Cesium and rubidium brazing flux containing zinc tetrafluoroborate hydrate

A zinc fluoroborate and cesium-rubidium brazing technology, which is applied in the field of cesium-rubidium flux containing zinc fluoroborate, can solve the problem that the mechanical properties of brazing joints are not given tensile strength or shear strength, and the quality and price of consumable materials cannot be satisfied. Inexpensive, inability to braze aluminum-copper dissimilar materials, etc., to achieve high-reliability green manufacturing, material cost reduction, and excellent wetting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

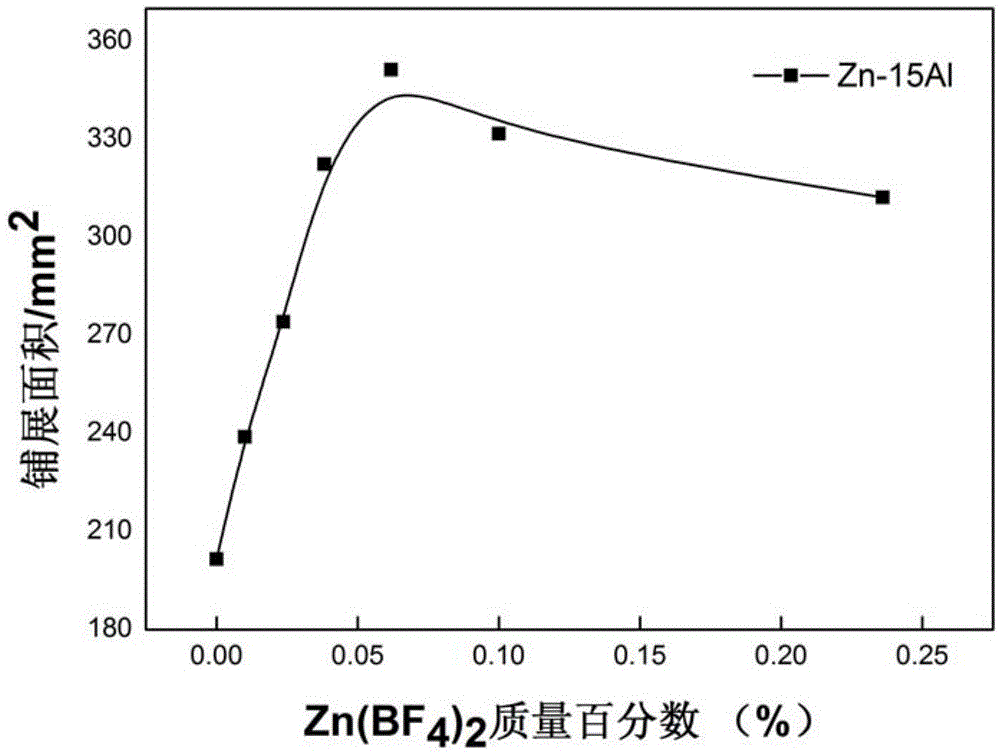

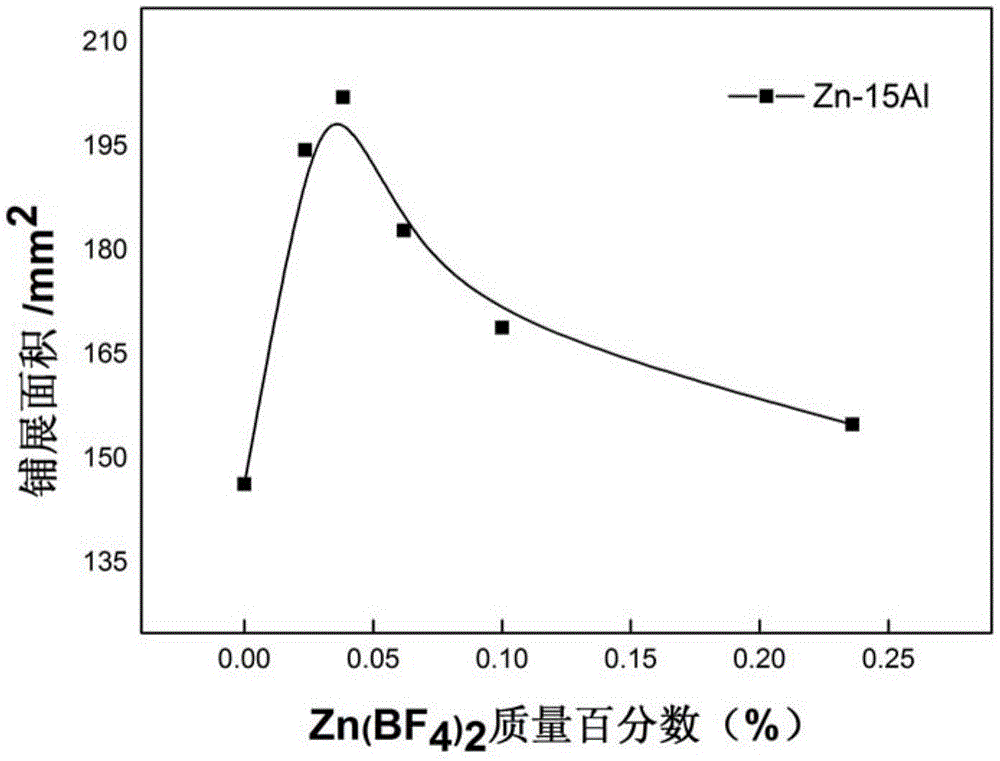

[0026] A cesium-rubidium brazing flux containing zinc fluoroborate, the chemical composition is: 0.001% rubidium fluoride (RbF), 50.0% cesium fluoride (CsF), 0.01% oxide Aluminum (Al 2 o 3 ), 5.0% potassium fluoride (KF), 0.001% zinc fluoroborate (Zn(BF 4 ) 2 ), the balance is aluminum fluoride (AlF 3 ).

[0027] The new cesium-rubidium brazing flux containing zinc fluorine borate obtained by the above-mentioned ratio adopts propane as combustible gas for flame brazing, cooperates with Zn85-Al15 solder, and uses Q235 steel plate+5052 aluminum alloy plate, T 2 The copper + 6063 aluminum alloy plate combination is tested according to GB / T11363-2008 "Test Method for Brazed Joint Strength", and the shear strength of the brazed joint reaches 125MPa-145MPa respectively.

Embodiment 2

[0029] A cesium-rubidium brazing flux containing zinc fluoroborate, in terms of mass percentage (wt.%), the chemical composition is: 0.01% rubidium fluoride (RbF), 10.0% cesium fluoride (CsF), 5.0% oxide Aluminum (Al 2 o 3 ), 0.01% potassium fluoride (KF), 0.25% zinc fluoroborate (Zn(BF 4 ) 2 ), the balance is aluminum fluoride (AlF 3 ).

[0030] The new cesium-rubidium brazing flux containing zinc fluorine borate obtained by the above-mentioned ratio adopts propane as combustible gas for flame brazing, cooperates with Zn85-Al15 solder, and uses Q235 steel plate+5052 aluminum alloy plate, T 2 The copper + 6063 aluminum alloy plate combination is tested according to GB / T11363-2008 "Test Method for Brazed Joint Strength", and the shear strength of the brazed joint reaches 125MPa-145MPa respectively.

Embodiment 3

[0032] A cesium-rubidium brazing flux containing zinc fluoroborate, in terms of mass percentage (wt.%), the chemical composition is: 0.005% rubidium fluoride (RbF), 30.0% cesium fluoride (CsF), 2.5% oxide Aluminum (Al 2 o 3 ), 2.5% potassium fluoride (KF), 0.05% zinc fluoroborate (Zn(BF 4 ) 2 ), the balance is aluminum fluoride (AlF 3 ). The new cesium-rubidium brazing flux containing zinc fluorine borate obtained by the above-mentioned ratio adopts propane as combustible gas for flame brazing, cooperates with Zn85-Al15 solder, and uses Q235 steel plate+5052 aluminum alloy plate, T 2 The copper + 6063 aluminum alloy plate combination is tested according to GB / T11363-2008 "Test Method for Brazed Joint Strength", and the shear strength of the brazed joint reaches 125MPa-145MPa respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com