Double-roll crusher

A crusher, double-roller technology, applied in the direction of grain processing, etc., can solve the problems of hydraulic cylinder strain, short crushing cavity, low reliability, etc., to achieve the effect of avoiding over-rolling, avoiding edge effect, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

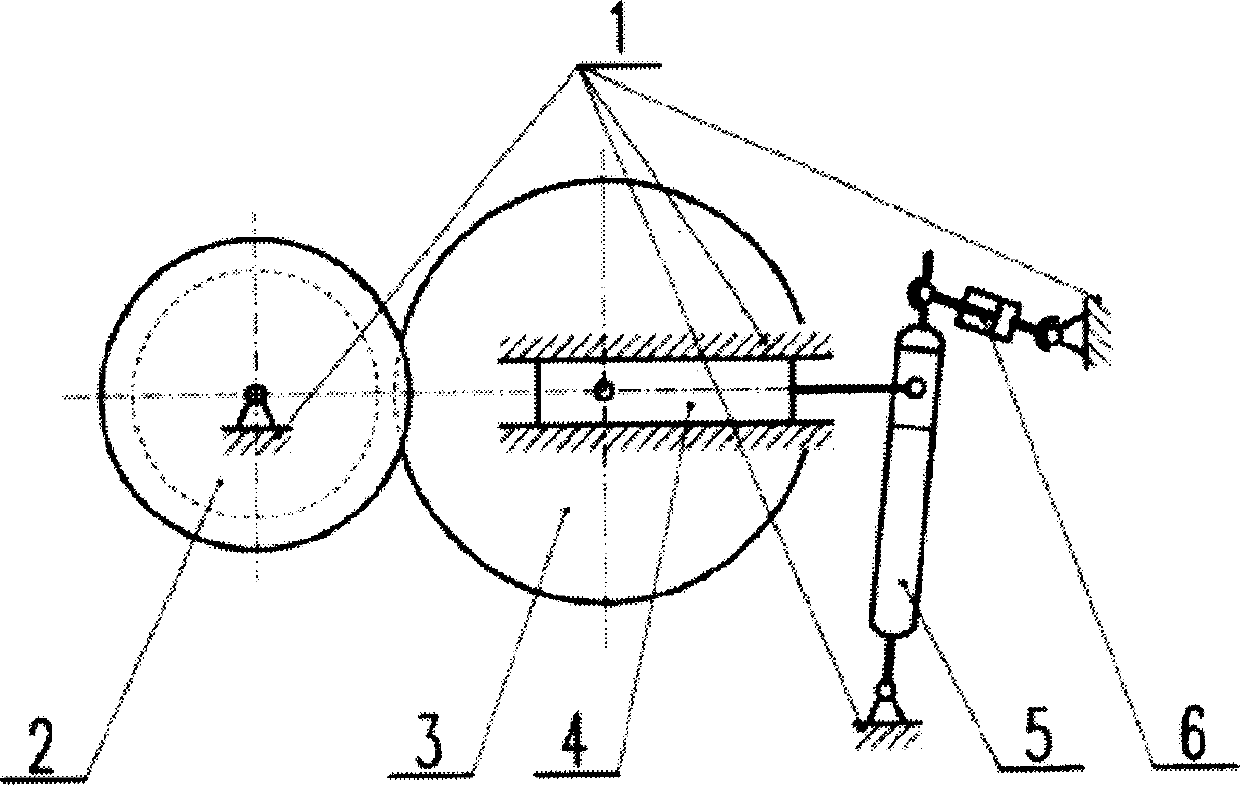

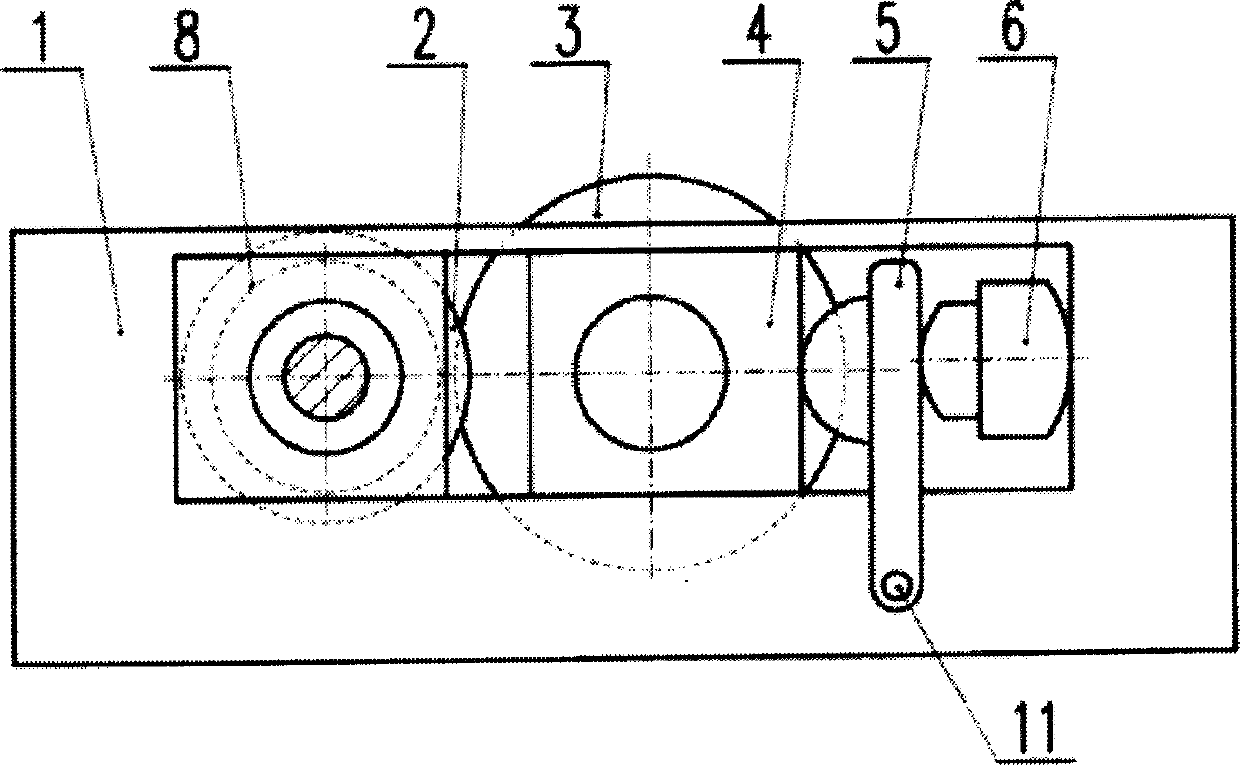

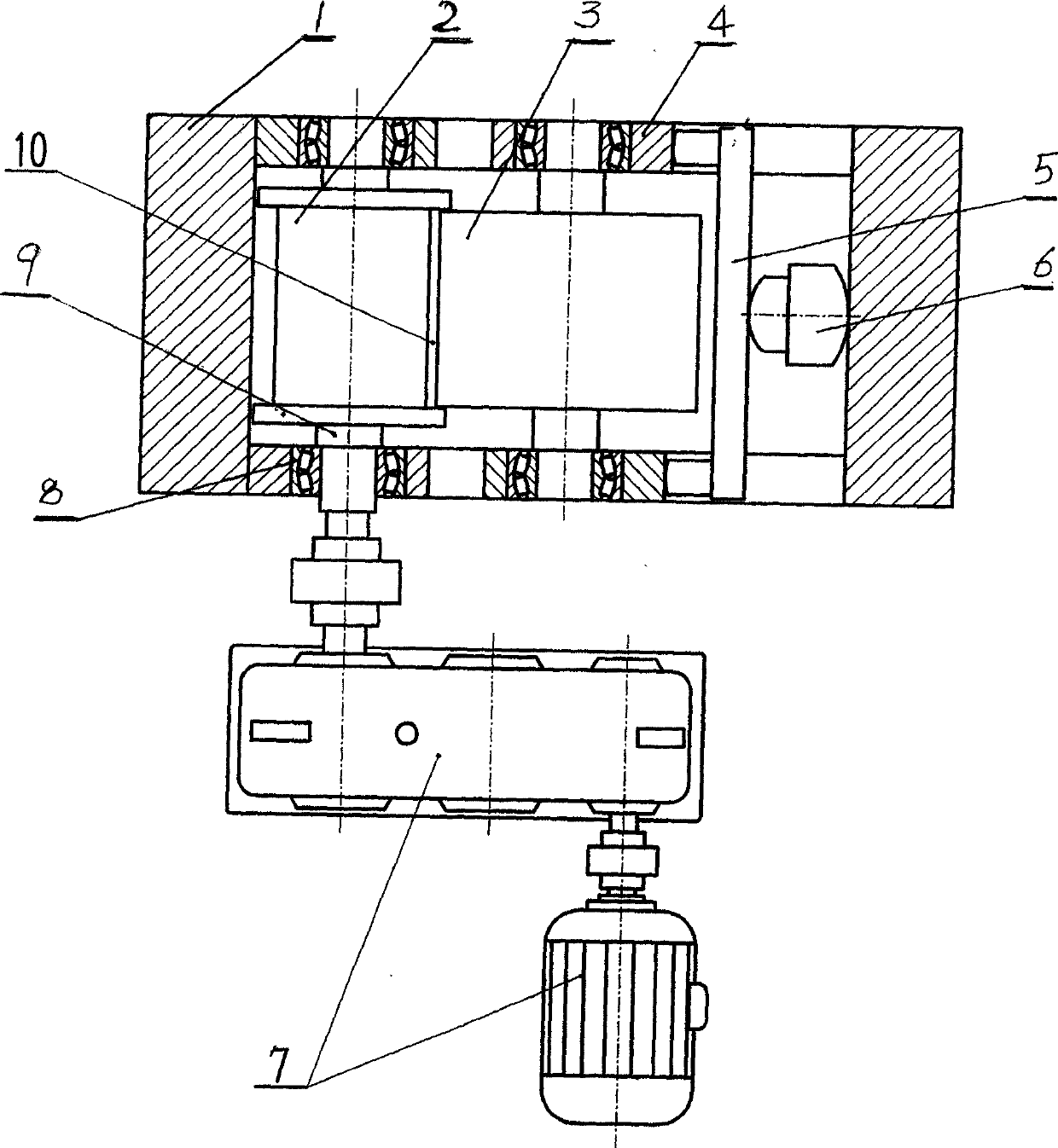

[0018] As shown in Figure 1, Figure 2, and Figure 3, the driving roller 2 is installed on the frame 1 through two bearing housings 8, and the passive roller 3 is installed through two bearing housings 4, and the driving roller bearing housing 8 is fixed in the frame 1 Can not slide, the passive roller bearing seat 4 can slide in the frame 1; the active roller shaft is connected to the power device 7, which is composed of a motor and a reducer; a synchronous plate 5 is installed behind the passive roller bearing seat 4, and the lower end of the synchronous plate 5 is hinged On the bottom frame of the frame 1, there is a hydraulic cylinder 6 on the back of the synchronization plate 5, and the other end of the hydraulic cylinder 6 is pushed on the frame 1. The diameter ratio of the two rollers is designed to be 1:1.5.

[0019] As shown in Figure 3, the driving roller 2 has shaft shoulders 9 at both ends, and the passive roller 3 is a smooth roller, and the crushing chamber 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com