Quaternary alloy brazing filler metal

A quaternary alloy and brazing material technology, which is applied in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problems of high brazing price and consumption of precious metal silver, etc., and achieve improved wettability and fluidity , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

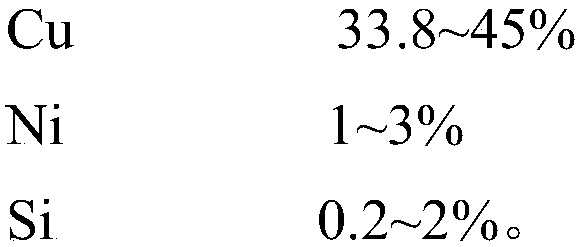

[0020] A kind of quaternary alloy brazing filler metal, its preparation method comprises the steps: (element ratio as shown in Table 1)

[0021] (1) Put the raw materials Ag, Cu, Ni, and Si into the vacuum melting furnace according to the ratio. After the vacuum degree in the furnace reaches 0.04Pa, the furnace is heated to 1200 ° C and kept for 30 minutes to obtain an ingot;

[0022] (2) Peel the ingot obtained in step (1) first, peel off the dirt and oxide layer on the surface of the ingot, and then carry out cold rolling in a rolling mill. When the thickness reaches 2mm, coil it and place it at 550°C for 2 hours, and then Naturally cool to room temperature, take out the strip after annealing;

[0023] (3) Continue to cold-roll the strip after the annealing treatment in step (2) to a thickness of 0.04 mm, then cut it into strips of a certain width and punch out the desired shape.

Embodiment 2

[0025] A kind of quaternary alloy brazing filler metal, its preparation method comprises the steps: (element ratio as shown in Table 1)

[0026] (1) put raw material Ag, Cu, Ni, Si into the vacuum smelting furnace according to the proportion, after the vacuum degree in the furnace reaches 0.2Pa, then heat the furnace to 1250°C, keep the temperature for 35 minutes, and make the ingot;

[0027] (2) The ingot obtained in step (1) is first peeled off to remove the dirt and oxide layer on the surface of the ingot, and then cold rolled in a rolling mill. When the thickness reaches 2.5mm, it is coiled and placed at 600°C for 2.5 hours. Then naturally cool to room temperature, take out the strip after annealing;

[0028] (3) Continue to cold-roll the strip after the annealing treatment in step (2) to a thickness of 0.1 mm, and then cut it into strips of a certain width and punch out the desired shape.

Embodiment 3

[0030] A kind of quaternary alloy brazing filler metal, its preparation method comprises the steps: (element ratio as shown in Table 1)

[0031] (1) put raw materials Ag, Cu, Ni, Si into the vacuum smelting furnace according to the proportioning, after the vacuum degree in the furnace reaches 0.4Pa, then heat the furnace to 1300°C, keep the temperature for 40 minutes, and make the ingot;

[0032] (2) The ingot obtained in step (1) is first peeled by car to remove the dirt and oxide layer on the surface of the ingot, and then cold rolled in a rolling mill. When the thickness reaches 3mm, it is coiled and placed at 650 ° C for 3 hours, and then Naturally cool to room temperature, take out the strip after annealing;

[0033] (3) Continue to cold-roll the strip after the annealing treatment in step (2) to a thickness of 0.15 mm, then cut it into strips of a certain width and punch out the desired shape.

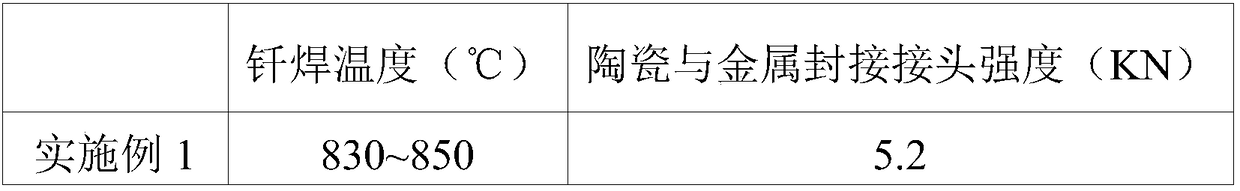

[0034] Table 1 (unit: weight %)

[0035] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com