Cylinder head for internal combustion engine

A technology of cylinder head and internal combustion engine, which is applied to the direction of internal combustion piston engine, cylinder head, combustion engine, etc., can solve the problem of the deterioration of the warm-up performance of the catalyst, and achieve the effect of reducing the surface area of the passage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

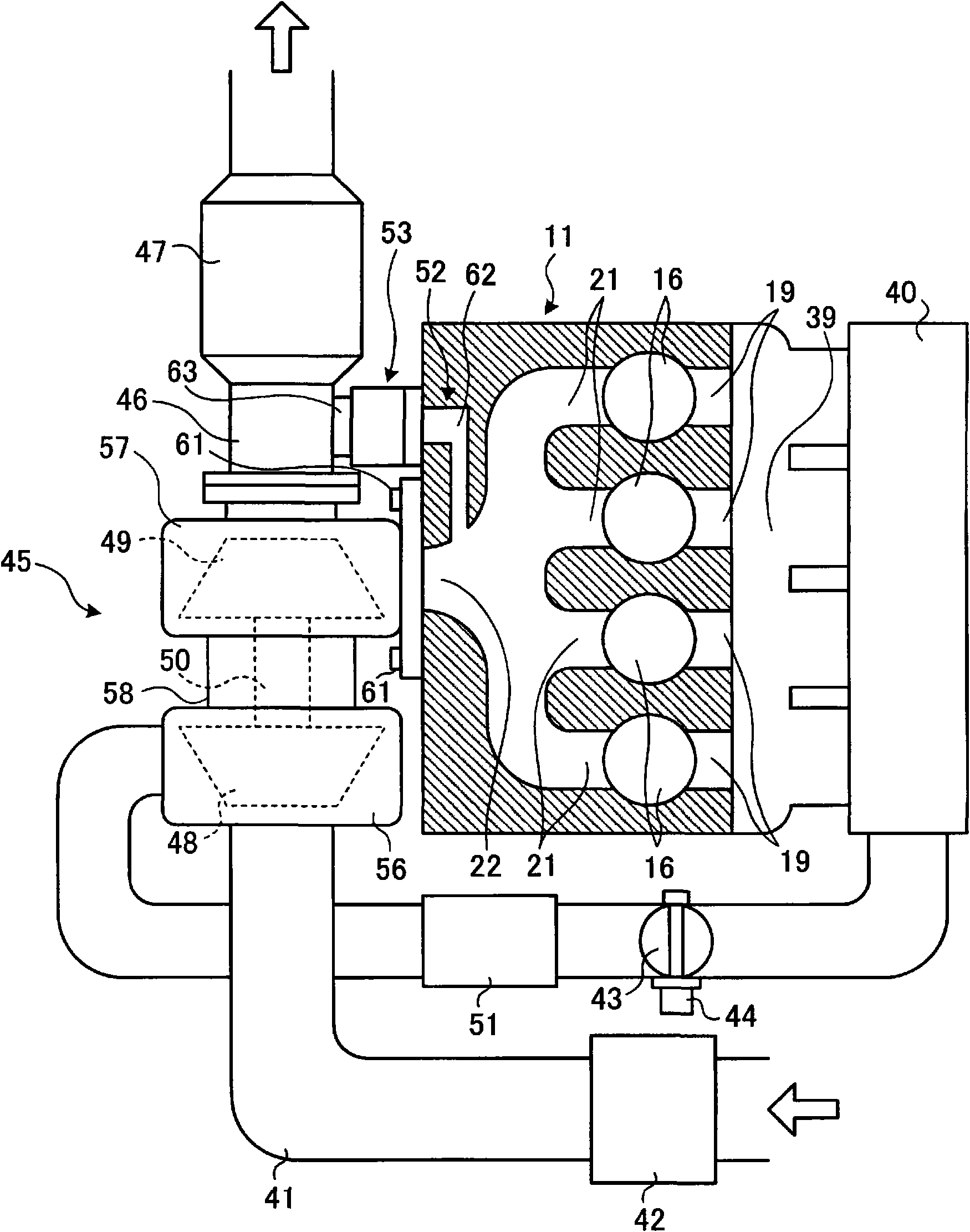

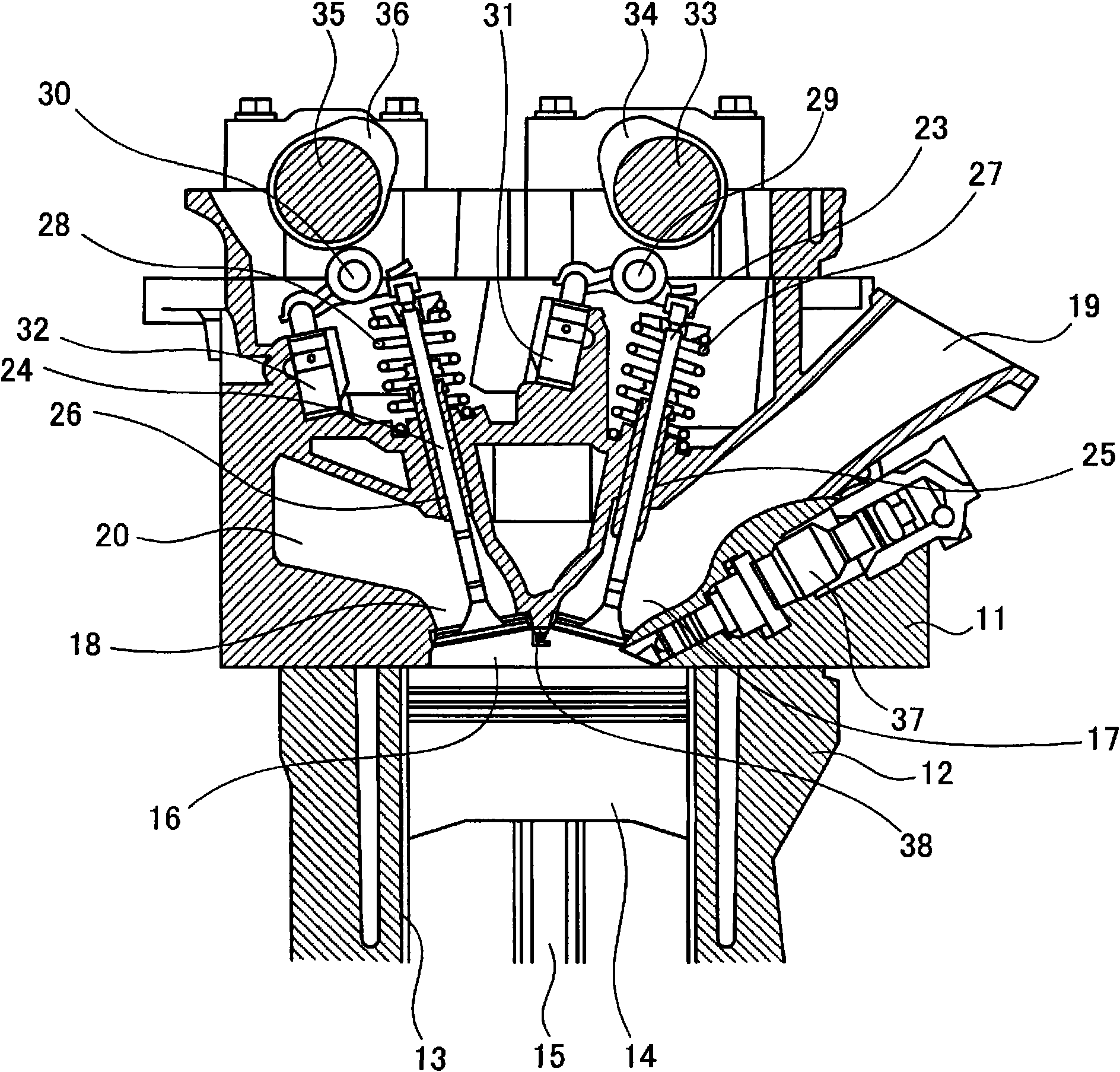

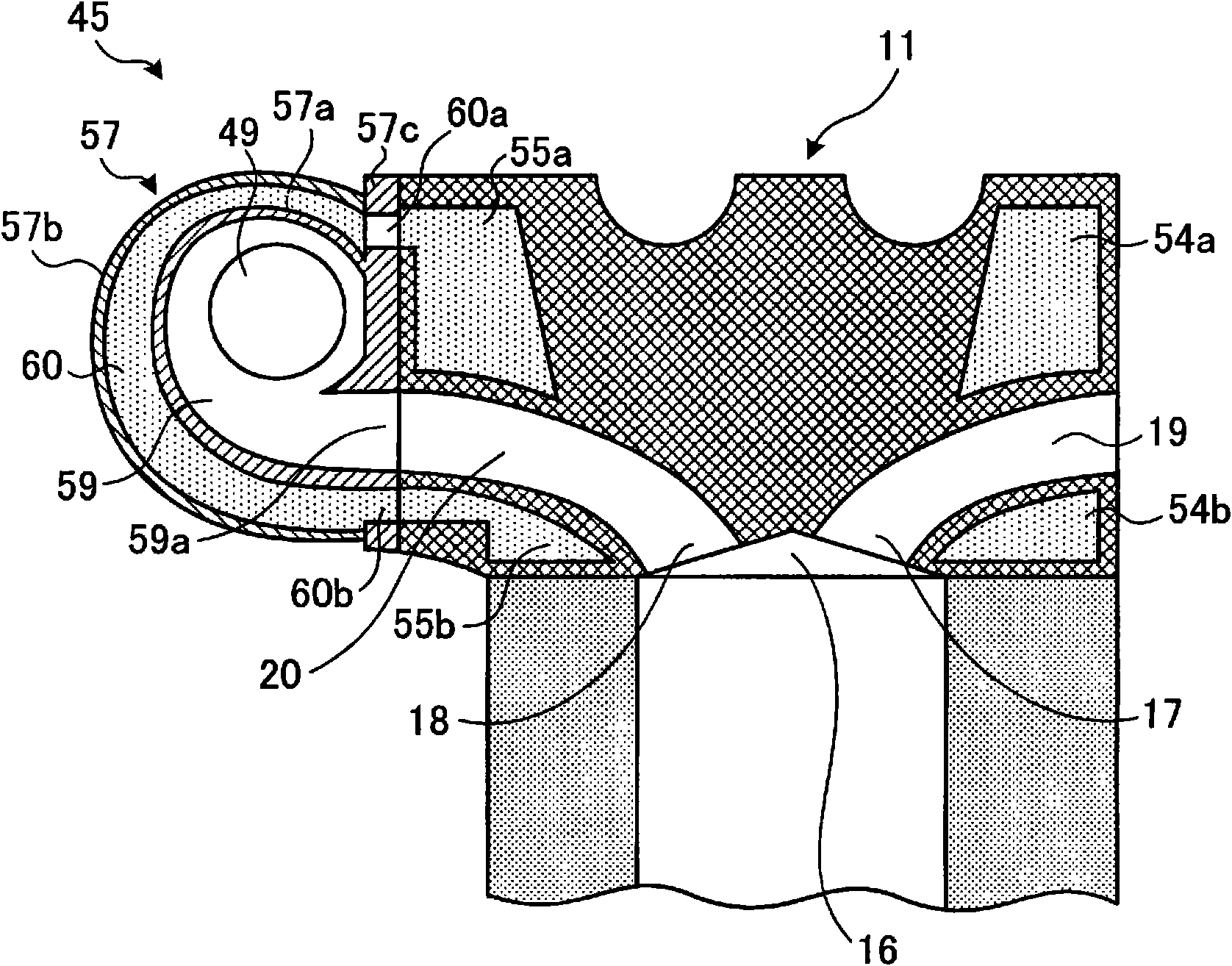

[0045] figure 1 is a schematic diagram showing a cylinder head of an internal combustion engine according to Embodiment 1 of the present invention, figure 2 is a longitudinal sectional view showing the internal combustion engine of Embodiment 1, image 3 is a longitudinal sectional view showing the cylinder head of the internal combustion engine of Embodiment 1, Figure 4 It is a sectional view showing the waist gate valve in the internal combustion engine of the first embodiment.

[0046] The internal combustion engine of embodiment 1 is an in-line 4-cylinder engine, such as figure 1 and figure 2 As shown, the cylinder head 11 is assembled with the cylinder block 12 at the lower part thereof, and is fastened by a plurality of fastening bolts not shown. A plurality of (four in this embodiment) cylinder bores 13 are formed in a line on the cylinder block 12 , and a piston 14 is fitted to each cylinder bore 13 so as to be movable in the axial direction thereof. Further, a...

Embodiment 2

[0076] Figure 5 is a schematic diagram showing a cylinder head of an internal combustion engine according to Embodiment 2 of the present invention, Figure 6 It is a longitudinal sectional view showing a cylinder head of the internal combustion engine of the second embodiment. In addition, components having the same functions as those described in the above-mentioned embodiments are denoted by the same reference numerals, and repeated explanations are omitted.

[0077] In the internal combustion engine of embodiment 2, as Figure 5 , Figure 6 As shown, the cylinder head 71 is assembled with the cylinder block 12 at the lower part thereof, and is fastened by a plurality of fastening bolts not shown. A plurality of combustion chambers 16 are formed in the cylinder head 71 , and the intake port 17 opens opposite to the exhaust port 18 , and the intake passage 19 communicates with the intake passage 19 through the intake port 17 , and the exhaust passage 20 communicates with ...

Embodiment 3

[0087] Figure 7 is a schematic diagram showing a cylinder head of an internal combustion engine according to Embodiment 3 of the present invention, Figure 8 is a longitudinal sectional view showing the main parts of the cylinder head of the internal combustion engine of Embodiment 3 ( Figure 7 VIII-VIII sectional view). In addition, components having the same functions as those described in the above-mentioned embodiments are assigned the same reference numerals, and repeated explanations are omitted.

[0088] In the internal combustion engine of embodiment 3, as Figure 7 and Figure 8 As shown, a plurality of combustion chambers 82a, 82b, 82c, and 82d are formed in the cylinder head 81, and intake ports 83a, 83b, 83c, and 83d open opposite to exhaust ports 84a, 84b, 84c, and 84d. The air ports 83a, 83b, 83c, 83d communicate with four intake passages 85a, 85b, 85c, 85d, and communicate with one exhaust passage 86 through the exhaust ports 84a, 84b, 84c, 84d, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com