Sn-Zn lead-free solder containing Pr, Ga and Se

A lead-free solder, sn-zn technology, applied in the field of Sn-Zn lead-free solder of Se, Ga, containing Pr, can solve difficult industrial production, poor wettability, solder cost, solder melting point gap And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

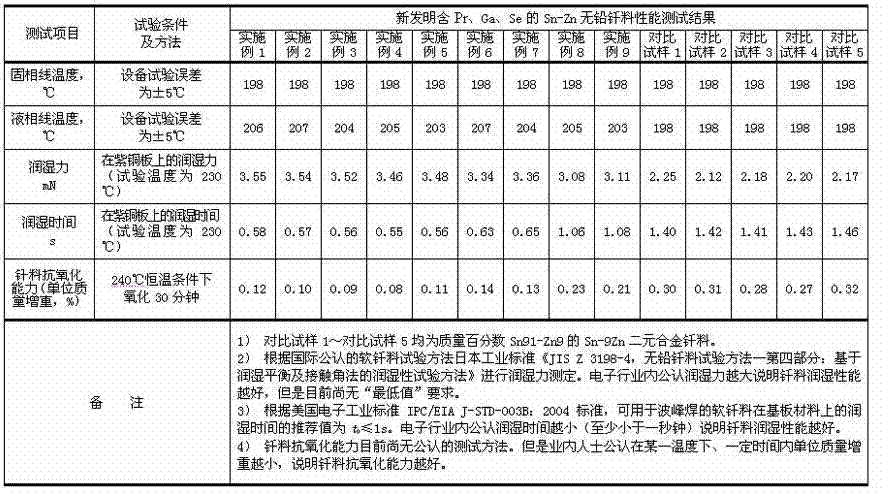

Embodiment 1

[0021] A kind of Sn-Zn lead-free solder containing Pr, Ga, Se, proportioned by mass percentage, its composition is: 6.0% of Zn, 0.5% of Pr, 0.005% of Ga, 0.001% of Se, remaining The amount is Sn.

[0022] The solidus temperature of the "Sn-Zn lead-free solder containing Pr, Ga, Se" obtained from the above composition ratio is about 198°C, and the liquidus temperature is about 206°C (both taking into account experimental errors). Cooperating with commercially available RMA flux has excellent wettability on the copper plate, and the tensile strength of the brazing seam reaches 75MPa±15MPa.

Embodiment 2

[0024] A kind of Sn-Zn lead-free solder containing Pr, Ga, Se, proportioning by mass percentage, its composition is: 10.5% Zn, 0.005% Pr, 1.5% Ga, 0.3% Se, the balance is Sn.

[0025] The solidus temperature of the "Sn-Zn lead-free solder containing Pr, Ga, Se" obtained by the above-mentioned composition ratio is about 198°C, and the liquidus temperature is about 207°C (all considering experimental errors). Cooperating with commercially available RMA flux has excellent wettability on the copper plate, and the tensile strength of the brazing seam reaches 75MPa±15MPa.

Embodiment 3

[0027] A kind of Sn-Zn lead-free solder containing Pr, Ga, Se, proportioning by mass percentage, its composition is: the Zn of 8.5%, the Pr of 0.25%, the Ga of 1.0%, the Se of 0.2%, the surplus is Sn.

[0028] The solidus temperature of the "Sn-Zn lead-free solder containing Pr, Ga, Se" obtained by the above composition ratio is about 198°C, and the liquidus temperature is about 204°C (both taking into account the experimental error). Cooperating with commercially available RMA flux has excellent wettability on the copper plate, and the tensile strength of the brazing seam reaches 75MPa±15MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com