Burning control method for waste incineration

A waste incineration and control method technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problem that the air supply cannot be controlled according to the degree of combustion, and achieve reliable and stable flue gas emission quality, accurate monitoring, and accurate air supply volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below through specific embodiments.

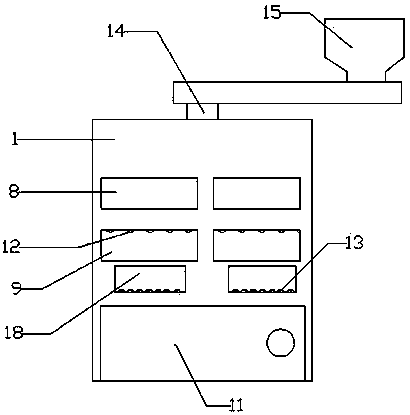

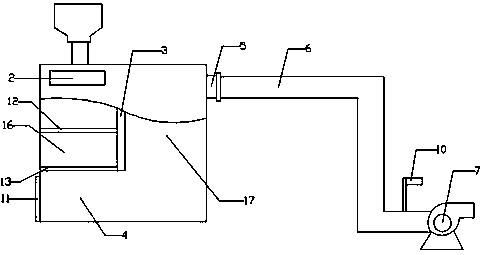

[0022] A combustion control method in waste incineration treatment, an oxygen sensor 10 is installed on the flue gas pipe 6 between the flue gas outlet 5 of the second combustion chamber 17 provided in the incinerator and the induced draft fan 7, and the oxygen sensor 10 detects The oxygen content in the flue gas,

[0023] According to the index of the gas content, the opening and closing degree of the damper of the secondary air supply is controlled, and the air volume of the secondary air supply is adjusted to realize the control of the air supply so that the oxygen content detected by the oxygen sensor 10 is maintained at a volume fraction of 5-13%. At the same time, the induced draft fan 7 is controlled within the range of -1000 to -100 Pa according to the negative pressure value.

[0024] Described incinerator comprises furnace body 1, and the upper part of this furnace body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com