Antistatic access floor

An anti-static and access technology, applied in the field of flooring, can solve the problems of inconvenient transportation and installation, unsuitable for use in high-rise buildings, and increase the load of high-rise buildings, achieving the effects of low cost, weight reduction, and difficulty in layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

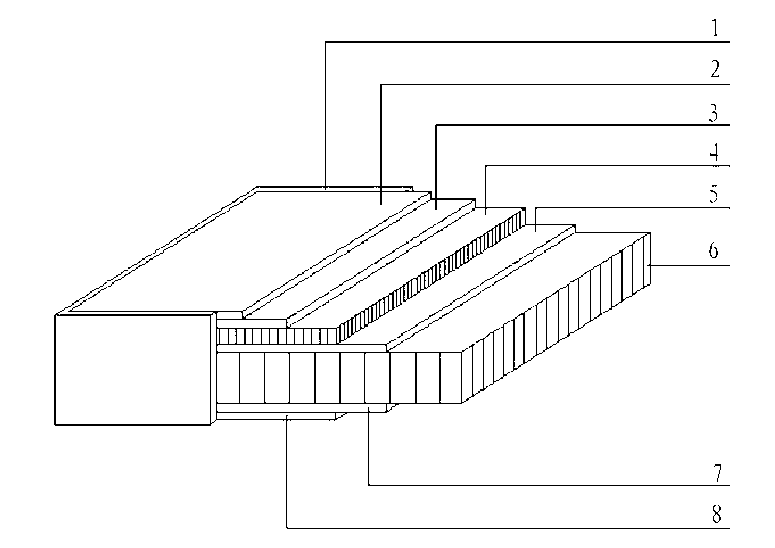

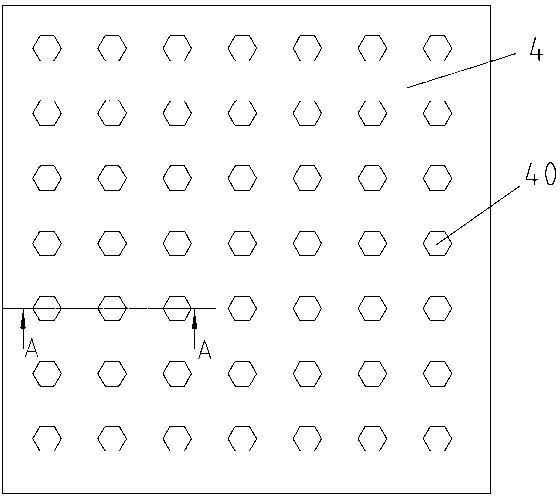

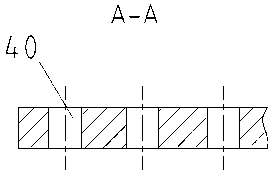

[0020] like figure 1 As shown, the present invention is provided with an antistatic surface layer 2, an upper skin layer 3, an upper honeycomb layer 4, a middle skin layer 5, a lower honeycomb layer 6, a lower skin layer 7, and a bottom surface layer from top to bottom through the surrounding edge banding 1. 8; The size of the anti-static surface layer 2, the upper skin layer 3, the upper honeycomb layer 4, the middle skin layer 5, the lower honeycomb layer 6, the lower skin layer 7, and the bottom surface layer 8 matches the size of the surrounding edge banding 1, and electrostatic glue is used on each layer Bonding; the upper skin layer 3, the middle skin layer 5, and the lower skin layer 7 are all made of kraft paper and phenolic resin glue, such as figure 2 As shown, the upper honeycomb layer 4 is an aluminum alloy material, such as image 3 As shown, it is cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com