Gypsum powder preparation process and system

A production system and gypsum powder technology, applied in grain processing and other directions, can solve the problems of increasing production energy consumption, reducing production efficiency, consuming large energy, etc., and achieving the effects of improving efficiency, reducing water content, and expanding spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

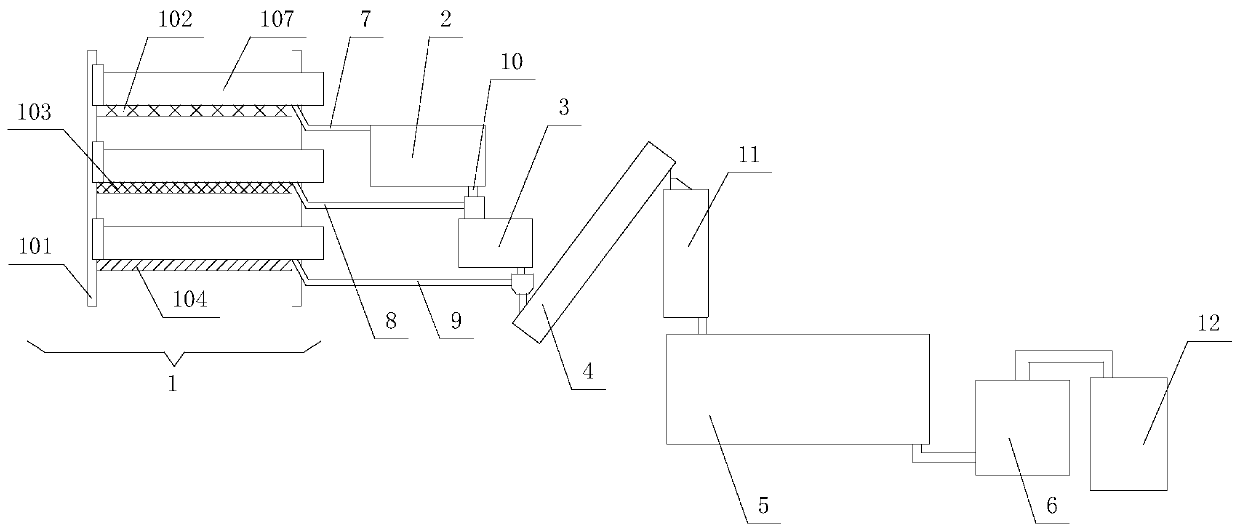

[0037] Such as figure 1 As shown, the gypsum powder production system provided in this embodiment includes a feeding device 1, a conveying device 10, a jaw crusher, a hammer crusher 3, a feeding device 4, a waste heat channel 11, and a rotary kiln calciner 5 arranged in sequence. , Centrifugal mill 6 and material storage box 12, wherein conveying device 10 is used for the material transfer between equipment, and conveying device 10 adopts screw feeder;

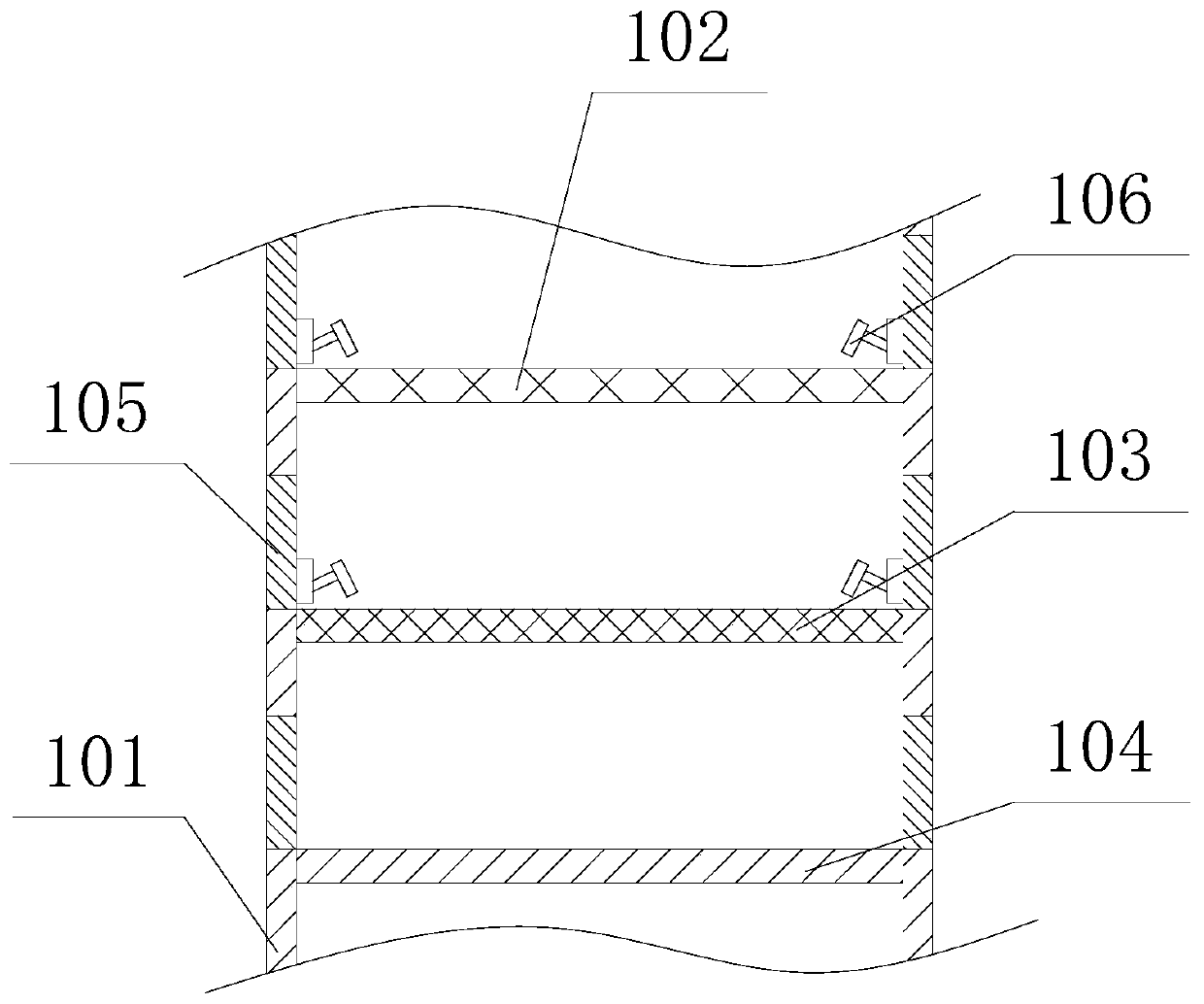

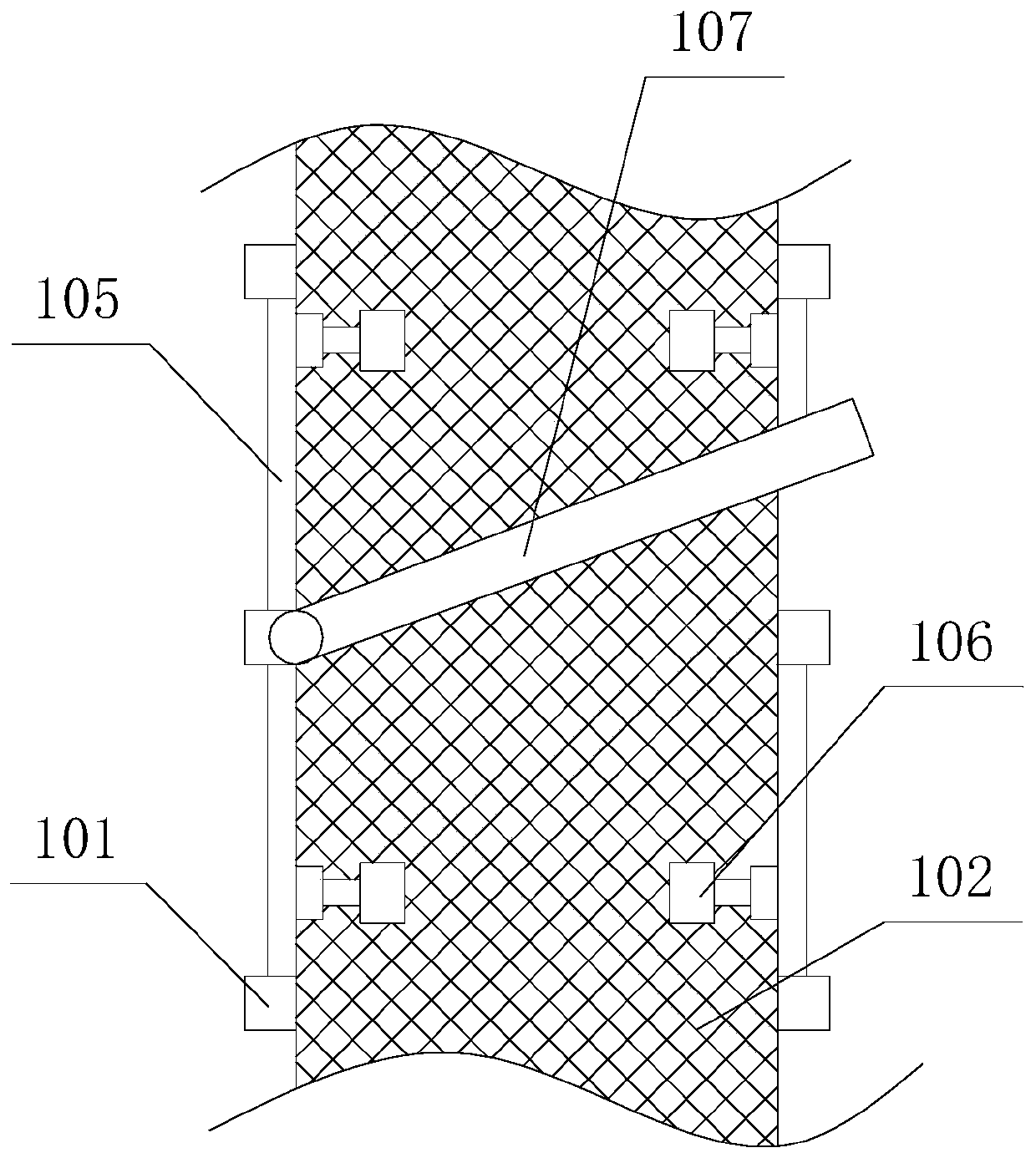

[0038] Described feeding device 1 comprises frame 101, and on frame 101, first-level conveyor belt 102, secondary conveyor belt 103 and tertiary conveyor belt 104 are respectively installed from top to bottom, primary conveyor belt 102, secondary conveyor belt 103 and The tertiary conveyor belts 104 are evenly spaced and aligned with each other in the vertical direction. The belt bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com