Speed-increasing drilling bit for downhole local pressure reducing

A kind of drill bit and partial technology, applied in the direction of drill bit, drilling equipment, earthwork drilling and production, etc., can solve the problems of mud column pressure drop, unusable, blowout accidents, etc., to improve drilling speed, improve cutting efficiency, and ensure pressure reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

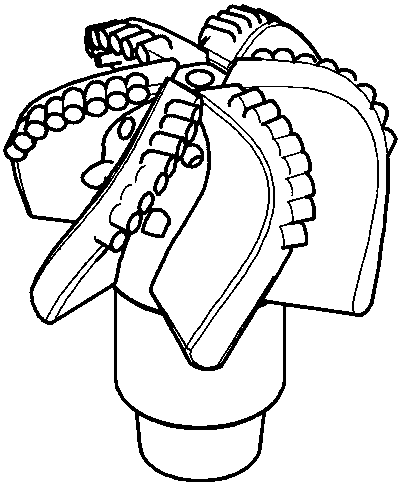

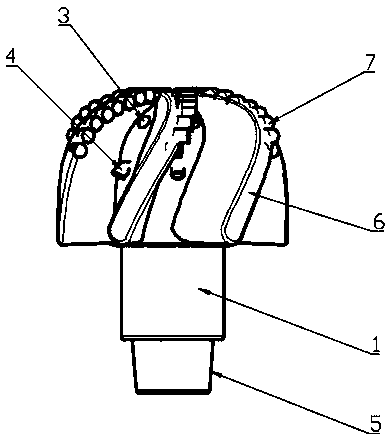

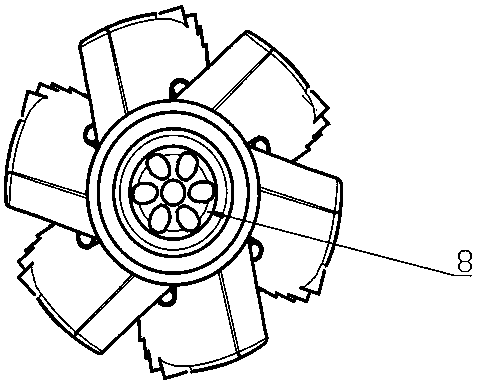

[0022] A speed-increasing drill bit for local decompression at the bottom of a well, such as Figure 1-7 As shown, including an alloy steel core 1, a plurality of blades 6 are evenly distributed on the alloy steel core 1, and the blades 6 are in the shape of turbine blades and the tops are gathered on the center line of the alloy steel core 1; the blades 6 are provided with diamond The cutting teeth 7; the number of blades 6 are six; the blades 6 and the alloy steel core 1 are of an integrated structure.

[0023] The alloy steel core 1 is provided with a central water hole 8; the top confluence of the blades 6 is provided with a central nozzle 2 communicating with the central water hole 8, and an upper side nozzle 3 is provided between adjacent blades 6. Reverse nozzles 4 are also provided between adjacent blades 6 . The upper side nozzle 3 is located between the reverse nozzle 6 and the central nozzle 2 ; the upper side nozzle 3 and the reverse nozzle 6 are both in communica...

Embodiment 2

[0025] A speed-increasing drill bit for partial decompression at the bottom of a well, comprising an alloy steel core, on which a plurality of blades are uniformly distributed, the blades are in the shape of turbine blades and their tops are gathered on the center line of the alloy steel core; There are diamond cutting teeth; the number of blades is 9; the blades and the alloy steel core are an integrated structure.

[0026] A central water hole is provided inside the alloy steel core; a central nozzle connected to the central water hole is provided at the top confluence of the blades, and upper side nozzles are also provided between adjacent blades. Reverse nozzles are also provided between adjacent blades. The upper side nozzle is located between the reverse nozzle and the central nozzle; the upper side nozzle and the reverse nozzle are both in communication with the central water hole. The blades are set obliquely and the angle of inclination is 75°. The reverse nozzle is...

Embodiment 3

[0028] The reverse nozzle is arranged on the blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com