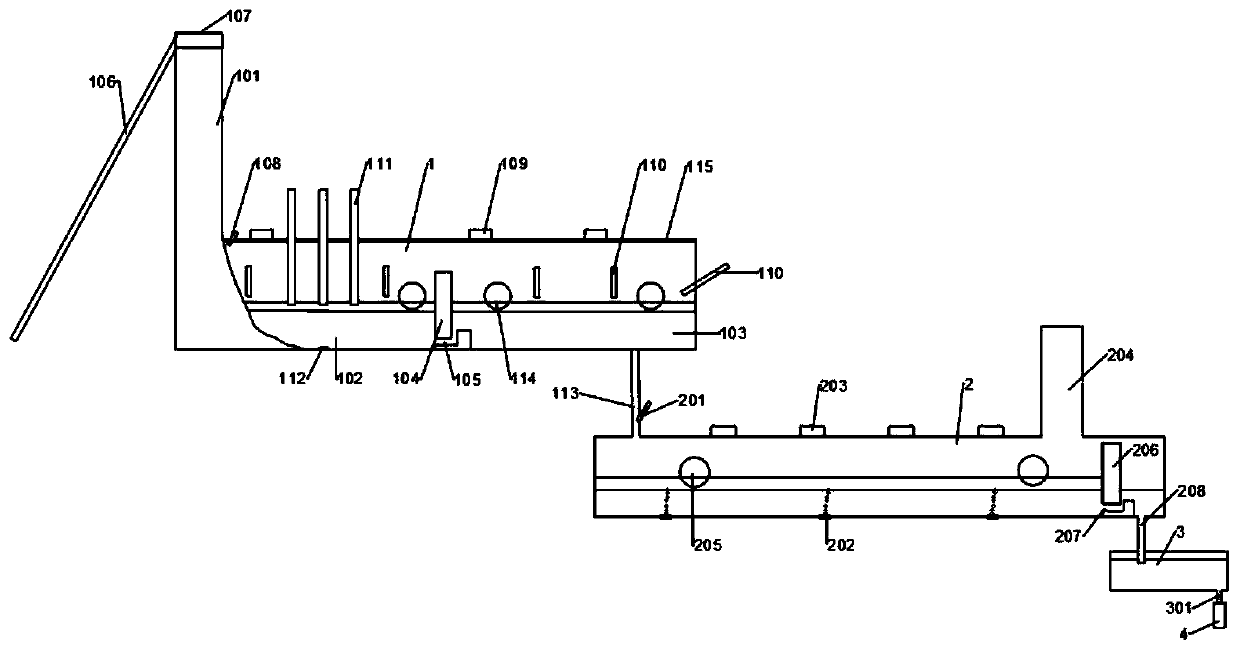

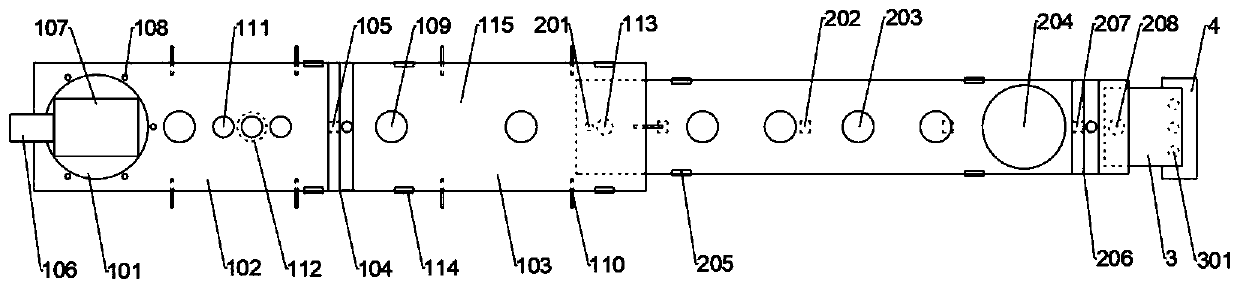

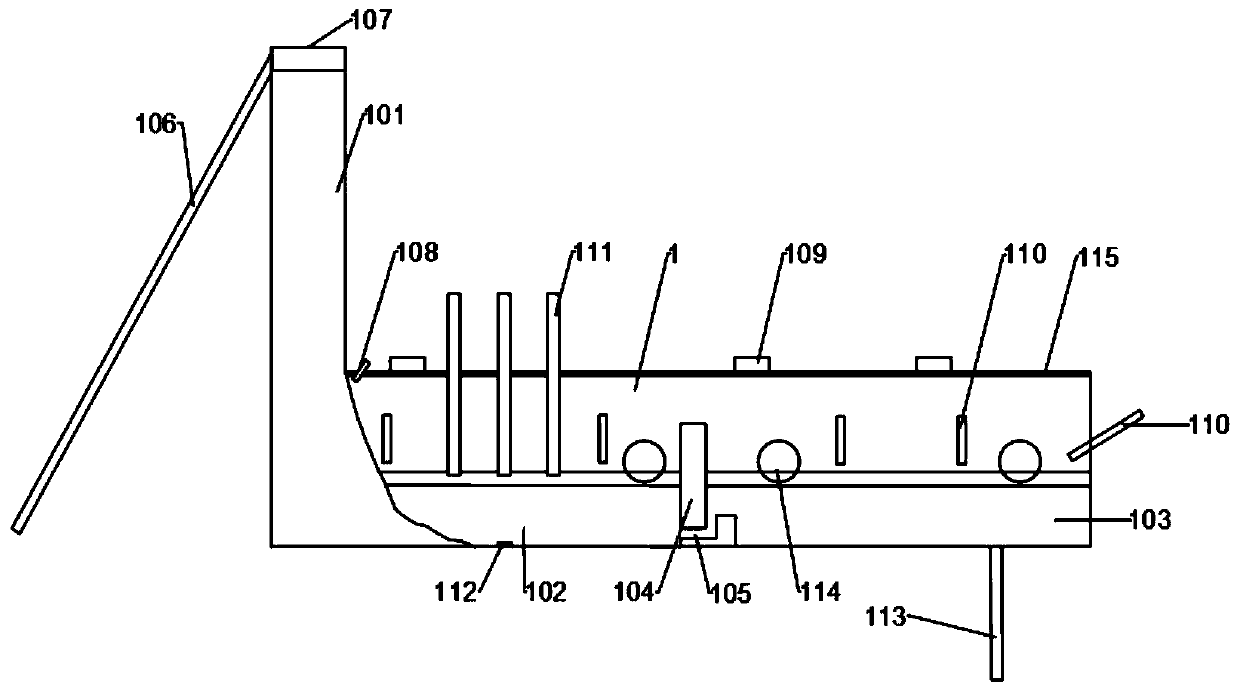

All-scrap continuous steelmaking system and smelting process

An all-scrap steel and process technology, applied in the field of steelmaking, can solve problems such as increasing the utilization efficiency of transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, the process of the present invention is applied to the implementation of the present invention when the first furnace of an all-scrap continuous steelmaking system starts smelting, and the specific process is as follows:

[0049] (1) 0 to 10 minutes: this stage is the stage of distributing materials in the melting section;

[0050] Specific process: open the hearth cover to distribute material evenly at the bottom of the melting section, and close the retaining wall channel;

[0051] (2) 10 to 30 minutes: this stage is the stage where scrap steel is melted into molten steel in the melting section and flows to the oxidation section;

[0052] Specific process: the electrodes are dropped, the furnace wall cluster oxygen lance is used to assist melting, lime, carbon powder and other auxiliary materials are added through the feeding port, and the automatic slag flow is controlled at the slag outlet; after the scrap steel in the melting section is complete...

Embodiment 2

[0062] In this embodiment, the process of the present invention is applied to smelting Q235A in an all-scrap continuous steelmaking system in the present invention, and the specific process is:

[0063] (1) 0~5min: This stage is the stage where scrap steel is preheated in the continuous feeding shaft until it enters the smelting bed:

[0064] Specific process: steel scrap is added into the shaft, and the flue gas of the smelting bed is combusted by oxygen burners, and the high-temperature flue gas enters the shaft to heat the scrap steel;

[0065] (2) 5 to 20 minutes: This stage is the melting and heating stage of scrap steel in the melting section:

[0066] Specific process: energize to melt scrap steel, use the furnace wall cluster oxygen lance 203 to assist melting or slagging, further, add lime, carbon powder and other auxiliary materials through the feeding port, and control the automatic slag flow at the slag outlet;

[0067](3) 20 to 35 minutes: This stage is the stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com