Device for preheating and conveying scrap steel

A conveying device and scrap steel technology, applied in the metallurgical field, can solve the problems of increasing equipment wear and increasing the transmission power of the mechanism, and achieve the effects of small equipment vibration, simple maintenance and production, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

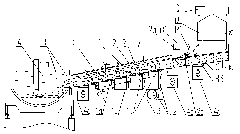

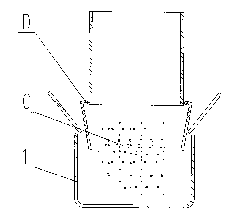

[0034] Example 1 as figure 1 As shown, the conveying trough 1 is installed obliquely, and the lower end extends into the electric furnace A. The conveying trough is covered with a smoke guide 2. The movement gap between the two is kept sealed by a dynamic sealing device 2b to prevent cold air from being sucked in. The tail of the smoke guide 2 There is an adjustable smoke port 2a; the flue gas B fills the entire electric furnace A and the cavity channel formed by the scrap steel preheating conveying chute 1 and the smoke guide hood 2, and the bottom of the conveying trough 1 adopts a stepped staggered superposition structure from bottom to high, The joint gap between every two layers is designed as the smoke outlet 1a at the bottom of the tank, and the lower layer is connected with the bottom exhaust pipe 1b, and several smoke outlets 1a at the bottom of the tank can be set in the whole scrap steel preheating conveying chute. Steel scrap C is hoisted into several bottom-openin...

Embodiment 2

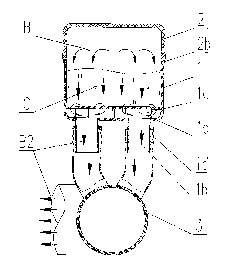

[0039] Embodiment 2: what is different from Embodiment 1 is the structure of the delivery trough, such as Figure 5 As shown, the inclined conveying trough 1 adopts the embodiment of suction on both sides, the two side walls are double-layered, and the inner side wall is separated from the bottom of the tank to form a side-inclined smoking port 1a.

[0040] It should be pointed out that the above-mentioned conveying trough 1, smoke guide 2 and other related parts that are in contact with high-temperature flue gas B can be made into a water-cooled structure to withstand high temperatures, and some components can also be coated with heat-insulating and refractory materials to increase the life of the components and reduce the discharge. The temperature loss of the flue gas and improve the thermal efficiency of the subsequent system.

[0041] It is also necessary to set some sensors for this device to cooperate with the production process and improve the working conditions of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com