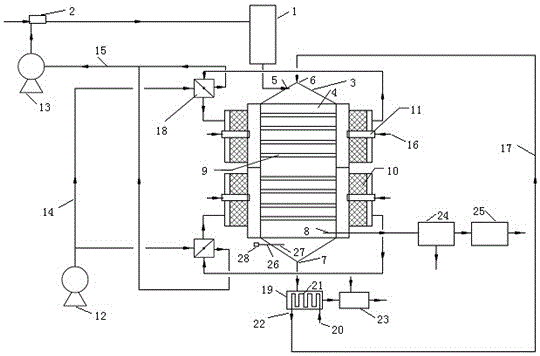

Regenerative fast biomass pyrolysis system and fast biomass pyrolysis method

A regenerative, biomass technology, used in biofuels, special forms of dry distillation, heating of coke ovens, etc., can solve the problems of waste of resources, high pressure of dust removal and condenser, low product utilization rate, etc., and reduce investment costs. , improve efficiency, simplify the design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0052] Implementation Case 1: The regenerative rapid pyrolysis reaction system is used to process sawn wood as a biomass raw material. The sawdust analysis data, process operation parameters and material balance are shown in Table 1-Table 3. The bio-oil yield obtained from Table 3 was as high as 63.3%.

[0053] Table 1: Sawdust Analysis Data

[0054] .

[0055] Table 2: Process operating parameters

[0056] serial number parameter name parameter value serial number parameter name parameter value 1 Drying inlet temperature 203℃ 6 Reactor outlet temperature 505℃ 2 Drying outlet temperature 82℃ 7 3 Reactor upper temperature 492℃ 8 4 The temperature in the middle of the reactor 501℃ 9 5 The temperature of the lower part of the reactor 510℃ 10

[0057] Table 3: Material Balance Sheet

[0058] .

Embodiment example 2

[0059] Implementation case 2: The regenerative rapid pyrolysis reaction system is used to process corn stalks. The analysis data, process operation parameters and material balance of corn stalks are shown in Table 4-Table 6. The tar yield from Table 6 was 55%.

[0060] Table 4: Corn stover analysis data

[0061] .

[0062] Table 5: Process operating parameters

[0063] serial number parameter name parameter value serial number parameter name parameter value 1 Drying inlet temperature 250℃ 6 Reactor outlet temperature 496℃ 2 Drying outlet temperature 100℃ 7 Cyclone outlet temperature 485℃ 3 Reactor upper temperature 489℃ 8 4 The temperature in the middle of the reactor 503℃ 9 5 The temperature of the lower part of the reactor 509℃ 10

[0064] Table 6: Material Balance Sheet

[0065] .

[0066] The inventors found that, according to the reaction system of the embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com