Novel oxidation-resistant quarternary alloy solder

A quaternary alloy and anti-oxidation technology, which is applied in the sealing of ceramics and metals, and in the field of silver-based solder, can solve the problems of increasing solder cost, waste of resources, affecting the use of solder sealing, etc., and achieves the improvement of oxidation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of the novel anti-oxidation quaternary alloy solder, the preparation method comprising the steps of:

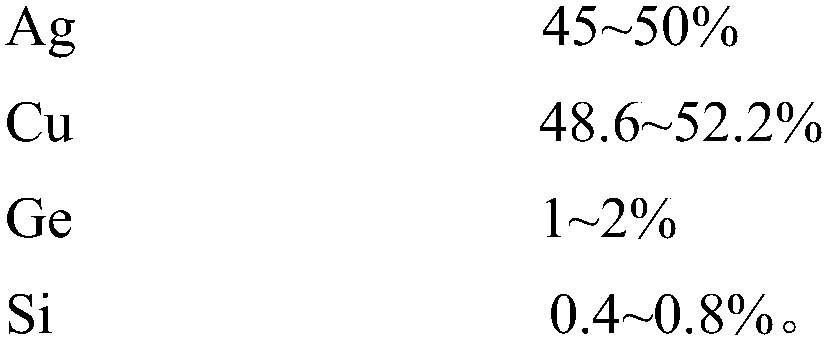

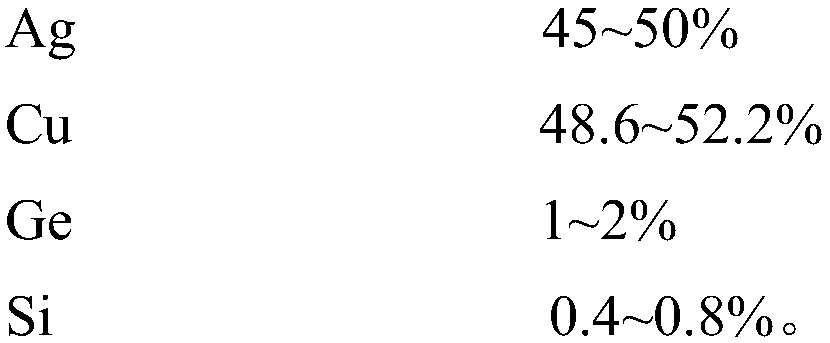

[0021] (1) Ag, Cu, Ge and Si with a purity of 99.9% are mixed according to the composition ratio of each element (see Table 1 for the amount of each element);

[0022] (2) Put it into a vacuum induction melting furnace, start heating after the vacuum degree in the furnace reaches 0.04Pa, raise the furnace temperature to 1200°C, and keep it warm for 30 minutes;

[0023] (3) After the alloy is completely melted, fill it with nitrogen gas, cool down to about 1000°C, and then pour the molten metal into the mold to obtain a solder alloy ingot;

[0024] (4) Peel the ingot, remove the oxide, then carry out cold rolling, and roll to a thickness of 1mm;

[0025] (5) Annealing at a temperature of 650°C, and then cold rolling to a 0.05mm thick foil.

Embodiment 2

[0027] A preparation method of the novel anti-oxidation quaternary alloy solder, the preparation method comprising the steps of:

[0028] (1) Ag, Cu, Ge and Si with a purity of 99.9% are mixed according to the composition ratio of each element (see Table 1 for the amount of each element);

[0029] (2) Put it into a vacuum induction melting furnace, start heating after the vacuum degree in the furnace reaches 0.2Pa, raise the furnace temperature to 1250°C, and keep it warm for 40 minutes;

[0030] (3) After the alloy is completely melted, fill it with nitrogen gas, cool down to about 1000°C, and then pour the molten metal into the mold to obtain a solder alloy ingot;

[0031] (4) The ingot is peeled, oxides are removed, and then cold rolled to a thickness of 1.5 mm;

[0032] (5) Annealing at a temperature of 650° C., and then cold rolling to a foil with a thickness of 0.07 mm.

Embodiment 3

[0034] A preparation method of the novel anti-oxidation quaternary alloy solder, the preparation method comprising the steps of:

[0035] (1) Ag, Cu, Ge and Si with a purity of 99.9% are mixed according to the composition ratio of each element (see Table 1 for the amount of each element);

[0036] (2) Put it into a vacuum induction melting furnace, start heating after the vacuum degree in the furnace reaches 0.4Pa, raise the furnace temperature to 1300°C, and keep it warm for 50 minutes;

[0037] (3) After the alloy is completely melted, fill it with nitrogen gas, cool down to about 1000°C, and then pour the molten metal into the mold to obtain a solder alloy ingot;

[0038] (4) peel the ingot, remove the oxide, then carry out cold rolling, and roll to a thickness of 2mm;

[0039] (5) Annealing at a temperature of 650° C., and then cold rolling to a 0.1 mm thick foil.

[0040] Table 1 (unit: weight %)

[0041] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com