Exhaust gas incinerator of compact structure

A compact incinerator technology, applied in the field of incinerators, can solve the problems of long preheater and bulky incinerator, and achieve the effect of high utilization rate of waste heat, good preheating effect and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

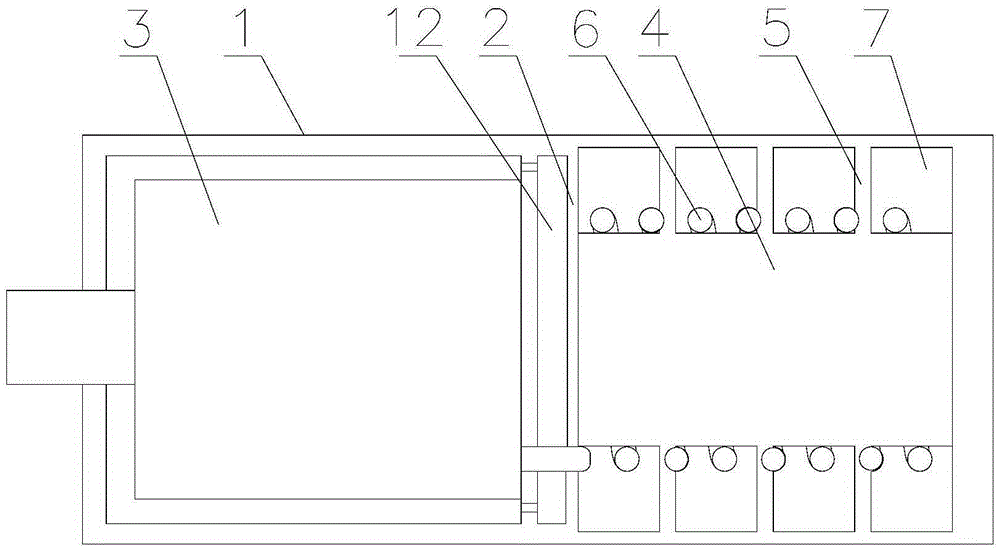

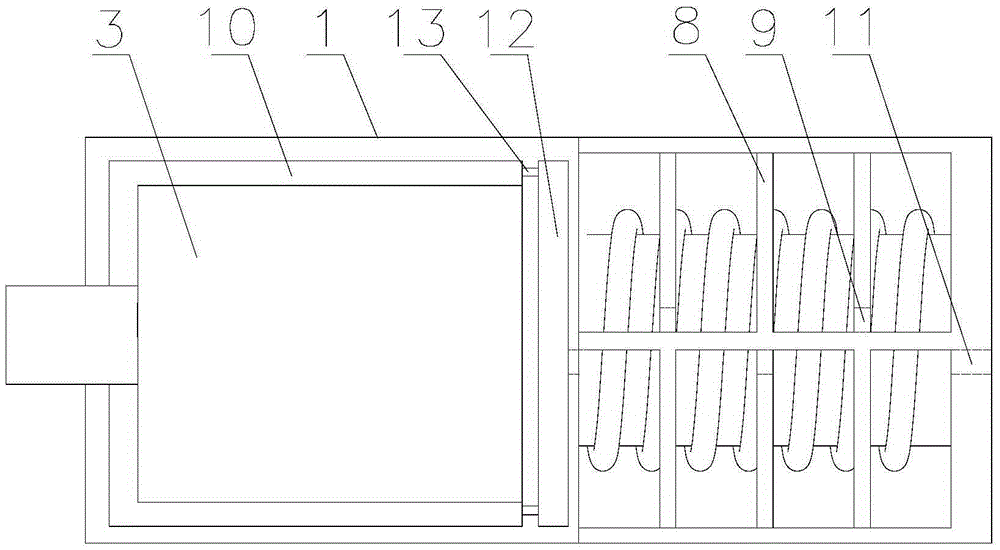

[0018] Such as Figure 1-3 As shown, a compact waste gas incinerator includes a furnace shell 1 and a partition plate 2 installed in the furnace shell 1, and the partition plate 2 divides the interior of the furnace shell 1 into a left chamber and a right chamber, A combustion chamber 3 is provided in the left chamber, and a preheating device is provided in the right chamber;

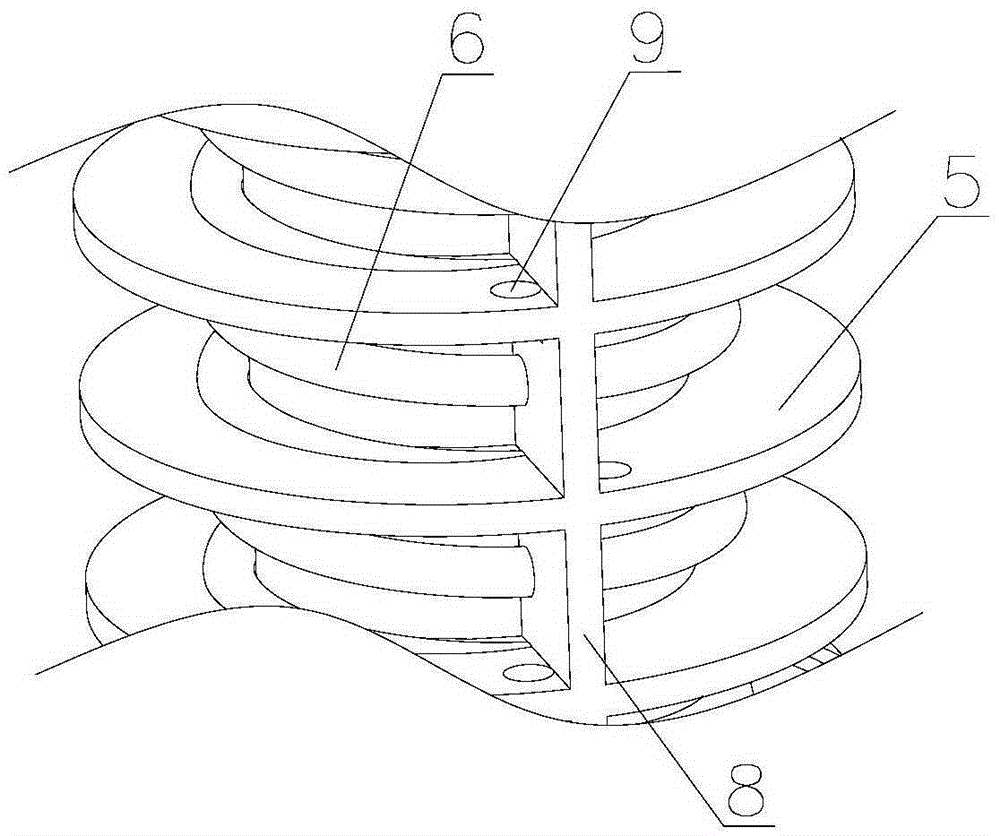

[0019] The preheating device includes a heat conduction column 4, a spiral pipe 6 sleeved on the heat conduction column 4 and several interlayers 5, the heat conduction column 4 is fixedly installed on the partition board 2, and the interlayer 5 is arranged along the The axial direction is sequentially arranged in the right chamber, and the partition layer 5 partitions the right chamber into several airtight circulation chambers 7, each of which is provided with a baffle plate 8 separating them, and the partition layer 5 There are through holes 9 connected to two adjacent circulation chambers 7 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com