Method for producing anatomy car trim ceiling through dry process

A dry process and production method technology, applied in chemical instruments and methods, layered products, vehicle parts, etc., can solve the problems of poor appearance quality, low dimensional accuracy, and unsatisfactory bonding effect between fabrics and knitted fabrics. Good molding effect, prevent the effect of ironing non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

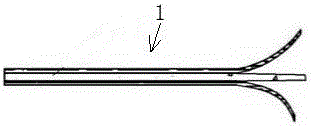

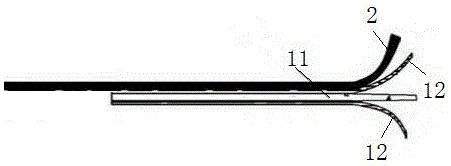

[0038] Step 1: heating the substrate 11;

[0039] In Step 1, the heating temperature of the substrate 11 is 120-170°C, and the heating time is 40-60s. The setting of the temperature and time can prevent the substrate 11 and the non-woven fabric 12 from being unable to be pasted due to the temperature being too low in Step 2. Or the bonding effect is not ideal, because there is PE or PP rubber powder on the surface of the substrate 11, by heating the substrate 11, the PE or PP rubber powder on the surface of the substrate 11 reaches a molten state, which is the subsequent substrate 11 and non-woven fabric 12. It can be firmly bonded together to provide a foundation, so that the ceiling prototype 1 can achieve a good molding effect; at the same time, it can prevent the non-woven fabric 12 from being damaged due to excessive temperature.

[0040] Specifically, in this embodiment, the heating temperature of the base material 11 is 120° C., and the heating time is 60 s. The setting...

Embodiment 2

[0065] Example 3

Embodiment 3

[0067] The above schematically describes the present invention and its implementation, which is not restrictive, and what is shown in the drawings is only one of the implementations of the present invention, and the actual structure is not limited thereto. Therefore, if a person of ordinary skill in the art is inspired by it, without departing from the inventive concept of the present invention, without creatively designing a structural mode and embodiment similar to the technical solution, it shall all belong to the protection scope of the present invention .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com