Automatic hydrogen fluoride feeding device for electrolytic bath and using method of automatic hydrogen fluoride feeding device

A feeding device and hydrogen fluoride technology, applied in the electrolysis process, electrolysis components, etc., can solve problems such as unstable pressure of hydrogen fluoride cylinders, unstable feeding speed control, waste of hydrogen fluoride, etc., to avoid potential safety hazards and increase labor costs, avoid The effect of venting loss and reducing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to introduce the technical solutions provided by the present invention in more detail, the following will be described in conjunction with the examples.

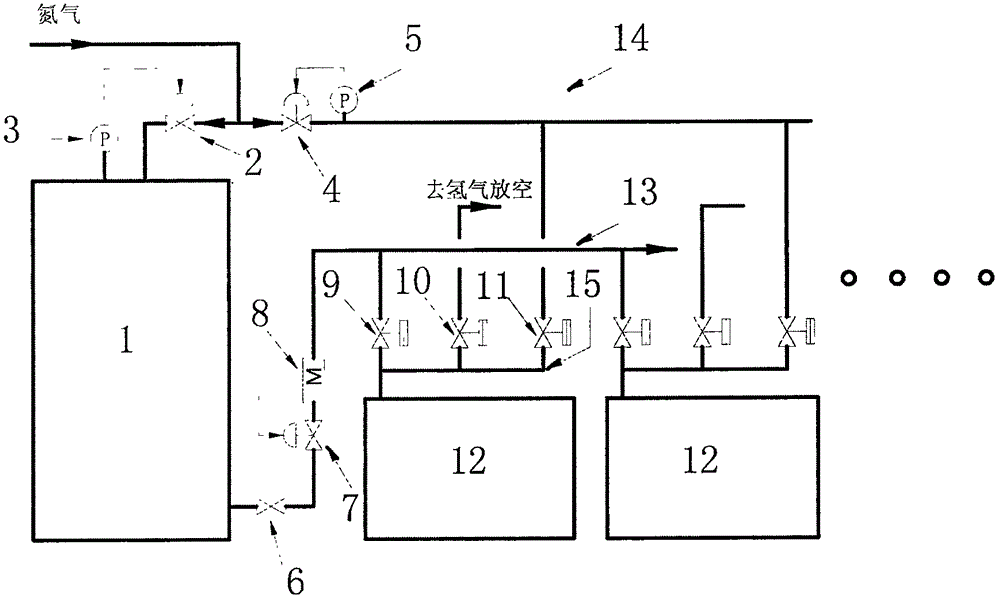

[0031] Such as figure 1 As shown, the hydrogen fluoride automatic feeding device for the electrolytic cell provided by the present invention includes a large-capacity hydrogen fluoride storage tank, a regulating valve, a flow meter, a hydrogen fluoride main pipe, a nitrogen main pipe, a feed pipe and an electrical circuit; the top pipes of the hydrogen fluoride storage tank 1 are connected in sequence Storage tank pressure regulating valve 2 and corresponding storage tank pressure sensor 3, nitrogen pressure regulating valve 4 and corresponding nitrogen pressure sensor 5, nitrogen main pipe 14; the pipeline between storage tank pressure regulating valve 2 and nitrogen pressure regulating valve 4 communicates with nitrogen source One end of the nitrogen replacement valve 11 is connected to the nitrogen main pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com