Special cut-off pulverizer for enteromorpha

A pulverizer and prolifera technology, applied in grain processing and other directions, can solve the problems that materials cannot be transported continuously in large quantities, the dehydration efficiency is reduced, and the feeding difficulty is difficult, so as to achieve the effect of less investment, low energy consumption for pulverization, and good pulverization quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

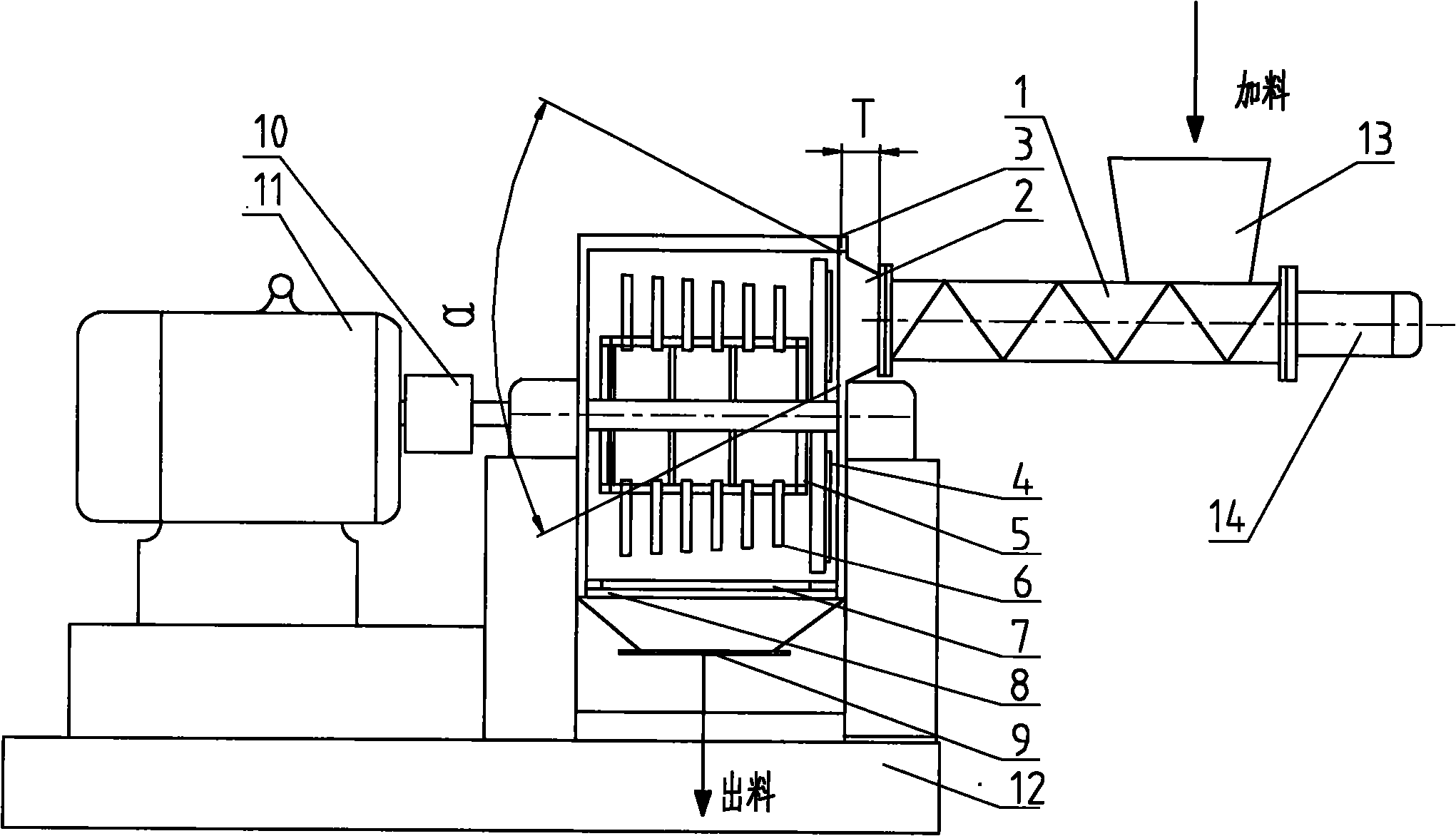

[0033] Referring to the accompanying drawings, the present invention will be further described.

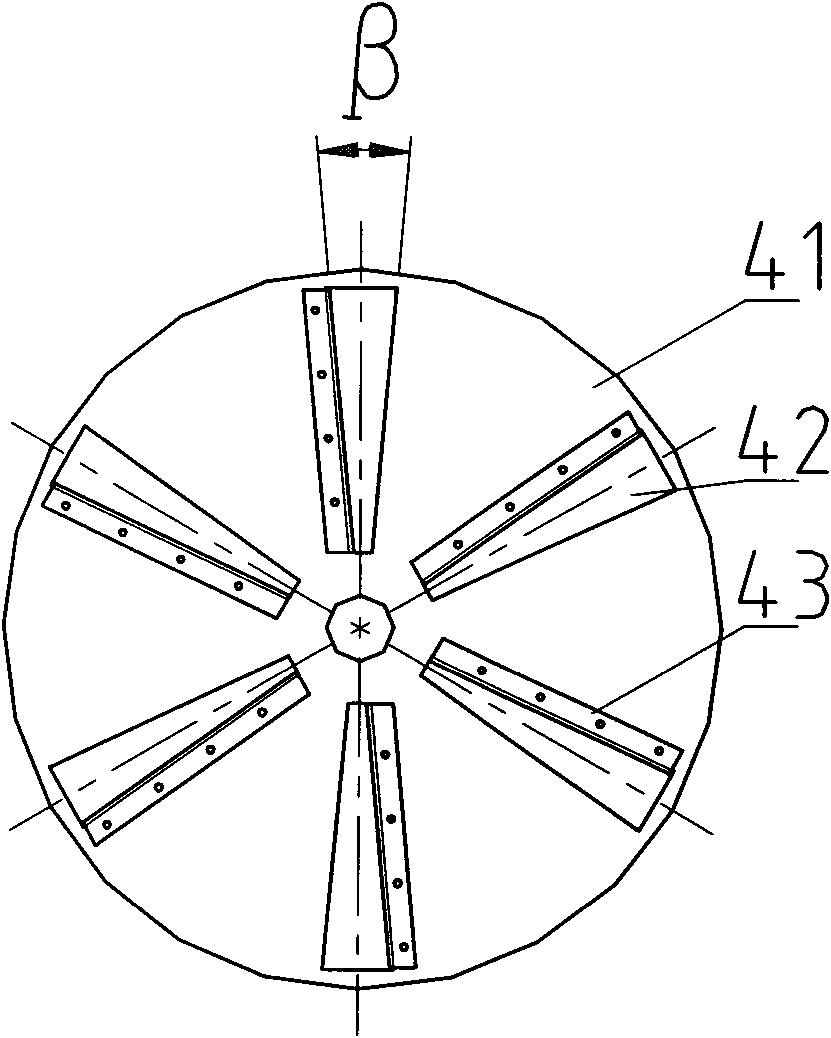

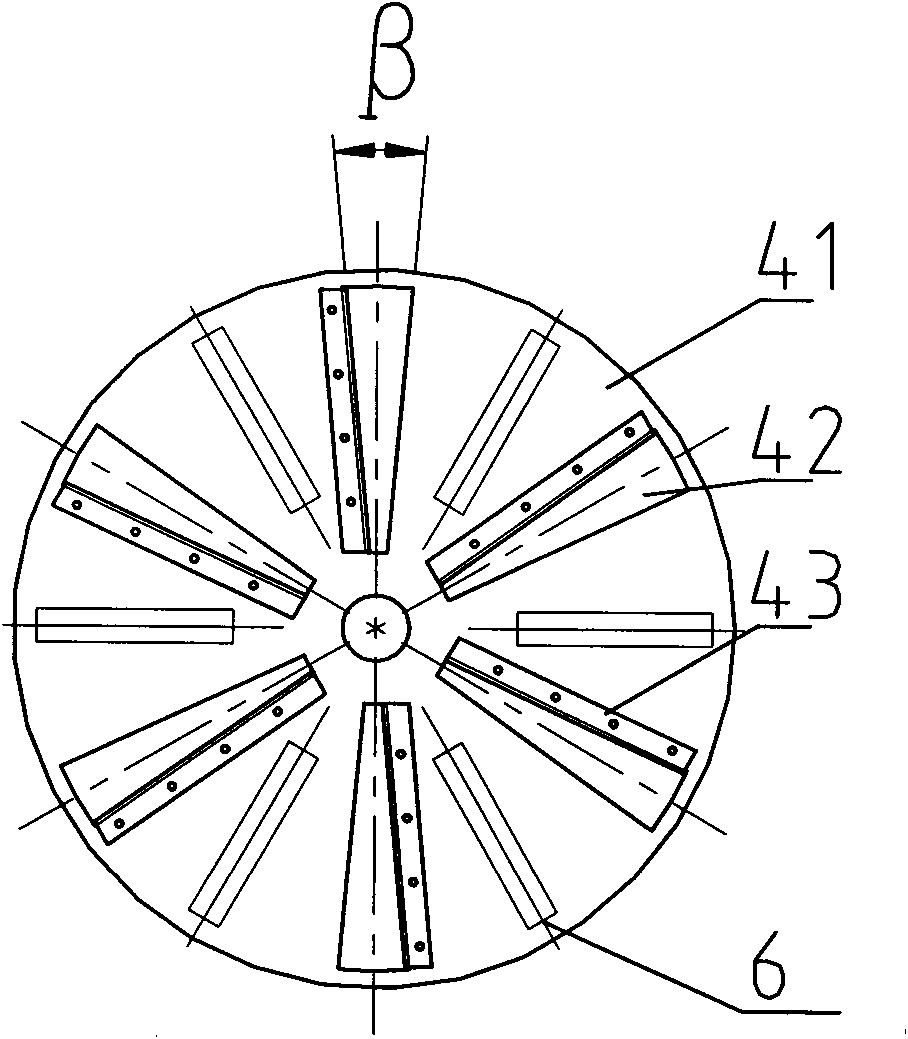

[0034]A special cutting pulverizer for enteromorpha, a motor 11 is arranged on one side of the frame 12, and the power shaft of the motor 11 stretches into the two ends fixed in the housing 3 on the other side of the frame 12 through the coupling 10, and the power A cylindrical rotor 5 is fixed on the shaft along the shaft, and multiple rows of hammer blades 6 are fixed on the outer surface of the cylindrical rotor 5 along the shaft;

[0035] A feeding hole is set on the upper part of the other side of the housing 3, and a cylindrical feeding barrel is protruded from the feeding hole through the inner large outer small diffusion feeding section 2, and a forced feeding twist is arranged in the feeding barrel. The dragon 1 is driven by the feeding motor 14 arranged on the outside, and a feeding port 13 with an upward opening is opened at the beginning of the feeding cylinder near th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com