Multistage separation device for animal and plant raw materials as well as method and application thereof

A separation device and multi-stage separation technology, which is applied in the fields of application, food science, essential oils/spices, etc., can solve the problems of difficult extraction, low extraction efficiency, and low extraction efficiency of active ingredients, and achieve improved yield and leaching efficiency, High yield, leaching efficiency, and high solid-liquid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

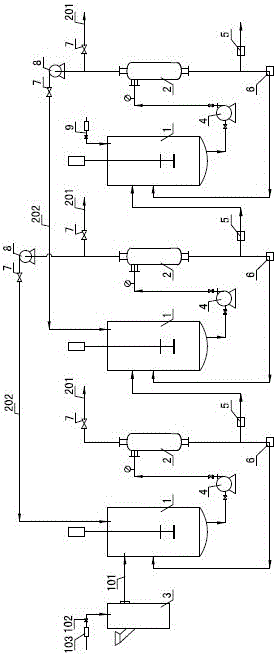

[0034] refer to figure 1 , the multi-stage separation device for animal and plant raw materials includes a separation device and a pulverizer 3, the separation device includes a leaching tank 1 and a solid-liquid separator 2, the leaching tank 1 is connected with the pulverizer 3 through a raw material delivery pipe 101, and the leaching The discharge port of the tank 1 is connected with the feed port pipeline of the solid-liquid separator 2 through the pump 4, the separation liquid outlet of the solid-liquid separator 2 is connected with a separation liquid output pipe 201, and the solid material outlet of the solid-liquid separator 2 is connected with a second A conveyor 5; there are multiple separation devices, and the multiple separation devices are arranged in multi-stages from top to bottom along the solid material conveying direction; among adjacent separation devices: the upper separation device passes through the first conveyor 5 and the lower separation device The le...

Embodiment 2

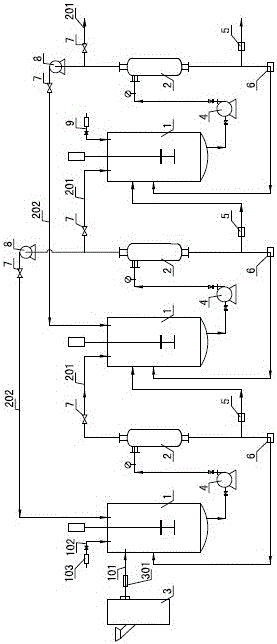

[0040] refer to figure 2 , The difference between this embodiment and Embodiment 1 is: the pulverizer 3 is a dry pulverizer, a solvent delivery pipe 102 is connected to the leaching tank 1, and a feeder 301 is provided on the raw material delivery pipe 101 . The solvent delivery pipe 102 is provided with a temperature regulator 103 .

[0041] The working process of the multi-stage separation device for animal and plant raw materials is as follows:

[0042] a) Pulverizer 3 pulverizes the raw material into powder to increase the yield of active ingredients and leaching efficiency in the leaching tank 1; add the pulverized powdery raw material and solvent into the leaching tank 1 according to the ratio, and mix and leaching in the leaching tank 1; The material discharged from the leaching tank 1 enters the solid-liquid separator 2 through the pump 4 for separation;

[0043] b) The separation liquid separated by the solid-liquid separator 2 is discharged from the separation liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com