Cooling system of power assembly

A cooling system and powertrain technology, applied in the direction of engine cooling, liquid cooling, coolant flow control, etc., can solve the problems of insufficient water pump capacity, cooling system distribution, waste, etc., to achieve improved cooling effect, reasonable control, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

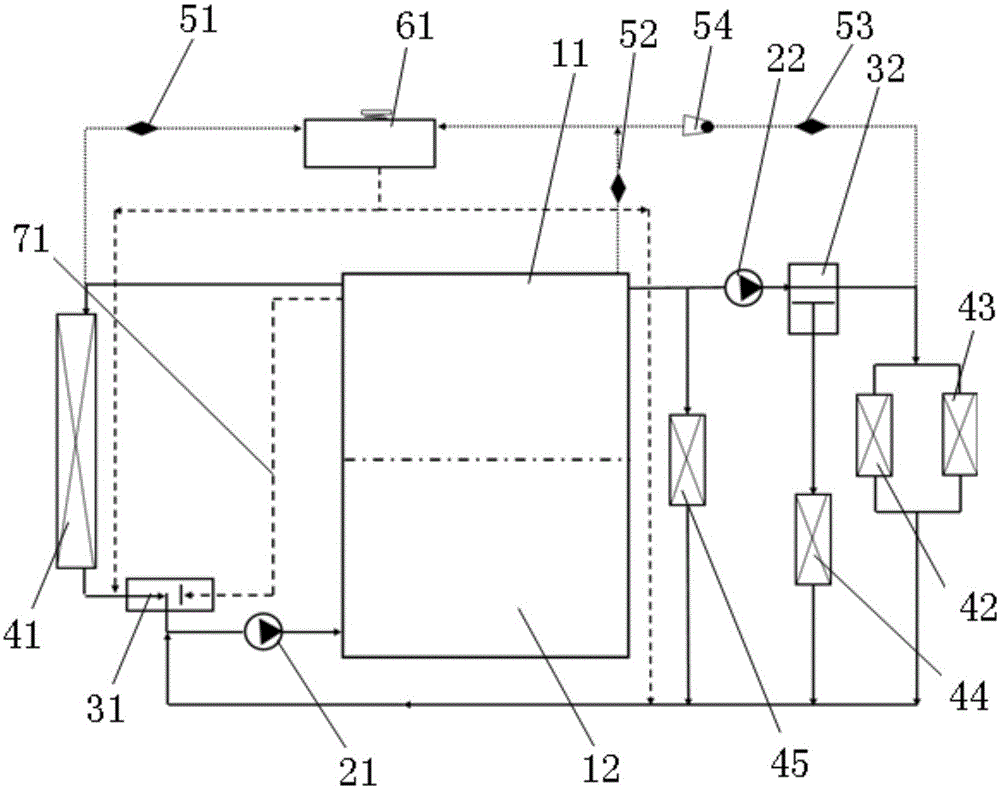

[0045] The invention provides a powertrain cooling system, such as figure 1 As shown, it includes an engine, a first cooling water pump 21, a radiator 41, a second cooling water pump 22, a first thermostat 31, a second thermostat 32, an oil cooler 45, a transmission oil cooler 44, a warmer Fan, connecting pipeline, expansion kettle 61 , first throttle valve 51 , second throttle valve 52 , third throttle valve 53 and one-way valve 54 .

[0046] In the present application, the engine includes an engine cylinder head 11 and an engine block 12, wherein the engine cylinder head is provided with a water outlet, and the engine block is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com