Biomass crusher

A shredder and biomass technology, applied in the field of agricultural and forestry waste, can solve the problems such as the inability to meet the requirements of the particle size of the crushed products and the complex structure, and achieve the effects of compact structure, low energy consumption for crushing, and small particle size of the crushed products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

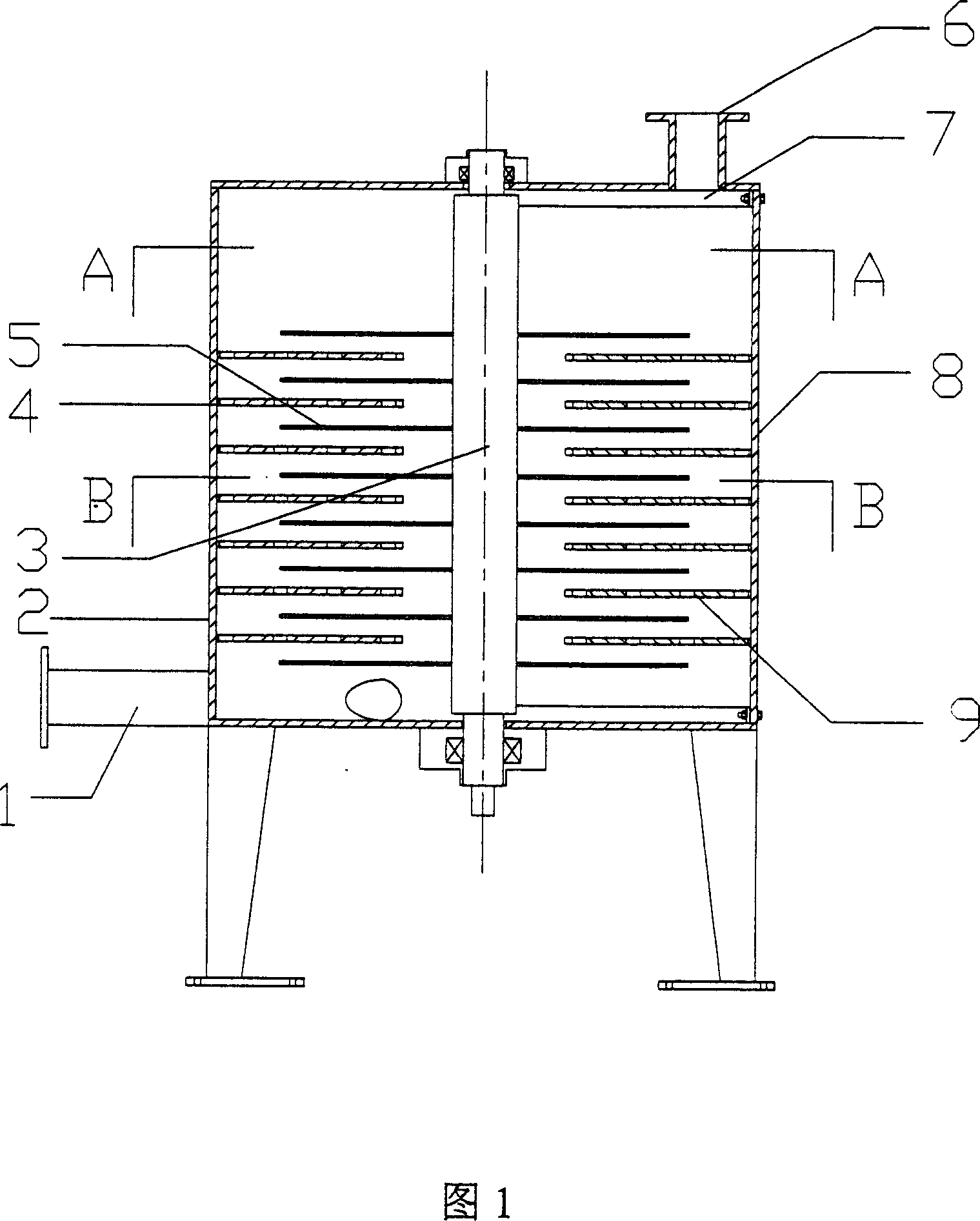

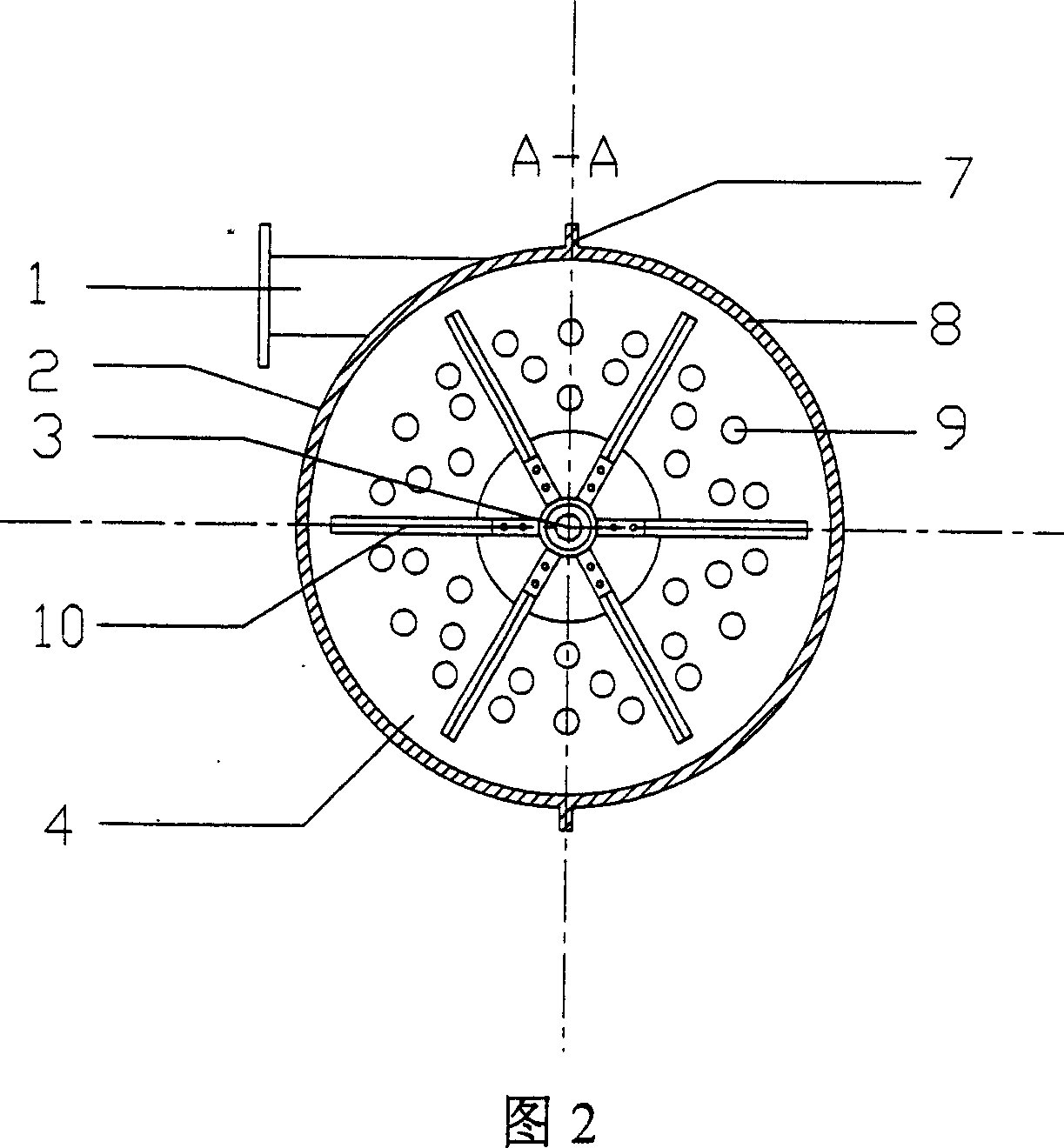

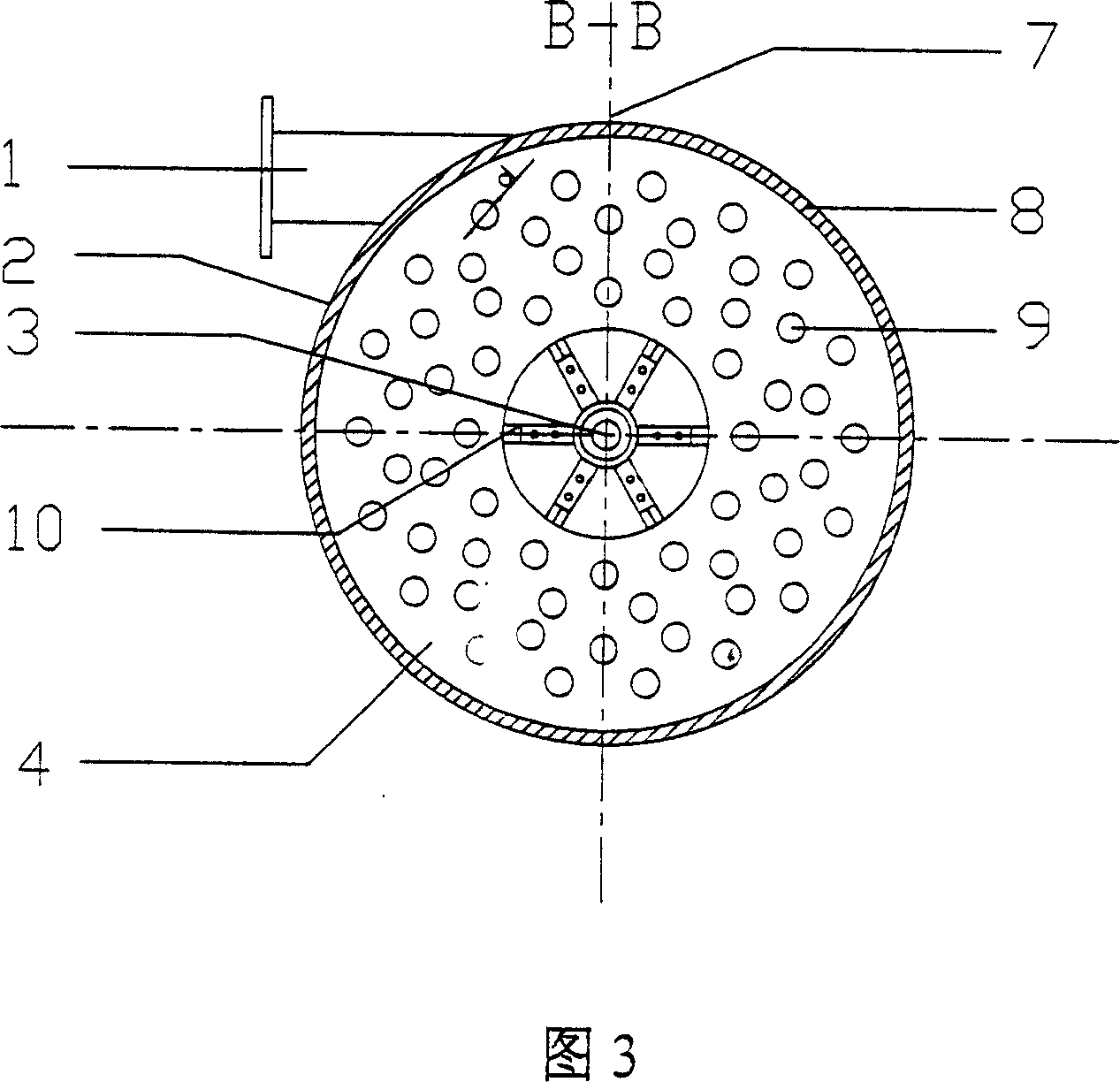

[0027] As shown in FIGS. 1 to 3 , the present invention is a vertical installation or a horizontal installation, and its cylinder includes a bottom surface, a top surface and a side wall, which can be cylindrical, and the cylinder is divided into a first half cylinder 2 and a cylinder along the axial direction. The second half cylinder 8 is fixed with the flange 7, the main shaft 3 is axially installed in the center of the cylinder, and the multi-layer cutter 5 is installed along the main shaft in the direction perpendicular to the main shaft 3. The cutter 5 is connected to the wall of the cylinder. There is a gap between them, the cutter 5 is composed of straight-edged blades 10, a multi-layer annular plate 4 is installed on the wall of the cylinder, a plurality of holes 9 are opened on the annular plate 4, and between the annular plate 4 and the main shaft 3. There is a gap between the two layers of cutters 5, between the two layers of annular plates 4 or between the cutters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com