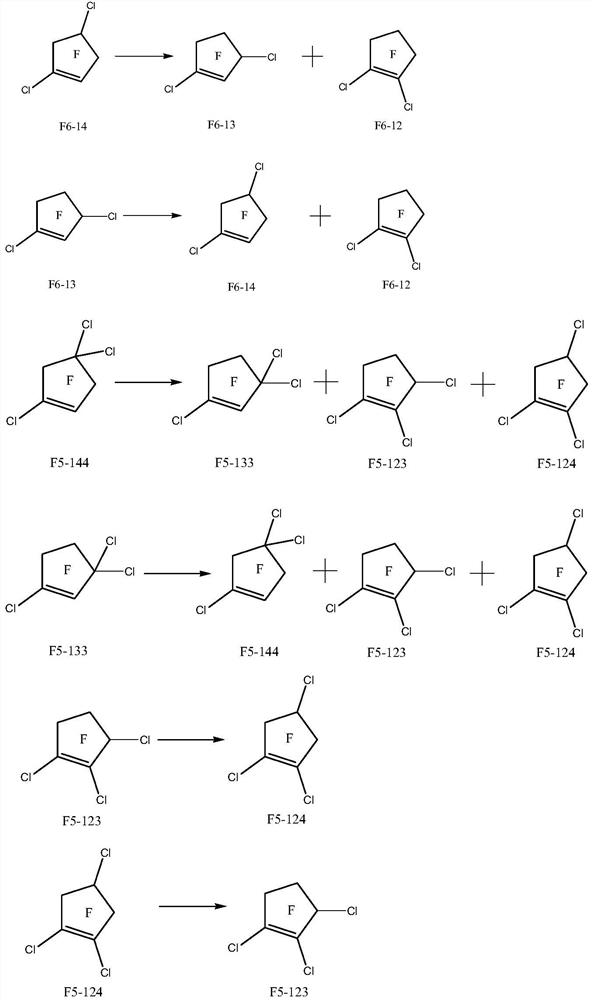

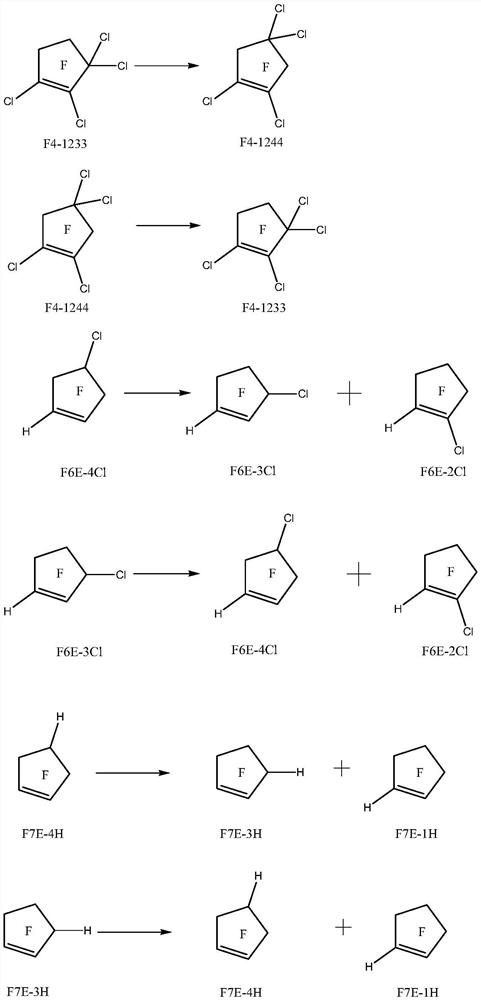

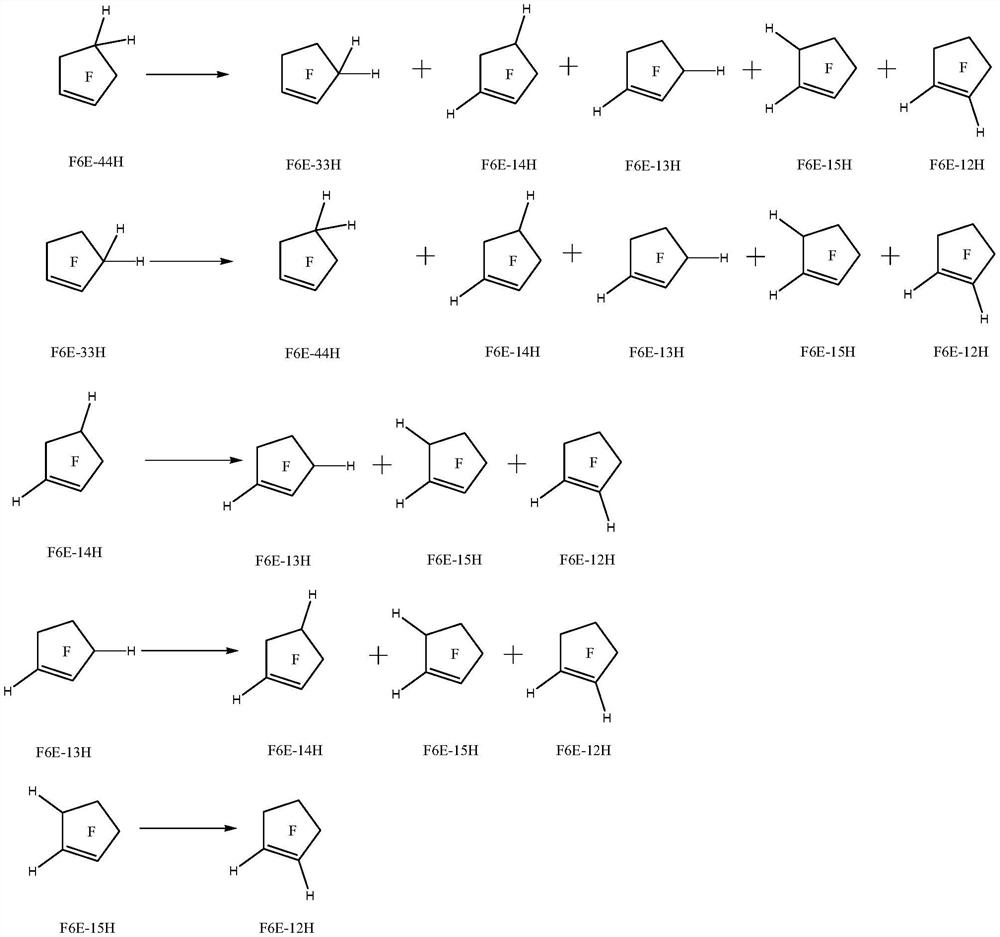

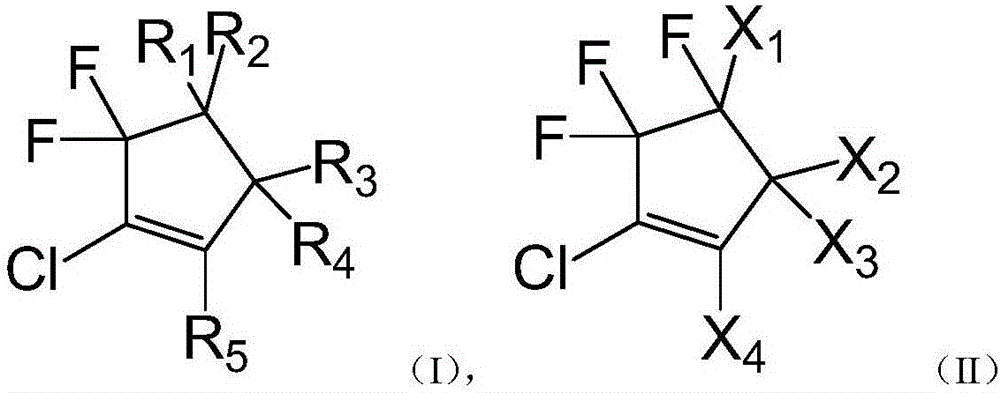

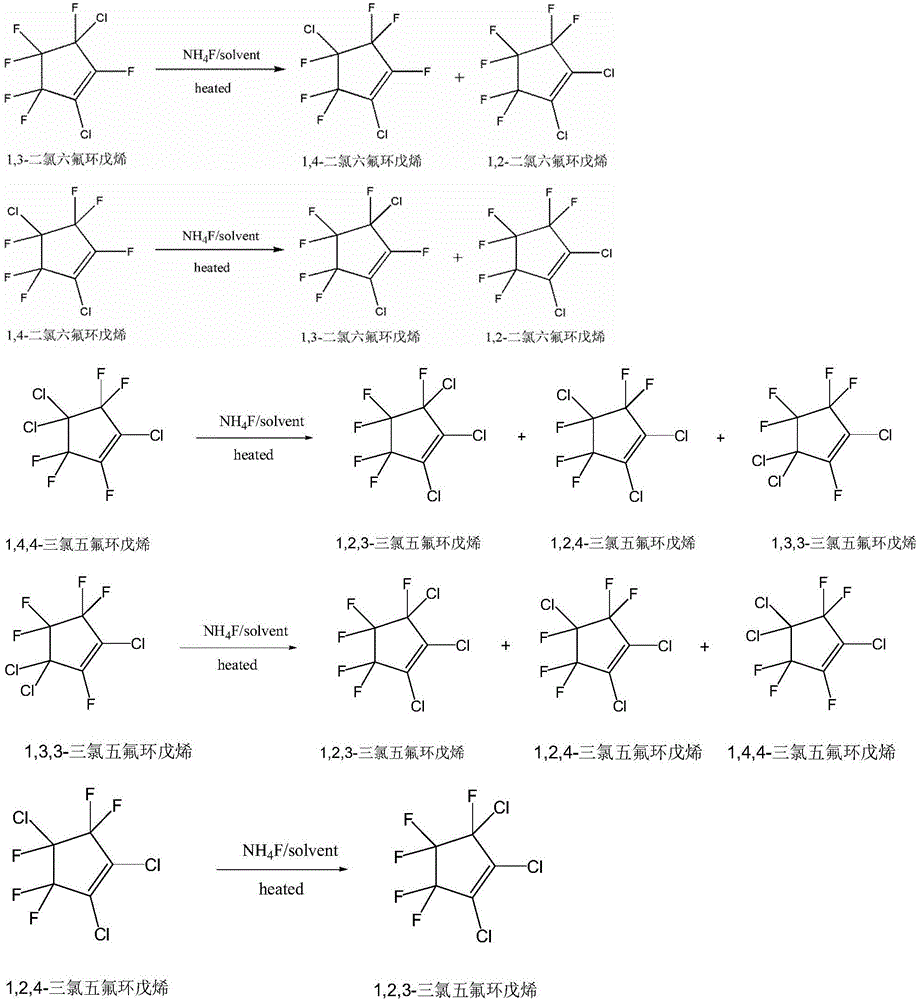

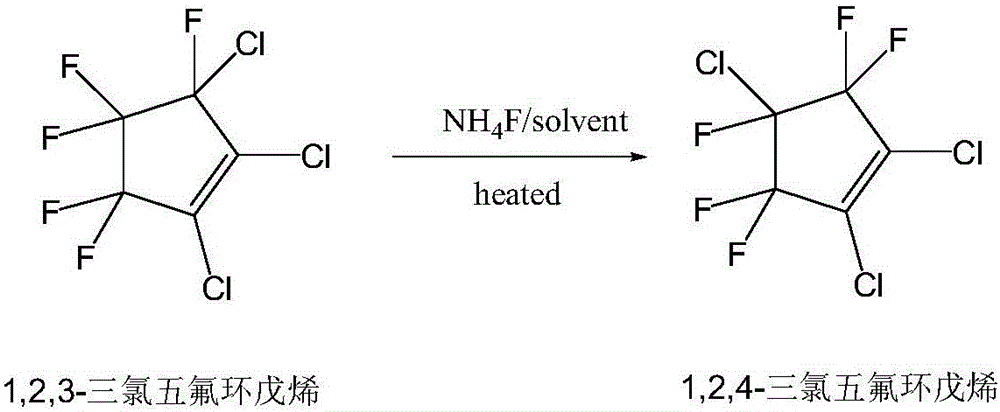

Method for preparing chlorine fluorine cyclopentene isomeride

The invention relates to a method for preparing chlorine fluorine cyclopentene isomeride in the formula (II) (please see the formula in the specification). The chlorine fluorine cyclopentene isomeride is obtained with chlorine fluorine cyclopentene in the formula (I) (please see the formula in the specification) as the raw material in solvent dimethylformamide, dimethyl sulfoxide or sulfolane by conducting an isomerization reaction in catalysts ammonium fluoride, ammonium bifluoride, potassium fluoride, lithium fluoride, sodium fluoride, rubidium fluoride or cesium fluoride. The technological method is little in raw material toxicity and mild in reaction conditions, the reaction is easy to control, the isomeride yield of chlorine fluorine cyclopentene is high, and industrialization is easy.

Owner:BEIJING YUJI SCI & TECH +1

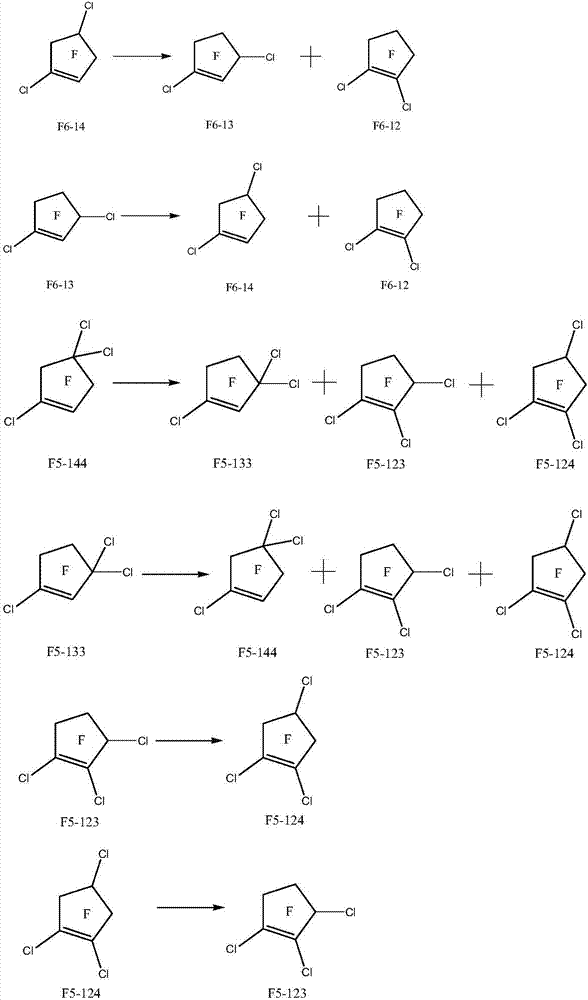

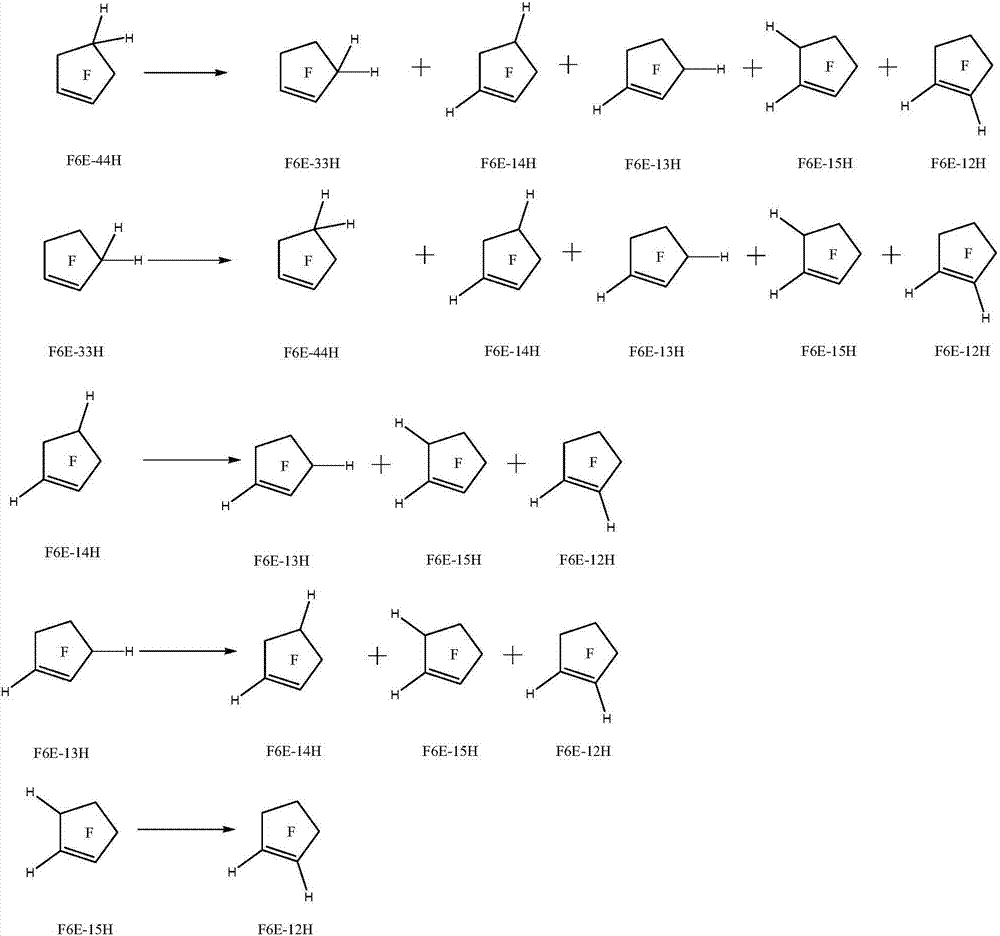

Method for preparing halogenated pentacyclic olefin by gas-phase isomerization reaction

ActiveCN107445794ARaw materials are easy to getPhysical/chemical process catalystsHalogenated hydrocarbon preparationIsomerizationGas phase

The invention relates to a method for preparing halogenated pentacyclic olefin by gas-phase isomerization reaction. The method comprises the following steps of: by adopting the halogenated pentacyclic olefin C5HxFyClz as a material, under the existence of an isomerization catalyst, generating the gas-phase isomerization reaction to obtain isomers of the halogenated pentacyclic olefin, wherein X is an integer from 0 to 2, Y is an integer from 4 to 7, Z is an integer from 0 to 4, the sum of X and Y and Z is 8, and the isomerization catalyst is prepared by adopting at least one of lithium fluoride, potassium fluoride, sodium fluoride, rubidium fluoride or cesium fluoride as an active component and loading the active component on at least one of carriers such as aluminium fluoride, magnesium fluoride, iron fluoride, chromium fluoride and zinc fluoride. The method has the advantages that the material is easy to obtain, the isomerization catalyst is low in price, the yield of the isomer is higher, and the method is applicable to large-scale preparation of the isomers of the halogenated pentacyclic olefin by gas-phase reaction.

Owner:BEIJING YUJI SCI & TECH

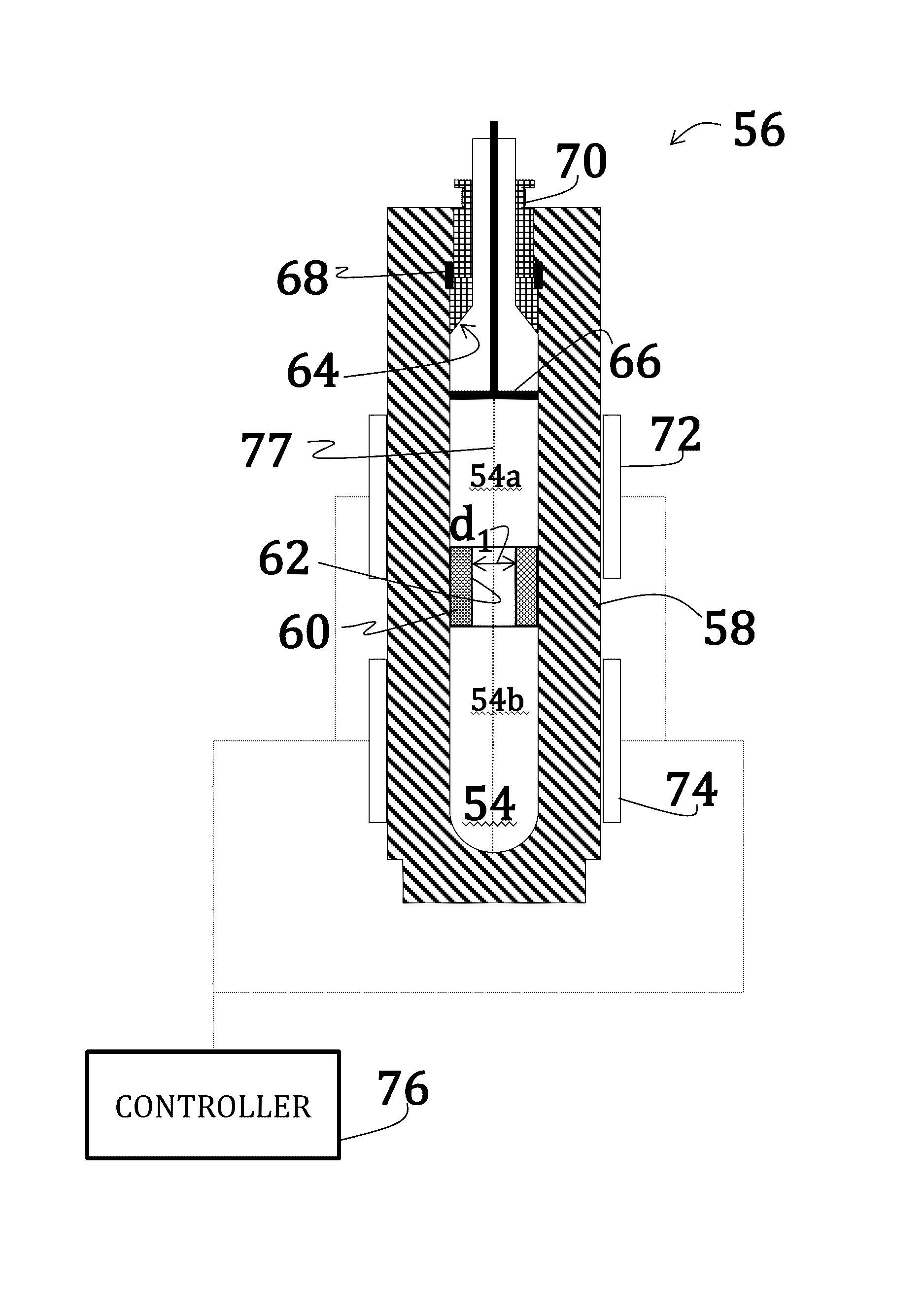

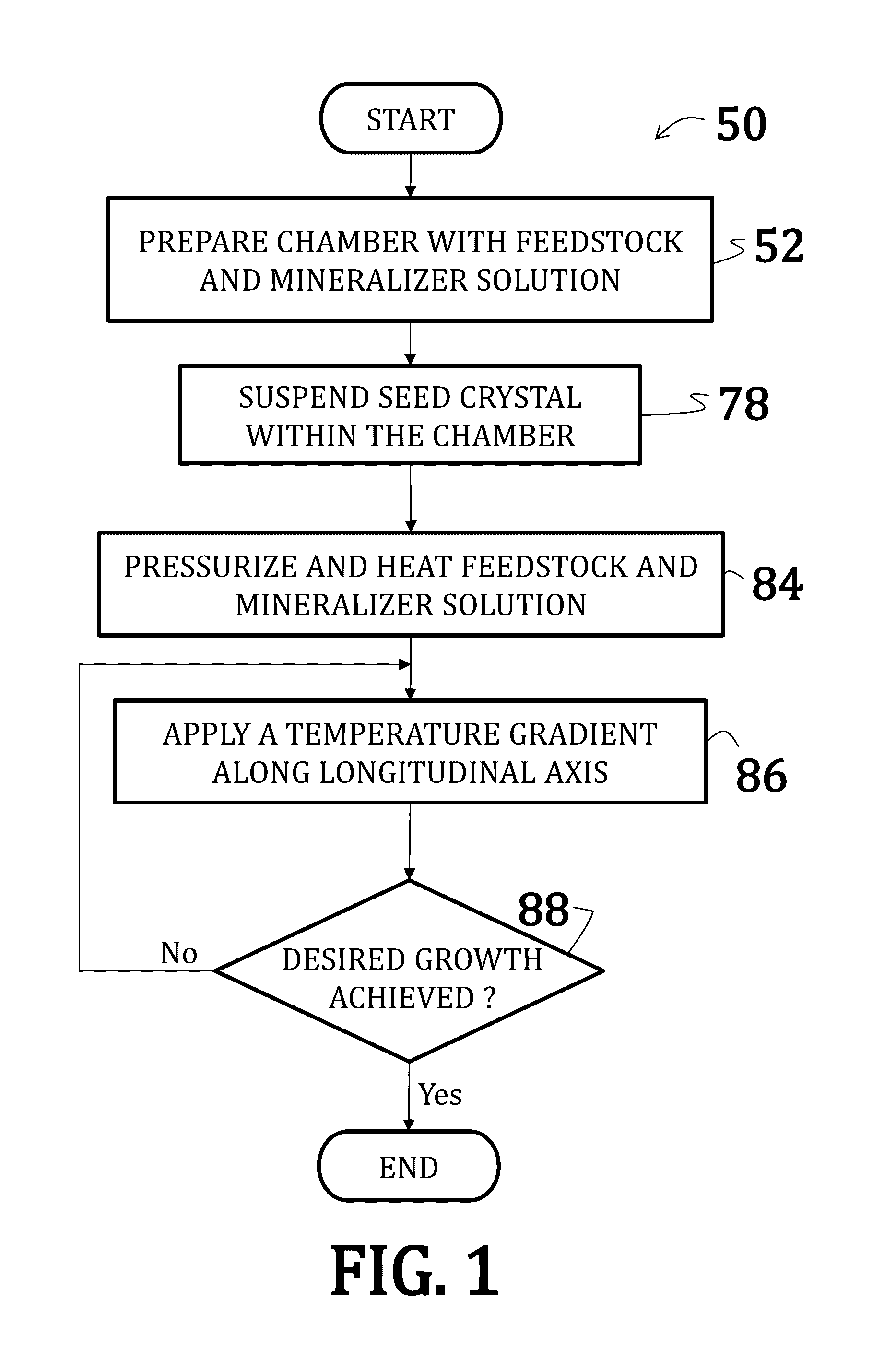

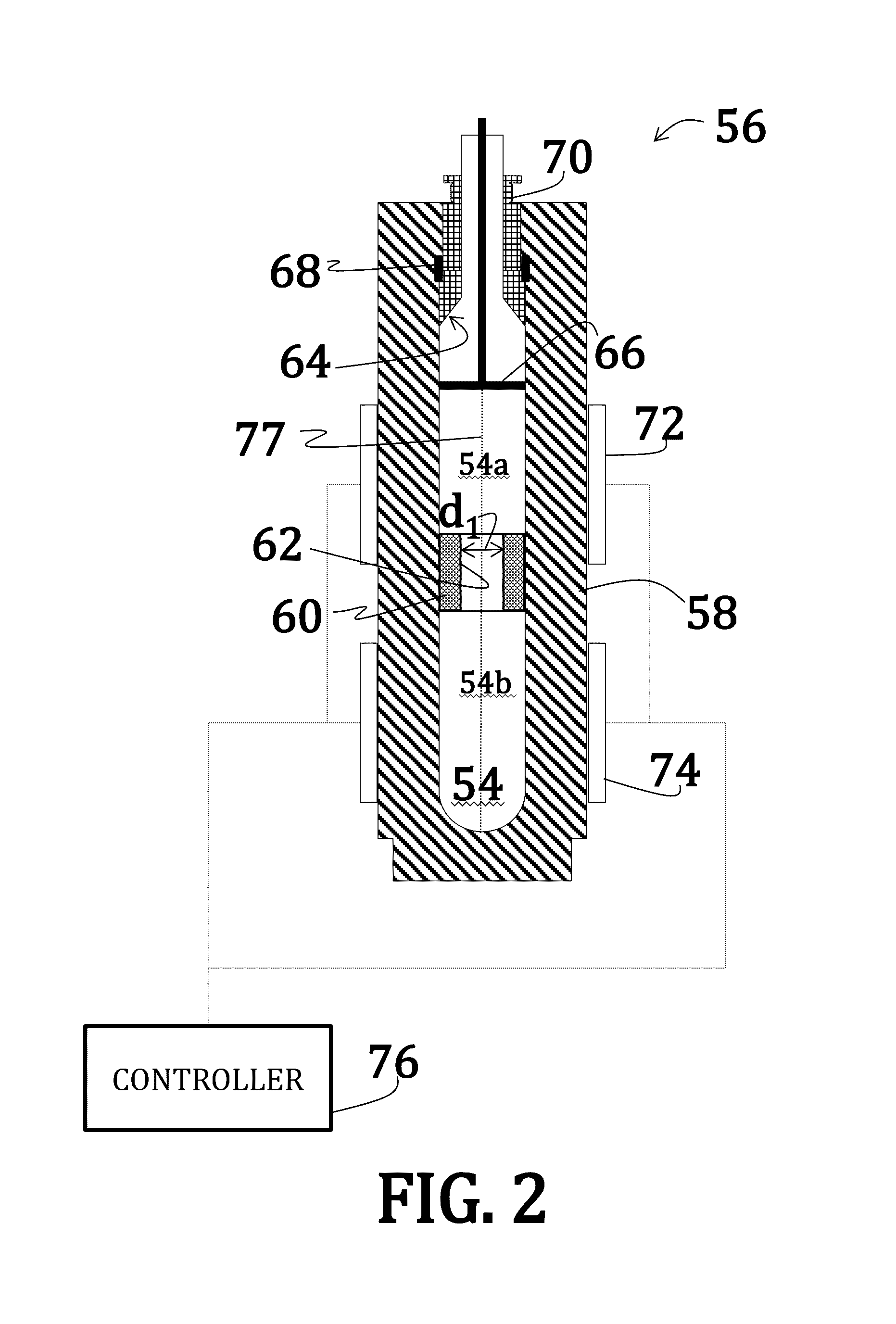

Rubidium uranium fluoride-based crystals and methods of fabrication

ActiveUS20160348268A1Polycrystalline material growthFrom normal temperature solutionsFluoride crystalsRubidium

A method of synthesizing rubidium uranium fluoride crystals. The method includes combining uranium-based feedstock with a mineralizer solution that includes a rubidium fluoride. The feedstock and mineralizer solution are pressurized and a thermal gradient applied thereto such that a first portion of the feedstock and the mineralizer solution is heated to a temperature that is greater than a temperature of a second portion of the feedstock and the mineralizer solution. Uranium nutrient enters the mineralizer solution from the feedstock in the first portion and uranium nutrient precipitates to spontaneously form crystals in the second portion.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

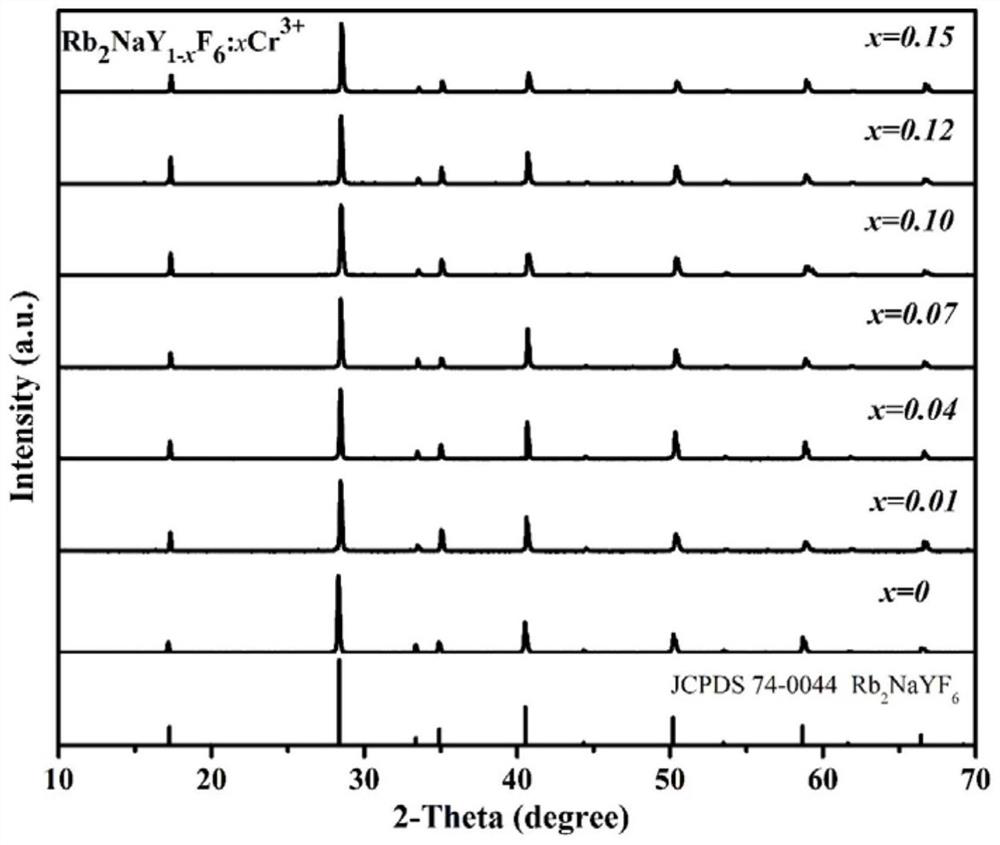

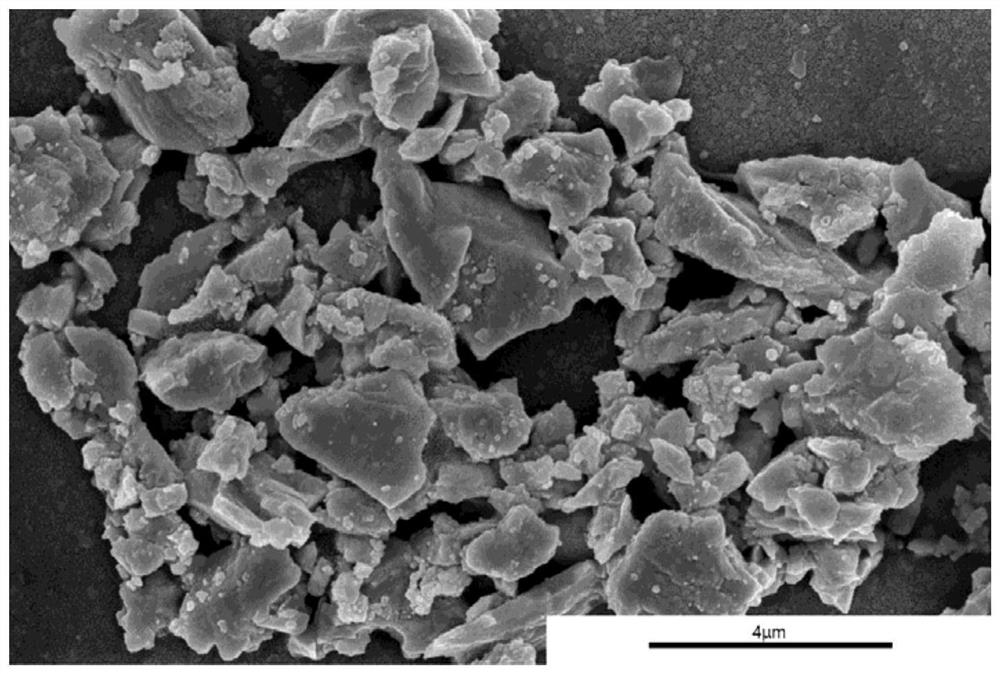

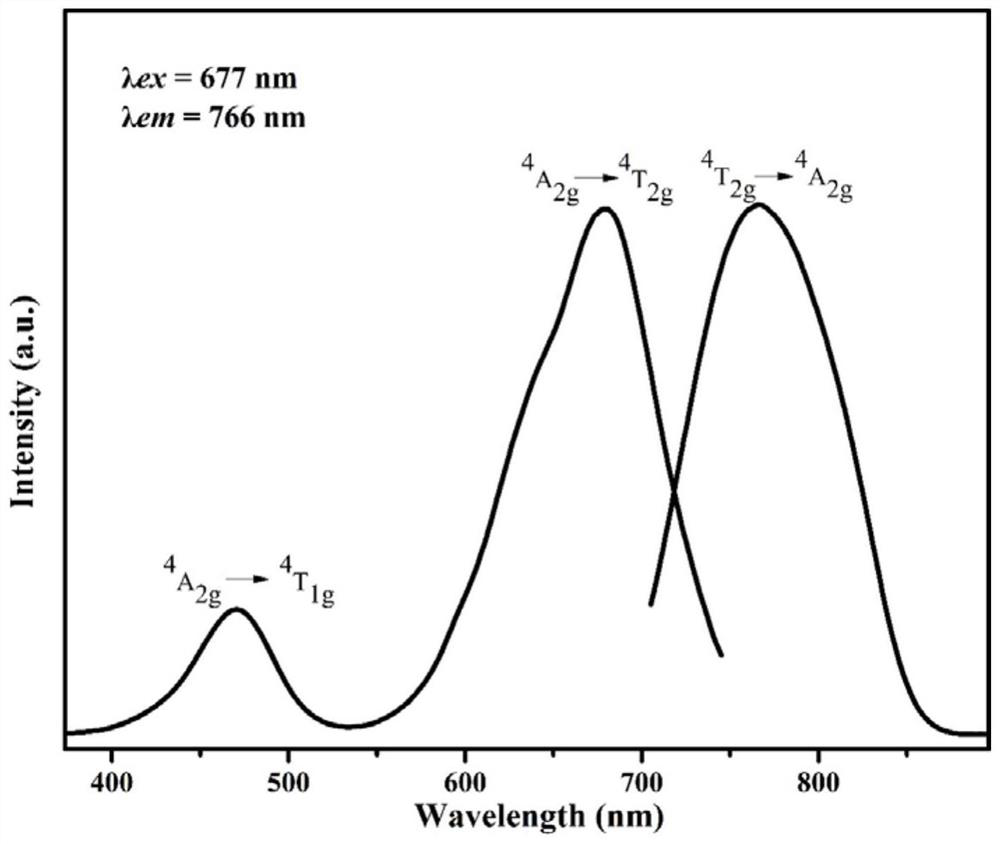

Double-perovskite type near-infrared luminescent material and preparation method thereof

PendingCN114196404AUniform particlesClear edges and cornersLuminescent compositionsNear infrared luminescenceChromic Ion

The invention discloses a double perovskite type near-infrared luminescent material, the chemical composition is Rb2NaY (1-x) F6: xCr < 3 + >, x is the mole percentage coefficient of doped chromium ions relative to yttrium ions, and 0 lt; x is greater than or equal to 0.15; the preparation method comprises the following steps: (1) weighing 80-85 parts of rubidium fluoride, 15-20 parts of sodium fluoride, 55-40 parts of yttrium fluoride and 0-6 parts of chromium fluoride; (2) adding the weighed rubidium fluoride, sodium fluoride, yttrium fluoride and chromium fluoride into a mortar, and grinding for more than 30 minutes to fully and uniformly mix the raw materials; and (3) putting the ground raw materials into a tubular furnace, and reacting at the high temperature of 650-700 DEG C for 8-10 hours to obtain the product. The luminescent material capable of emitting near-infrared light is prepared by taking positive trivalent transition metal Cr < 3 + > as doping ions and double perovskite fluoride as a matrix.

Owner:YUNNAN MINZU UNIV

Radiation image storage panel and method of preparing said panel

InactiveUS20070181824A1Apparent advantageElectrical apparatusElectroluminescent light sourcesFluorescenceRubidium bromide

In a radiation image storage panel, as a layer arrangement of consecutive layers, a support, a sublayer and a stimulable phosphor layer having needle-shaped stimulable phosphor crystals is comprised, said sublayer is a binderless non-vapor deposited layer, at least comprising as a halide compound an inorganic alkali halide salt selected from the group consisting of sodium fluoride, sodium chloride, sodium bromide, potassium fluoride, potassium chloride, potassium bromide, rubidium fluoride, rubidium chloride, rubidium bromide, cesium fluoride, cesium chloride and cesium bromide, thereby providing good adhesiveness between phosphor layer and support.

Owner:T2PHARMA GMBH

A cesium-rubidium brazing flux containing zinc fluorine borate

ActiveCN105618961BSimple preparation processQuality is easy to controlWelding/cutting media/materialsSoldering mediaTetrafluoroborateRubidium

Owner:NANJING UNIV OF SCI & TECH

Preparation method of efficient aluminum alloy refining agent

PendingCN113122706AImprove refining effectImprove adsorption capacityLanthanum fluorideSodium aluminate

The invention discloses a preparation method of an efficient aluminum alloy refining agent. The efficient aluminum alloy refining agent comprises the following raw materials of 20-30 parts of sodium chloride, 30-40 parts of potassium chloride, 6-10 parts of aluminum fluoride, 4-10 parts of sodium hexafluoroaluminate, 2-7 parts of sodium fluosilicate, 0.2-0.5 part of rubidium fluoride, 0.5-1 part of lanthanum fluoride and 10-30 parts of magnesium nitride. According to the method, by adding the powdery magnesium nitride additive into the refining agent, in the impurity removal process, agglomerated inclusions are dispersed and can be adsorbed, dissolved and crushed by the refining agent, and in the process, nitrogen generated by the reaction of magnesium nitride and oxidized impurities can effectively adsorb aluminum oxide impurities and take away hydrogen in a solution; and the refining agent with added magnesium nitride is a purification mechanism of cooperative action of adsorption diffusion, dissolution reaction and bubble floating, and the impurity removal rate can be effectively increased to 80% by adding the magnesium nitride, so that the refining effect of the refining agent can be effectively improved, and the aluminum alloy refining quality is ensured.

Owner:徐州立伟铝业有限公司

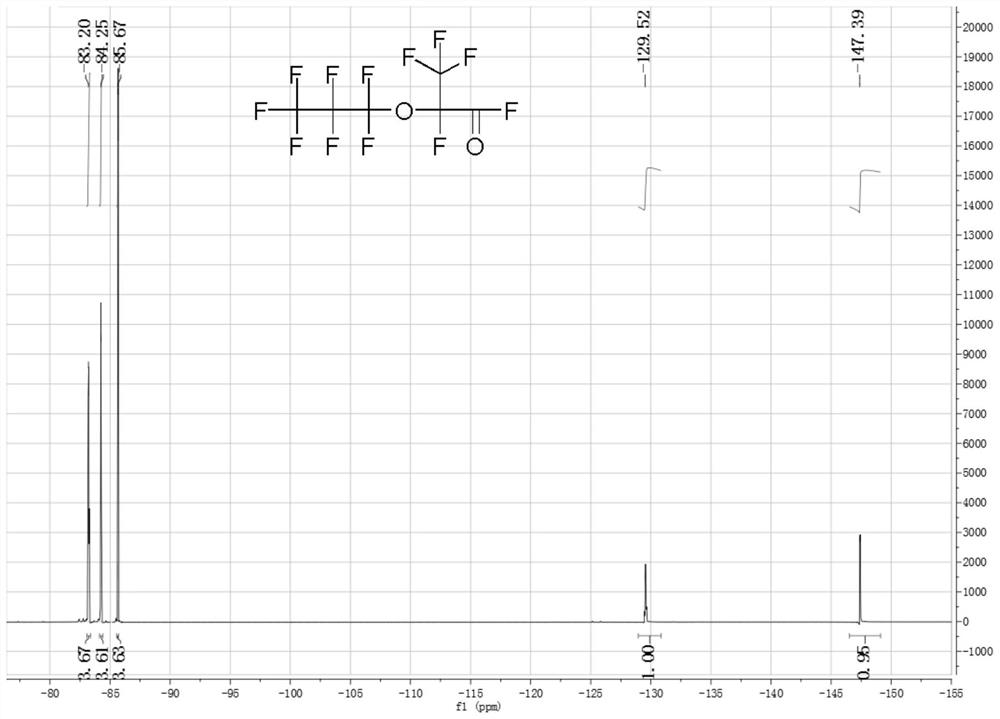

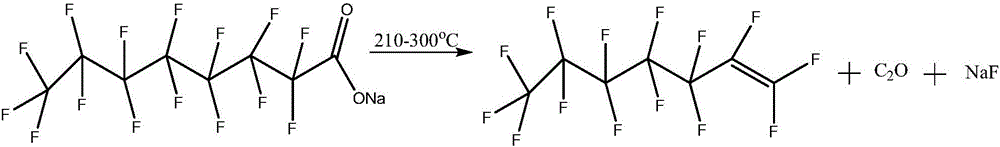

A kind of method of selective synthesis hexafluoropropylene oxide oligomer

ActiveCN109485560BCatalytic activity can be tunedCatalytic activity regulationCarboxylic acid halides preparationOrganosolvHexafluoropropylene oxide

The invention provides a method for selectively synthesizing hexafluoropropylene oxide oligomers, comprising the following steps: A) adding phosphonamide, metal fluoride salt and organic solvent into a reaction device, and stirring in an airtight manner; the metal fluoride The salt is a monovalent metal fluoride salt or a divalent metal fluoride salt, and the monovalent metal fluoride salt is one or more of lithium fluoride, sodium fluoride, potassium fluoride, rubidium fluoride and cesium fluoride kind, the divalent metal fluoride salt is one or more of zinc fluoride, barium fluoride and magnesium fluoride; B) passing hexafluoropropylene oxide into the reaction device for reaction to obtain Hexafluoropropylene oxide dimer or hexafluoropropylene oxide trimer. The invention has low raw material cost, does not need low temperature and dry environment, and is environmentally friendly, and can selectively synthesize hexafluoropropylene oxide dimer or trimer with a content of more than 80%.

Owner:湖南有色郴州氟化学有限公司

Method for preparing halogenated five-membered cycloolefin by gas phase isomerization reaction

ActiveCN107445794BRaw materials are easy to getPhysical/chemical process catalystsHalogenated hydrocarbon preparationIsomerizationPtru catalyst

The invention relates to a method for preparing halogenated pentacyclic olefin by gas-phase isomerization reaction. The method comprises the following steps of: by adopting the halogenated pentacyclic olefin C5HxFyClz as a material, under the existence of an isomerization catalyst, generating the gas-phase isomerization reaction to obtain isomers of the halogenated pentacyclic olefin, wherein X is an integer from 0 to 2, Y is an integer from 4 to 7, Z is an integer from 0 to 4, the sum of X and Y and Z is 8, and the isomerization catalyst is prepared by adopting at least one of lithium fluoride, potassium fluoride, sodium fluoride, rubidium fluoride or cesium fluoride as an active component and loading the active component on at least one of carriers such as aluminium fluoride, magnesium fluoride, iron fluoride, chromium fluoride and zinc fluoride. The method has the advantages that the material is easy to obtain, the isomerization catalyst is low in price, the yield of the isomer is higher, and the method is applicable to large-scale preparation of the isomers of the halogenated pentacyclic olefin by gas-phase reaction.

Owner:BEIJING YUJI SCI & TECH

A kind of ceramic target material and preparation method thereof

The invention relates to the technical field of sputtering targets, in particular to a ceramic target and a preparation method thereof. The preparation method includes: A) homogeneously mixing the copper-zinc-tin-selenium powder and rubidium fluoride powder, and pre-pressing the homogeneously mixed powder to obtain a green body; B) in a vacuum Under certain conditions, heat the green body to 200-400°C and keep it warm; C) then heat it to 600-700°C, heat it and carry out hot-press sintering at 25-50MPa, after cooling down and decompressing, the target blank is obtained ; D) machining the target blank to obtain a ceramic target material. The ceramic target material prepared by the preparation method provided by the invention has high purity and density and uniform components. It provides a certain theoretical reference for the preparation of high-performance doped targets. The results show that the purity of the ceramic target prepared by the present invention is >99.99%, and the density is 5.53-5.58g / cm 3 , The relative density is 94-95%.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559BImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

CSF-RBF-ALF3 Flux Containing Nanometer Rare Earth Fluoride

ActiveCN106825996BExcellent mechanical properties of the brazing seamHigh activityWelding/cutting media/materialsWelding/soldering/cutting articlesAluminum fluorideRare earth

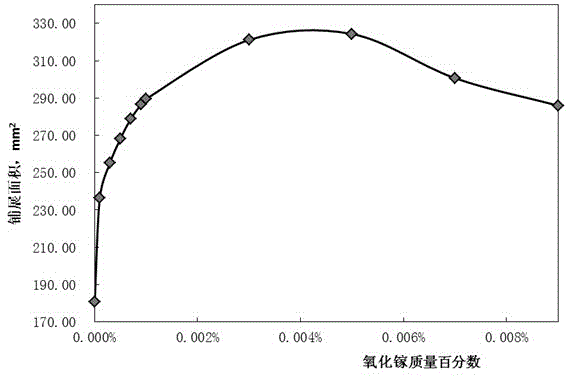

The invention discloses a CsF-RbF-AlF3 brazing flux containing nano rare-earth fluoride. The CsF-RbF-AlF3 brazing flux is characterized by comprising the following chemical components, by weight percent (wt.%), 0.02-0.2% of rubidium fluoride (RbF), 20.0-48.0% of cesium fluoride (CsF), 0.01-2.0% of aluminum oxide (Al2O3), 0.01-1.0% of potassium fluoride (KF), 0.001-0.05% of nano ceric fluoride (CeF4), and the balance aluminum fluoride (AlF3). The CsF-RbF-AlF3 brazing flux has higher activity than the existing brazing flux, and can meet the brazing requirements of aluminum-steel, aluminum-copper and aluminum-aluminum structures simultaneously.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

CsF-RbF-AlF3 brazing flux containing nano rare-earth fluoride

ActiveCN106825996AExcellent mechanical properties of the brazing seamHigh activityWelding/cutting media/materialsWelding/soldering/cutting articlesAluminum fluorideRare earth

The invention discloses a CsF-RbF-AlF3 brazing flux containing nano rare-earth fluoride. The CsF-RbF-AlF3 brazing flux is characterized by comprising the following chemical components, by weight percent (wt.%), 0.02-0.2% of rubidium fluoride (RbF), 20.0-48.0% of cesium fluoride (CsF), 0.01-2.0% of aluminum oxide (Al2O3), 0.01-1.0% of potassium fluoride (KF), 0.001-0.05% of nano ceric fluoride (CeF4), and the balance aluminum fluoride (AlF3). The CsF-RbF-AlF3 brazing flux has higher activity than the existing brazing flux, and can meet the brazing requirements of aluminum-steel, aluminum-copper and aluminum-aluminum structures simultaneously.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Process for preparing isomers of chlorofluorocyclopentene

The invention relates to a method for preparing chlorine fluorine cyclopentene isomeride in the formula (II) (please see the formula in the specification). The chlorine fluorine cyclopentene isomeride is obtained with chlorine fluorine cyclopentene in the formula (I) (please see the formula in the specification) as the raw material in solvent dimethylformamide, dimethyl sulfoxide or sulfolane by conducting an isomerization reaction in catalysts ammonium fluoride, ammonium bifluoride, potassium fluoride, lithium fluoride, sodium fluoride, rubidium fluoride or cesium fluoride. The technological method is little in raw material toxicity and mild in reaction conditions, the reaction is easy to control, the isomeride yield of chlorine fluorine cyclopentene is high, and industrialization is easy.

Owner:BEIJING YUJI SCI & TECH +1

A kind of flux suitable for aluminum steel brazing

ActiveCN105643144BHigh activityLow priceWelding/cutting media/materialsWelding/soldering/cutting articlesAluminum fluorideAluminium hydroxide

Owner:ZHEJIANG XINRUI WELDING MATERIAL

Cesium Rubidium Flux Containing Gallium Oxide

ActiveCN104551450BSimple preparation processImprove performanceWelding/cutting media/materialsSoldering mediaRubidiumMetallic materials

The invention discloses a caesium rubidium soldering flux containing gallium oxide, belonging to the brazing material field of non-metallic materials. The caesium rubidium soldering flux containing gallium oxide is characterized in that the caesium rubidium soldering flux containing gallium oxide comprises the following components in proportion in mole number: 0.12-0.5 mole of rubidium fluoride (RbF), 0.12-0.5 mole of cesium fluoride (CsF), 0.001-0.2 mole of aluminium oxide (Al2O3), 0.001-0.02 mole of potassium fluoride (KF), 0.0001-0.02 mole of gallium oxide (Ga2O3), and 0.159-0.479 mole of aluminium fluoride (AlF3). According to the caesium rubidium soldering flux containing the gallium oxide, the requirement on brazing the aluminium-copper, the aluminium-steel and the aluminium-aluminium can be satisfied simultaneously and the caesium rubidium soldering flux containing gallium oxide has high activity.

Owner:ZHEJIANG YONGWANG WELDING MATERIALS CO LTD

Medium-temperature anti-corrosion fluoroaluminate flux and preparation method thereof

ActiveCN104816107BLower melting temperatureImprove liquidityWelding/cutting media/materialsSoldering mediaRubidiumLepidolite

The invention relates to medium-temperature type anti-corrosion fluoroaluminate soldering flux and a preparation method thereof. The soldering flux takes lithium-settling mother liquor obtained by extracting lithium from Jiangxi lepidolite as a base solution; the base solution is subjected to impurity removal to obtain a solution rich in k, Rb and Cs as a raw material solution; one or more of aluminum fluoride, potassium fluoride, rubidium fluoride and cesium fluoride are dosed and added to prepare mixed type soldering flux; the added metal salts can be extracted from the lepidolite. The lepidolite is rich in rubidium and cesium, so that the production cost of the novel soldering flux is greatly reduced, and the Jiangxi lepidolite realizes resource maximum utilization. The medium-temperature type anti-corrosion fluoroaluminate soldering flux is suitable for welding aluminum alloy and high-magnesium alloy, and has special activity on alloy with high magnesium content.

Owner:JIANGXI HZONE LITHIUM TECH

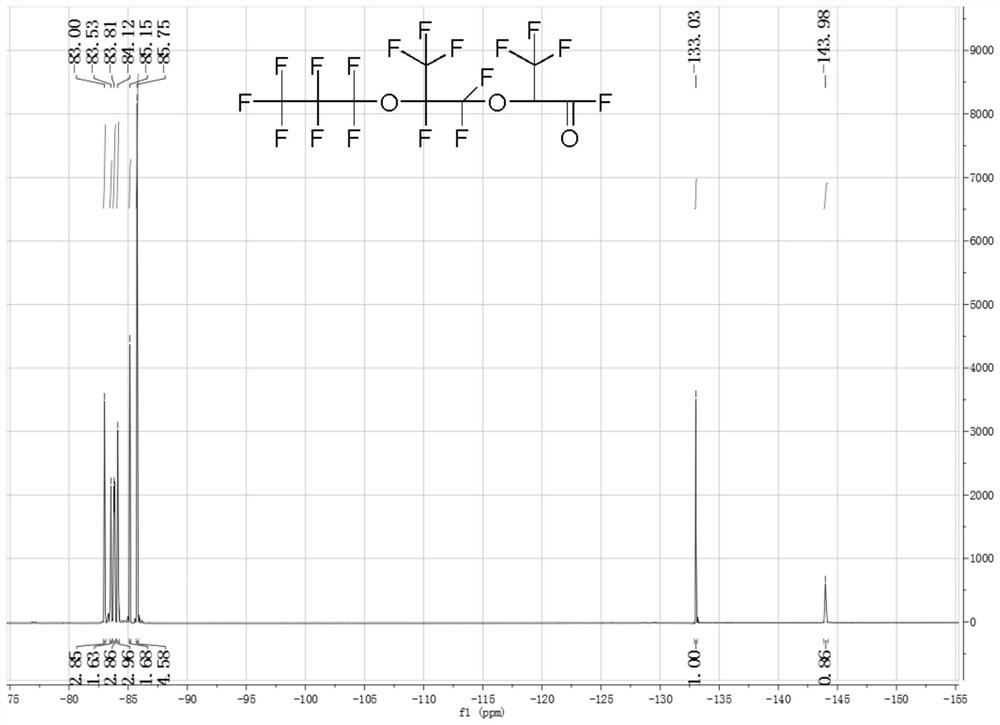

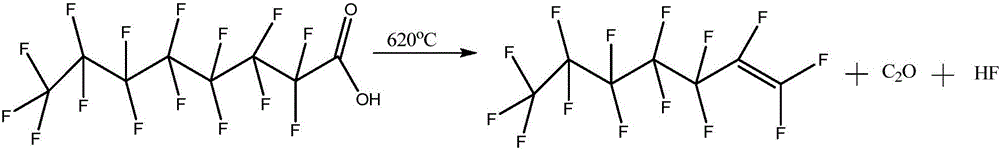

Method for preparing perfluoroheptene isomers

ActiveCN105949030AHigh yieldMild reaction conditionsOrganic chemistry methodsHalogenated hydrocarbon preparationSulfolaneIsomerization

The invention relates to a method for preparing perfluoroheptene isomers. The method comprises the following steps: using perfluoroheptene with a formula of F(CF2)xCF=CF(CF2)yF(x+y=5, and x=0,1,2) as the raw material, so as to perform isomerization reaction in a solvent such as dimethylformamide, dimethylsulfoxide or sulfolane in the presence of a catalyst such as ammonium fluoride, potassium fluoride, lithium fluoride, sodium fluoride, rubidium fluoride or cesium fluoride, so as to obtain F(CF2)nCF=CF(CF2)mF(m+n=5, and n=0,1,2). The technical method provided by the invention is mild in reaction condition, easy in reaction control, free of water-free and oxygen-free operation, high in yield of perfluoroheptene isomers, and easy to industrialize.

Owner:泉州宇极新材料科技有限公司

Ceramic target and preparation method thereof

The invention relates to the technical field of sputtering targets, in particular to a ceramic target and a preparation method thereof. The preparation method comprises the following steps: (A) homogeneously mixing a copper-zinc-tin-selenium powder with a barium fluoride powder, pre-pressing the homogenously mixed power to obtain a green body; (B) under a vacuum condition, heating the green body to 200 to 400 DEG C, and performing heat preservation; (C) then heating to 600 to 700 DEG C, performing heat preservation at 25 to 50 MPa for hot pressing sintering, and performing cooling and decompression to obtain a target blank; and (D) machining the target blank to obtain the ceramic target. The ceramic target prepared by the preparation method provided by the invention is relatively high in purity and density and uniform in composition. A theoretical reference is provided for the preparation of high-performance doped targets. The results show that the ceramic target prepared by the invention has a purity more than 99.99 percent, a density of 5.53 to 5.58 g / cm<3> and a relative density of 94 to 95 percent.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com