Engine system having coolant control valve

An engine system, coolant valve technology, applied in the control of coolant flow, engine components, cooling of the engine, etc., can solve problems such as prolonged standardization of heater operation time, increased fuel consumption, and cold passengers or drivers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

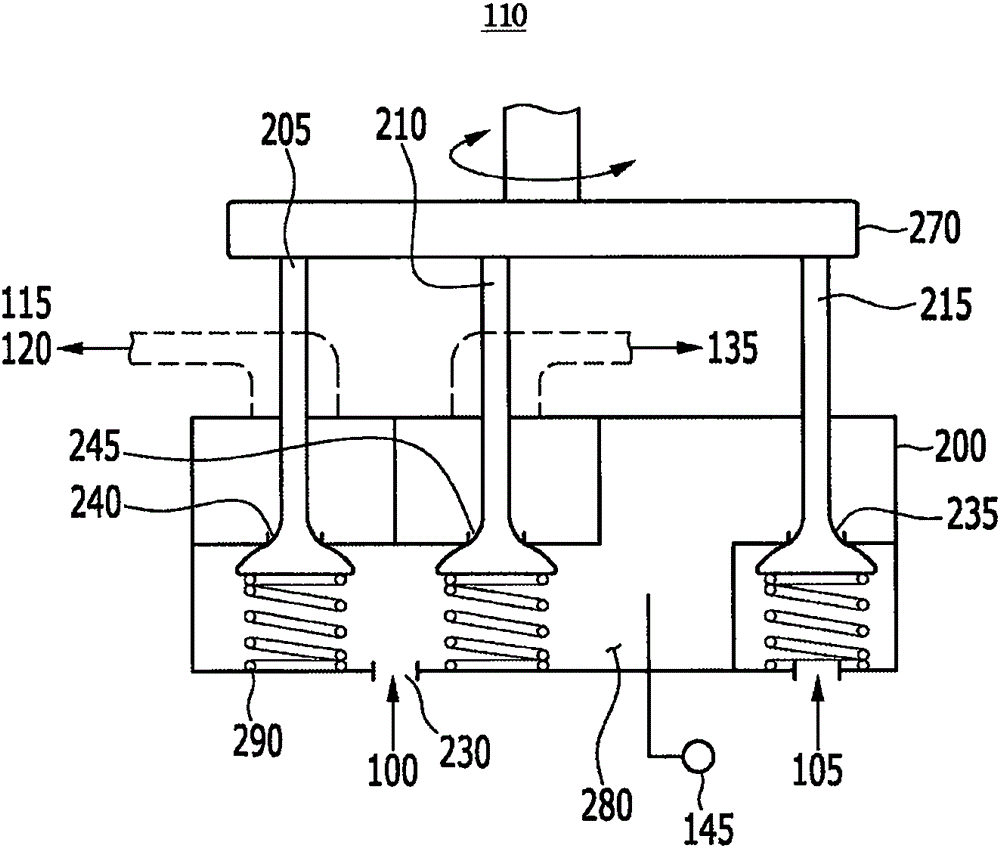

[0033] An exemplary embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

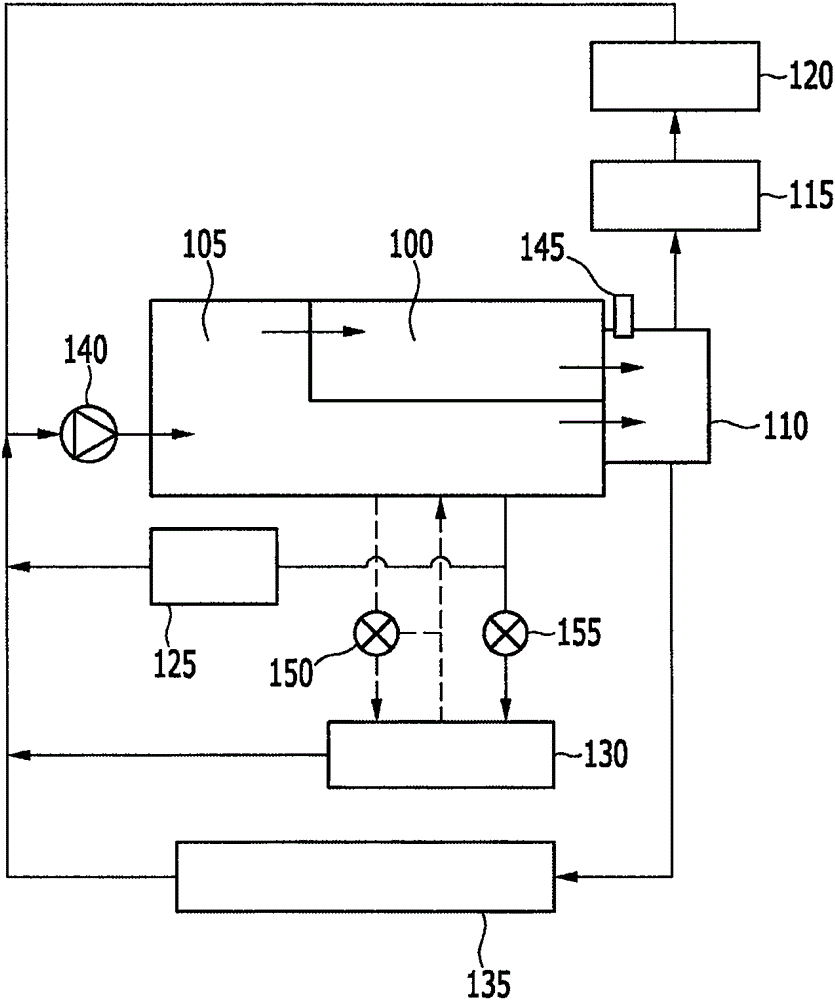

[0034] figure 1 is a schematic diagram showing typical coolant flow in an engine system with a conventional coolant control valve unit.

[0035] refer to figure 1 , the engine system includes a cylinder head 100, a cylinder block 105, a coolant pump 140, a high-pressure exhaust gas recirculation (EGR) valve 125, a bypass valve 150, a thermostat (thermostat) 155, an oil cooler 130, a radiator 135, The coolant controls the valve unit 110 , the temperature sensor 145 , the low pressure EGR cooler 115 and the heater 120 .

[0036] The cylinder head 100 is arranged on the cylinder block 105 . A combustion chamber in which a piston is arranged is formed in the cylinder block 105 , and an exhaust port and an intake port communicating with the combustion chamber are formed in the cylinder head 100 .

[0037] The coolant control valve unit 110 dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com