Hyperbranched epoxy resin and preparation method and application thereof

An epoxy resin and hyperbranched polymer technology, applied in the direction of organic chemistry, can solve the problems of low heat resistance and toughness, difficult to control the structure of hyperbranched epoxy resin, and achieve low viscosity, high toughness, and structural flexibility. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

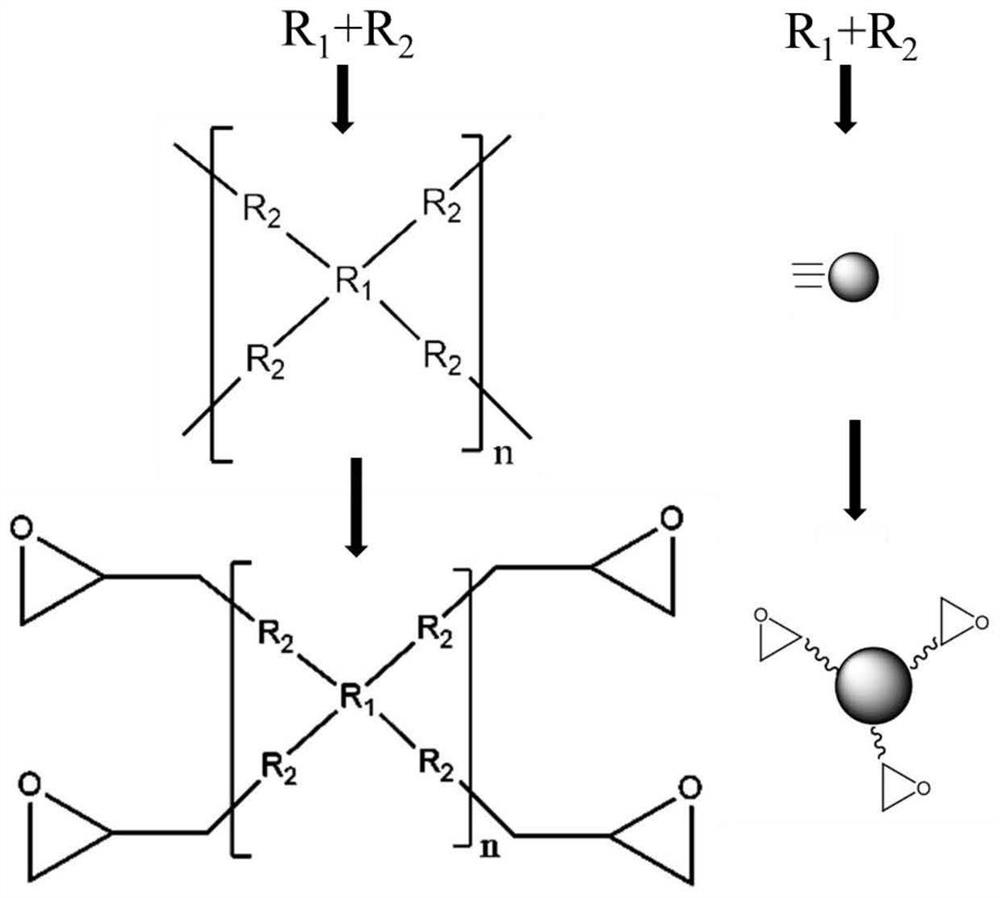

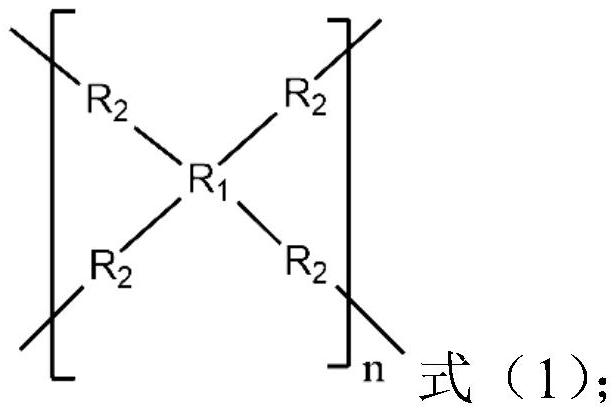

[0079] The schematic flow sheet of the preparation method of hyperbranched epoxy resin provided by the invention is as figure 1 As shown, it specifically includes the following steps:

[0080] (1) Using ethylenediaminetetraacetic acid as the first core monomer and organic alcohol as the second monomer, under the action of catalyst and water-carrying agent, synthesize hyperbranched polymer through esterification reaction at 120-200°C for 2-18 hours The molar ratio of the ethylenediaminetetraacetic acid to the organic alcohol is 5 to 35, and the mass ratio of the water-carrying agent to the ethylenediaminetetraacetic acid is 1 to 5:1; the catalyst accounts for the mass of the ethylenediaminetetraacetic acid 2-10% of

[0081] (2) Mix the solvent, inorganic salt and the hyperbranched polymer first, heat-preserve and reflux for 2 to 6 hours, then mix epichlorohydrin, phase transfer catalyst and the system after heat-preserving and reflux, and carry out 80-220°C end group Epoxidat...

Embodiment 1

[0085] The present embodiment provides a kind of preparation method of hyperbranched epoxy resin, and described preparation method comprises the steps:

[0086] (1) Add 200g of ethylenediaminetetraacetic acid as the first nuclear monomer and 212g of 1,2-ethanediol as the second monomer in a 1L reactor, and use 4g of zinc oxide as a catalyst and 200g of toluene as a water-carrying agent The temperature was raised to 120°C under stirring conditions, and the hyperbranched polymer was synthesized by esterification reaction for 2 hours under the condition of stirring. In the presence of toluene, the water produced by the reaction was taken out of the reaction system by a water separator, and the temperature was lowered to room temperature after the end of the heat preservation. The product is filtered, the catalyst is recovered, and the solvent is removed under negative pressure to obtain a hyperbranched polymer;

[0087] (2) First mix 200gDMF, 40g sodium carbonate and the hyperbra...

Embodiment 2

[0092] The present embodiment provides a kind of preparation method of hyperbranched epoxy resin, and described preparation method comprises the steps:

[0093] (1) Add 200g of ethylenediaminetetraacetic acid to the 2L reactor as the first nuclear monomer, 520g of 1,3-propanediol as the second monomer, and heat up under the action of 10g of tin oxide as a catalyst and 400g of toluene as a water-carrying agent To 130°C, esterify under stirring conditions for 6 hours to synthesize hyperbranched polymers, use a water separator to take the water out of the reaction system in the presence of toluene, and cool down to room temperature after the heat preservation is over, and carry out the esterification reaction product Filtration, catalyst recovery, solvent removal under negative pressure conditions, to obtain hyperbranched polymers;

[0094] (2) first mix 400gN-methylpyrrolidone, 50g sodium bicarbonate and described hyperbranched polymer, 180 ℃ of insulation reflux 3h, then mix 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com