Gap-type high-pressure boiling device for seed nut food

A high-pressure cooking and gap-type technology, applied in the direction of food science, etc., can solve the problems of inability to realize large-scale production in the production workshop, restrict the healthy and rapid development of the industry, and make the seeds and nuts difficult to taste, so as to achieve convenient installation, assembly, disassembly and cleaning and other operations, realize large-scale nut food production, and improve the effect of cooking efficiency and cooking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

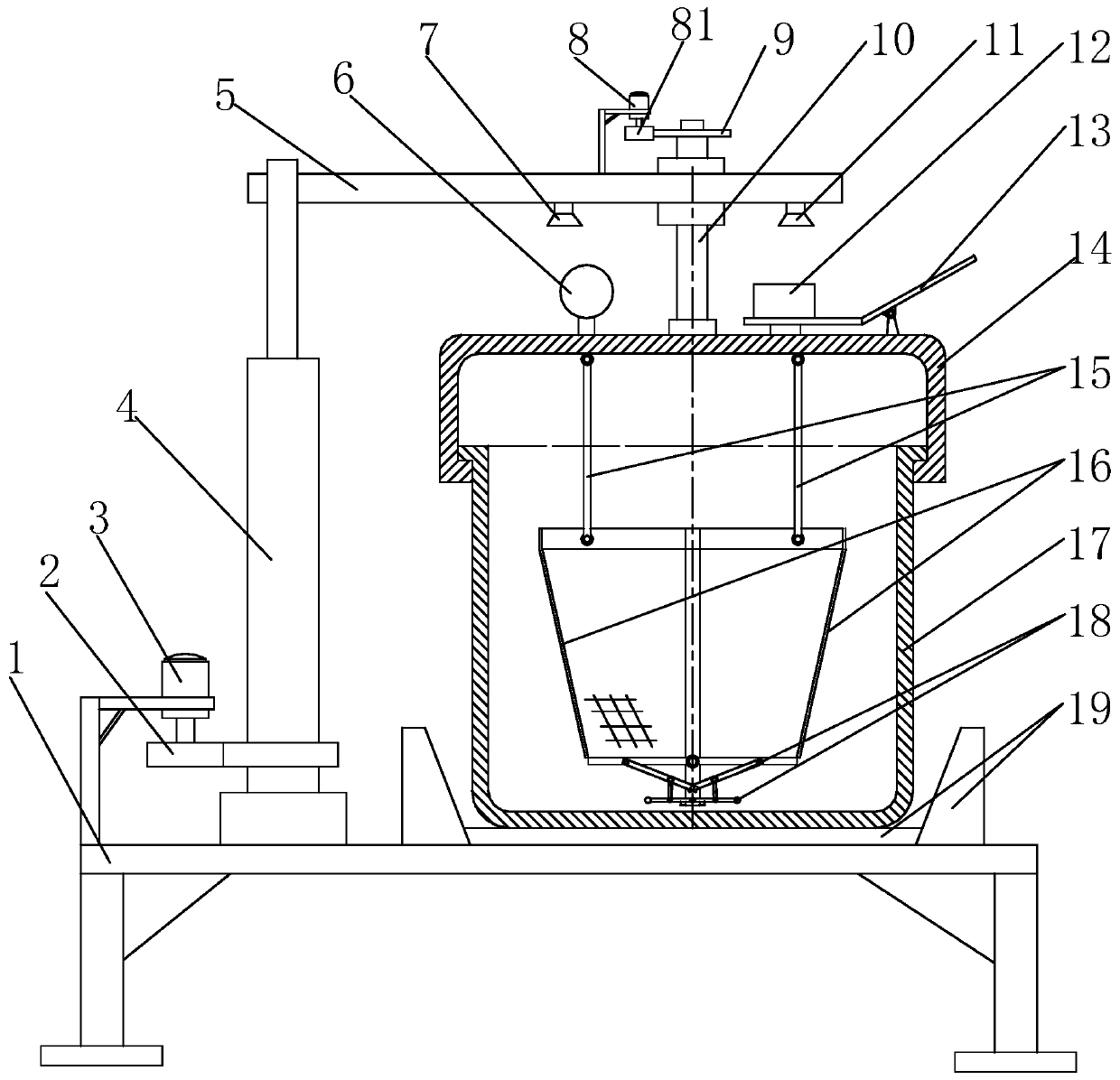

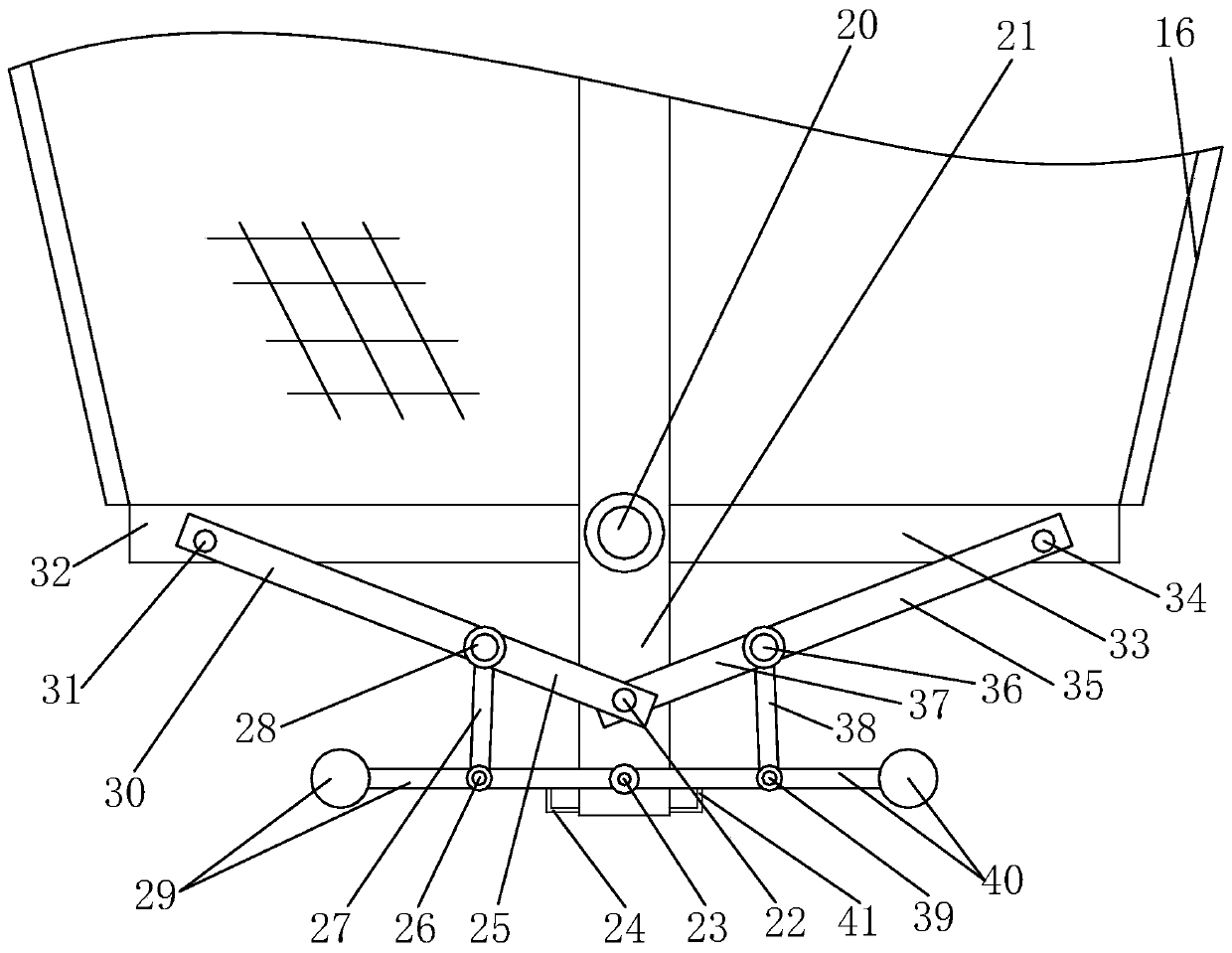

[0030] Such as figure 1 , figure 2 As shown, a gap-type high-pressure cooking device for seed nut food includes a frame 1, a rotating power mechanism A3, a top cover lifting cylinder 4, a boom 5, a rotating power mechanism B8, a top cover rotating shaft 10, and a top cover. Cover 14, cooking pot body 17 and mesh material barrel 16, electric heating seat 19 is installed on the top of frame 1, and rotating power mechanism A3 is installed on the top of frame 1 through a bracket. The rotating power mechanism A3 is preferably a motor or a cylinder seat rudder machine, the rotating power mechanism A3 has a power output shaft, the driving gear A2 is installed on the power output shaft of the rotating power mechanism A3, the top cover lifting cylinder 4 has a lifting rod, and the top cover lifting cylinder 4 is equipped with a gear that meshes with the driving gear A2. Driven gear A. Boom 5 is fixed on the lifting rod top of roof lifting cylinder 4, and rotating power mechanism B8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com