A kind of flux suitable for aluminum steel brazing

A technology of brazing flux and steel brazing, which is applied in the direction of welding medium, welding equipment, welding/welding/cutting items, etc., can solve the problems of complex formula, high price and difficulty, and achieve simple preparation process, low price and high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

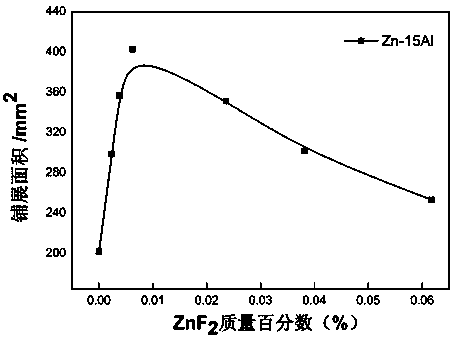

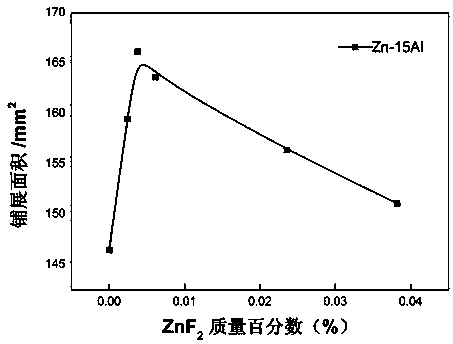

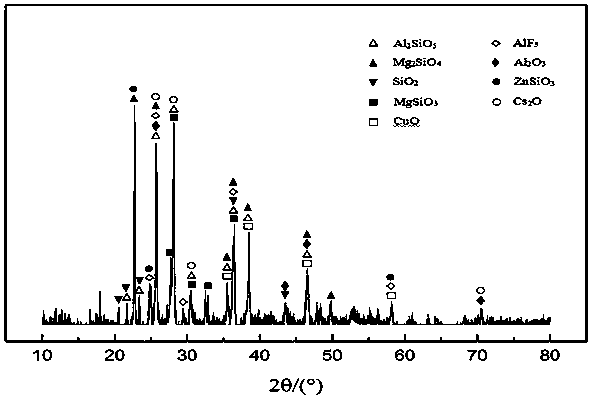

[0029] A flux suitable for brazing of aluminum and steel, in terms of mass percentage (wt.%), the chemical composition is: 0.001% rubidium fluoride (RbF), 45.0% cesium fluoride (CsF), 2.0% hydrogen Alumina (Al(HO) 3 ), 0.01% potassium fluoride (KF), 0.04% zinc fluoride (ZnF 2 ), the balance being aluminum fluoride (AlF 3 ).

[0030] The new brazing flux suitable for aluminum-steel brazing obtained by the above-mentioned proportions uses propane as a combustible gas for flame brazing, cooperates with Zn85-Al15 brazing filler metal, and uses Q235 steel plate + 5052 aluminum alloy plate, T 2 The copper + 6063 aluminum alloy plate combination is tested according to GB / T11363-2008 "Test Method for Brazed Joint Strength", and the shear strength of the brazed joint reaches 120MPa-145MPa respectively.

Embodiment 2

[0032] A flux suitable for brazing aluminum and steel, in terms of mass percentage (wt.%), the chemical composition is: 0.01% rubidium fluoride (RbF), 11.0% cesium fluoride (CsF), 0.01% hydrogen Alumina (Al(HO) 3 ), 5.0% potassium fluoride (KF), 0.001% zinc fluoride (ZnF 2 ), the balance being aluminum fluoride (AlF 3 ).

[0033] The new brazing flux suitable for aluminum-steel brazing obtained by the above-mentioned proportions uses propane as a combustible gas for flame brazing, cooperates with Zn85-Al15 brazing filler metal, and uses Q235 steel plate + 5052 aluminum alloy plate, T 2 The copper + 6063 aluminum alloy plate combination is tested according to GB / T11363-2008 "Test Method for Brazed Joint Strength", and the shear strength of the brazed joint reaches 120MPa-145MPa respectively.

Embodiment 3

[0035] A flux suitable for brazing aluminum and steel, in terms of mass percentage (wt.%), the chemical composition is: 0.005% rubidium fluoride (RbF), 25.0% cesium fluoride (CsF), 0.5% hydrogen Alumina (Al(HO) 3 ), 1.5% potassium fluoride (KF), 0.01% zinc fluoride (ZnF 2 ), the balance being aluminum fluoride (AlF 3 ).

[0036] The new brazing flux suitable for aluminum-steel brazing obtained by the above-mentioned proportions uses propane as a combustible gas for flame brazing, cooperates with Zn85-Al15 brazing filler metal, and uses Q235 steel plate + 5052 aluminum alloy plate, T 2 The copper + 6063 aluminum alloy plate combination is tested according to GB / T11363-2008 "Test Method for Brazed Joint Strength", and the shear strength of the brazed joint reaches 120MPa-145MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com