Treatment device and treatment method for civil engineering construction waste

A technology of construction waste and civil engineering, applied in construction waste recycling, separation methods, grain processing, etc., can solve problems affecting air quality, reducing soil quality, hidden safety hazards, etc., and achieve the effect of reasonable utilization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

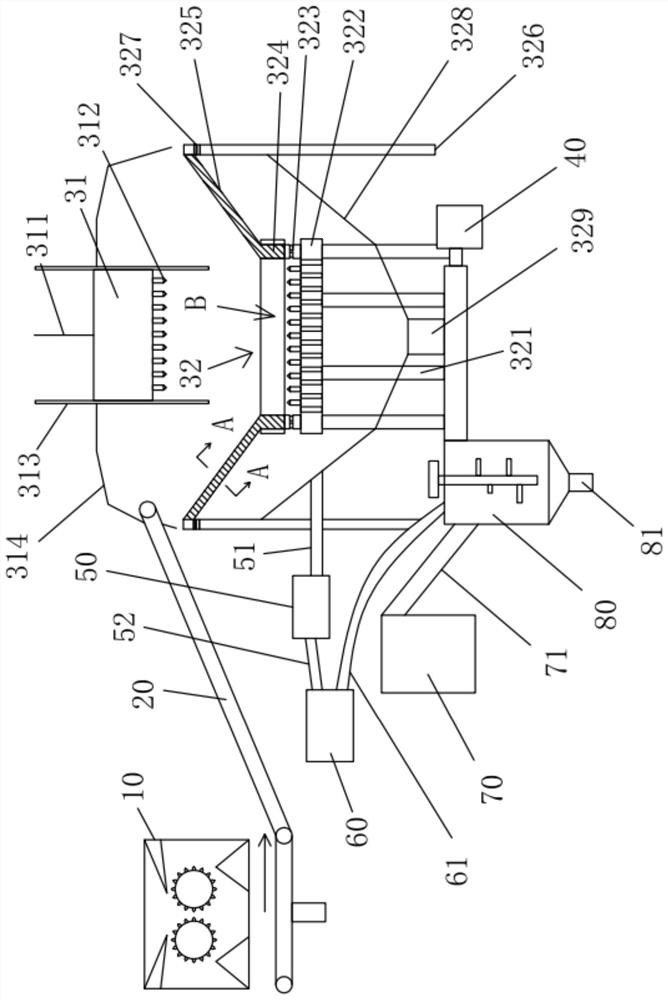

[0033] Such as figure 1 As shown, this embodiment proposes a treatment device for civil engineering construction waste, including a universal pulverizer 10, a magnetic separation conveyor 20, a crushing filter device and a conveying device, wherein the output end of the universal pulverizer 10 is used to put construction waste, The output end of the universal pulverizer 10 is docked with the input end of the magnetic separation conveyor 20. The magnetic separation conveyor 20 is used to remove metal impurities in the primary crushed building materials. The output end of the magnetic separation conveyor 20 is arranged to crush and filter At the input end of the device, the crushing and filtering device is used to filter the primary crushed building materials and re-shred the bulky building materials.

[0034]The device has a two-stage crushing structure, and the unbroken part of the first-stage universal pulverizer 10 is first filtered and then crushed by the second-stage crush...

Embodiment 2

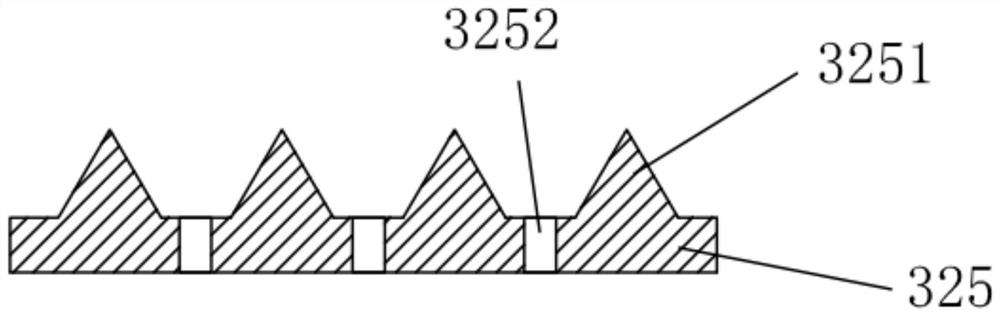

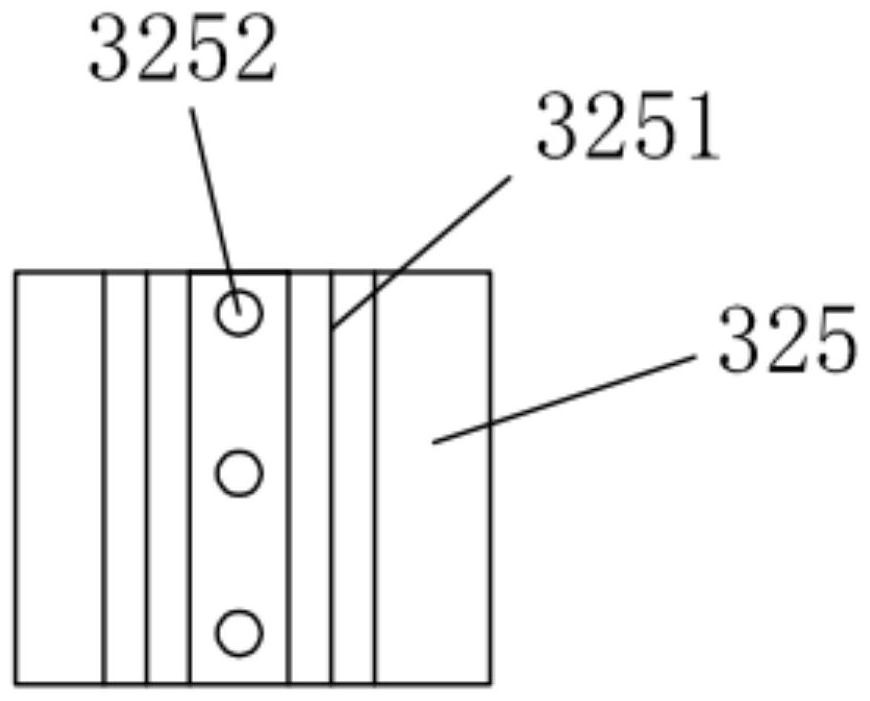

[0052] A method for processing civil engineering construction waste proposed in this embodiment uses the processing device for civil engineering construction waste as in Embodiment 1, specifically, putting construction waste into a universal pulverizer 10, and crushing the construction waste through the universal pulverizer 10 Finally, the metal impurities are filtered by the magnetic separation conveyor 20, and then the construction waste after the filtered metal impurities is put into the crushing and filtering device. The construction waste enters the particle concentration bucket 328 from the filter extension 325, and the large construction waste falls into the top surface of the crushing backing plate 322, drives the breaking hammer 31 to fall, passes through the first crushing tooth 312 and the second crushing tooth, and the crushing hammer 31 and The cooperation of the crushing backing plate 322 breaks the large particles of construction waste into small particles and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com