Control device for internal combustion engine

A technology for a control device and an internal combustion engine, which is applied to the control of coolant flow, the cooling of the engine, and the pressure of the lubricant, etc., can solve the problems of narrowing of the execution area, difficulty in suitable coordinated control, and inability to greatly improve the warm-up performance of the internal combustion engine, etc. To achieve the effect of improving preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

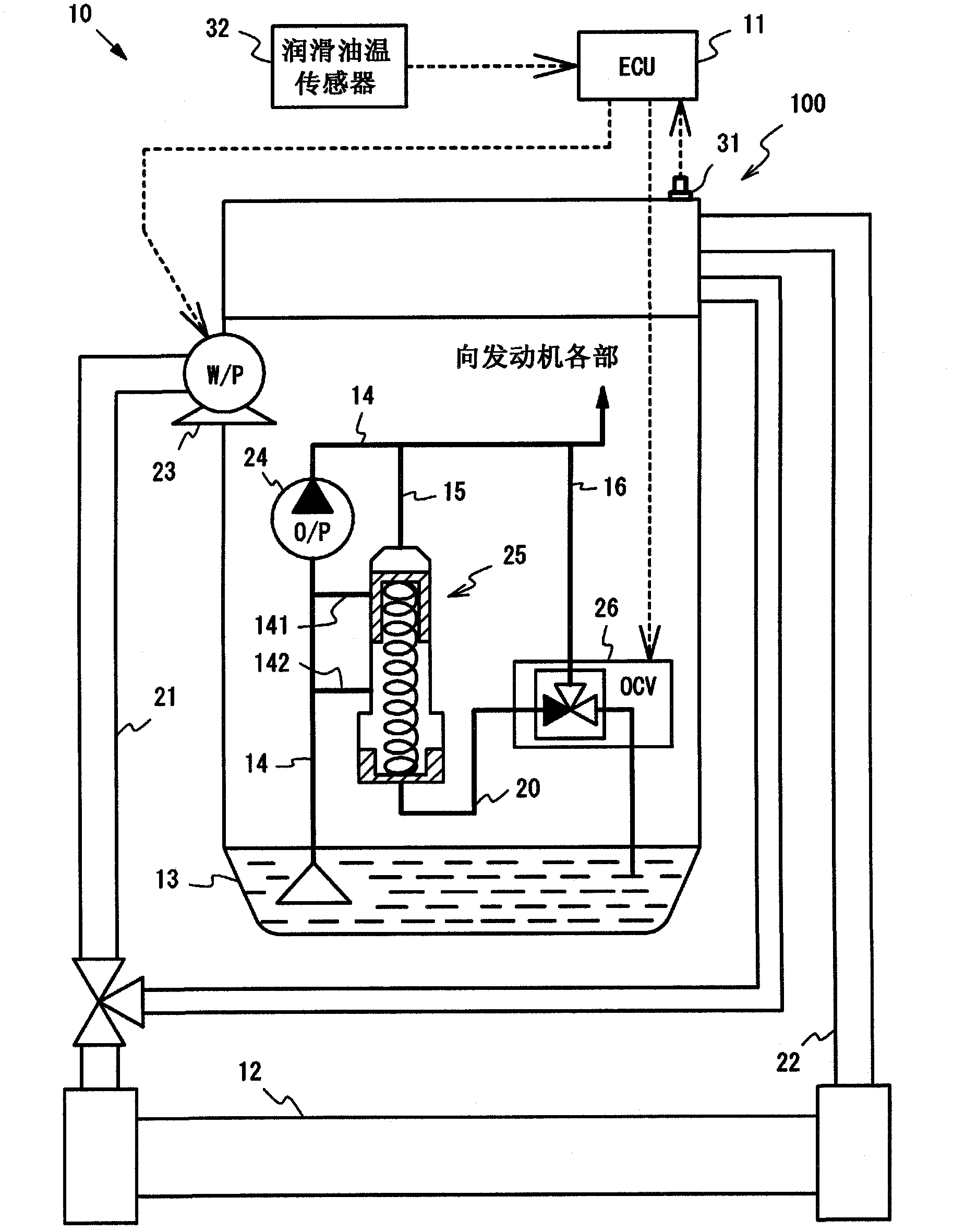

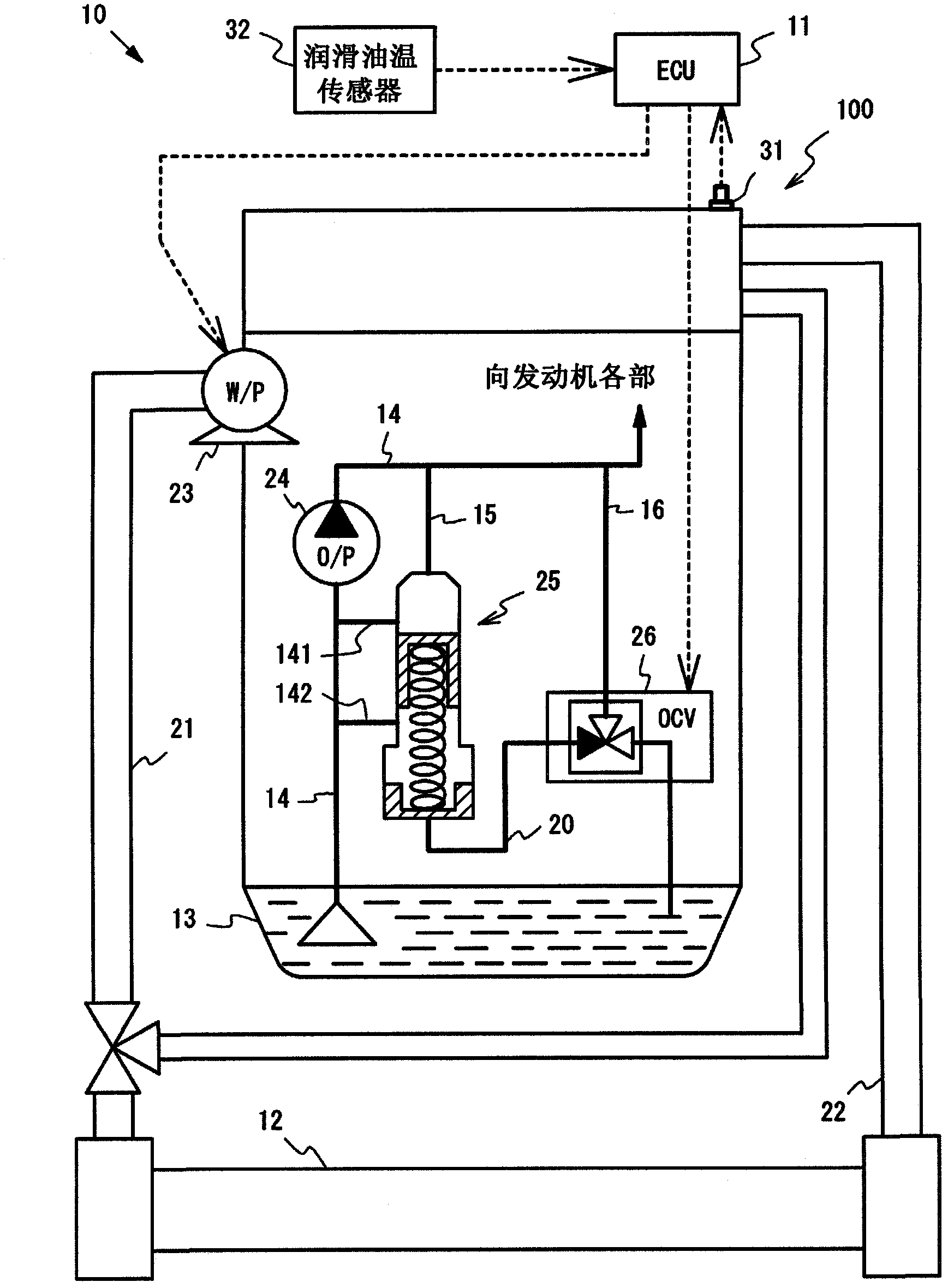

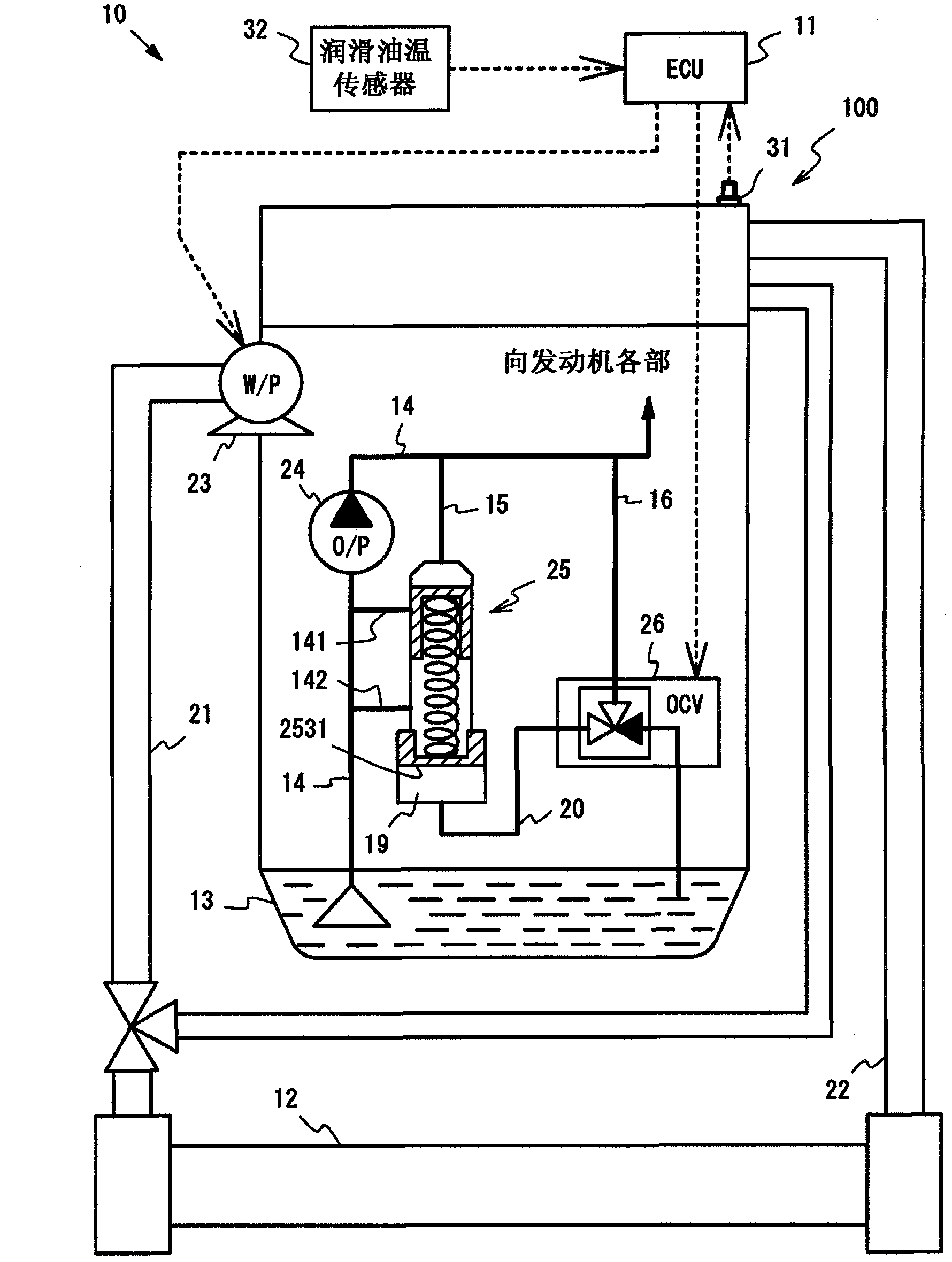

[0047] Figure 1~4 It is a configuration diagram showing a schematic configuration of a vehicle control system 10 incorporating a control device for an internal combustion engine according to the present invention. The vehicle control system 10 includes an engine 100 as a power source. In addition, the vehicle control system 10 includes an ECU (Electronic Control Unit: Electronic Control Unit) 11 that collectively controls the operation of the vehicle control system 10 . Further, the vehicle control system 10 includes a first flow path 21 and a second flow path 22 through which the refrigerant circulating between the radiator 12 and the engine 100 flows, and a water pump 23 that pressurizes and circulates the refrigerant. Further, the vehicle control system 10 includes an oil pump 24 for pressure-feeding and circulating lubricating oil, an oil overflow device 25 for adjusting the supply pressure of lubricating oil, and an oil control valve (hereinafter abbreviated as OCV) 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com