CsF-RbF-AlF3 brazing flux containing nano rare-earth fluoride

A nano-rare earth and fluoride technology, which is applied in the direction of welding/welding/cutting articles, welding media, welding/cutting media/materials, etc., to achieve the effect of increasing the spreading area and high flux activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] CsF-RbF-AlF3 brazing flux containing nano-rare earth fluoride, by mass percentage (wt.%), chemical composition is: 0.02% rubidium fluoride (RbF), 48.0% cesium fluoride (CsF), 0.01% Aluminum oxide (Al 2 o 3 ), 1.0% potassium fluoride (KF), 0.001% nano cerium tetrafluoride (CeF 4 ), the balance is aluminum fluoride (AlF 3 ).

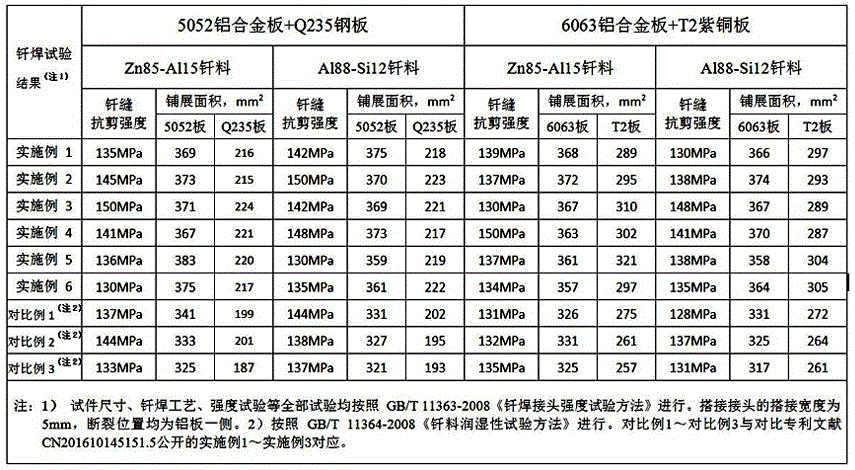

[0039] The new type of CsF-RbF-AlF3 brazing flux containing nano-rare earth fluorides obtained by the above proportioning, adopts propane as a combustible gas for flame brazing, cooperates with Zn85-Al15 brazing filler metal, Al88-Si12 brazing filler metal, and uses 5052 aluminum alloy plate+Q235 The combination of steel plate, 6063 aluminum alloy plate + T2 red copper is tested according to GB / T 11363-2008 "Test Method for Strength of Brazed Joint", and the shear strength of the brazed joint reaches 130MPa-150MPa respectively.

Embodiment 2

[0041] CsF-RbF-AlF3 brazing flux containing nano-rare earth fluoride, by mass percentage (wt.%), chemical composition is: 0.2% rubidium fluoride (RbF), 20.0% cesium fluoride (CsF), 2.0% Aluminum oxide (Al 2 o 3 ), 0.01% potassium fluoride (KF), 0.05% nano cerium tetrafluoride (CeF 4 ), the balance is aluminum fluoride (AlF 3 ).

[0042] The new type of CsF-RbF-AlF3 brazing flux containing nano-rare earth fluorides obtained by the above proportioning, adopts propane as a combustible gas for flame brazing, cooperates with Zn85-Al15 brazing filler metal, Al88-Si12 brazing filler metal, and uses 5052 aluminum alloy plate+Q235 The combination of steel plate, 6063 aluminum alloy plate + T2 red copper is tested according to GB / T 11363-2008 "Test Method for Strength of Brazed Joint", and the shear strength of the brazed joint reaches 130MPa-150MPa respectively.

Embodiment 3

[0044] CsF-RbF-AlF3 brazing flux containing nano-rare earth fluoride, by mass percentage (wt.%), chemical composition is: 0.15% rubidium fluoride (RbF), 40.0% cesium fluoride (CsF), 1.0% Aluminum oxide (Al 2 o 3 ), 0.5% potassium fluoride (KF), 0.02% nano cerium tetrafluoride (CeF 4 ), the balance is aluminum fluoride (AlF 3 ).

[0045] The new type of CsF-RbF-AlF3 brazing flux containing nano-rare earth fluorides obtained by the above proportioning, adopts propane as a combustible gas for flame brazing, cooperates with Zn85-Al15 brazing filler metal, Al88-Si12 brazing filler metal, and uses 5052 aluminum alloy plate+Q235 The combination of steel plate, 6063 aluminum alloy plate + T2 red copper is tested according to GB / T 11363-2008 "Test Method for Strength of Brazed Joint", and the shear strength of the brazed joint reaches 130MPa-150MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com