Patents

Literature

64results about How to "High degree of structural automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

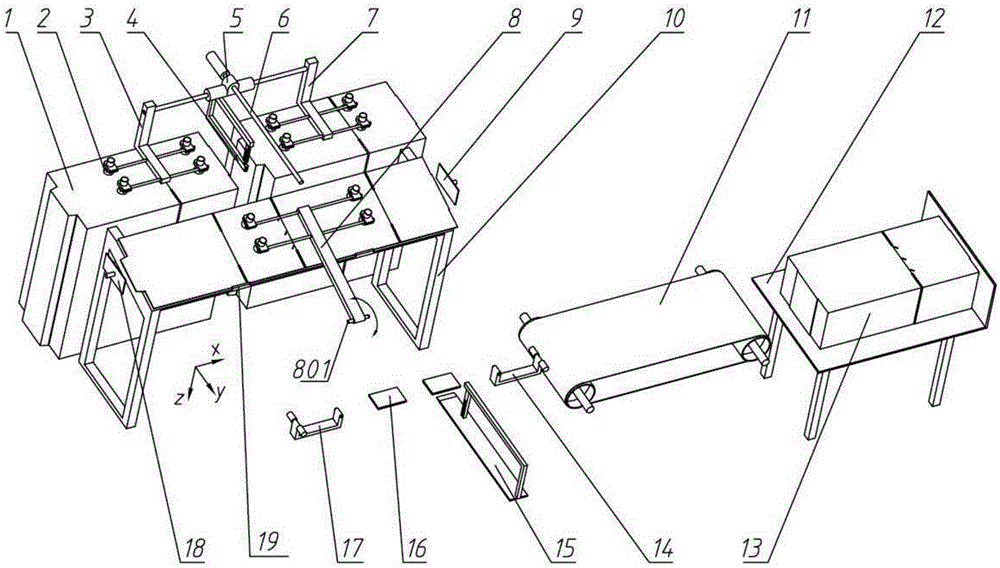

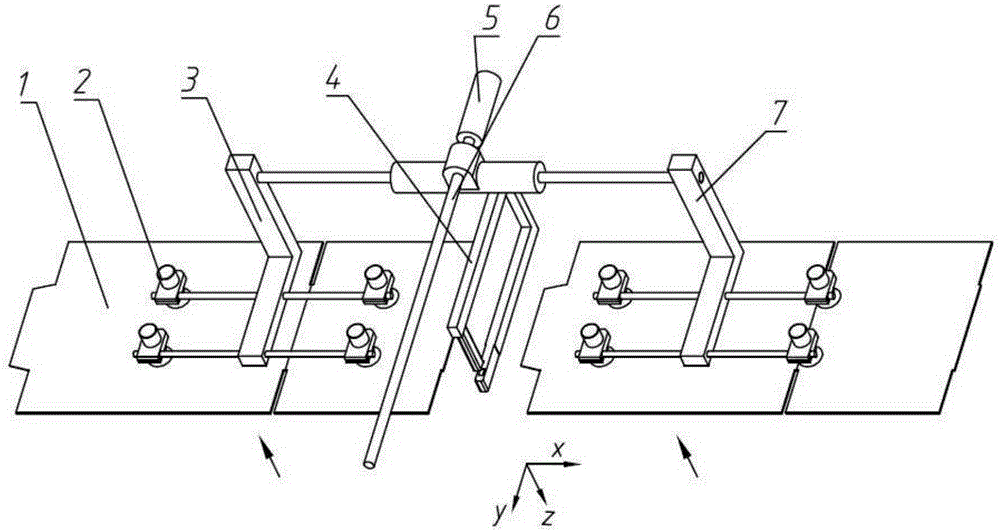

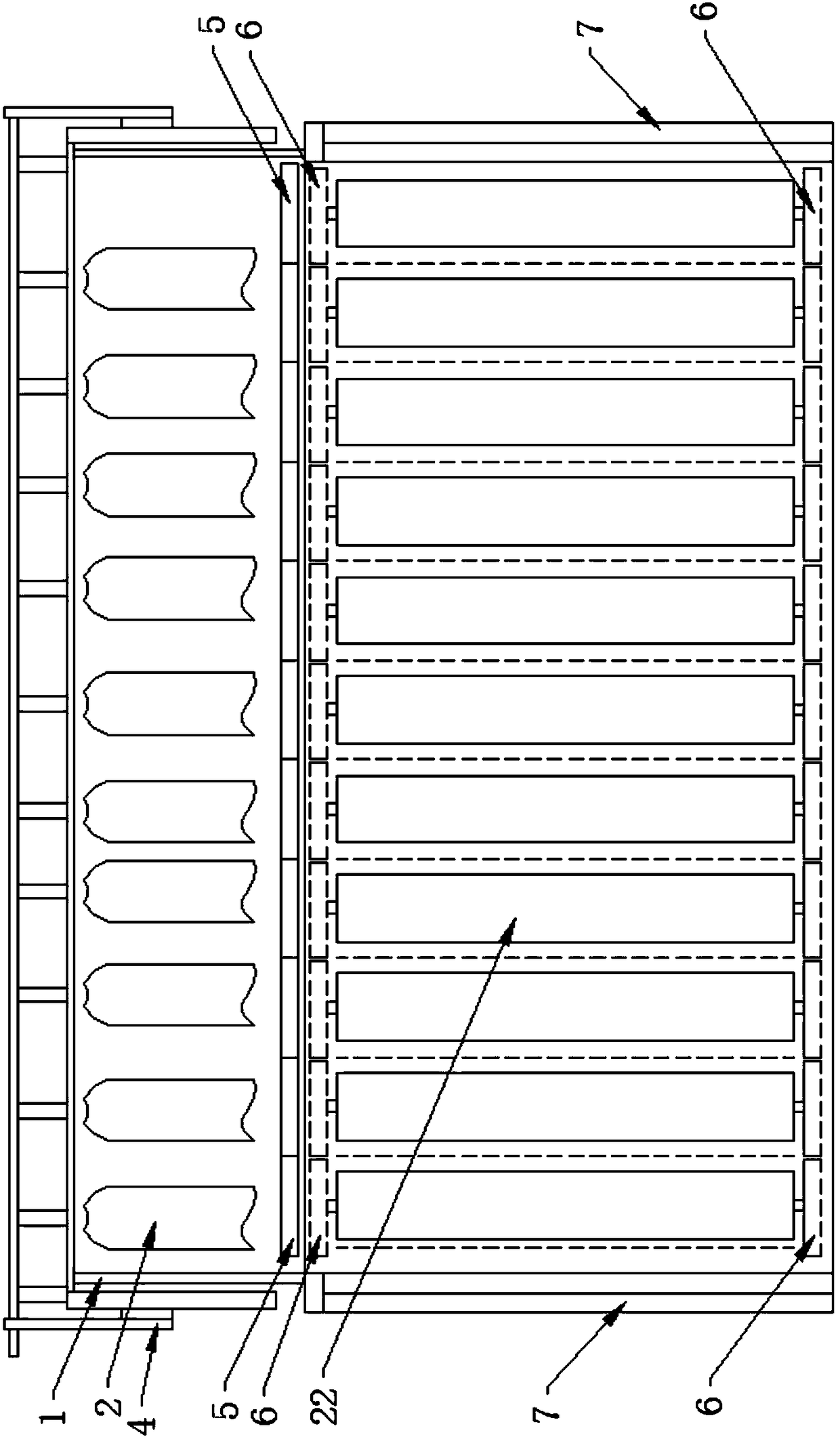

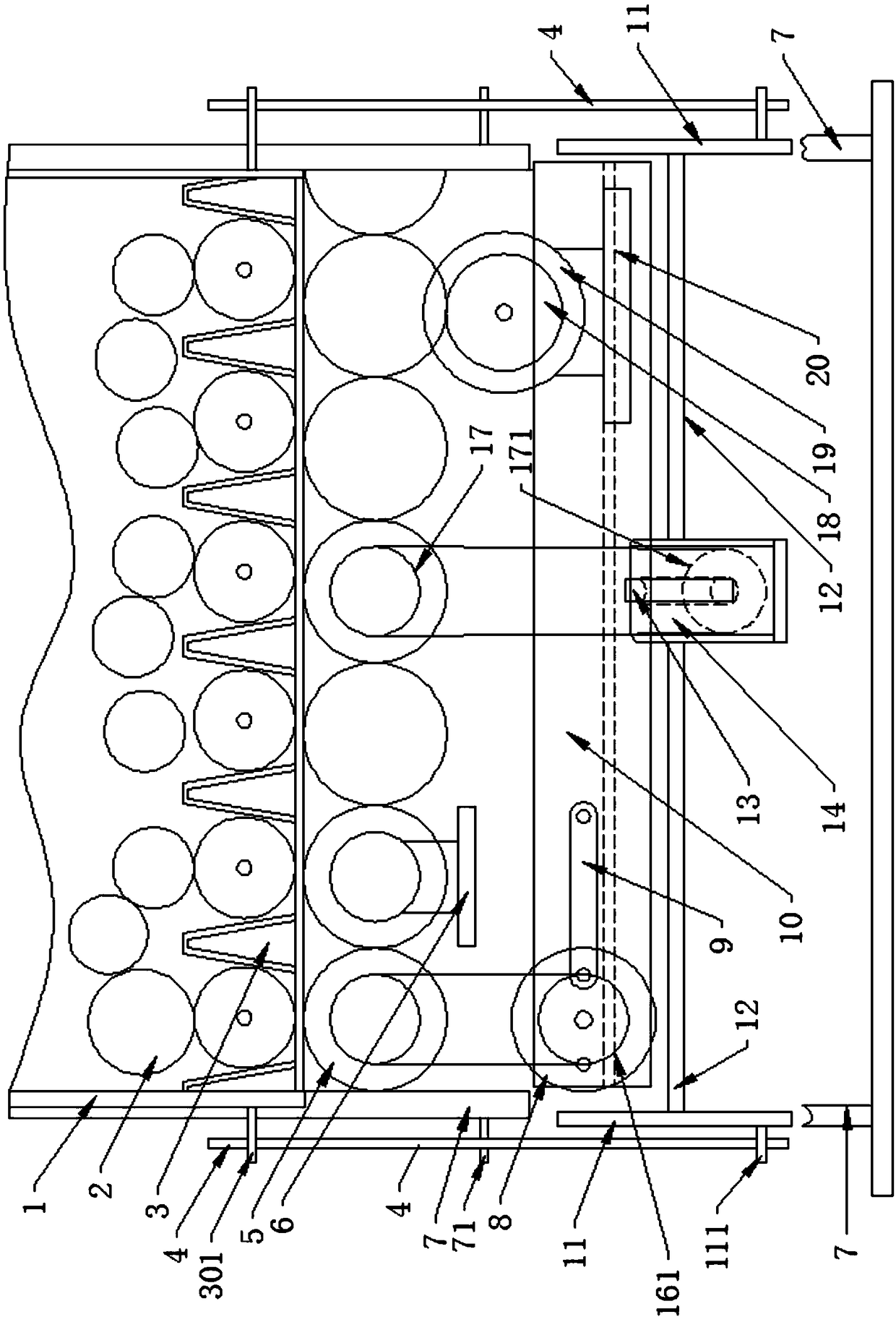

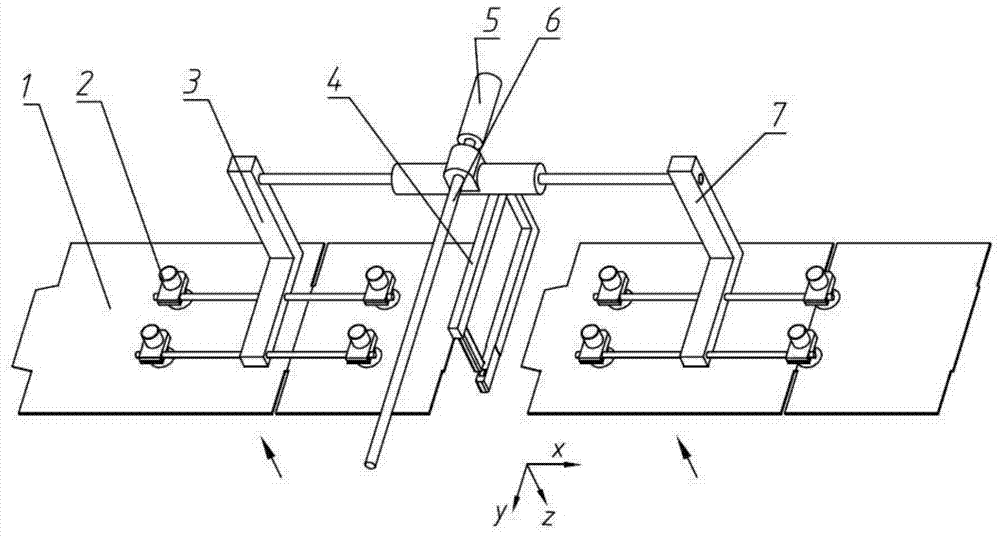

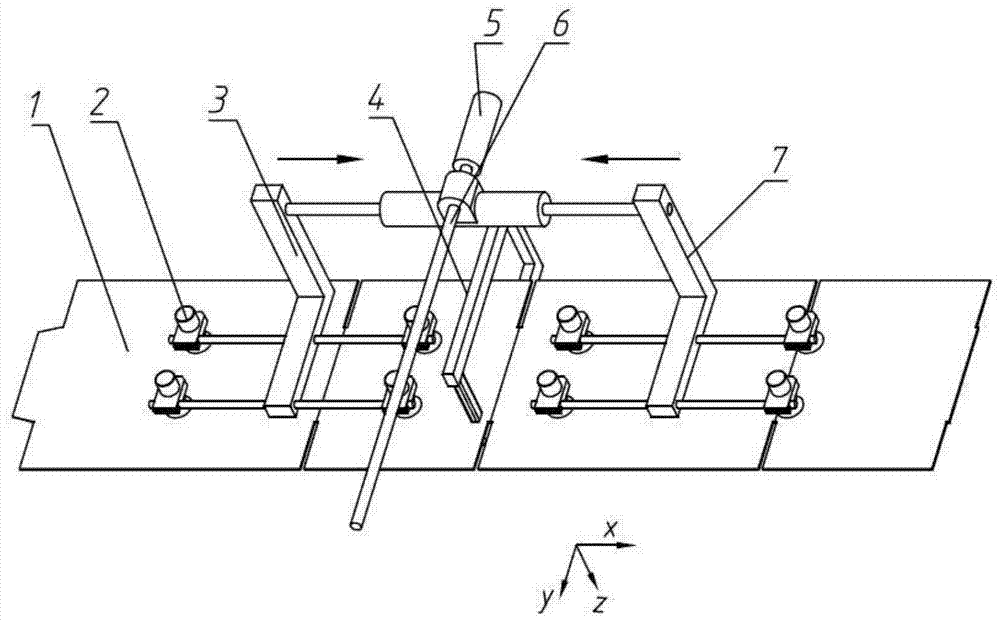

Three-dimensional multilayer pneumatic picking loom

InactiveCN105239256AImprove weaving efficiencyHigh degree of structural automationLoomsYarnAutomation

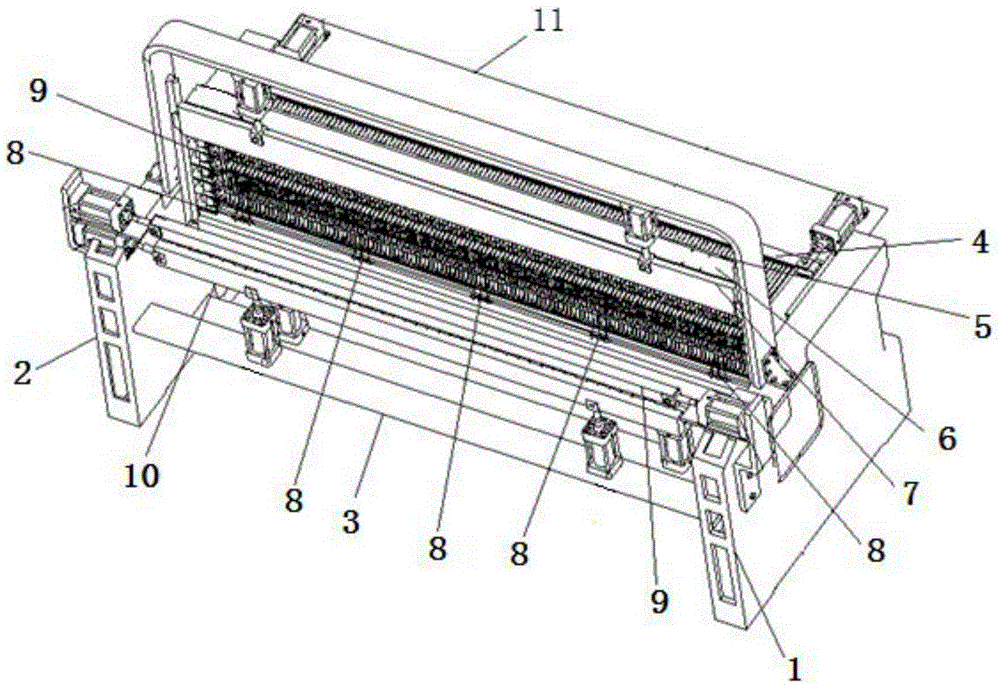

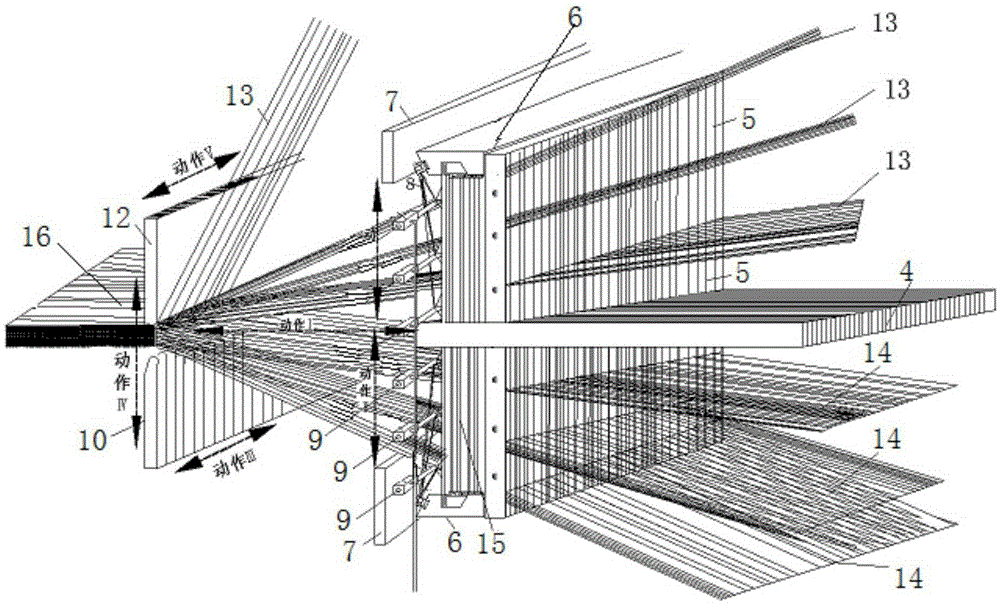

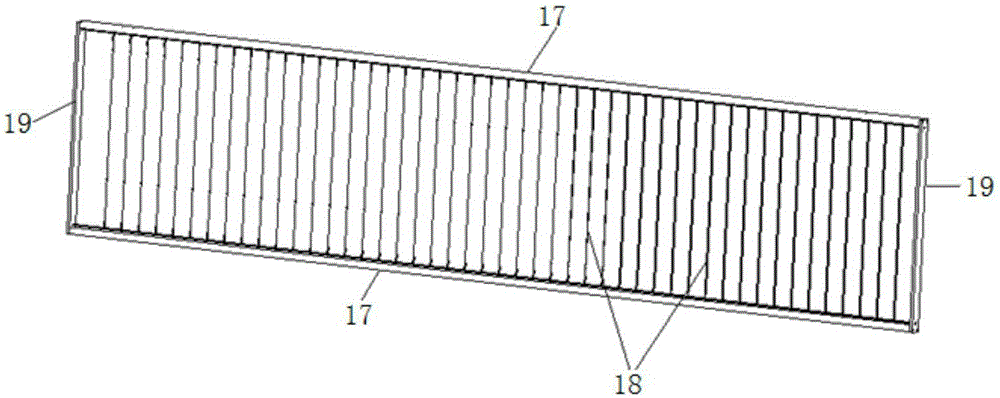

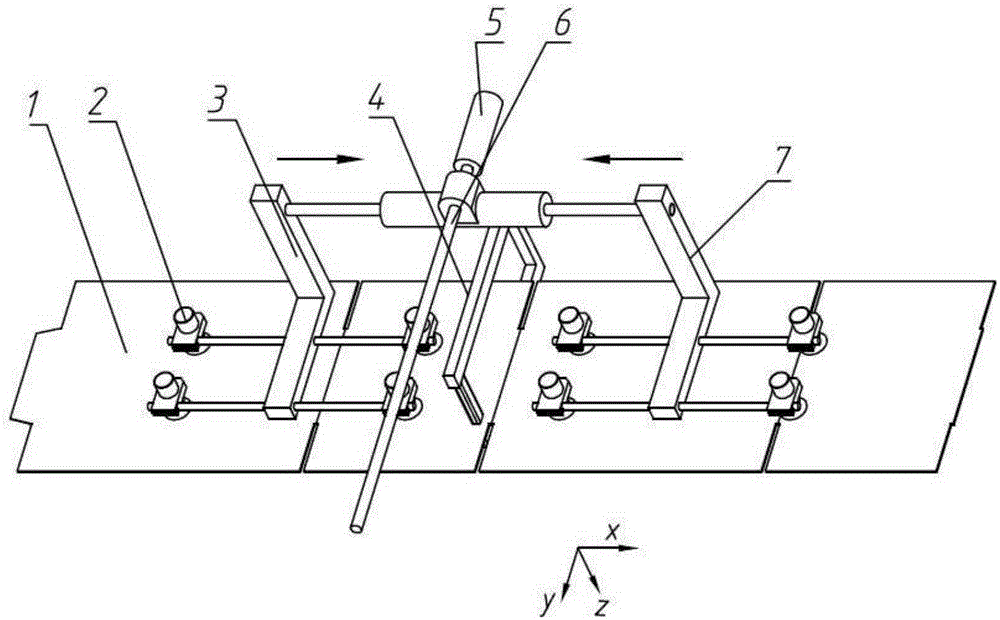

The invention discloses a three-dimensional multilayer pneumatic picking loom, comprising a wallboard a and a wallboard b which are arranged in parallel, and a rack beam used for supporting is horizontally arranged between the wallboard a and the wallboard b. A horizontal weft insertion mechanism is supported on the wallboard a and the wallboard b. An open harness frame, a weft insertion going part, and a closing mechanism are arranged in sequence along a horizontal moving direction of warp yarns between the wallboard a and the wallboard b. The open harness frame, the weft insertion going part, and the closing mechanism are arranged along a vertical direction and are parallel to each other. The open harness frame is arranged close to the weft insertion mechanism. A yarn carrying device is also arranged between the wallboard a and the wallboard b. Latch needles are arranged under the yarn carrying device. The yarn carrying device is arranged close to the closing mechanism. The inner side of the wallboard b is provided with a main nozzle along a vertical direction. The loom is used to solve problems of an existing three-dimensional loom that automation degree is low and weaving efficiency is low.

Owner:XI'AN POLYTECHNIC UNIVERSITY

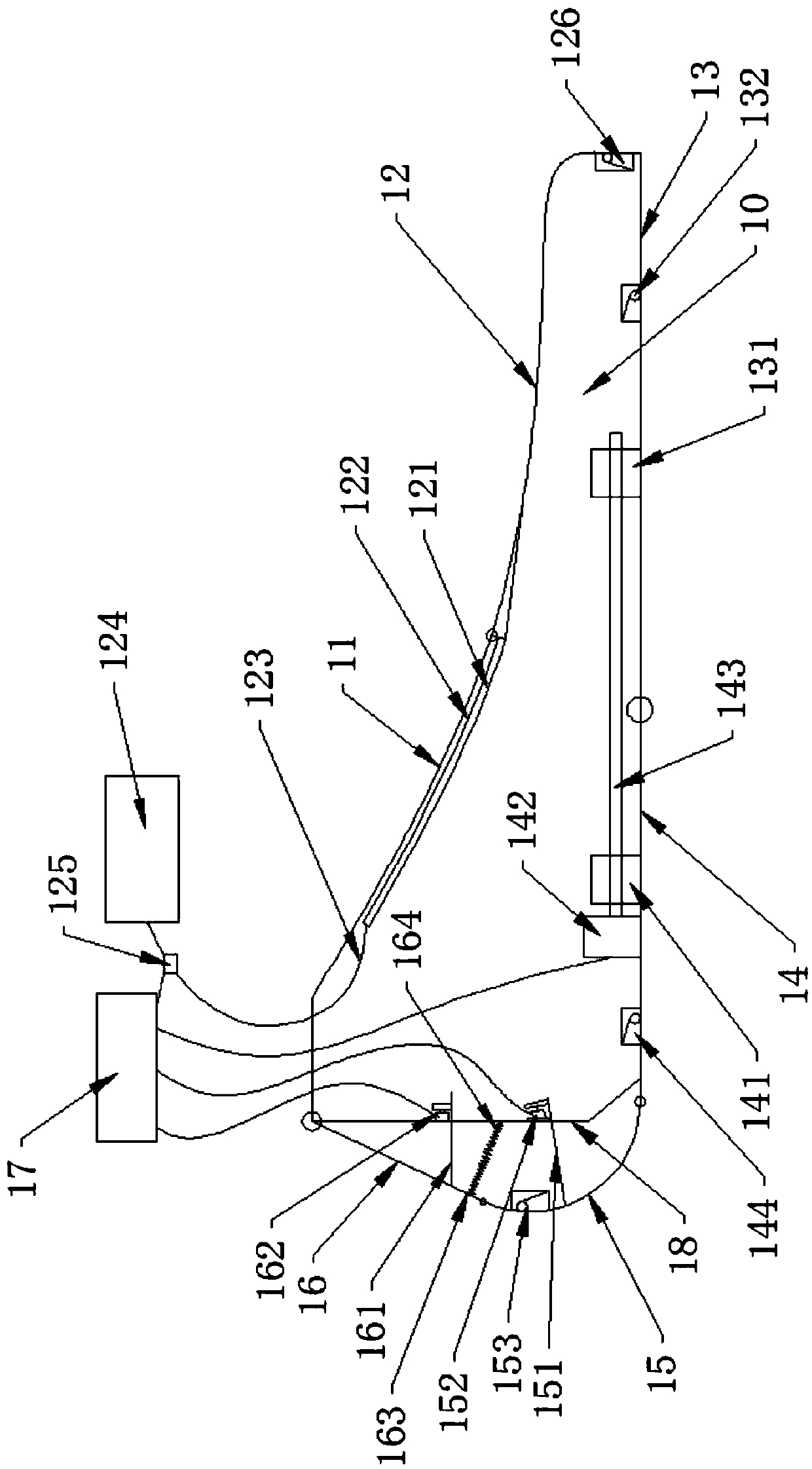

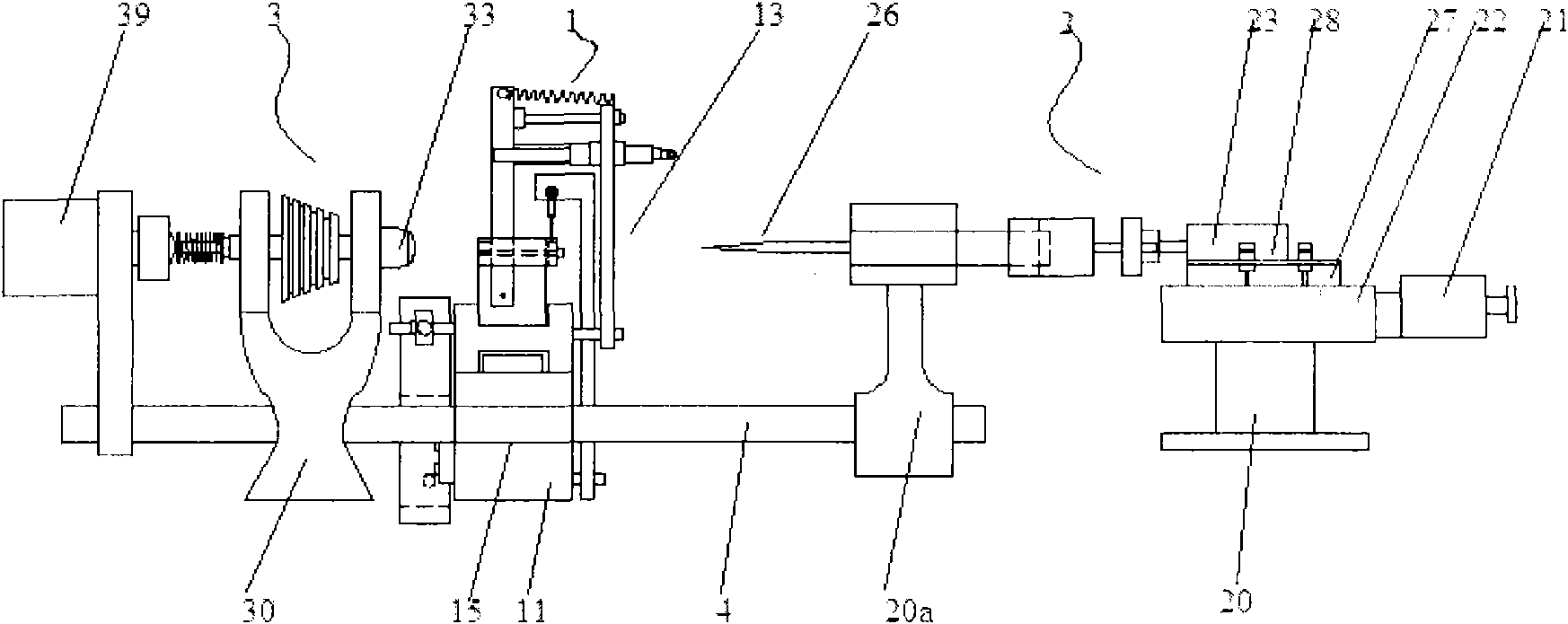

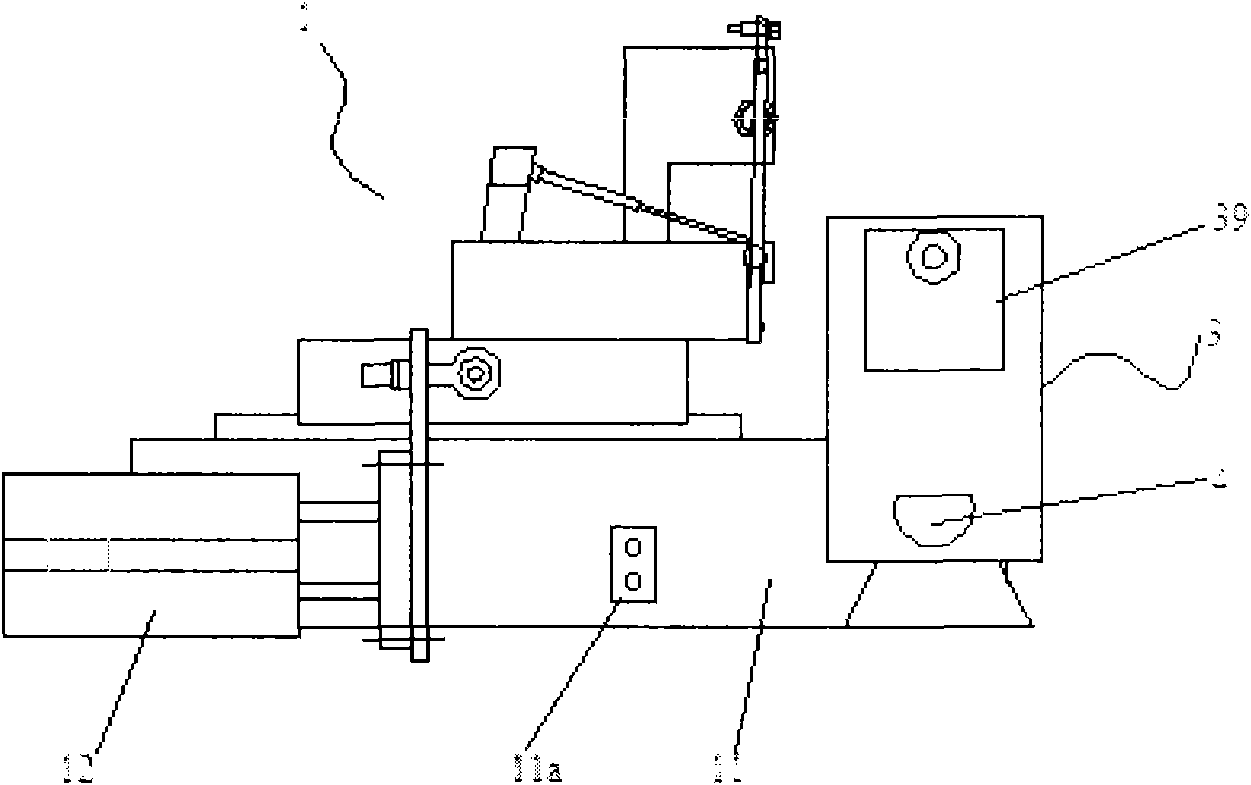

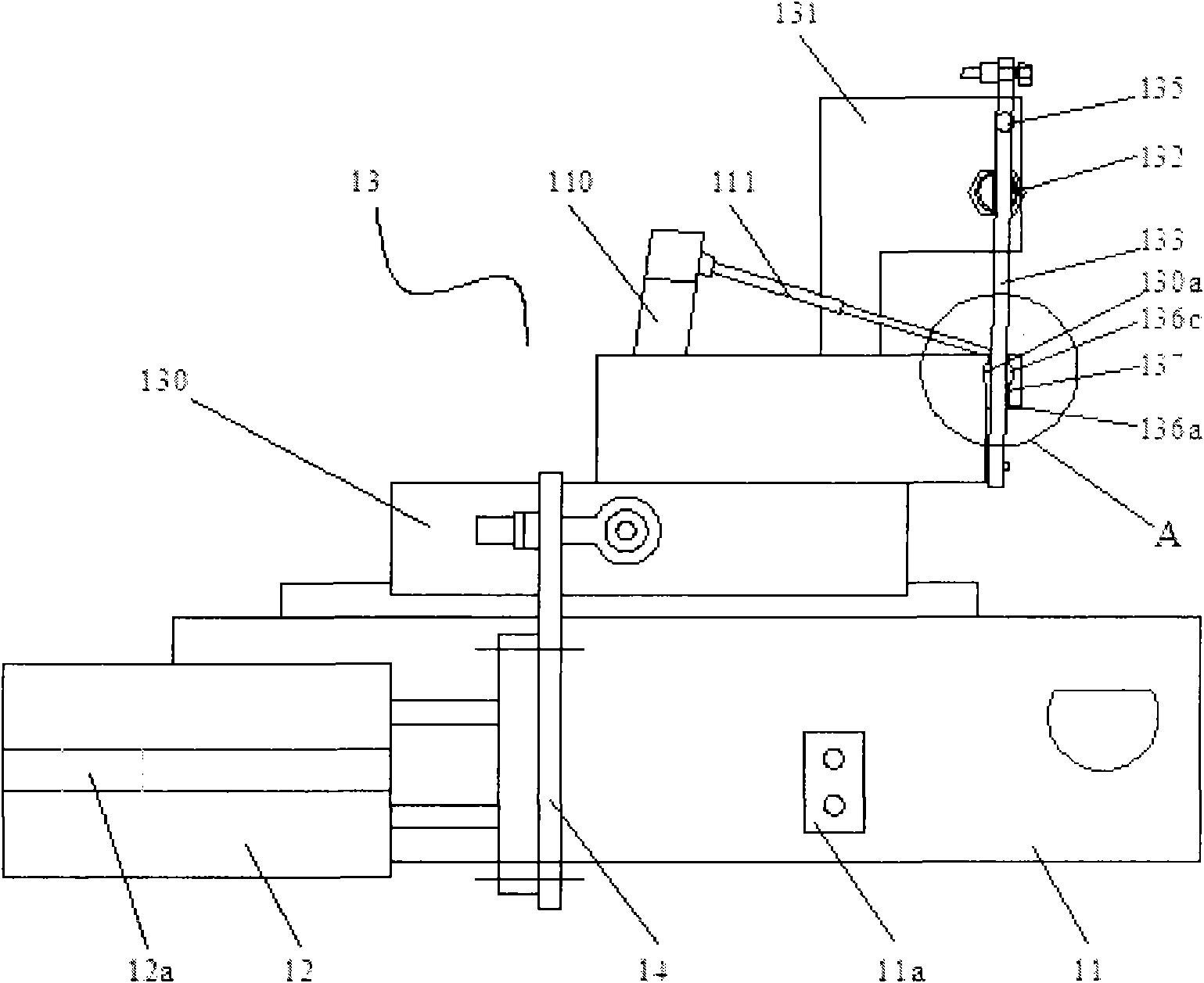

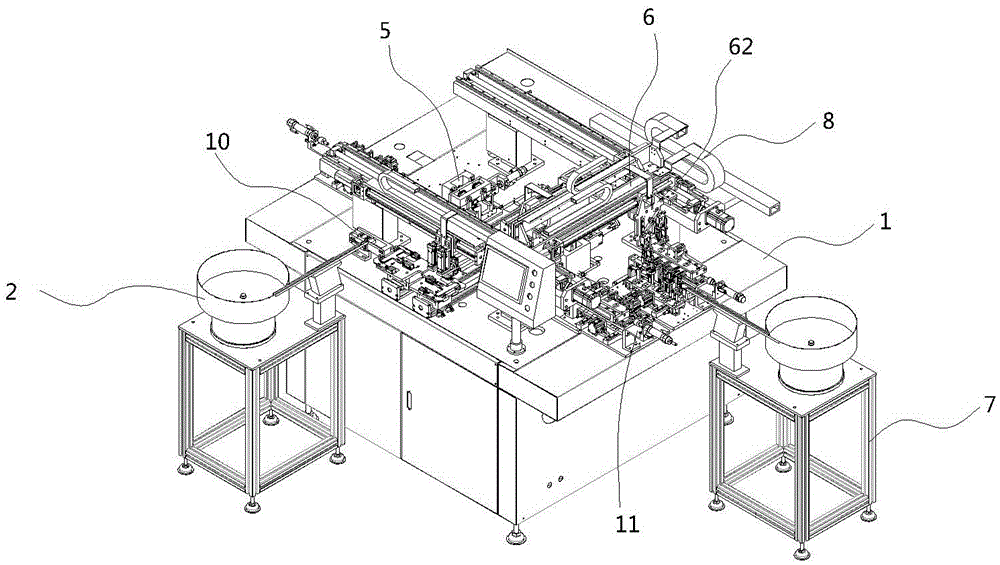

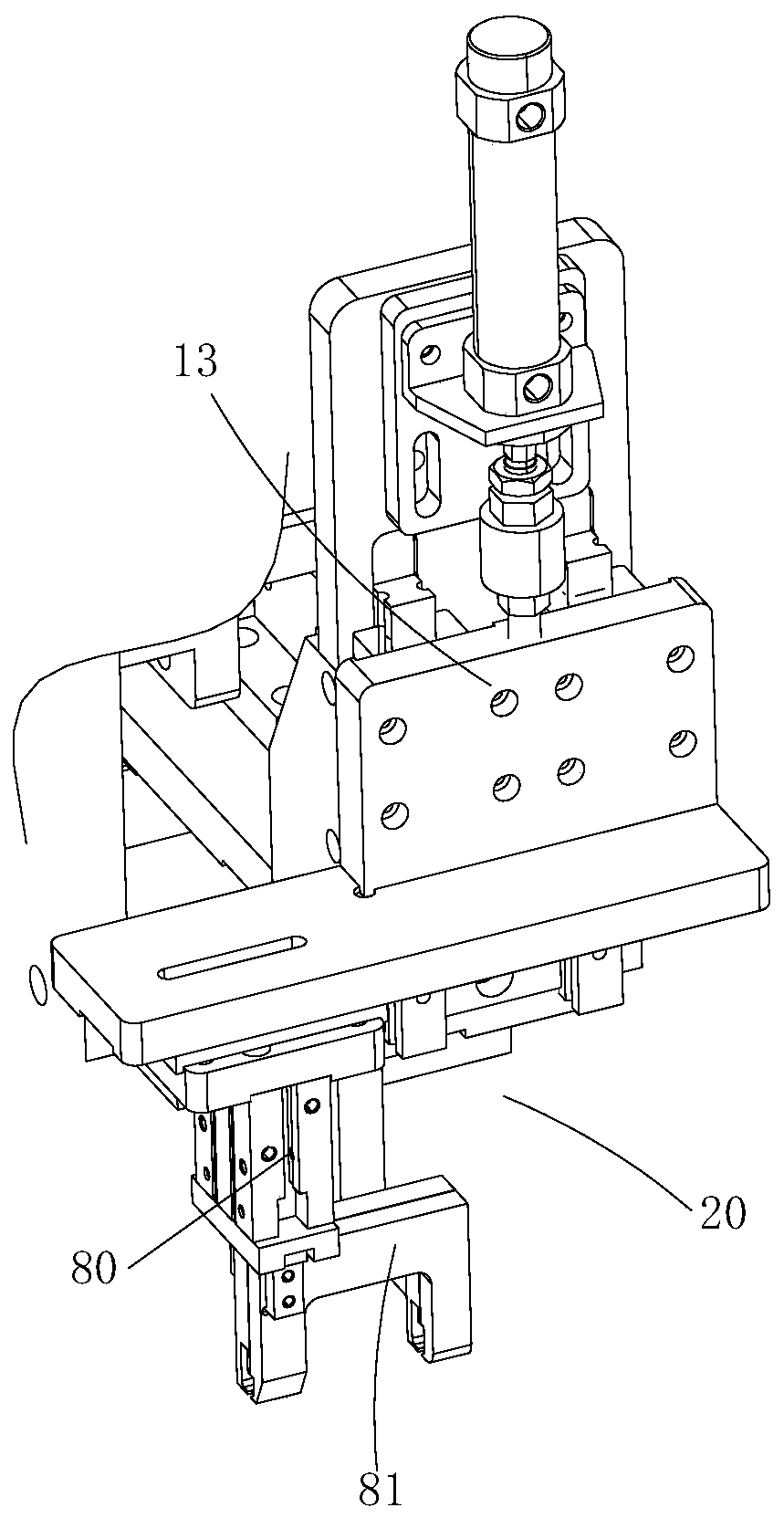

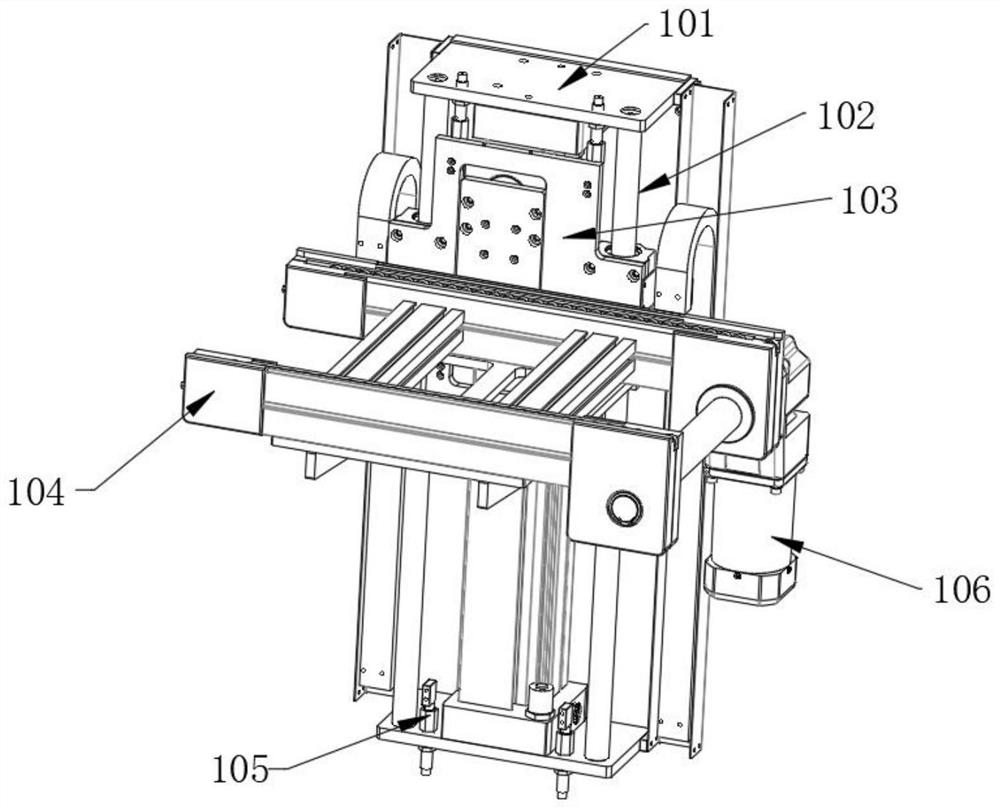

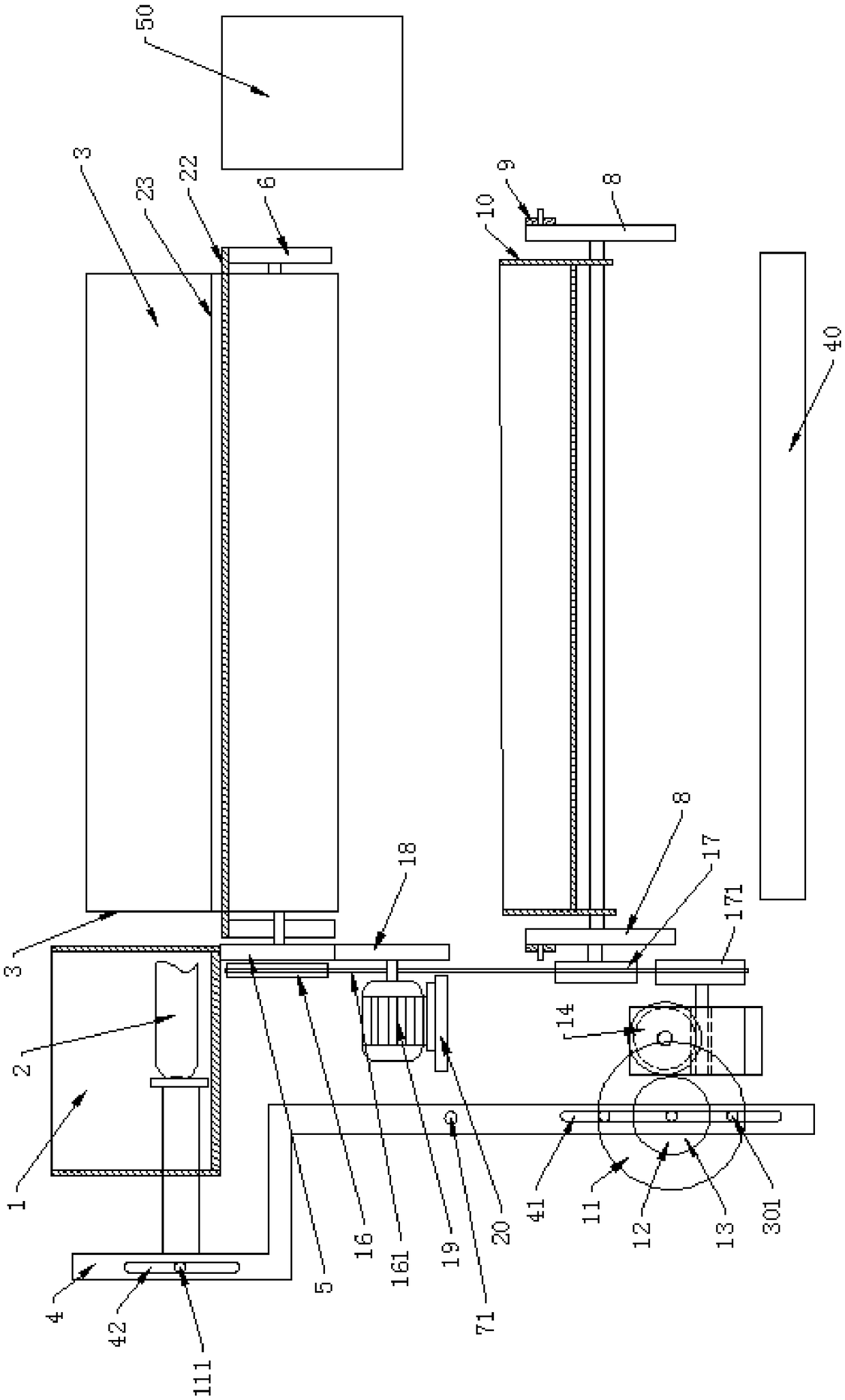

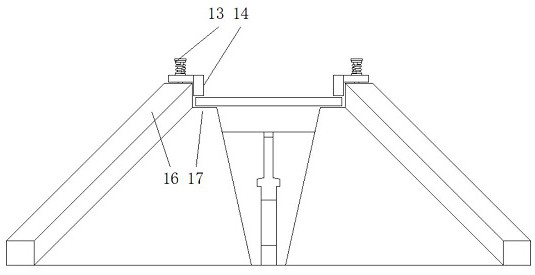

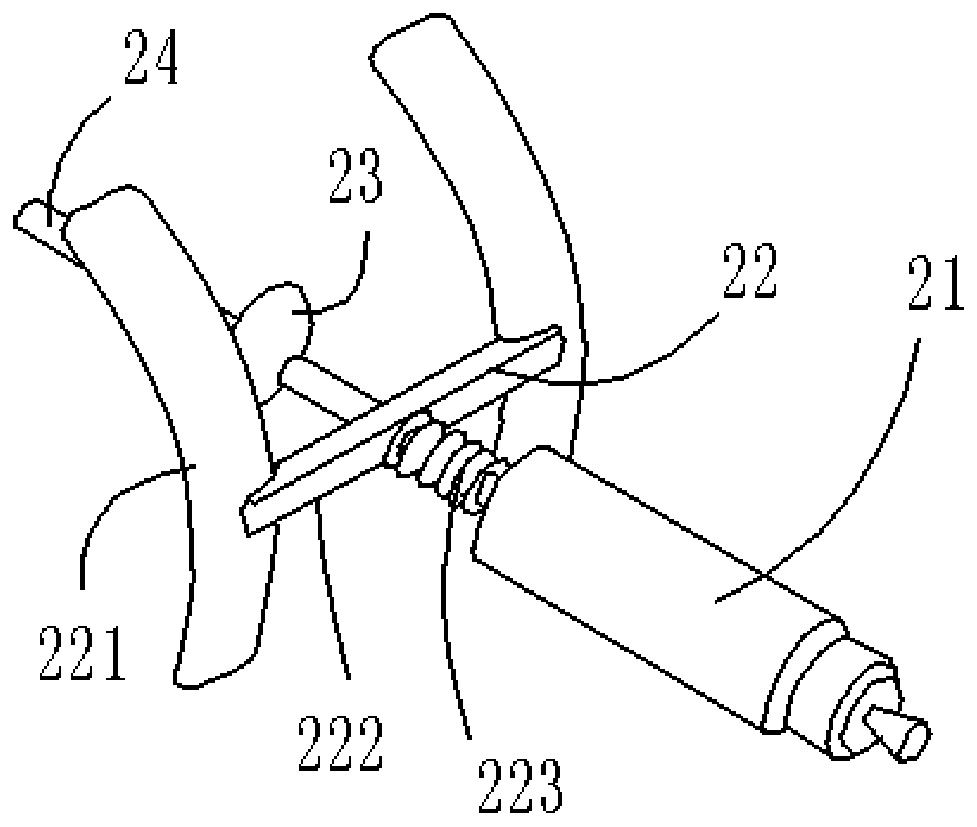

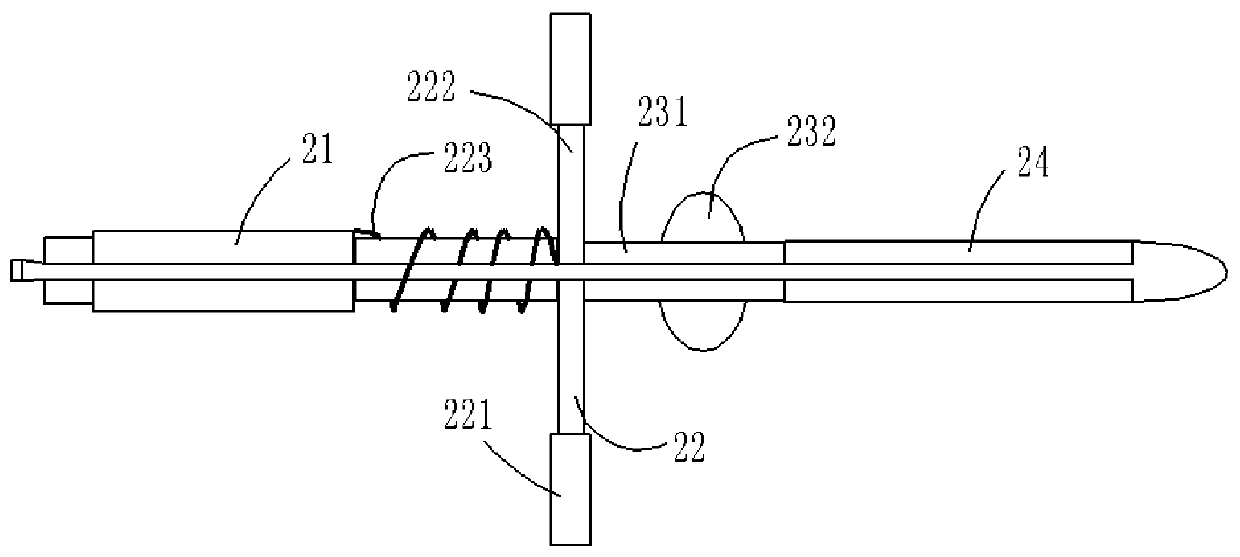

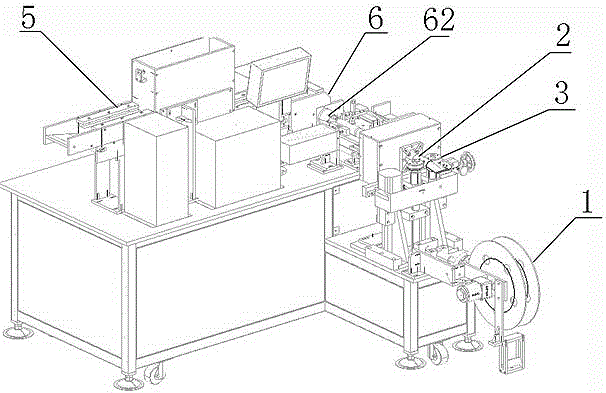

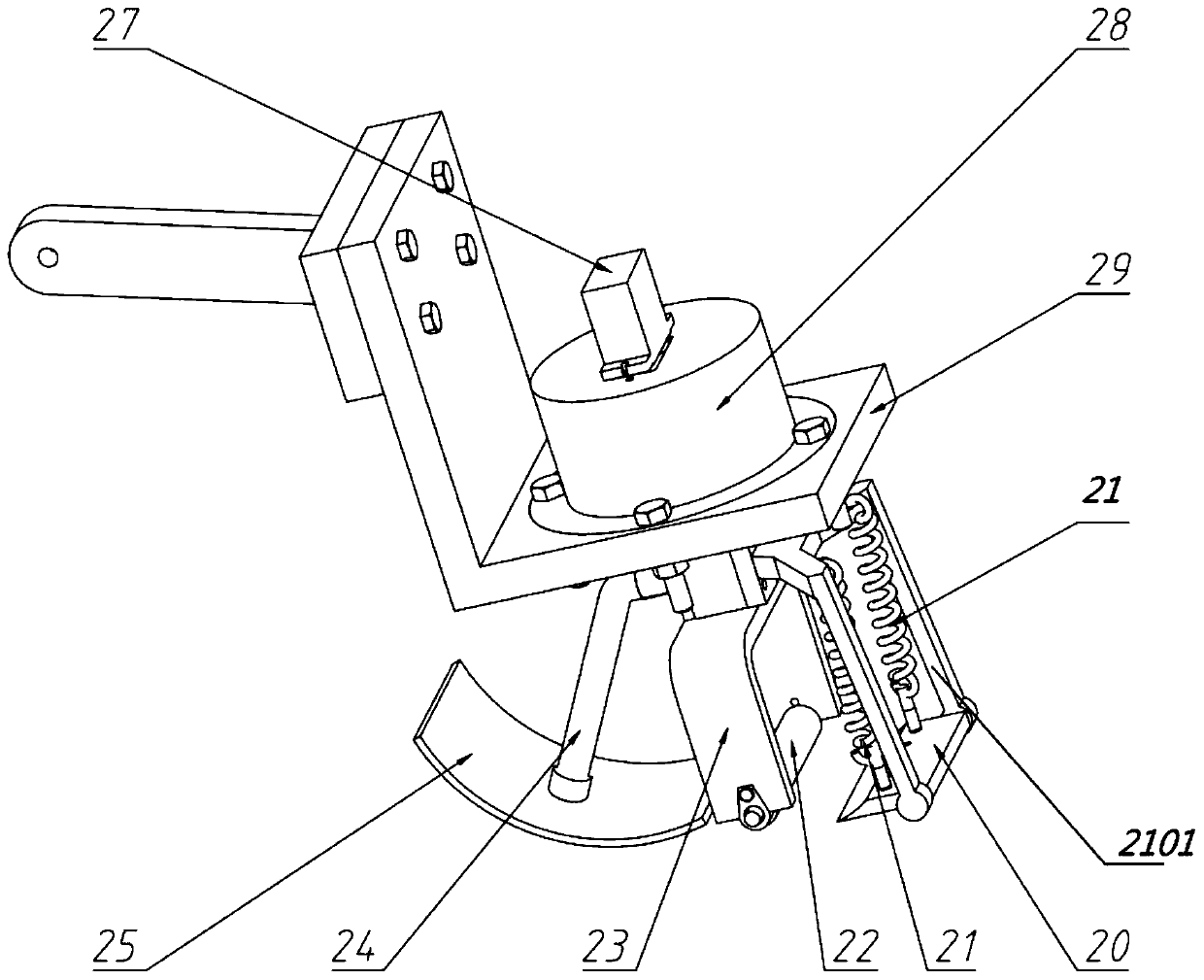

Cam-driven delasting-lasting integrated machine

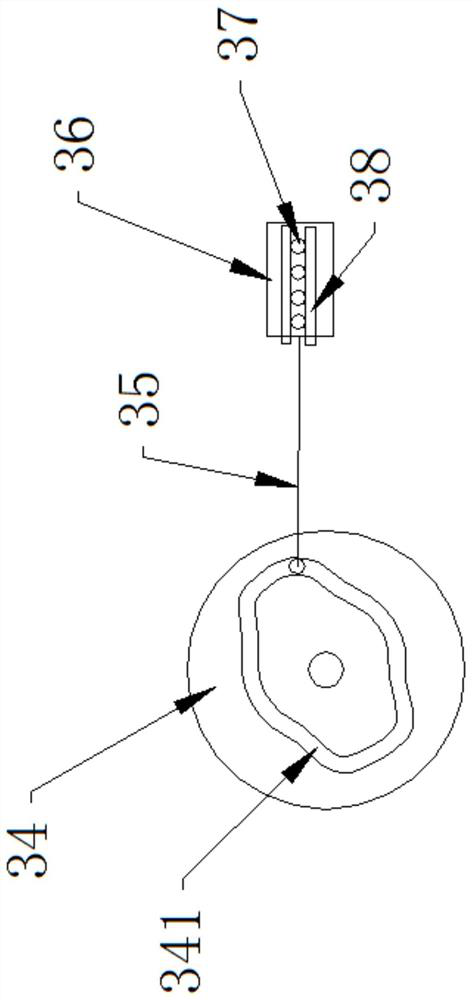

The invention provides a cam-driven delasting-lasting integrated machine, belonging to the shoemaking equipment field. The integrated machine comprises a fixed frame, wherein an inverted shoe tree isfixedly arranged on the fixed frame, a flat pressing assembly is arranged above the shoe tree, clamping assemblies are arranged on the left and right sides of the shoe tree; and a delasting assembly is arranged at the rear end of the shoe tree and comprises a raising cam, a raising driving rod and a lifting frame, the raising cam is rotatably connected to the fixed frame, a first driving slot is formed in the raising cam and is used for driving the lifting frame to move up and down through the raising driving rod, a translation cam, a translation driving rod and a delasting block are arrangedat the upper end of the lifting frame, the translation cam is horizontally arranged and is rotatably connected with the lifting frame, a second driving slot is formed in the translation cam and is used for driving the block to move leftwards and rightwards through the translation driving rod. The integrated machine is driven by a power supply, so that the operation of the whole structure is relatively stable and reliable, the failure rate is greatly decreased, the energy consumption is reduced, the energy source is saved, and the integrated machine is relatively environment-friendly.

Owner:JIHUA LAB

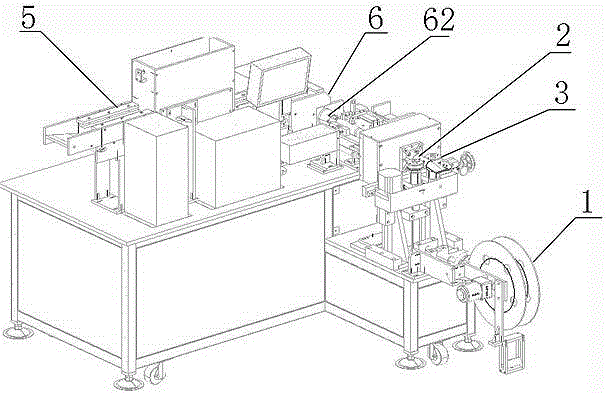

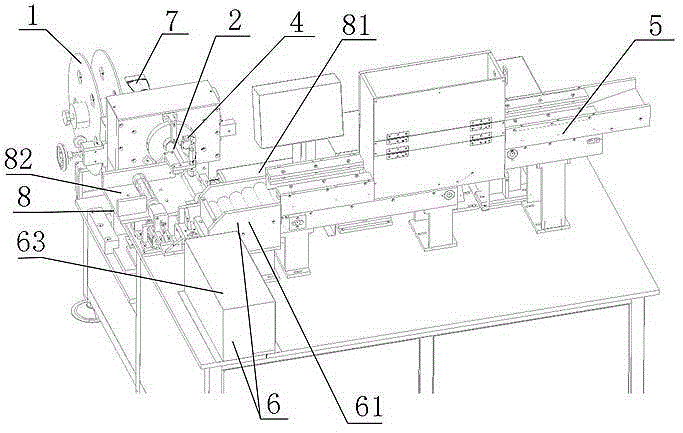

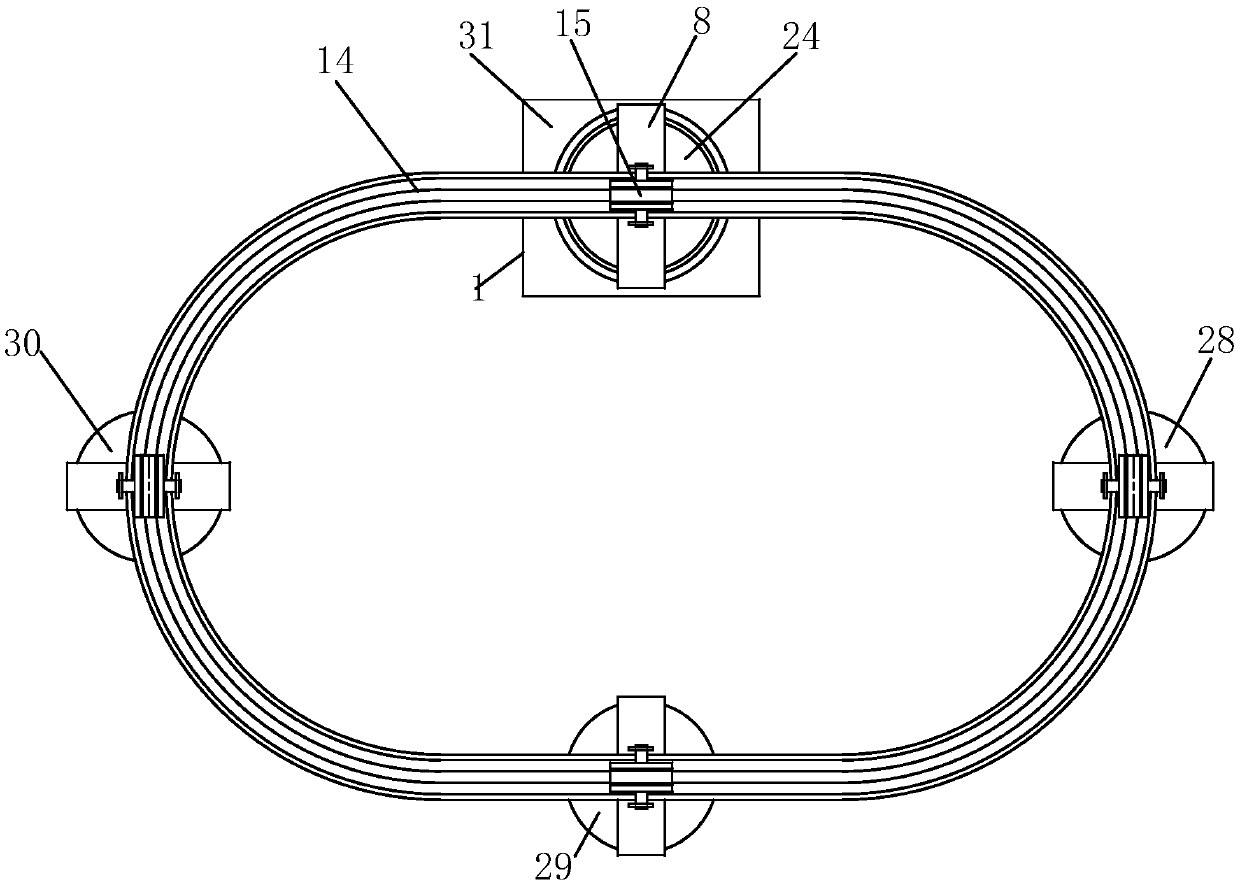

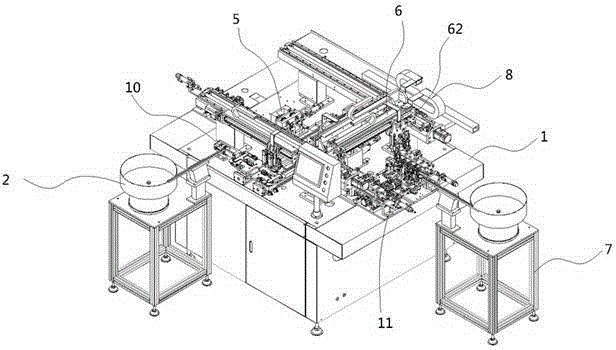

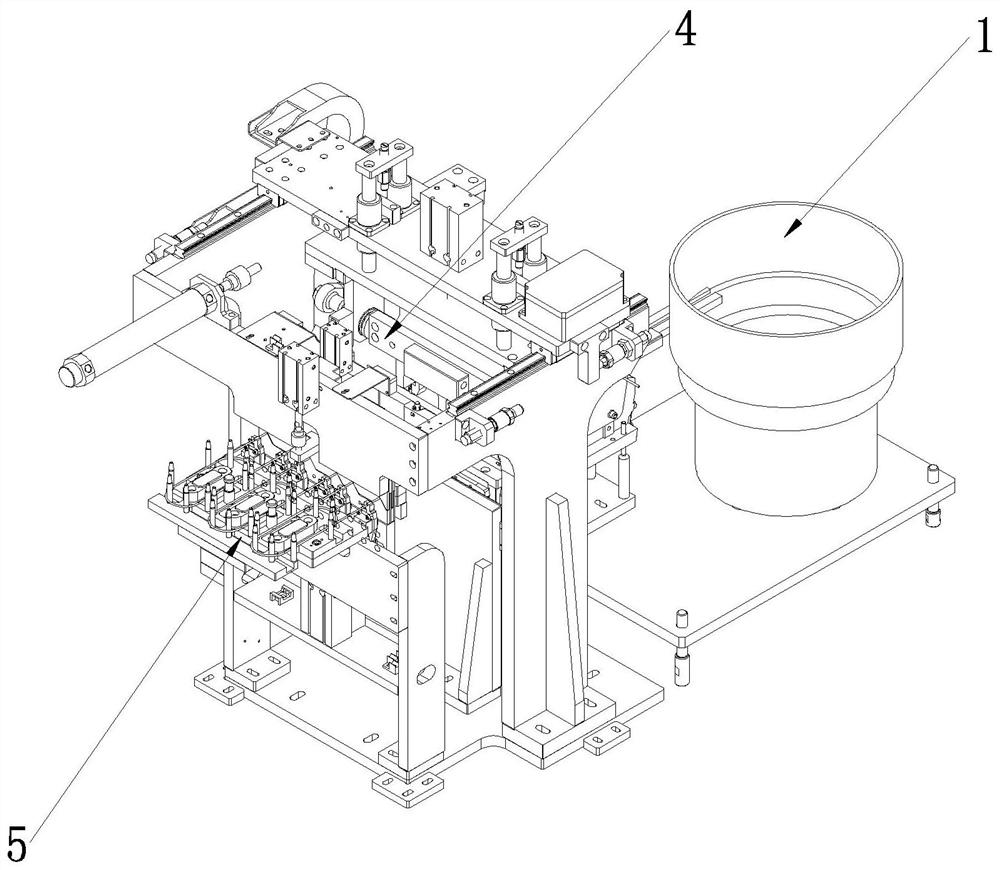

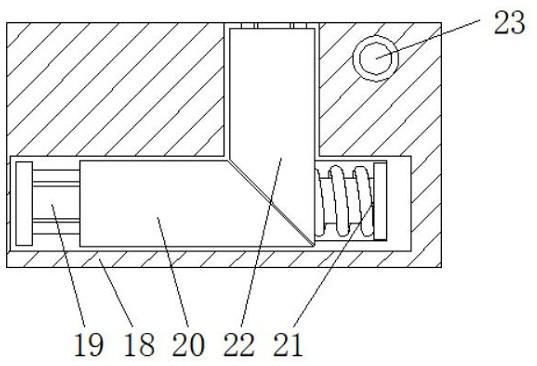

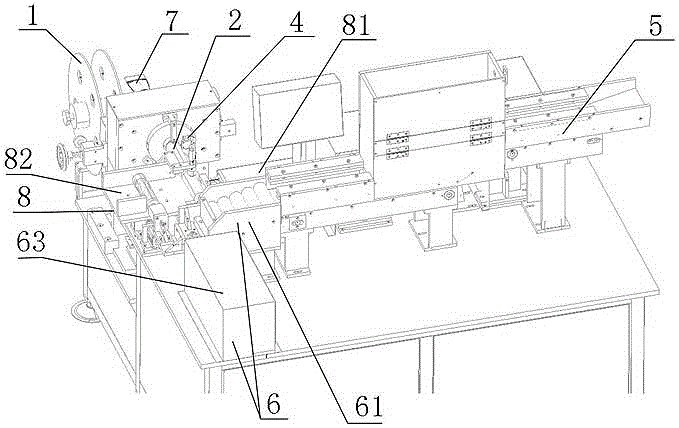

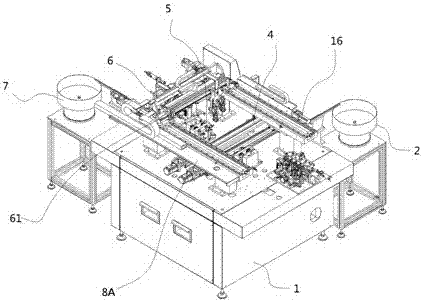

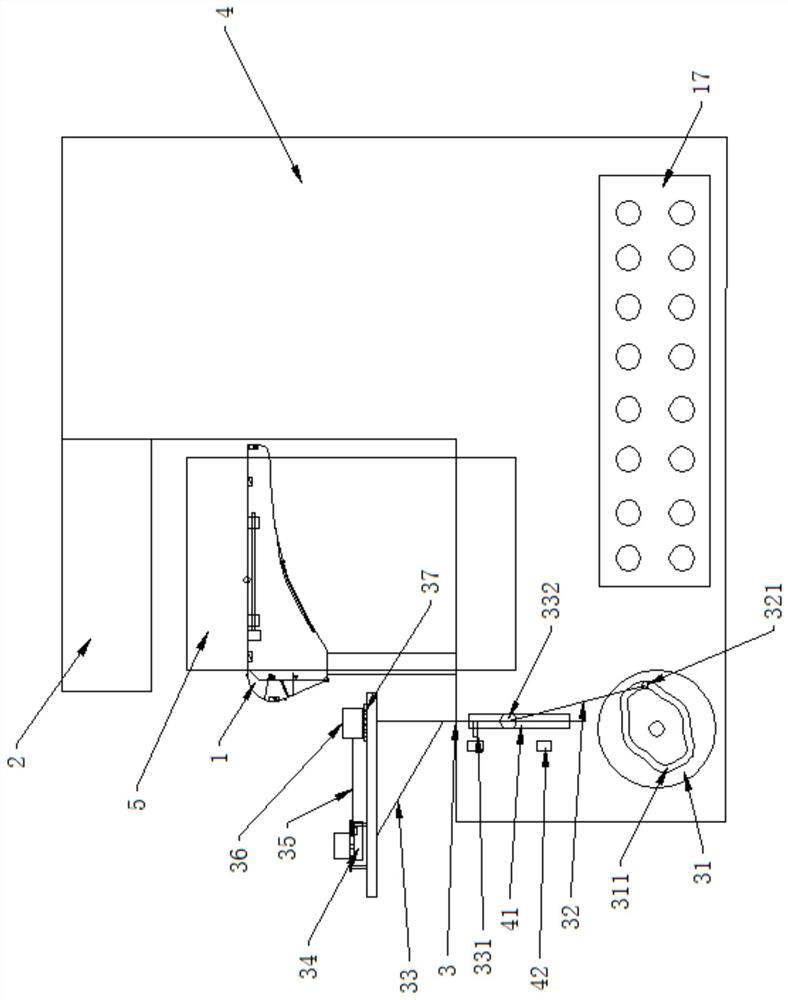

Battery sleeve machine

ActiveCN104966793AAvoid wastingScientific and reasonable structurePrimary cell manufactureAssembling battery machinesSuction forceEngineering

The invention provides a battery sleeve machine. The battery sleeve machine provided by the invention comprises a sleeve conveying and cutting mechanism and a battery cell conveying mechanism, wherein the sleeve conveying and cutting mechanism comprises a sleeve coil disc, an expanding column, a conveying wheel and a cutting device; the battery cell conveying mechanism comprises a battery cell conveying device and a battery cell ejection device; the battery cell ejection device is arranged at the tail end of the battery cell conveying device. According to the battery sleeve machine provided by the invention, the disadvantages of a vacuum suction force expansion sleeve technology in the prior art are overcome; an expanding column structure with a unique design is matched with the conveying wheel so that a battery thermal shrinkage film sleeve can be completely expanded and the waste of materials is avoided; the battery sleeve machine lays the foundation of full automatic proceeding of a battery cell sleeve procedure and has a good application prospect.

Owner:平南县富时达自动化设备有限公司

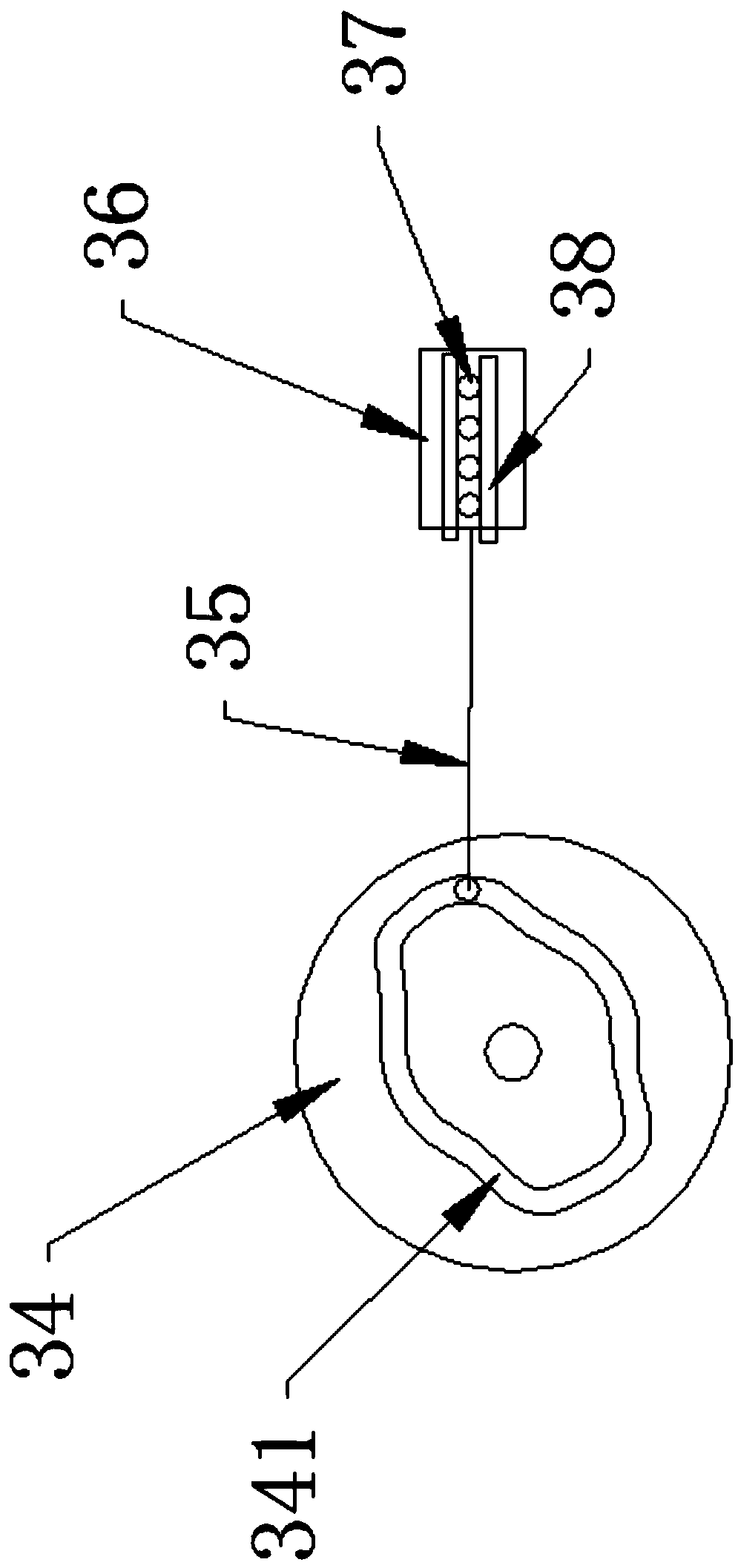

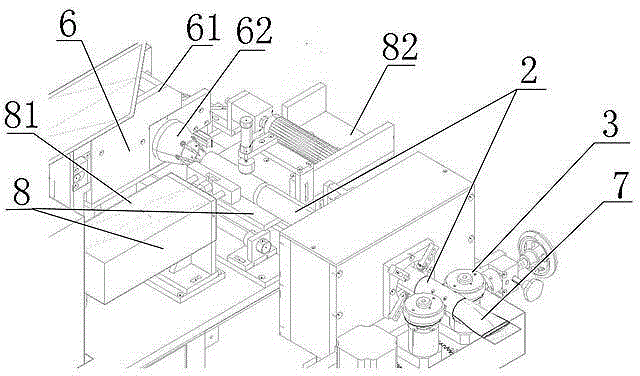

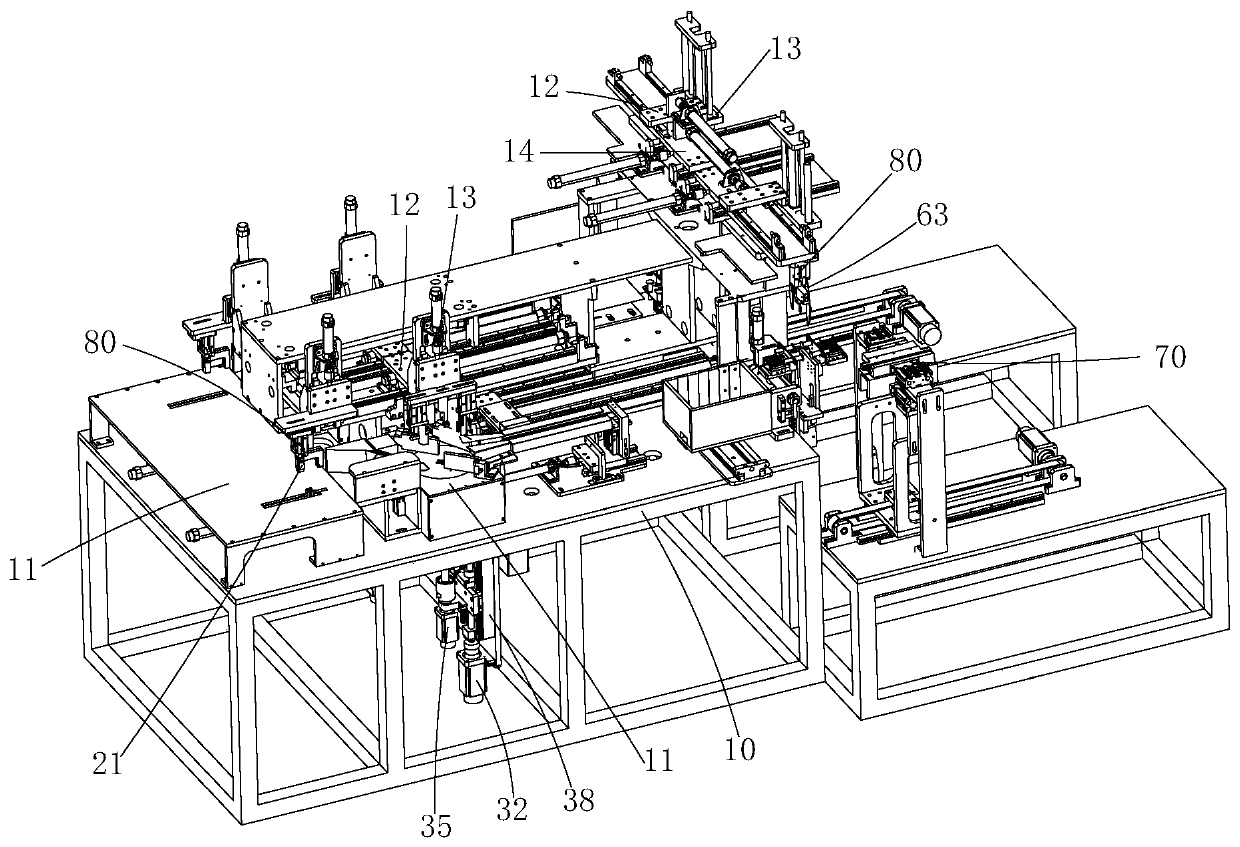

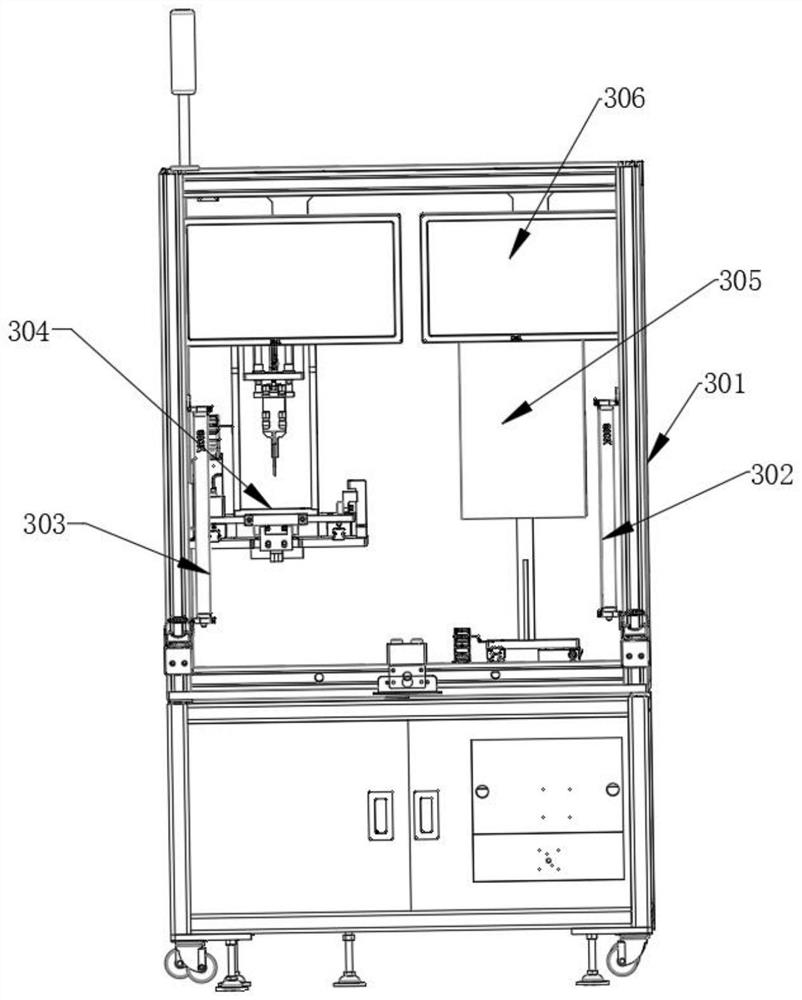

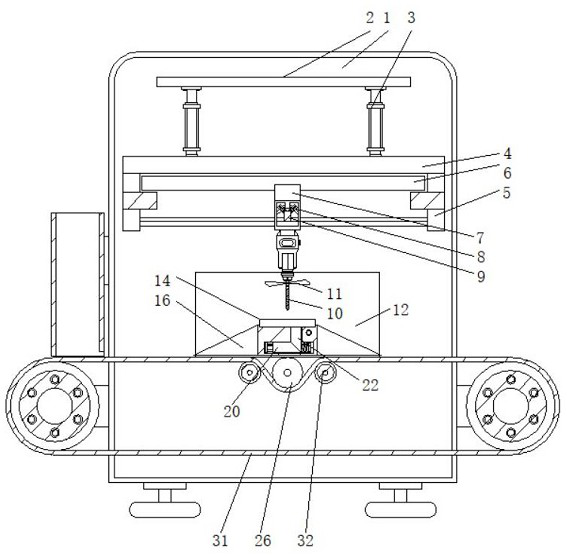

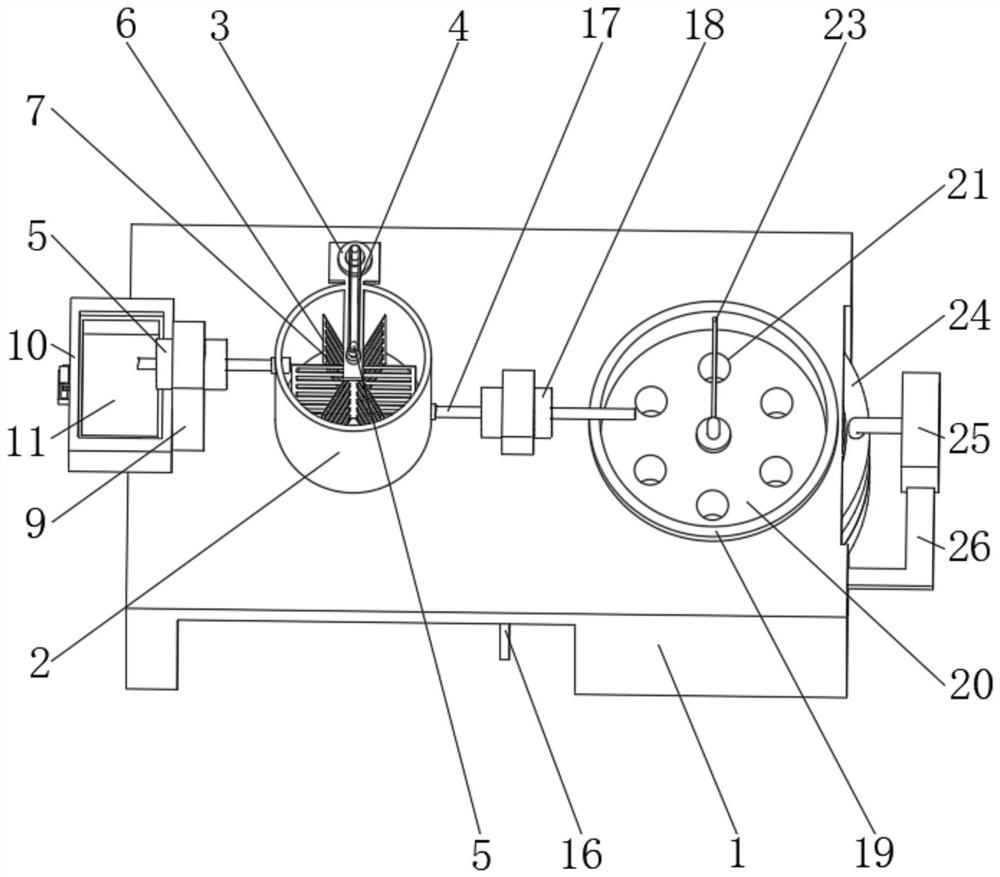

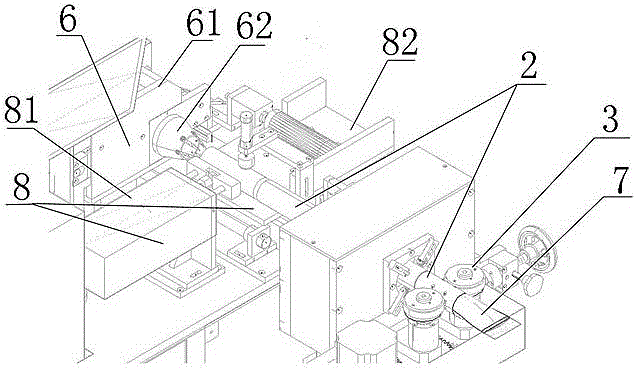

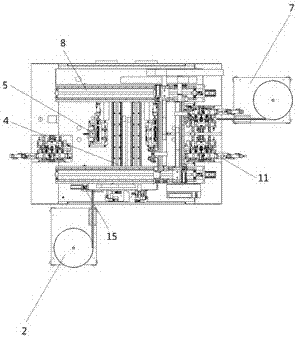

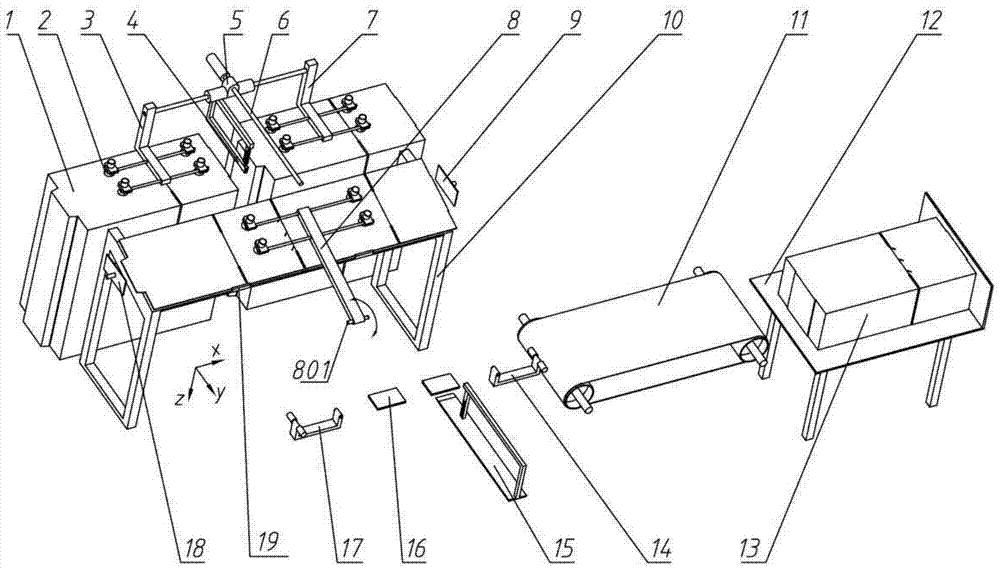

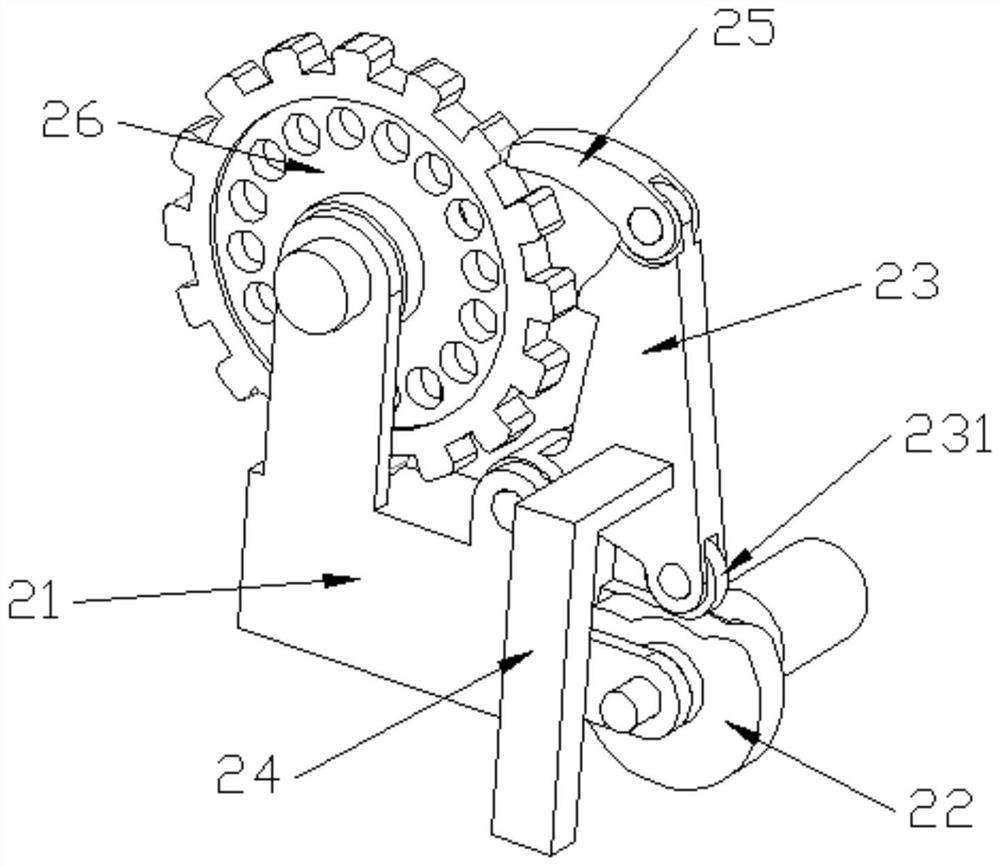

Fully-automatic magnetic core drilling machine tool

ActiveCN101992311AHigh degree of structural automationExtended service lifeMetal working apparatusBoring/drilling componentsEngineeringMachine tool

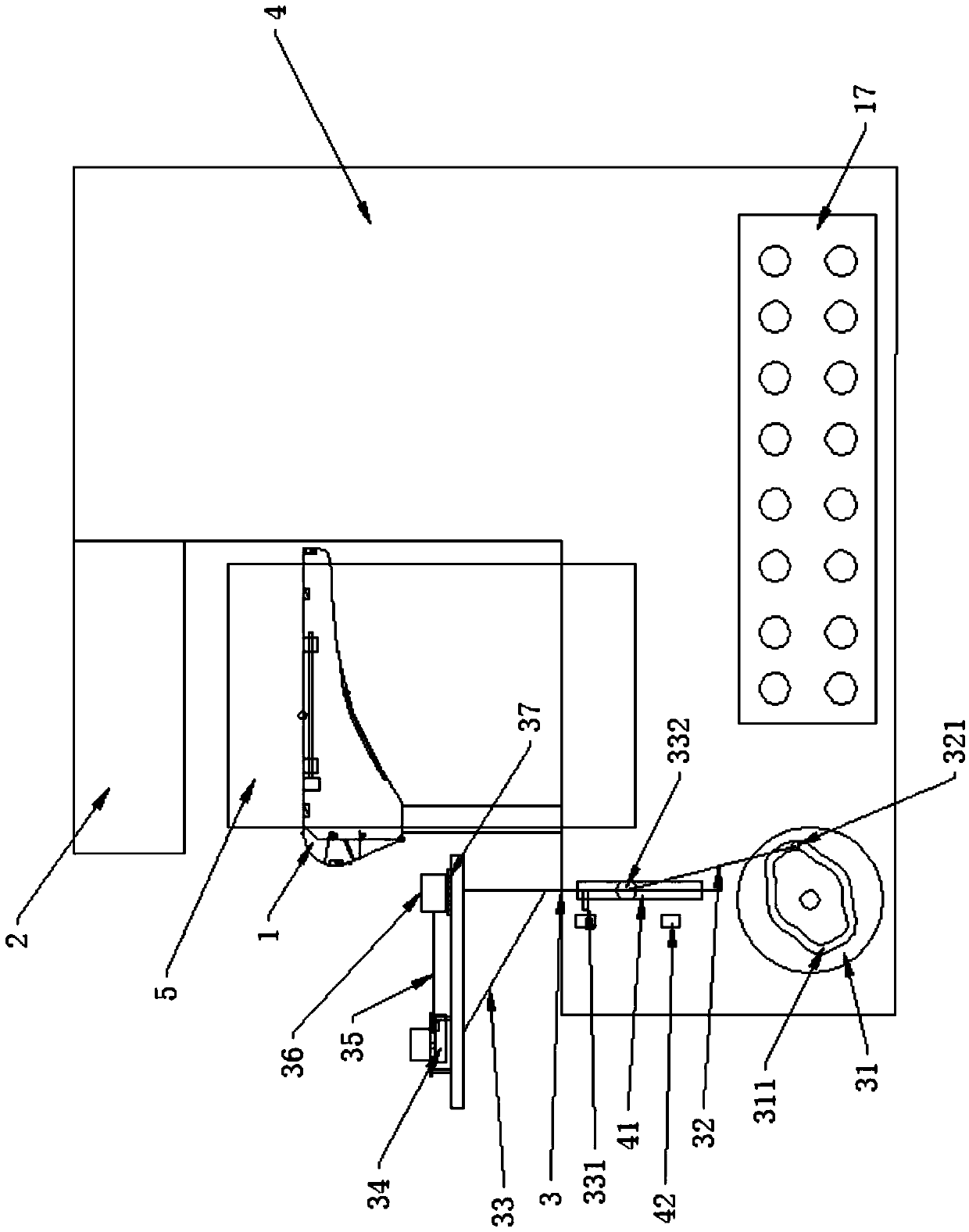

The invention discloses a fully-automatic magnetic core drilling machine tool, which comprises a discharge system (3), a feeding system (1) and a cutting feed system (2), wherein the discharge system (3) is arranged on a worktable and has a chuck (33) for holding a material; the feeding system (1) is arranged on the worktable and positioned on the same side as the discharge system (3), has a feeding block (13) for delivering the material to the chuck (33); and the cutting feed system (2) is arranged opposite to the discharge system and has a cutter (26) aimed at the chuck (33), and the cutter(26) can advance and retract on the material held by the chuck (33). The machine tool can realize the fully-automatic drilling of a magnetic core. The drilling function of the equipment is reliable and the automation of the equipment is high.

Owner:JIANGXI SENYANG TECH +1

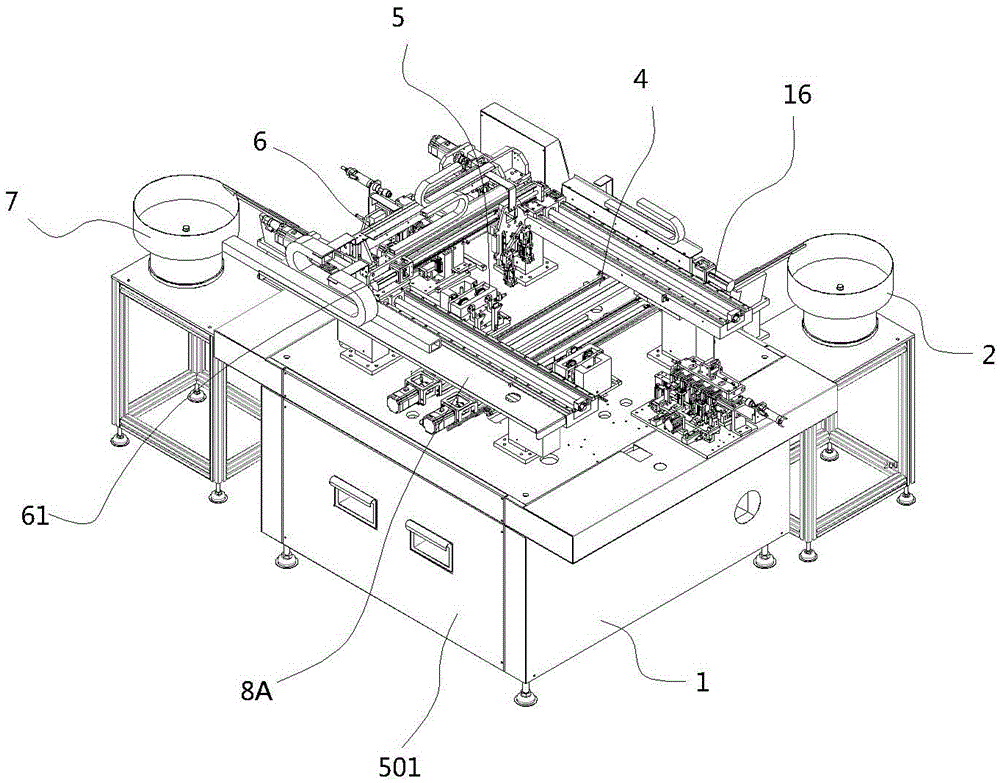

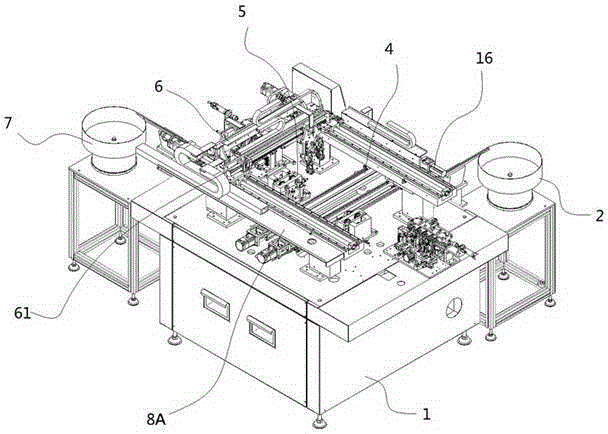

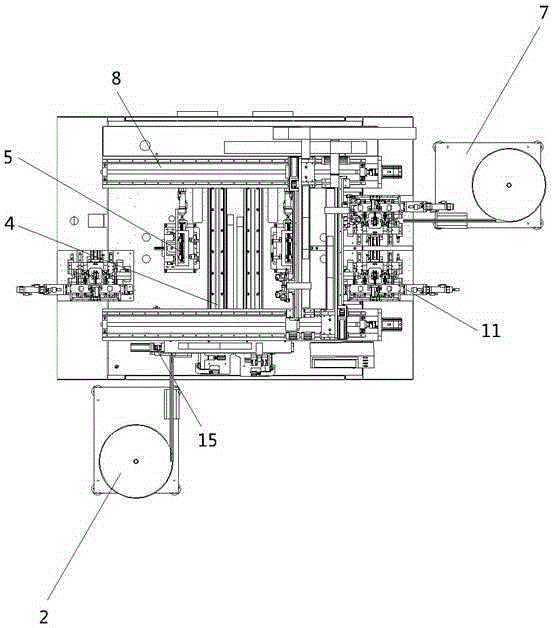

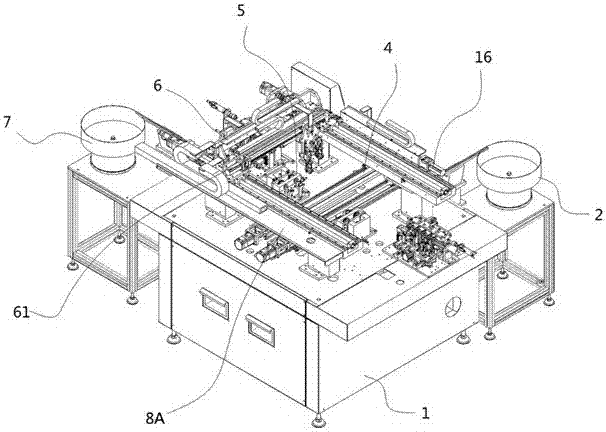

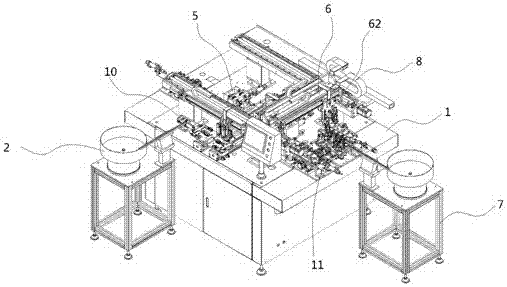

LED lamp bead assembling device

InactiveCN105149941AHigh degree of structural automationHigh speedAssembly machinesEngineeringLED lamp

The invention discloses an LED lamp bead assembling device. The LED lamp bead assembling device comprises a working table, and is characterized in that a first transverse rail and a second transverse rail are arranged on the two sides of the working table respectively, a lamp bead feed device is installed on the first transverse rail and the second transverse rail, a lamp holder feed device is vertically installed below the first transverse rail and the second transverse rail, and assembling device bodies are arranged on the two sides of the lamp holder feed device; a lamp bead taking device is installed on one side of the working table, a lamp holder taking device is installed on the other side of the working table, and a lamp holder assembling device is installed on the second transverse rail. The LED lamp bead assembling device has the advantages of being high in structure automation degree, capable of automatically conveying diode lamp beads into lamp holders, high in speed, capable of saving labor and suitable for being used and popularized.

Owner:中山市登皇灯饰有限公司

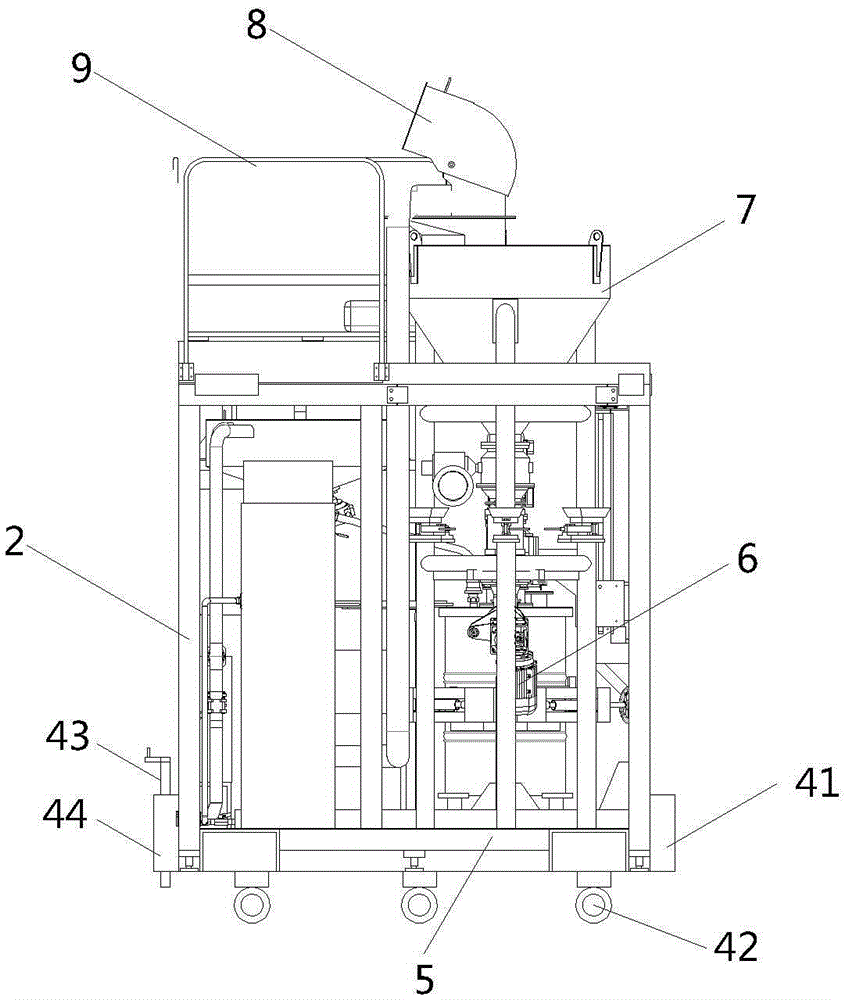

Infusion apparatus packaging machine

PendingCN110466840AReduce labor intensityHigh degree of structural automationPackaging by pressurising/gasifyingIndividual articlesEngineeringPackaging machine

The invention discloses an infusion apparatus packaging machine. The infusion apparatus packaging machine is characterized in that the infusion apparatus packaging machine comprises a machine frame, aline pipe grabbing device, a line pipe winding device, a line pipe pushing device, an automatic bag feeding device, a transposition bag supporting device and a packaging device; the line pipe grabbing device is used for grabbing the positioning end of an infusion apparatus and moving and positioning the infusion apparatus to the line pipe winding device through a mechanical gripper; the line pipewinding device is used for conducting winding on the infusion apparatus; the line pipe pushing device is used for clamping the infusion apparatus and pushing the infusion apparatus and a packaging bag onto the transposition bag supporting device; the automatic bag feeding device comprises a suction cup assembly for sucking the packaging bag out from a bag storage box and a pushing assembly for pushing the packaging bag onto a bagging route; the transposition supporting device makes the packaging bag rotate through a rotation shaft and a rotation cylinder after fixing the packaging bag, a mechanical bag supporting gripper on the transposition supporting device is used for supporting an opening of the packaging bag, and the transposition bag supporting device is provided with a movement device for moving the packaging bag onto the packaging device and an air extracting device for conducting vacuumizing on the inner portion of the packaging bag; and the packaging device is used for packaging the bag opening of the packaging bag. The infusion apparatus packaging machine has the beneficial effect that the packaging efficiency can be improved.

Owner:台州贝恩自动化设备科技有限公司

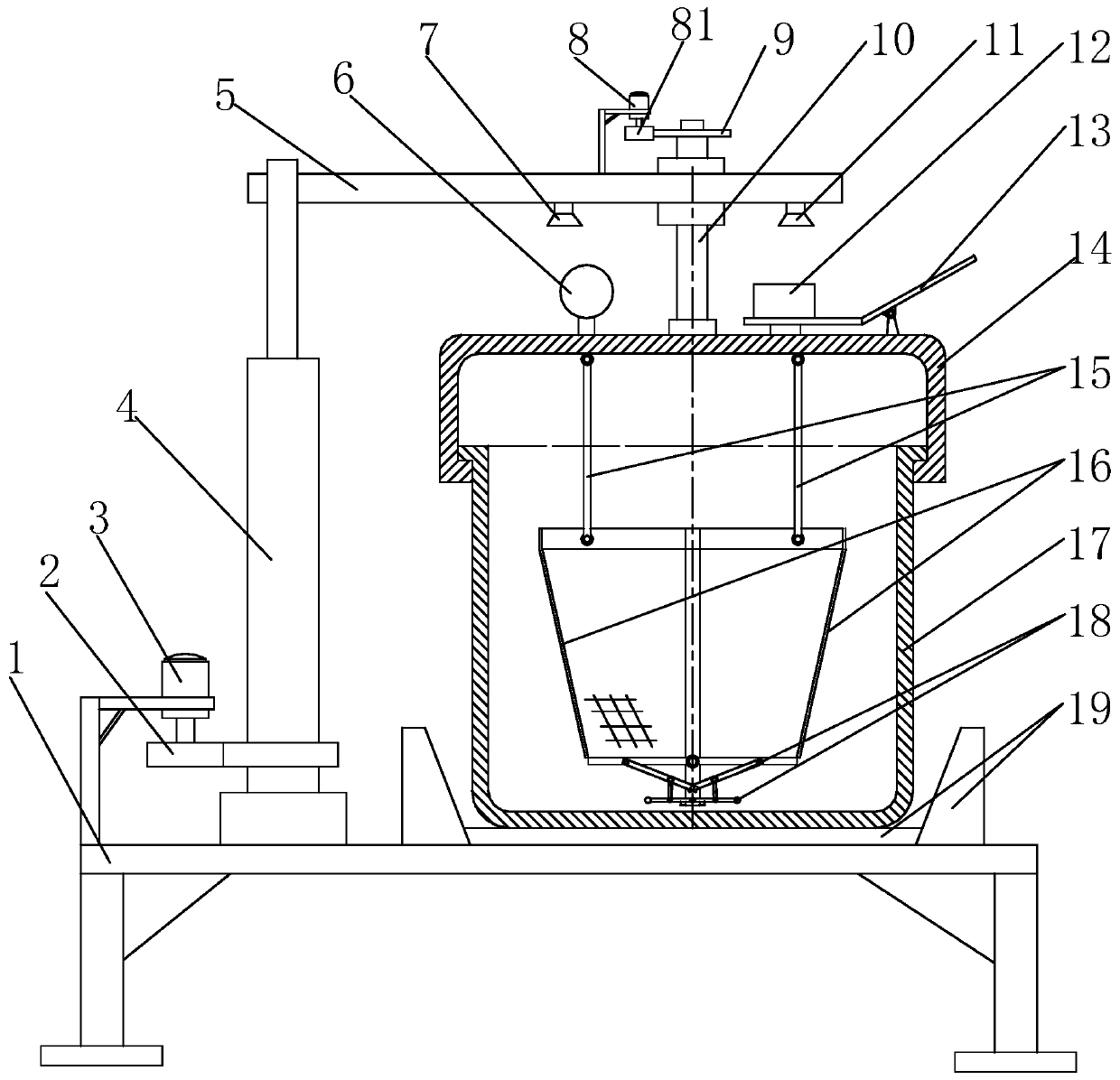

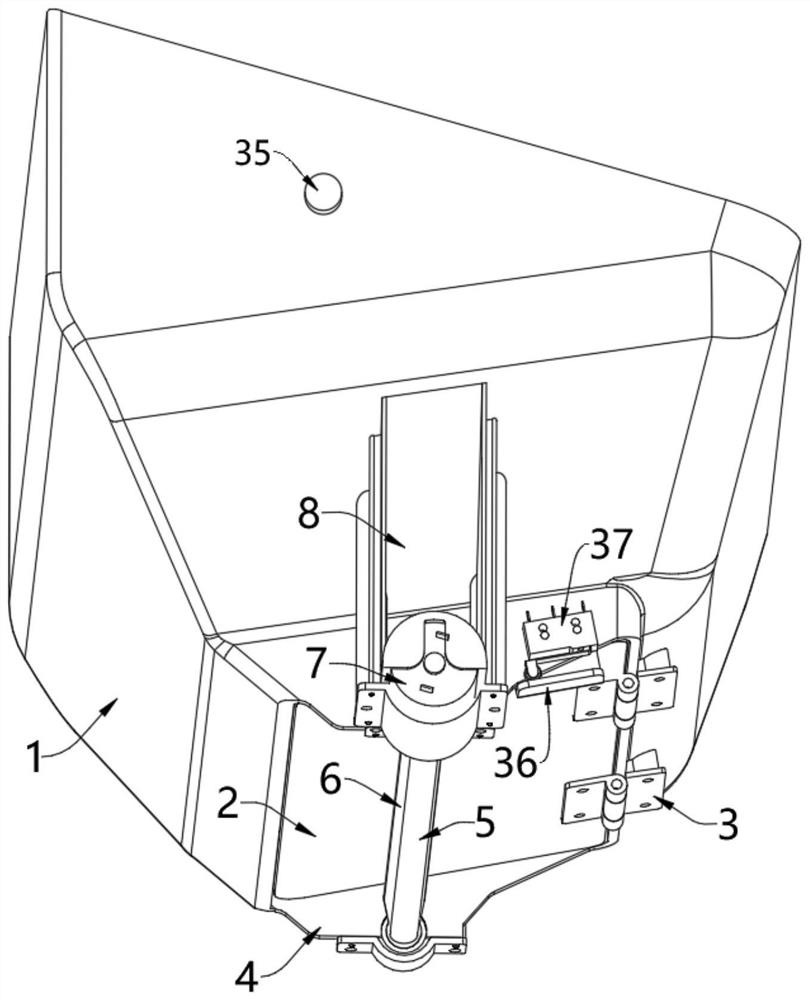

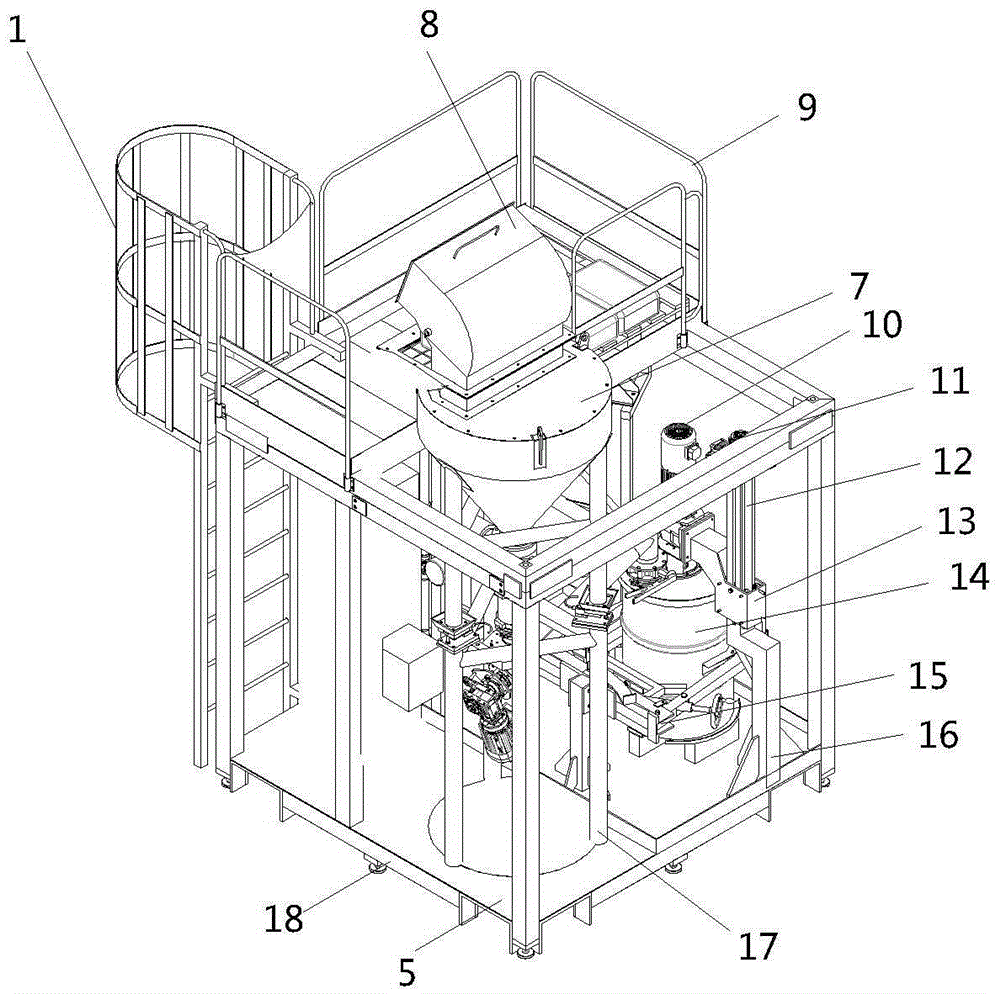

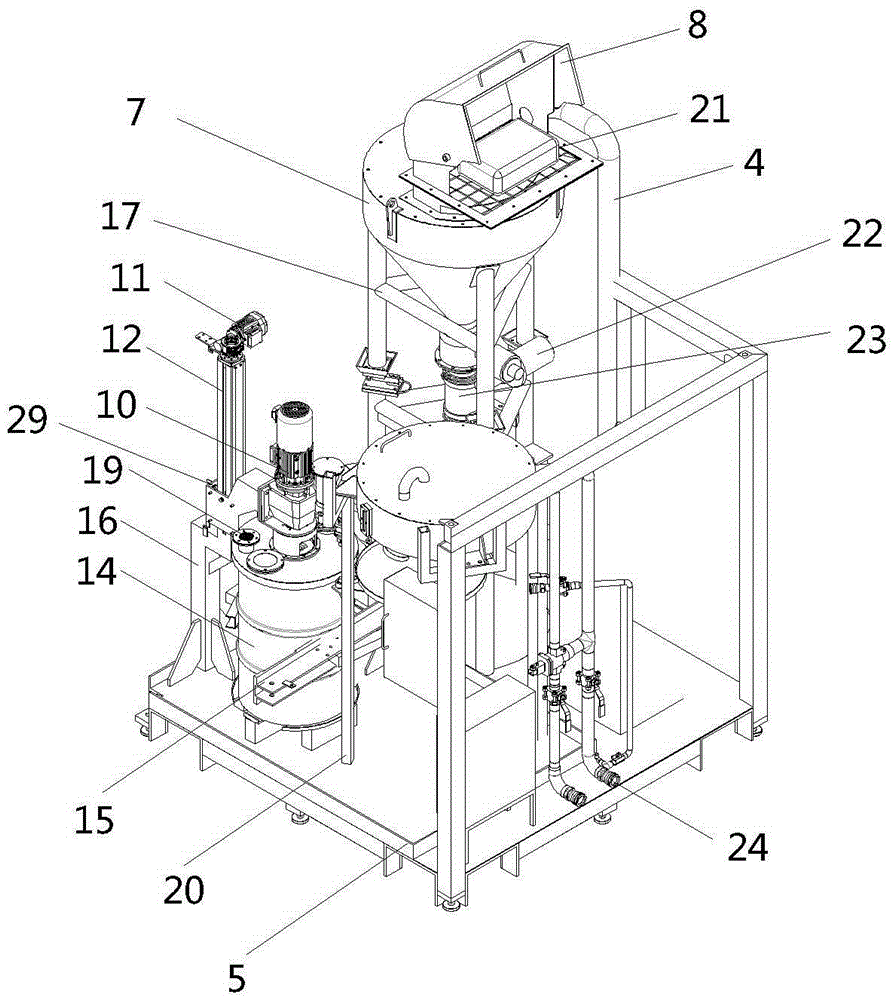

Continuous high-pressure cooking device used for seed nut food

PendingCN109566964AGood cooking effectImprove cooking efficiencyFood scienceFood processingSnack foodEngineering

The invention discloses a continuous high-pressure cooking device used for seed nut food. A top cover is rotatably connected with the top of a pot in a clamped mode, top cover lifting air cylinders are connected with the outer portion of the pot, a top cover fixing frame with a rotating shaft is connected with the top cover lifting air cylinders, a driven gear A is installed at the top end of therotating shaft, a rotating power mechanism is installed on the top cover fixing frame, a driving gear A is installed on a power output shaft of the rotating power mechanism, and the bottom end of therotating shaft is fixed to the top of the top cover; a walking motor is fixedly installed on the top of a walking fixing frame, a driving gear B is installed on a power output shaft of the walking motor, a driven gear B is fixed to the end portion of one end of a walking axle, a walking wheel is fixed to the end portion of the other end of the walking axle, the walking wheel is installed on a guiding rail in a walking matched suspended mode, and a netted material bucket is arranged in an inner cavity of the pot. By means of the continuous high-pressure cooking device used for the seed nut food, multi-station continuous cooking treatment can be conducted on the seed nut snack food, and the problems that kernels can hardly be tasty, shells are hard to crack, energy consumption is high, baking time is long, the efficiency is low, and the like are solved.

Owner:WUHAN XUDONG FOOD +1

Lamp bead taking device for LED lamps

ActiveCN105196020AHigh degree of structural automationHigh speedMetal working apparatusLED lampAutomation

The invention discloses a lamp bead taking device which comprises a track base, a clamping frame driven by a motor I is mounted on the track base, a toothed clamp port I and a toothed clamp port II for clamping workpieces input by a vibration feed tray are formed in a feeding end of the clamping frame, a clamping groove is formed in the discharge end of the clamping frame, and a pulling piece driven by a cylinder I to move back and forth in the clamping groove is mounted in the clamping groove; a fixture block I and a fixture block II are mounted between the clamping groove and the toothed clamp port II, the fixture block II is fixed on a support, and the fixture block I is driven by a cylinder II mounted on the support to realize opening and closing with the fixture block II. The lamp bead taking device is high in structural automation degree and high in speed, saves labor force and is applicable to popularization and usage.

Owner:江门市优光光电科技有限公司

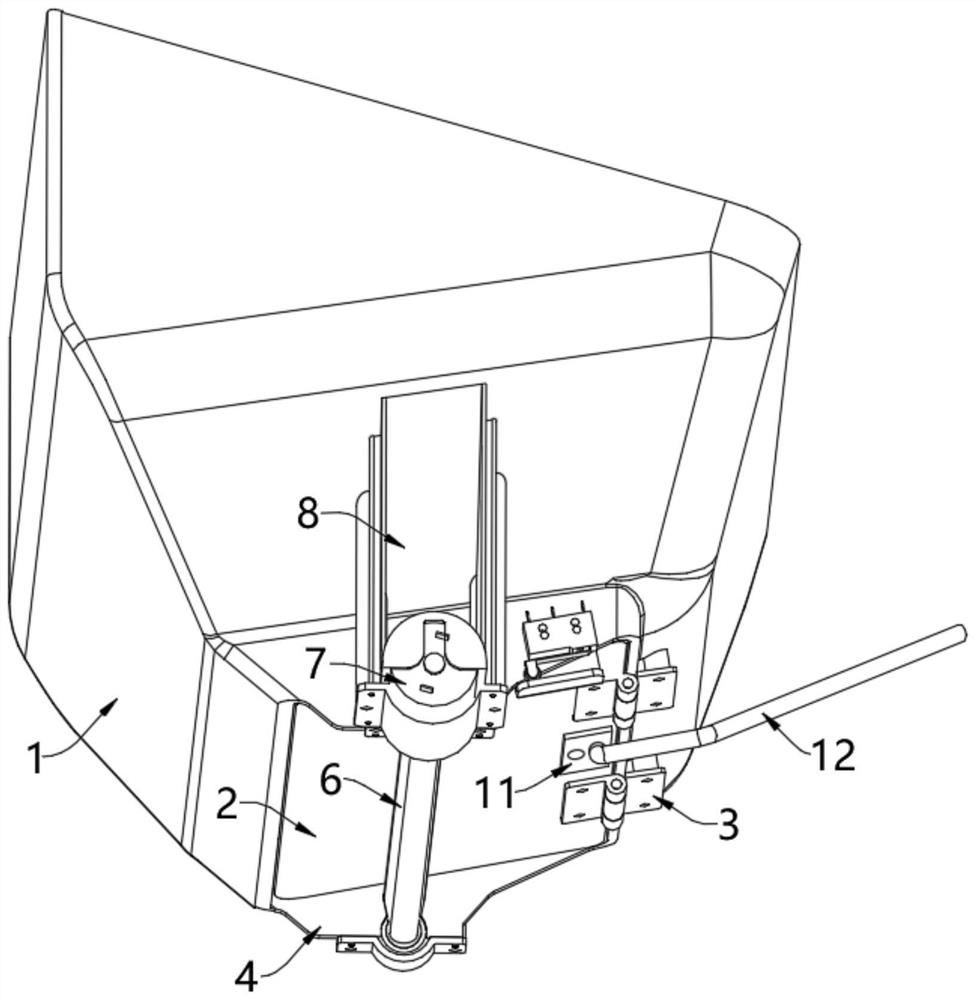

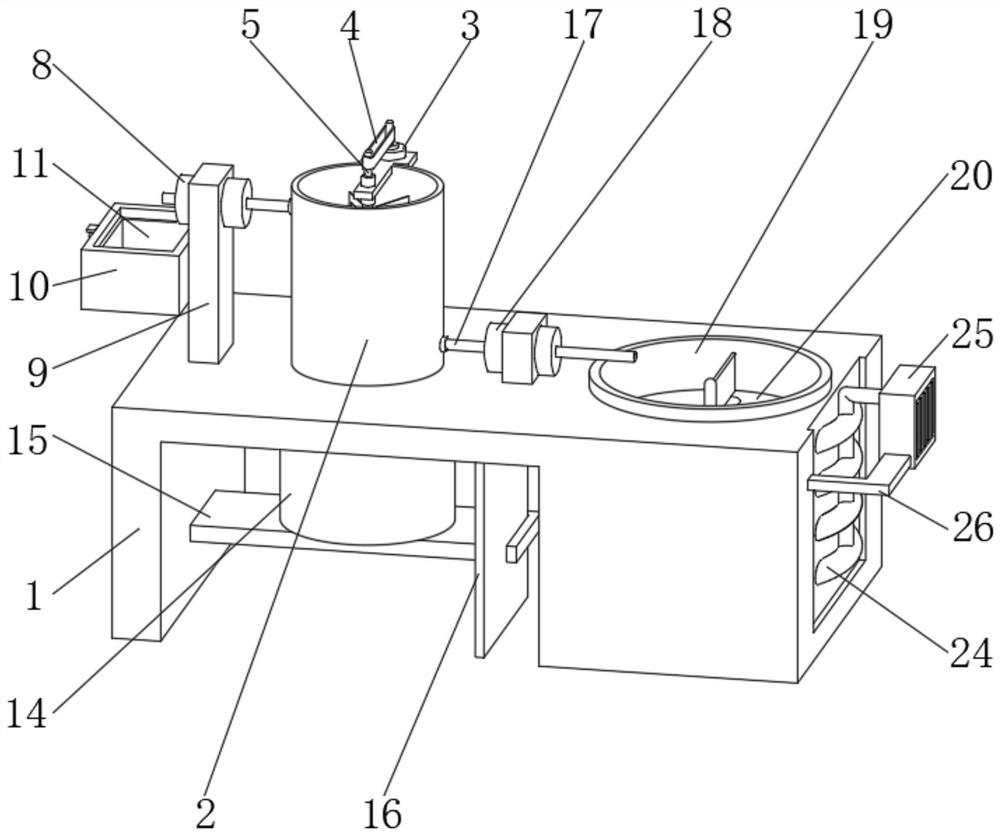

Gap-type high-pressure boiling device for seed nut food

The invention discloses a gap-type high-pressure boiling device for seed nut food. The gap-type high-pressure boiling device for seed nut food comprise a rack, a rotary power mechanism A, a top lift cylinder, a lifting arm, a rotary power mechanism B, a top cover rotating shaft, a top cover, a boiling pot body and a mesh material barrel, the top of the rack is mounted with the rotating power mechanism A through a bracket, a driving gear A is mounted on the rotating power mechanism A, and a driven gear A is mounted on the top lift cylinder; the lifting arm is fixed on the top of a lifting rod of the top lift cylinder, the rotary power mechanism B is mounted on the lifting arm, the driving gear A is mounted on the rotary power mechanism B, the top cover rotating shaft is rotatably mounted onthe lifting arm, and a driven gear B is mounted on the top end of the top cover rotating shaft, the boiling pot body is arranged on an electric heating seat, and the mesh material barrel is arrangedinside the boiling pot body. The device carries out high-pressure boiling treatment on the seed nut snack food, and solves the problems that the seed kernel is difficult to taste, the shell is difficult to remove, the energy consumption is high, the baking time is long, and the efficiency is low.

Owner:WUHAN XUDONG FOOD +1

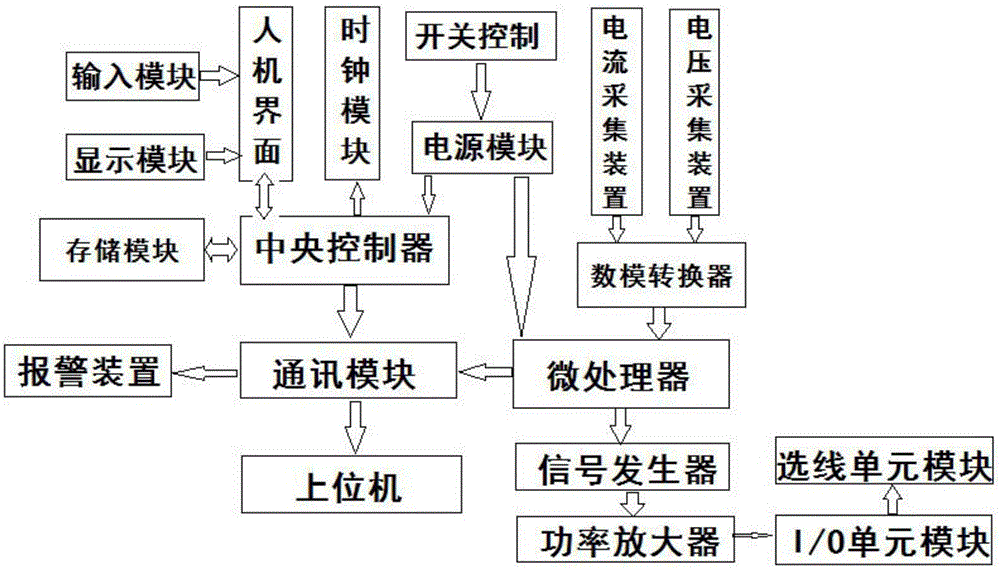

Measurement and control analysis system based on low-current grounding line selection device

InactiveCN106291231AReduce investmentThe test result is accurateFault location by conductor typesHuman–machine interfaceComputer module

The invention discloses a measurement and control analysis system based on a low-current grounding line selection device. The system comprises an input module, a display module, a man-machine interface, a current collector, a voltage collector, a central controller, a microprocessor and a line selection unit module, single-wire grounding fault information is collected by the current collector and the voltage collector, processed by a digital to analog converter, and transmitted to the microprocessor, and the microprocessor identifies the fault information and sends the processed fault information to a communication module and a signal generator. According to the invention, onsite condition can be detected in real time, a more real detection result is provided, the automatic degree of the whole system structure is higher, the labor cost is reduced to certain extent, operation is rapid and accurate, selection errors or missing selection are avoided, the central controller is combined with the microprocessor during use, man-machine interaction, communication management and line selection tasks are distinguished clearly, and convenience is provided for post management and operation.

Owner:安徽亚辉电气自动化有限公司

Double-plate type automatic box nailing machine for color box

The invention relates to a double-plate type automatic box nailing machine for a color box. The double-plate type automatic box nailing machine comprises a movable assembly which can slip on a paper feeding guide rod, wherein a fixed nailing head is further arranged below the paper feeding guide rod; the two ends of the movable assembly are respectively connected with a left suction nozzle supporting base and a right suction nozzle supporting base; a plurality of suction nozzles for adsorbing corrugated paper boards are respectively distributed on the left suction nozzle supporting base and the right suction nozzle supporting base; in a slip direction of the movable assembly, one side of the paper feeding guide rod is further provided with a plate placing table for bearing spliced corrugated paper boards; one side of the plate placing table is provided with a paper turnover swing rod capable of turning over; a swing end of the paper turnover swing rod is symmetrically provided with a plurality of suction nozzles; a pair of conveying platforms is further arranged in a turnover direction of the paper turnover swing rod; and the two ends of the conveying platform are provided with a left folding arm and a right folding arm. The double-plate type automatic box nailing machine for the color box is high in degree of automation of an integral structure, capable of releasing original labor personnel from complex double-plate type nailing operation and time-saving and labor-saving, thereby not only saving investment cost of manpower resource of enterprises, but also improving production efficiency.

Owner:泰州市华驰不锈钢制品有限公司

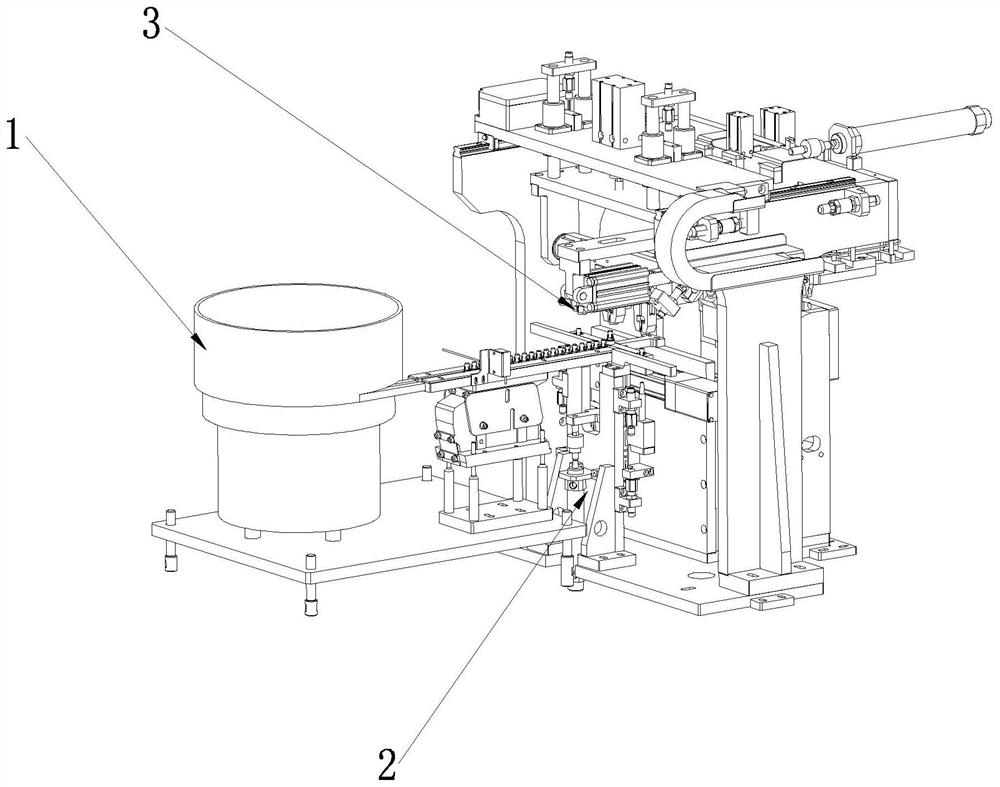

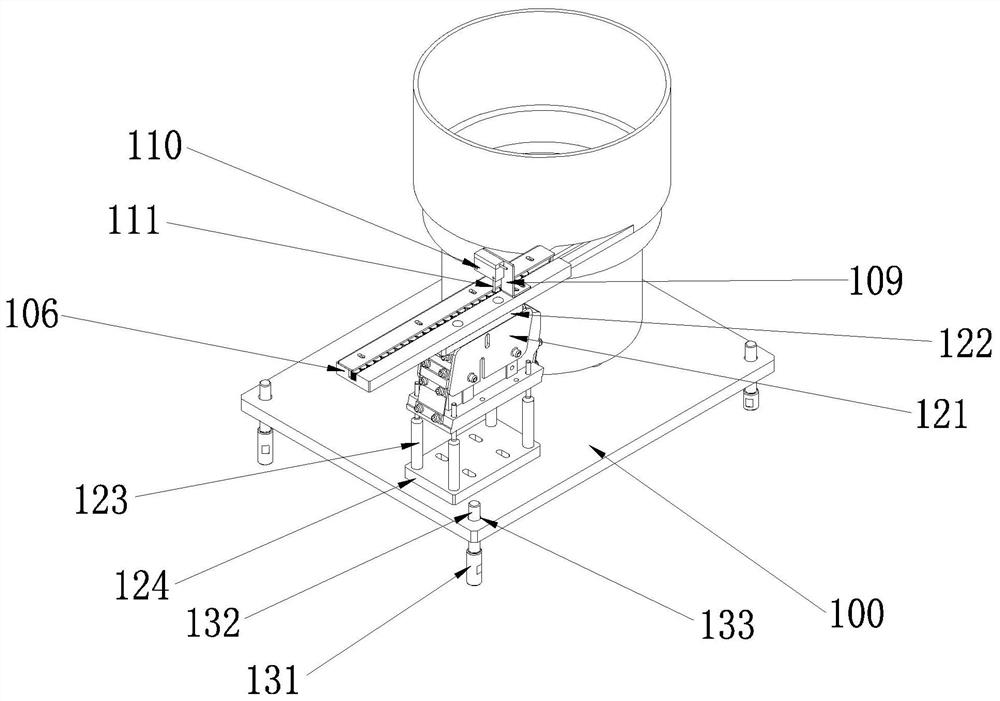

Luer shield feeding assembly of infusion apparatus

ActiveCN114044318ASimple structureIngenious designJigging conveyorsConveyor partsPhysical medicine and rehabilitationInfusion set

The invention relates to a Luer shield feeding assembly of an infusion apparatus. The Luer shield feeding assembly comprises a feeding mechanism and a pushing mechanism arranged opposite to the feeding mechanism, wherein a clamping mechanism is mounted on the pushing mechanism, and a turnover mechanism is mounted on the clamping mechanism; the clamping mechanism comprises a bottom plate and supporting plates fixedly arranged on the two sides of the bottom plate, sliding rails are fixedly arranged on the top parts of the two supporting plates, a translation plate is installed on the supporting plates, sliding blocks are installed at the bottom parts of the two sides of the translation plate, and the sliding blocks are slidably connected to the sliding rails; an upper alignment fixing plate is fixedly arranged on one side of the two supporting plates, and a clamping driving mechanism is installed on the upper alignment fixing plate; a clamping lifting mechanism for driving a clamping device to move up and down is mounted on the translation plate; and the clamping lifting mechanism drives the clamping device to move up and down. The Luer shield feeding assembly is simple in structure and ingenious in design, the clamping and lifting mechanism is arranged and used for assembling the turned Luer shield and an infusion apparatus catheter, and the requirement for rapid machining can be met.

Owner:ZHEJIANG MEDICAL COLLEGE

Automatic forming device for composite civil engineering drainage network

ActiveCN110948891AHigh degree of automationImprove finished product qualityDomestic netsAdhesiveStructural engineering

The invention relates to an automatic forming device for a composite civil engineering drainage network, which comprises: a drainage network loading mechanism including a rack and a pushing assembly arranged on the rack, wherein a drainage network is driven by the pushing assembly to be conveyed backwards; a double-sided coating mechanism including a first coating mechanism and a second coating mechanism each of which comprises a brushing component, a clamping component and a straightening component, wherein the brushing component, the clamping component and the straightening component are successively arranged along the pushing direction of the pushing assembly, the clamping component and the drainage network are synchronously conveyed under the driving of a driving component, and the straightening component is used for straightening coatings on the clamping component and coating the drainage network with the coatings. An upper coating is attached to the upper layer of the drainage network by the first coating mechanism and an lower coating is attached to the lower layer of the drainage network by the second coating mechanism, so that a composite civil engineering drainage networkis formed and is conveyed backwards and output along with the pushing assembly. The automatic forming device solves the technical problems that the work of manually bonding the upper coating and thelower coating to the drainage network through an adhesive is complicated and poor in precision, and causes an increase in the number of defective products.

Owner:安徽华汇建材有限公司

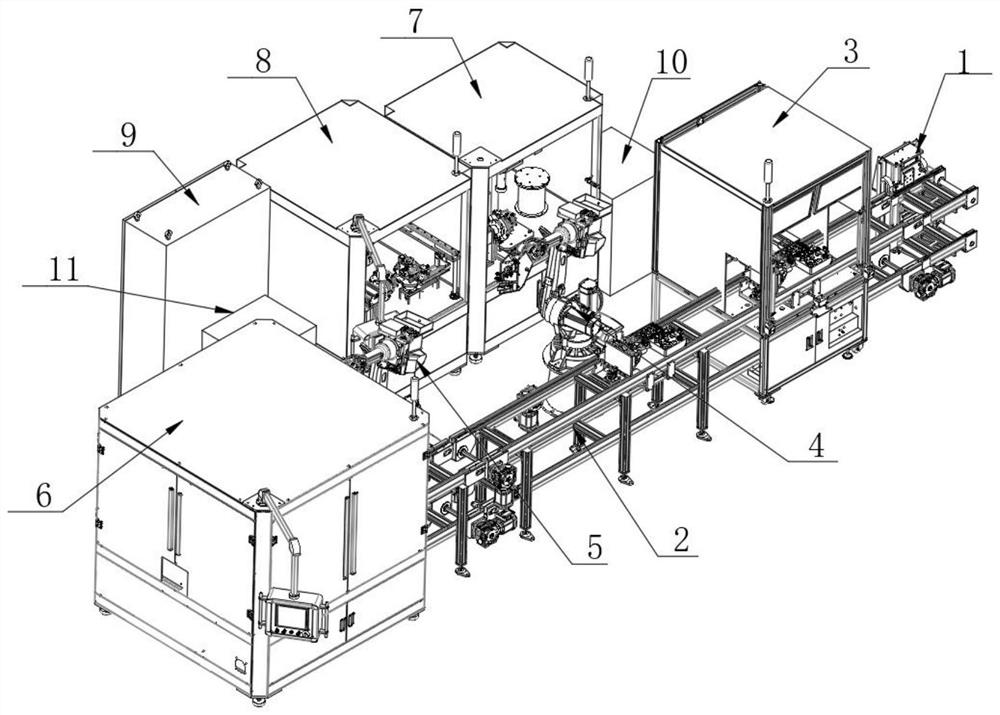

Automatic engine assembling production line

ActiveCN113172414AHigh degree of automationImprove processing efficiencyAssembly machinesMetal working apparatusRobot controlEngineering

The invention discloses an automatic engine assembling production line. The automatic engine assembling production line comprises a stroke dislocation lifting mechanism, wherein the stroke dislocation lifting mechanism is connected to the tail end of the right side of a product conveying device, the product conveying device penetrates through a visual detection mechanism and a wave spring assembling mechanism, and a first assembling carrying robot is arranged at the left side of the visual detection mechanism; a first assembly carrying robot control cabinet is arranged at the rear side of the visual detection mechanism, a second assembly carrying robot is arranged at the left side of the first assembly carrying robot, a bearing press-in section mechanism is arranged at the left side of the first assembly carrying robot control cabinet, and a locking detection mechanism is arranged at the left side of the bearing press-in section mechanism; and a master control box and a second assembly carrying robot control cabinet are arranged at the left side of the locking detection mechanism. According to the automatic engine assembling production line, the whole structure is high in automation degree, high-intensity work of too many workers is not needed, and only few workers are needed for real-time monitoring.

Owner:西交思创智能科技(河北雄安)有限公司

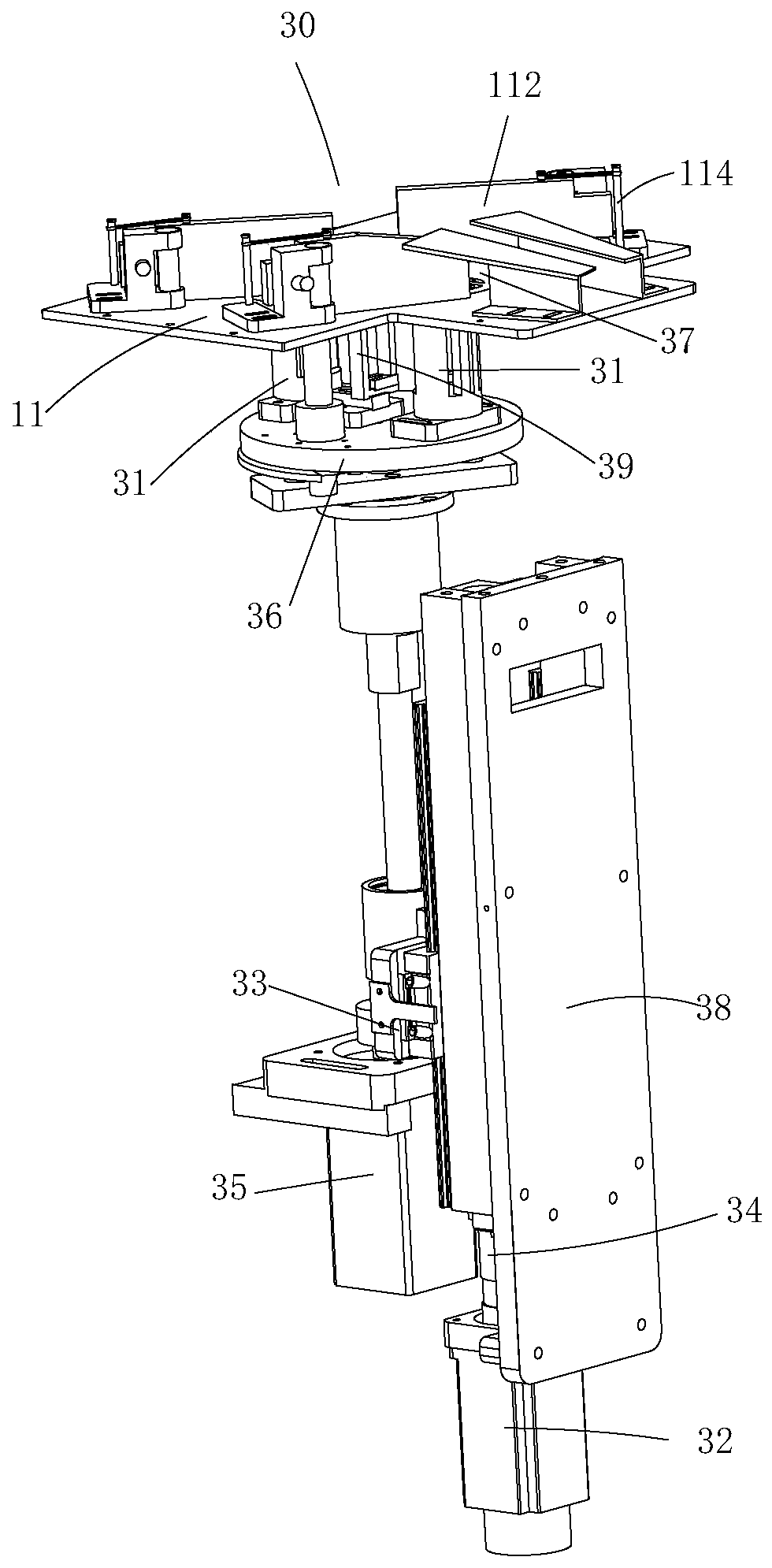

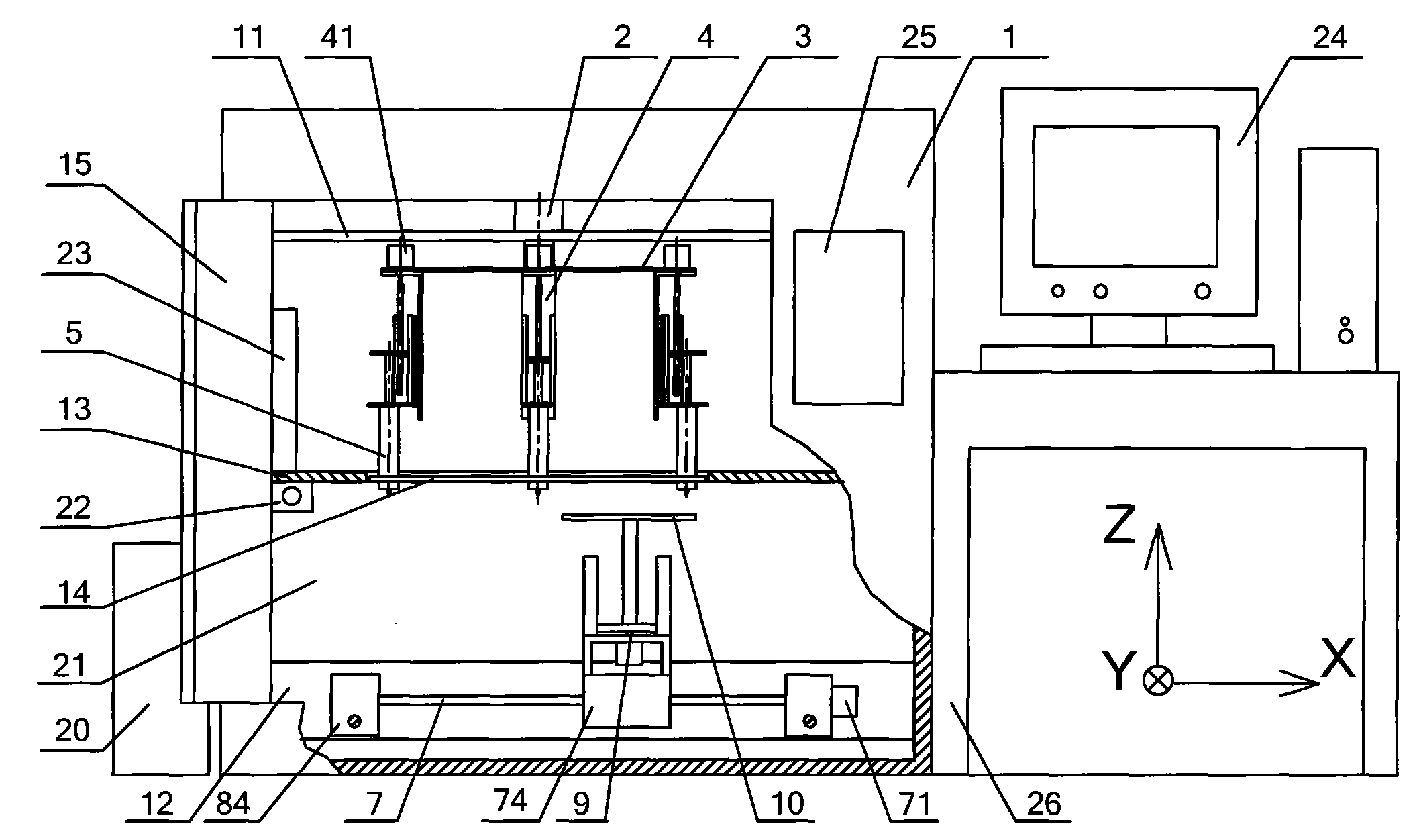

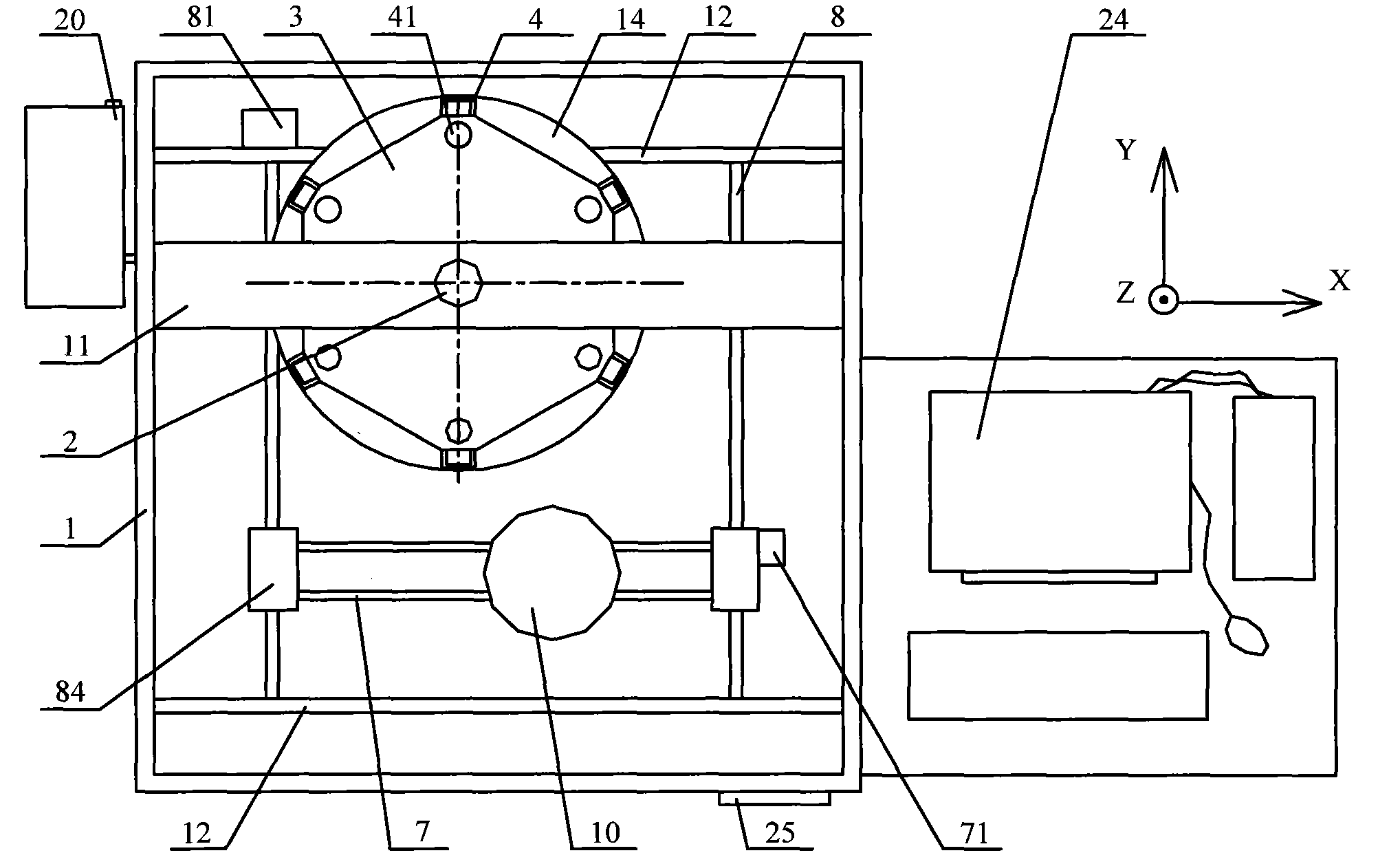

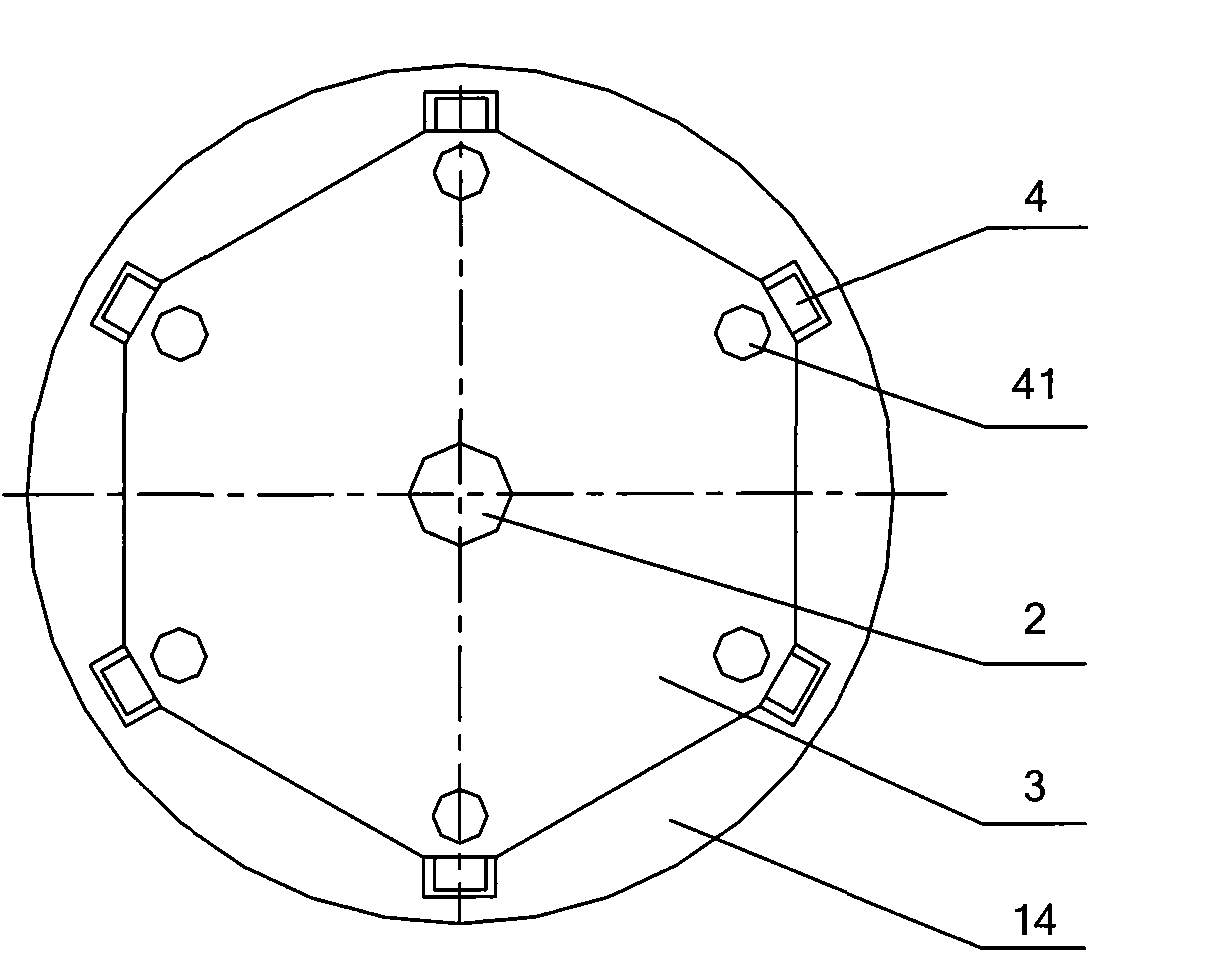

Rotating disc type multi-nozzle three-dimensional controlled forming system for complex organ precursor

InactiveCN101692987BRealize free switchingHigh degree of automationStentsProsthesisData processing systemLow temperature deposition

The invention relates to a rotating disc type multi-nozzle three-dimensional controlled forming system for a complex organ precursor, belonging to the technical field of tissue engineering. The system mainly comprises a box body, a bracket, a rotating disc type multi-nozzle jetting device, a forming chamber, a forming table, a three-dimensional moving mechanism, a refrigerating device, a control system and a data processing system, wherein the rotating disc type multi-nozzle jetting device comprises a rotating disc and nozzle assemblies, and the nozzle assemblies are uniformly and circumferentially distributed on the rotating disc. When a precursor of a complex organ, such as liver, heart, kidney and the like, is formed, by utilizing a low-temperature deposition manufacturing process theory, the forming chamber is firstly cooled, the motions of the three-dimensional moving mechanism and the rotation and the material jetting of the rotating disc type multi-nozzle jetting device are controlled by the control system, and the forming table does three-dimensional motions; different nozzle assemblies can be changed by the rotation of the rotating disc so as to extrude to form and accumulate matrix materials with different tissue scaffolds and cells on the forming table. The device adopts a rotating disc type multi-nozzle interactive forming mode and can realize the precise forming of various non-homogeneous materials with complex three-dimensional structures.

Owner:TSINGHUA UNIV

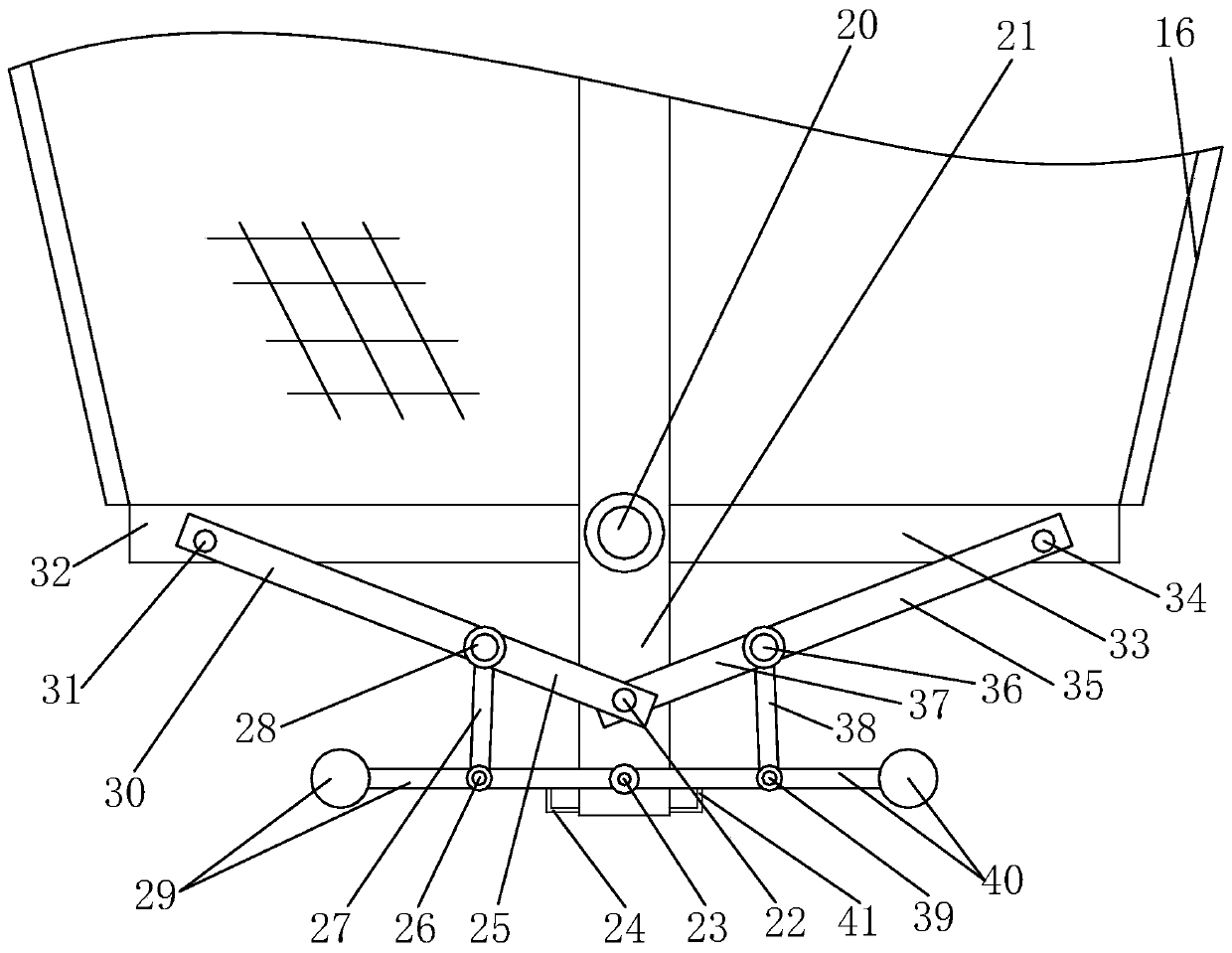

Automated corn thresher

PendingCN109479530ARealize the threshing actionHigh degree of structural automationSaving energy measuresThreshersEngineeringThreshing

The invention provides an automated corn thresher, belonging to the field of corn threshing devices. The automated corn thresher includes a machine frame, a feed bin, a push plate, a positioning groove and a threshing cylinder. The threshing cylinder is rotatably connected to the machine frame, an outer ring of the threshing cylinder is provided with a plurality of threshing teeth protruding outwards, the positioning groove is disposed in front of the threshing cylinder, the positioning groove is in a speaker shape with an upward opening, the feed bin is disposed at one end of the machine frame and disposed corresponding to the positioning groove, the push plate is slidably connected relative to the feed bin, and the movement direction of the push plate and a longitudinal center line of the positioning groove coincide. The automated corn thresher can perform automatic feeding and push, the automatic threshing of corn is completed, the efficiency is high, the feeding, threshing and screening share a power source, and the automated corn thresher saves energy and is environmentally friendly.

Owner:WUWEI JINWEI ENVIRONMENT TECH

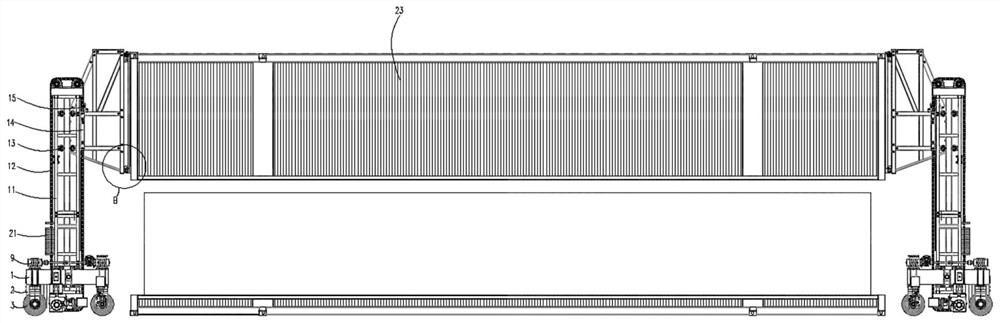

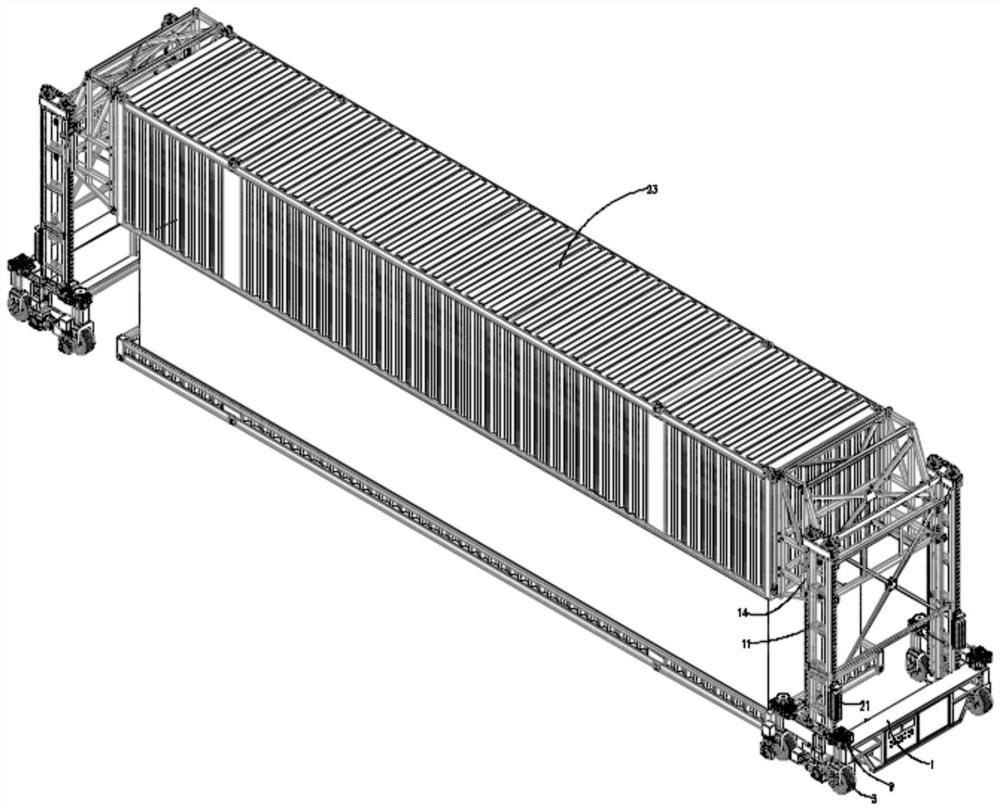

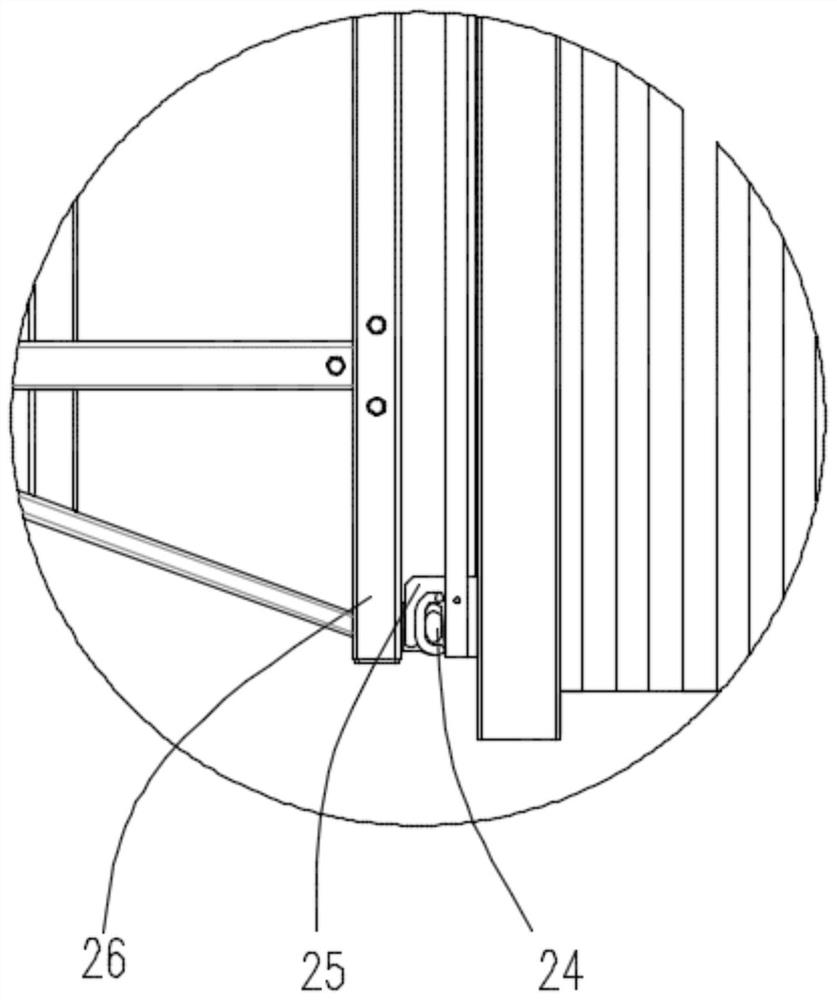

Walking control method of container cover opening machine

InactiveCN112722610AKeep awayHigh degree of structural automationOpening closed containersBottle/container closureVehicle frameMachine building

The invention discloses a walking control method of a container cover opening machine, and relates to the technical field of machine manufacturing. The container cover opening machine comprises two carrying trolleys, the two carrying trolleys are each provided with a lifting mechanism, a material taking and placing gripper is arranged on each lifting table, the material taking and placing grippers comprise taking and placing plates fixedly connected with the lifting tables, and lifting rods corresponding to clamping hooks on the upper edge and the lower edge of a container cover are arranged on the upper sides and the lower sides of the tail ends of the taking and placing plates correspondingly. Each carrying trolley comprises a trolley frame, four connecting columns are arranged at the four corners of the bottom of each trolley frame, each connecting column is rotationally provided with a conveying wheel, and each carrying trolley is provided with a magnetic strip navigation module. The whole structure is divided into two independent movable individuals, the site and space constraint generated during moving and scheduling is small, the large carrying function is achieved through cooperative operation of the two flexible individual structures, equipment mounting and fixing are not needed, multi-workstation work can be achieved, and universality and practicability are high.

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

Led lamp bead reclaiming device

ActiveCN105196020BHigh degree of structural automationHigh speedMetal working apparatusEngineeringLED lamp

The invention discloses a lamp bead taking device which comprises a track base, a clamping frame driven by a motor I is mounted on the track base, a toothed clamp port I and a toothed clamp port II for clamping workpieces input by a vibration feed tray are formed in a feeding end of the clamping frame, a clamping groove is formed in the discharge end of the clamping frame, and a pulling piece driven by a cylinder I to move back and forth in the clamping groove is mounted in the clamping groove; a fixture block I and a fixture block II are mounted between the clamping groove and the toothed clamp port II, the fixture block II is fixed on a support, and the fixture block I is driven by a cylinder II mounted on the support to realize opening and closing with the fixture block II. The lamp bead taking device is high in structural automation degree and high in speed, saves labor force and is applicable to popularization and usage.

Owner:江门市优光光电科技有限公司

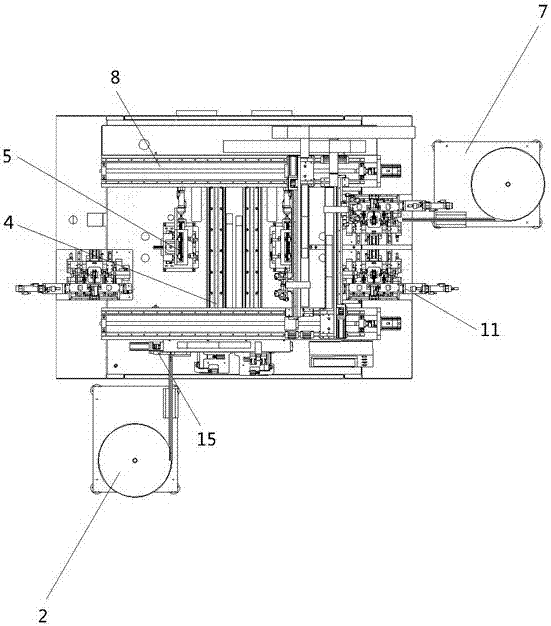

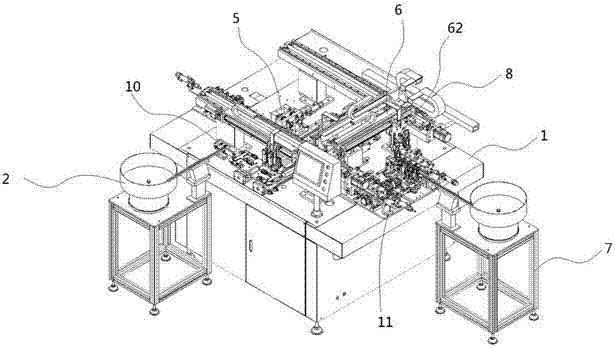

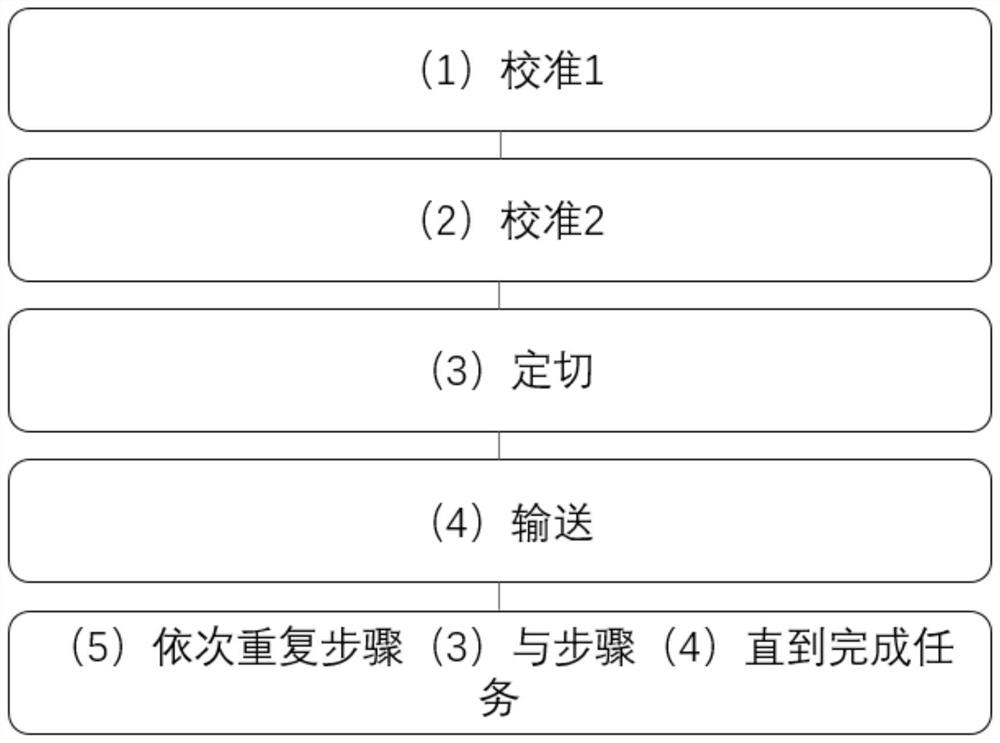

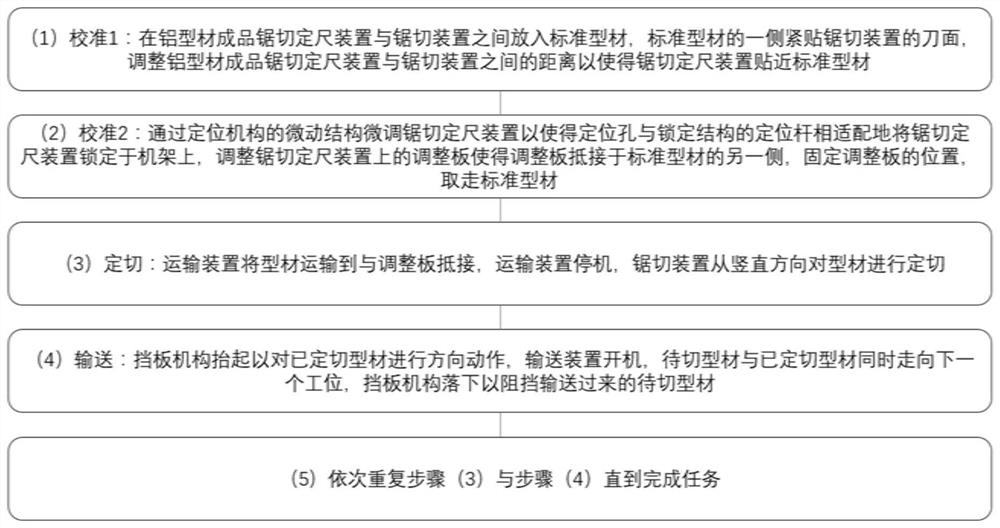

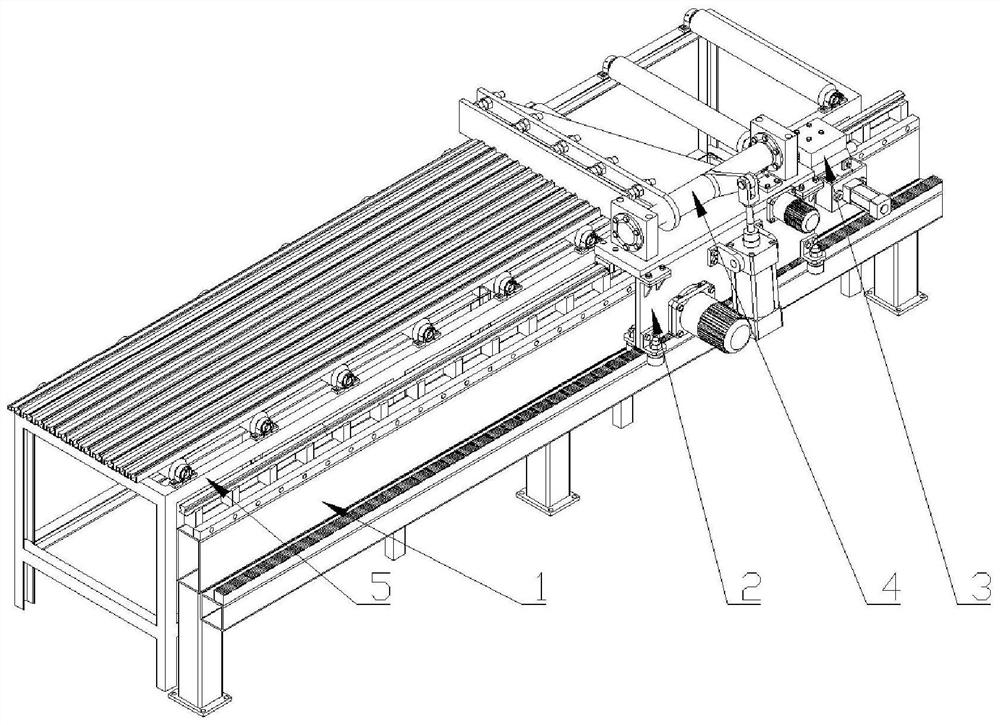

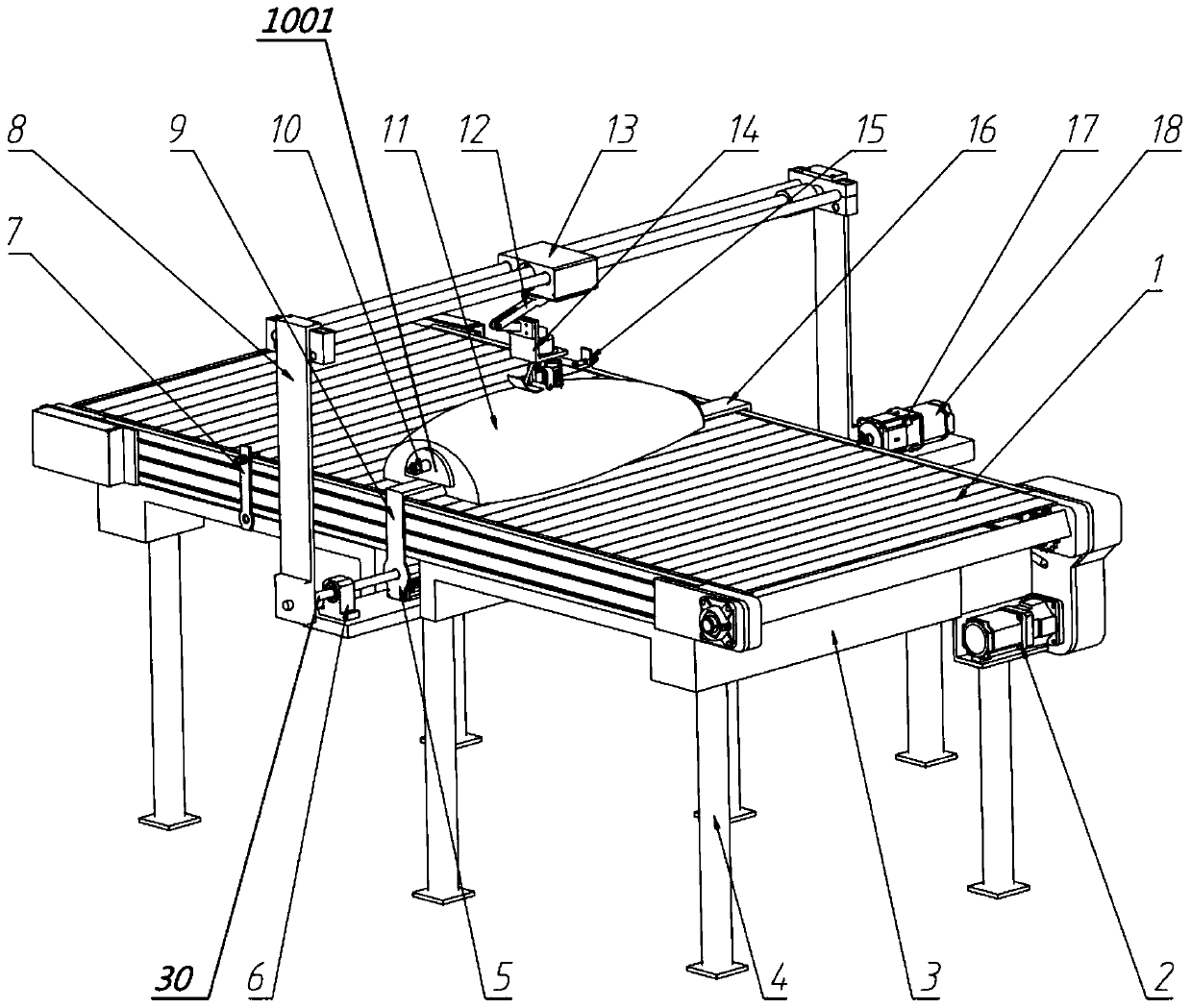

Aluminum profile finished product saw cutting sizing device and aluminum profile fixed cutting process

ActiveCN111975107APrecise sizing operationImprove work efficiencyMetal sawing devicesMetal sawing accessoriesMechanical engineeringIndustrial engineering

The invention provides an aluminum profile finished product saw cutting sizing device. The device comprises a rack, a traveling mechanism, a positioning mechanism and a baffle mechanism, wherein the rack is arranged on one side, in the conveying direction, of the conveying device, the traveling mechanism is used for moving on the rack in the length direction of the rack, the positioning mechanismis connected with the traveling mechanism and used for adjusting the position of the traveling mechanism and fixing the traveling mechanism and the rack through the positioning mechanism, the baffle mechanism is connected with the traveling mechanism and used for stopping a profile to be sawn and releasing the sawn profile, and meanwhile the aluminum profile fixed cutting process is provided. According to the device and the process, accurate sizing operation can be achieved, large-batch multi-time cutting can be conducted uninterruptedly, the working efficiency is improved, waste caused by inaccurate positioning is reduced, the overall structure is high in automation degree, the sizing precision is greatly improved, the operation intensity of workers is reduced, the stability and durability of the overall structure are greatly improved, and the service life of the device is prolonged.

Owner:GUANGDONG HAOMEI ALUMINUM

Machining equipment with automatic positioning structure for circuit board perforating

InactiveCN111975859AProcessing effectEasy to collectMetal working apparatusFan bladeIndustrial engineering

The invention discloses machining equipment with automatic positioning structure for circuit board perforating. The machining equipment comprises a box body and a rack, a top plate is arranged at thefront end of the box body, telescopic rods are arranged at the lower end of the top plate, a longitudinal sliding rail is fixed to the lower ends of the telescopic rods, a transverse rod is arranged at the upper end of the middle of a transverse sliding rail, a pulley is arranged inside a connecting plate, a drill bit is arranged at the lower end of the middle of a longitudinal rod, baffles are connected to the front ends and the rear ends of fan blades, pressing plates are arranged at the lower ends of first springs, limiting plates are arranged at the lower ends of the pressing plates, and collecting plates are arranged at the left ends of the limiting plates. Compared with an existing common circuit board production device, the machining equipment with the automatic positioning structure for circuit board perforating is provided with the automatic positioning structure, only the width between clamping structures of the equipment needs to be adjusted, and an automatic feeding structure is arranged, so that the situation that manual work or other structure is used for assisting the equipment in operation is avoided, the automation degree of the equipment is high, and the time required for machining a circuit board is shortened.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

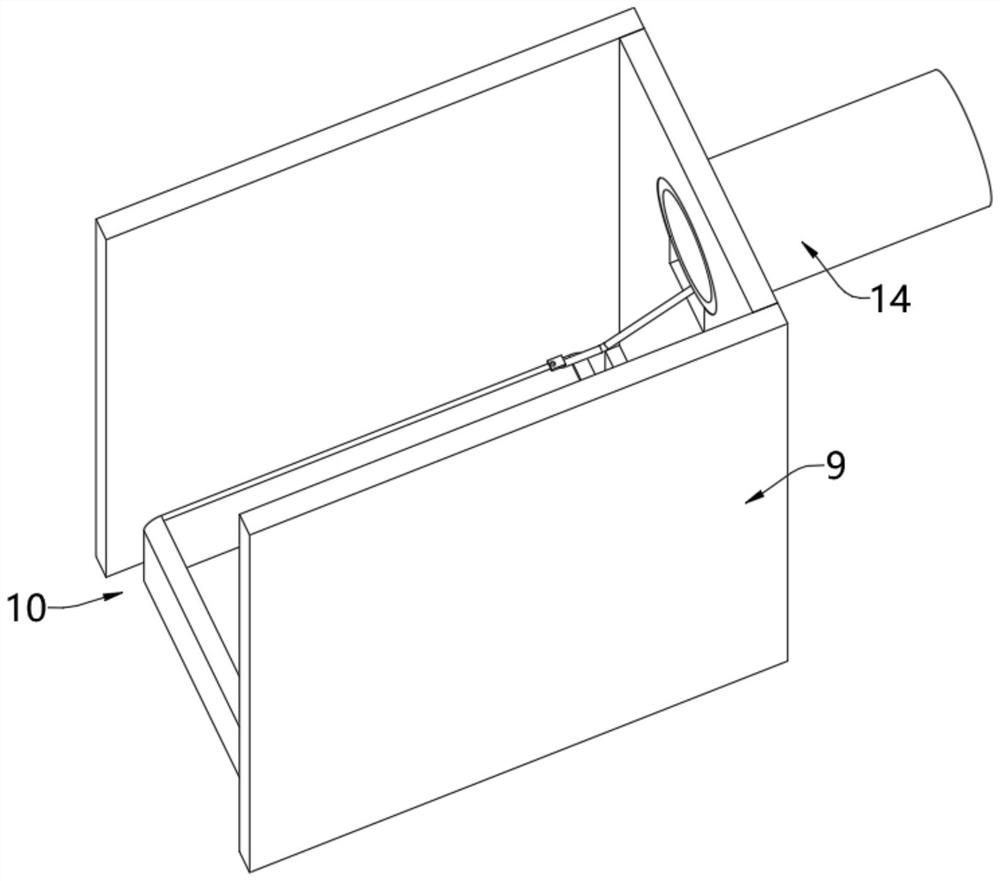

Automatic cat litter discharging mechanism

PendingCN113615581AReduce pollutionAchieve the effect of automatic cat litterAnimal housingAnimal scienceLitter

The invention relates to the technical field of pet cleaning supplies, and discloses an automatic cat litter discharging mechanism. The automatic cat litter discharging mechanism comprises a storage box used for storing cat litter, an opening is formed in the bottom of the storage box, a movable hinge is movably arranged at the opening, and the right side of the movable hinge is connected with the storage box through a hinge; a motor starts to drive a rotating shaft to rotate, when the rotating shaft rotates to enable a protruding part to be located at the top of the rotating shaft, the movable hinge is jacked up by the protruding part, the opening of the storage box is in a closed state, at the moment, cat litter in the storage box cannot be discharged; when the rotating shaft rotates to enable the protruding part not to be located at the top of the rotating shaft, the movable hinge loses support of the protruding part and rotates with the hinge as a circle center, the rotating movable hinge is in an inclined state and opens the opening of the storage box, at the moment, the cat litter in the storage box can be discharged through a gap between the opening and the movable hinge, the effect of automatically discharging the cat litter is achieved, moreover, the cat litter is discharged very smoothly and cannot be blocked, and the problem that the workload of manually and frequently adding the cat litter is relatively large is effectively solved.

Owner:PET LIFE (BEIJING) TECH CO LTD

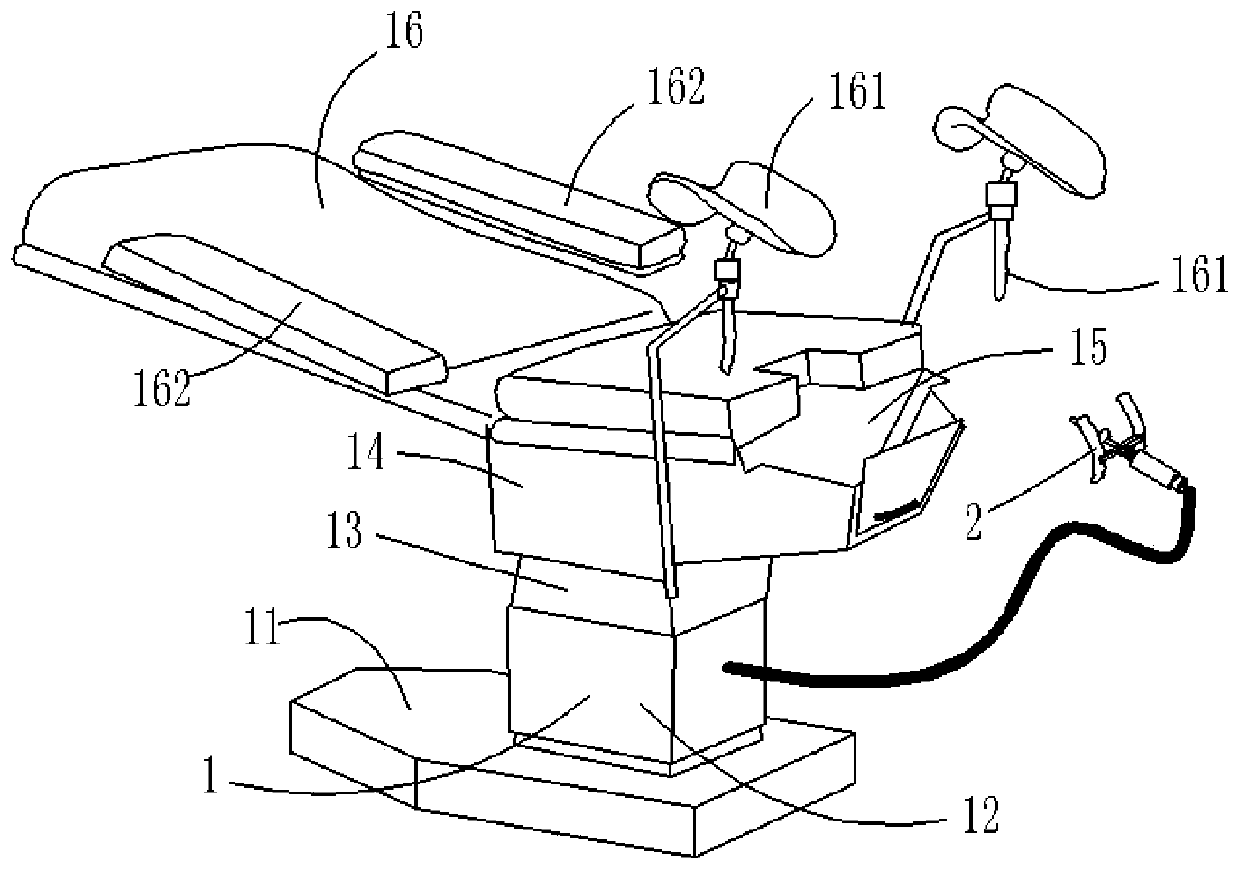

Special cervical anesthesia outfit for obstetrics and gynecology department

The invention discloses a special cervical anesthesia outfit for obstetrics and gynecology department. The outfit comprises a bed body, an anesthesia auxiliary device, a vaginal orifice expansion auxiliary device and an anesthesia gun; the anesthesia gun comprises a handheld part, a protection part, a vaginal orifice expansion part and an anesthesia part; the anesthesia auxiliary device comprisesa medicament box used for placing anaesthesia medicaments, a medicament pump used for being connected to the anesthesia part, and a liquid flow meter used for controlling the medicament flow; and thevaginal orifice expansion auxiliary device comprises an air pump used for being connected to an expansion air bag, and a rotor flow meter used for controlling gas flow. The outfit has high automationdegree, can greatly reduce the workload of medical personnel, and is suitable for mass popularization.

Owner:潍坊市妇幼保健院

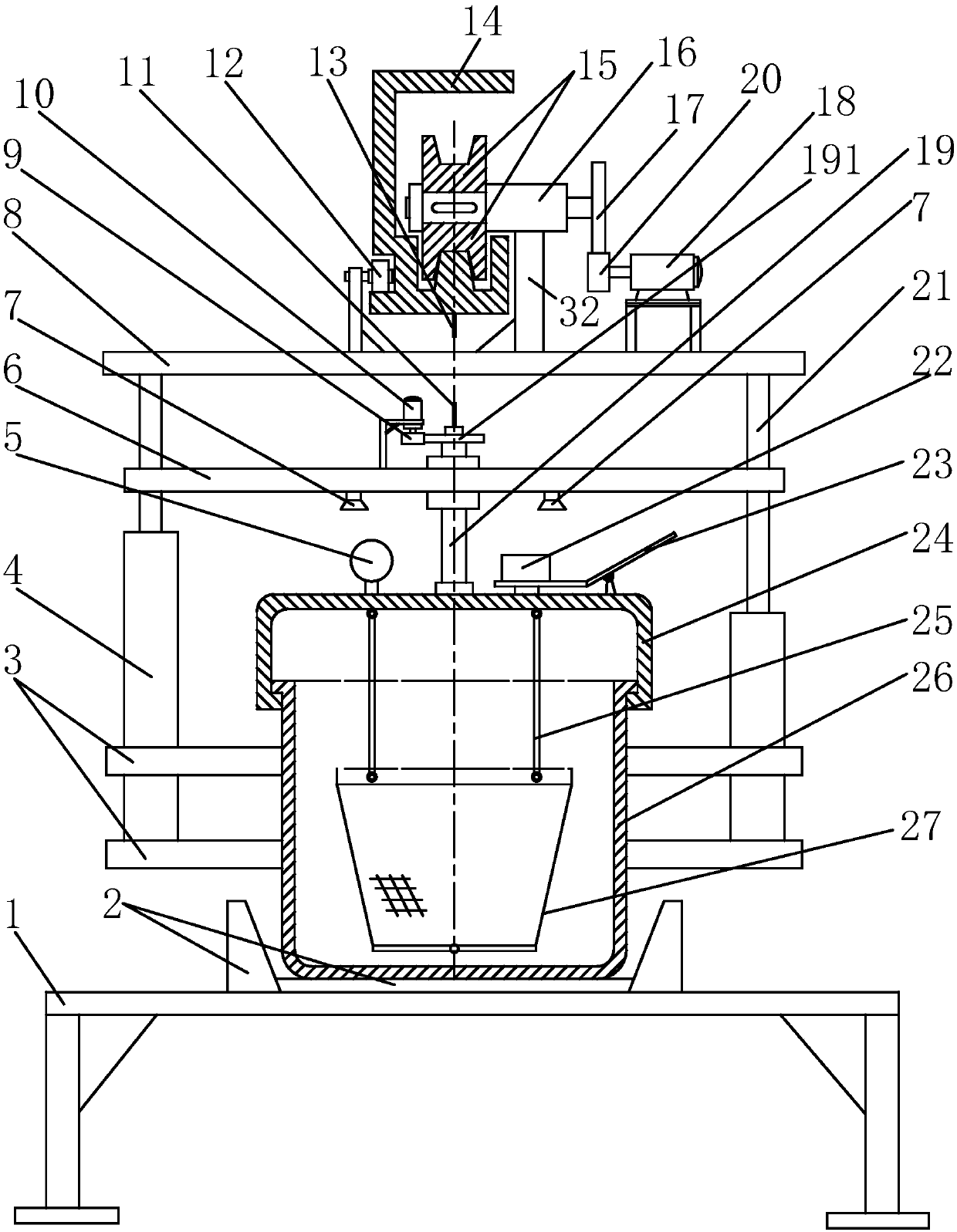

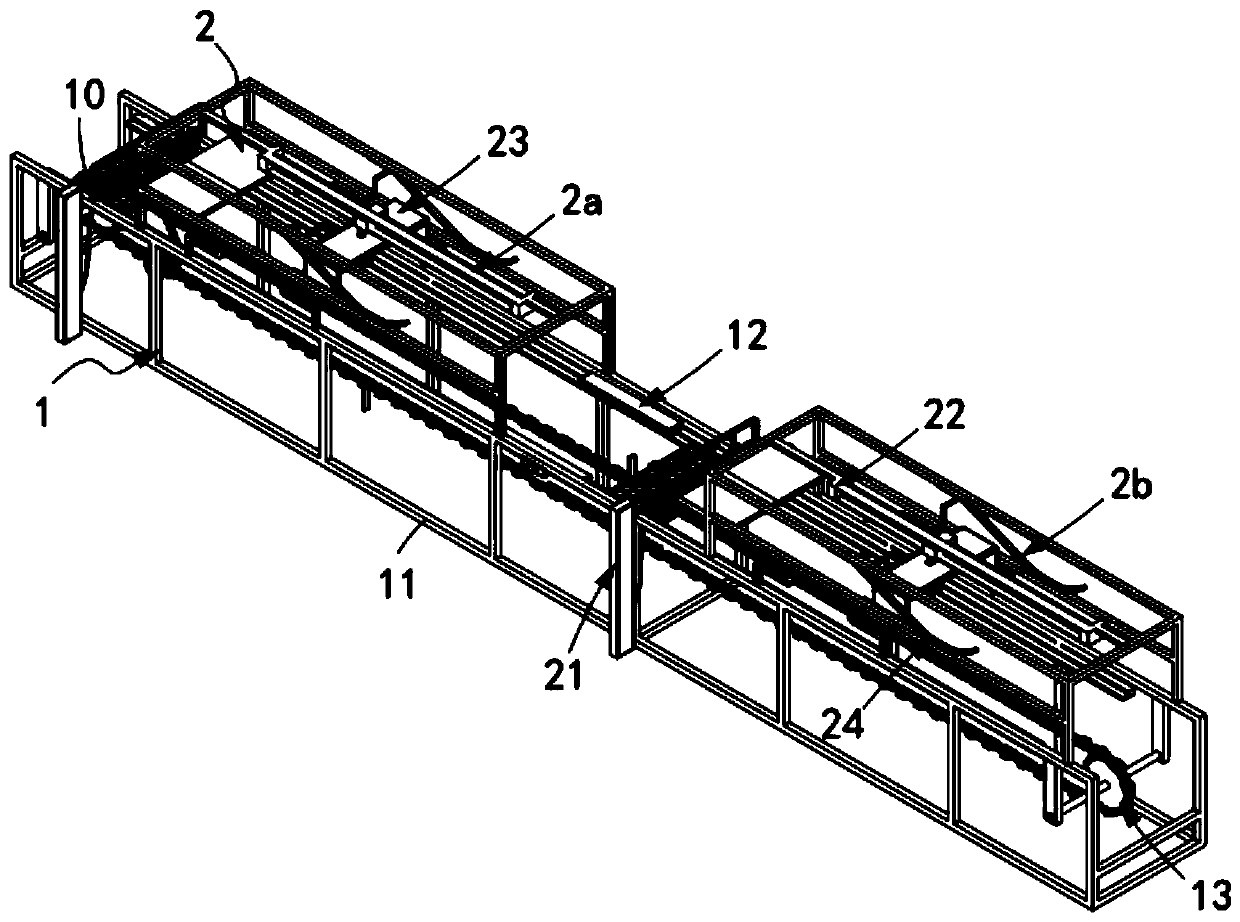

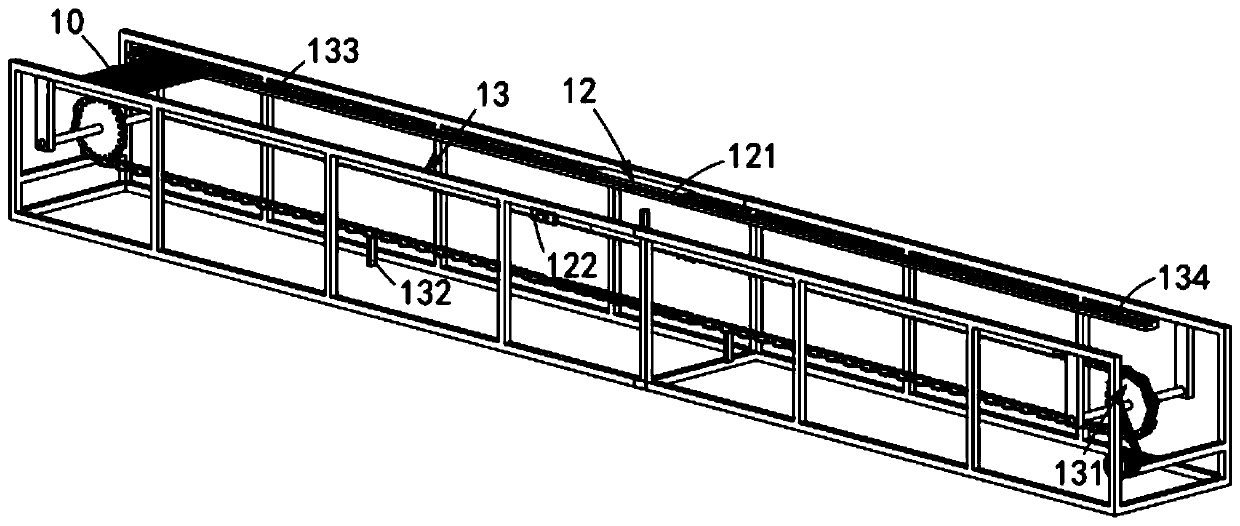

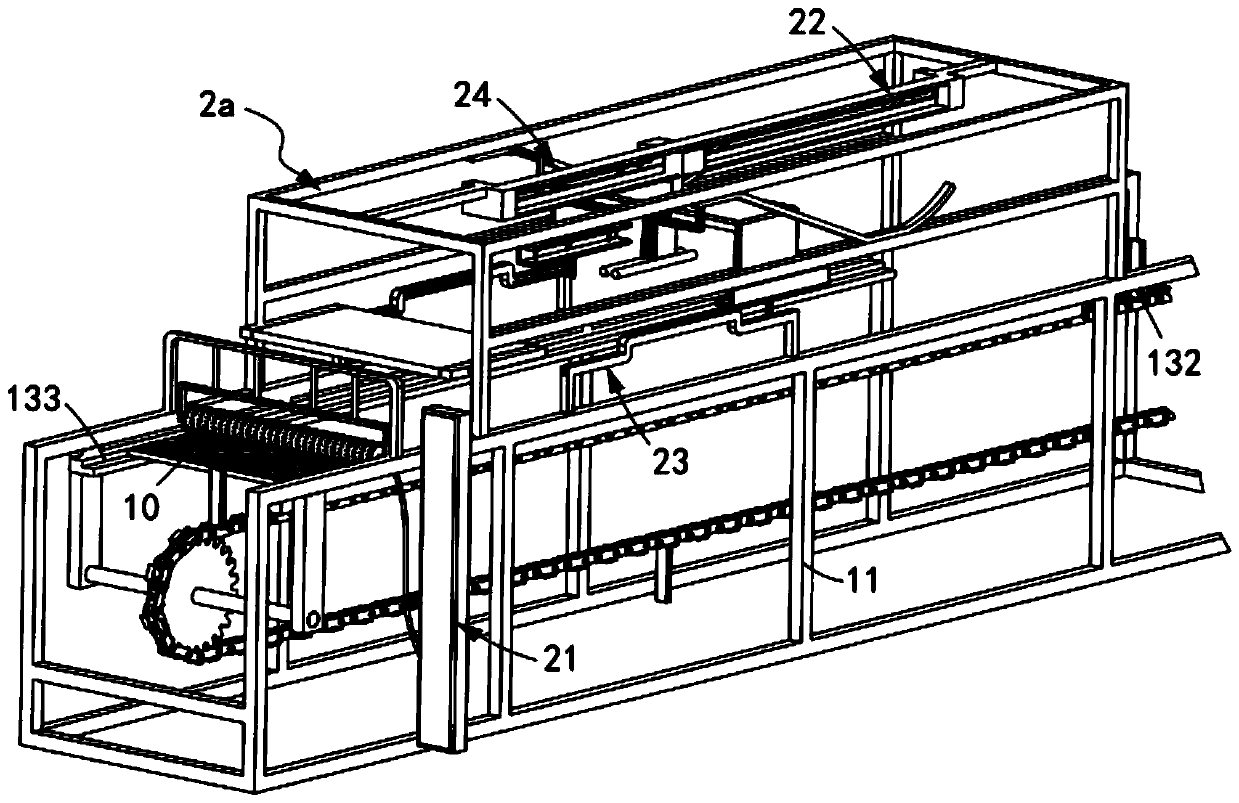

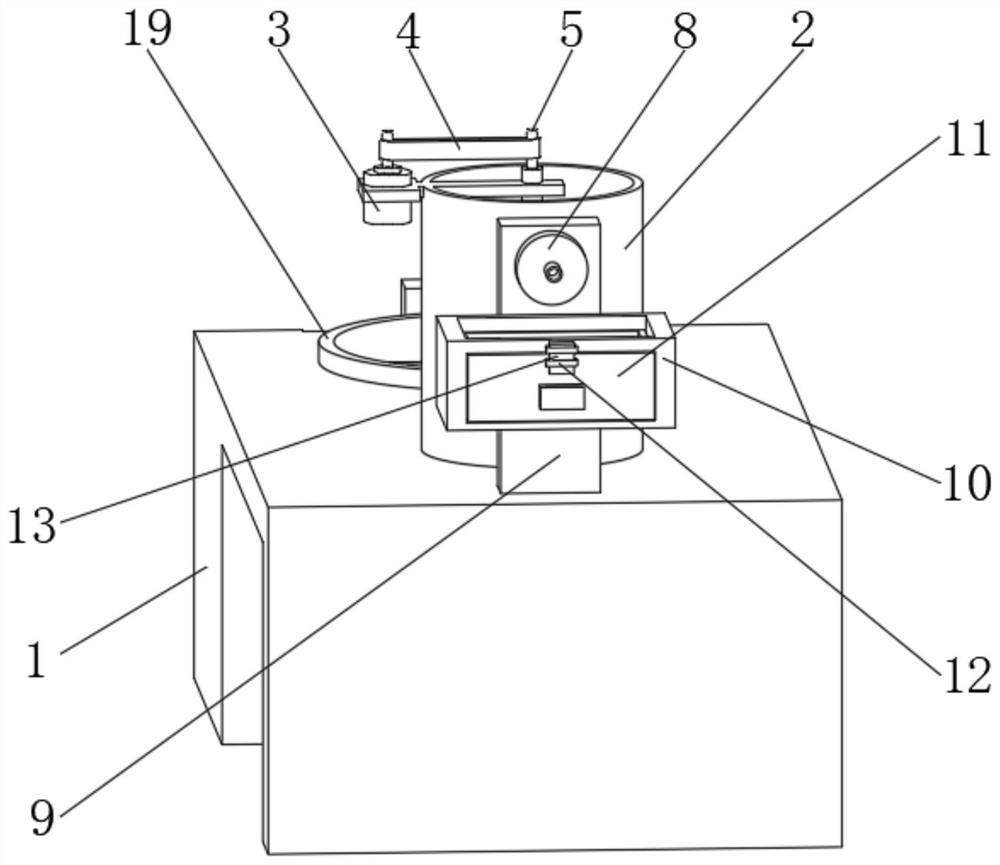

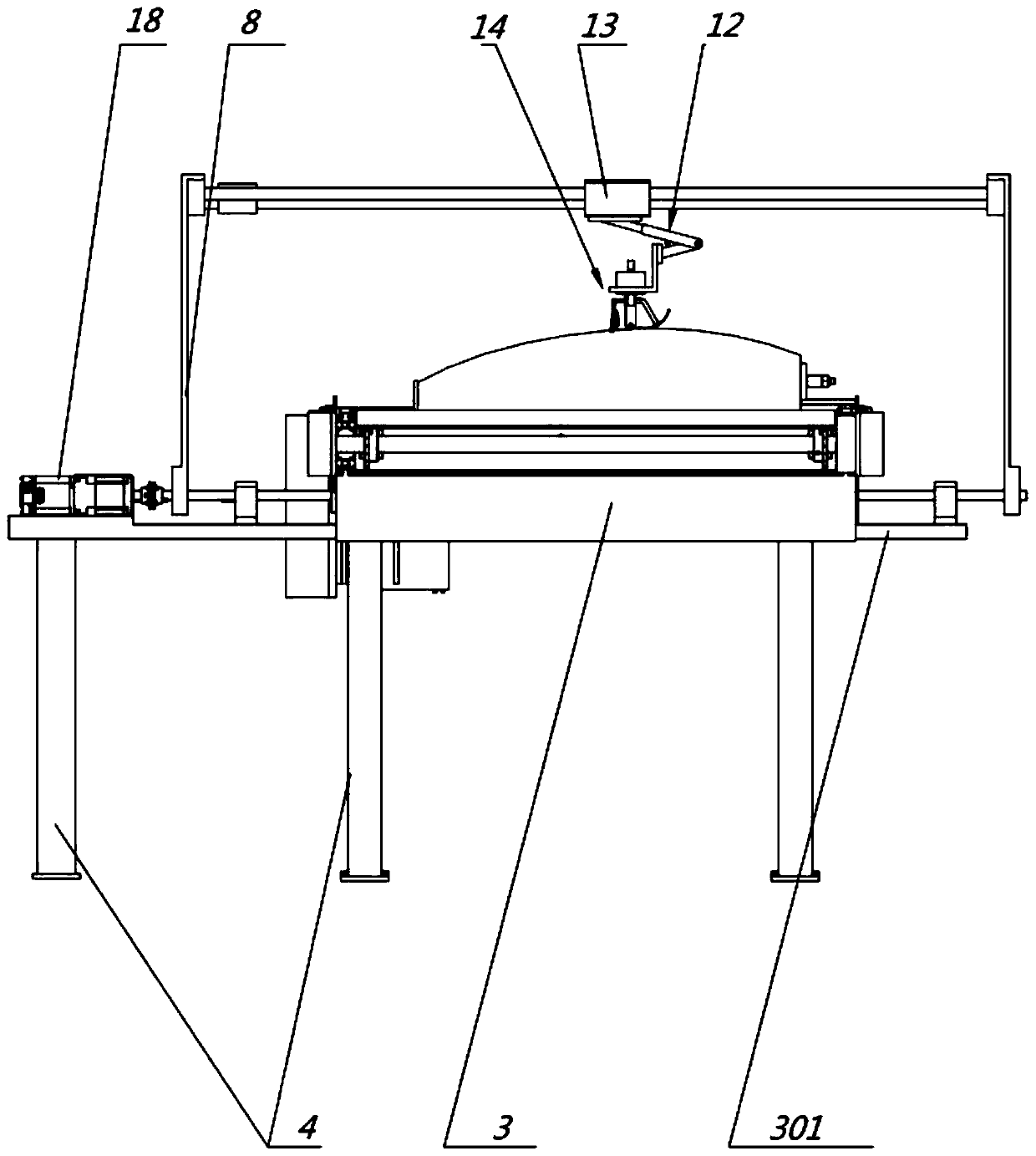

Experimental apparatus for curing and proportioning depositing silt in channel

InactiveCN105233741ABest ratioBest mixing timeSludge treatment by de-watering/drying/thickeningMixer accessoriesEngineeringCrusher

The invention discloses an experimental apparatus for curing and proportioning depositing silt in a channel. The experimental apparatus comprises a framework. A bottom plate is mounted in the bottom of the framework. The frame is characterized in that the framework is internally provided with a vertical support, wherein a mud supply box is mounted on the vertical support, a crushing chamber is connected below the mud supply box, a spiral crusher is mounted on the crushing chamber, and a moveable cover is mounted on the mud supply box. The experimental apparatus has the beneficial effects that the experimental apparatus is high in degree of structural automation, can determine the optimum proportion of silt and a cure agent, the stirring time and the sinking curing time, and provides scientific and reasonable construction with parameter guidance, thereby lowering the economical cost and being suitable for extended application.

Owner:ZHEJIANG OCEAN UNIV

Casting aluminum bar smelting device for aluminum profile production

PendingCN114812169AAchieve rotationReduce stirring resistanceStirring devicesCrucible furnacesMechanical engineeringManufacturing engineering

The invention belongs to the field of smelting devices, and particularly relates to a casting aluminum bar smelting device for aluminum profile production, which comprises a main frame body and a connecting pipe, the top of the main frame body is provided with a smelting furnace, the end part of the smelting furnace is provided with a servo motor, the end part of the servo motor is connected with a belt, and the end part of the belt is connected with a connecting shaft; a stirring plate is arranged on the outer side of the connecting shaft, a hollow groove is formed in the inner side of the stirring plate, a waste liquid pump is connected to one side of the smelting furnace, a fixing frame is arranged at the bottom of the waste liquid pump, a collecting box is arranged on the side of the fixing frame, a sliding drawer is arranged in the collecting box, and a fixing sleeve is arranged on the outer wall of the sliding drawer. A fixed clamping plate is arranged on the inner side of the fixed sleeve; according to the aluminum bar smelting device, impurities generated by aluminum bar smelting can be conveniently extracted and removed, smelted materials can be conveniently and fully stirred and purified, heat insulation protection can be conveniently carried out on the device, and automatic uniform distribution and cooling control can be conveniently carried out on an aluminum bar solution.

Owner:苏州首铝金属有限公司

A battery casing machine

ActiveCN104966793BAvoid wastingScientific and reasonable structurePrimary cell manufactureAssembling battery machinesDrive wheelFully automated

The invention provides a battery casing machine. The battery casing machine of the present invention includes a casing conveying and cutting mechanism and a battery core conveying mechanism; the casing conveying and cutting mechanism includes a casing reel, a spreading column, a transmission wheel, and a cutting device; The battery core conveying mechanism includes a battery core conveying device and a battery core ejection device; a battery core ejection device is provided at the end of the battery core conveying device; the battery casing machine of the present invention changes the vacuum suction tension used in the prior art. Disadvantages of the open casing technology, the uniquely designed expansion column structure and the transmission wheel are used to achieve 100% opening of the battery heat shrinkable film casing, avoiding the waste of materials, and fully automating the battery core casing process. It has laid a foundation and has good application prospects.

Owner:平南县富时达自动化设备有限公司

Fish skin removing structure and fish skin removing method thereof

PendingCN111264601AImprove the operating environmentHigh degree of structural automationFish skinningAnimal scienceZoology

The invention relates to a fish skin removing structure and a fish skin removing method thereof. The fish skin removing structure comprises at least one workbench, at least one conveying belt device,at least one scanning device, at least one rotating device, at least one clamping device, at least one first executing device and at least one cutter device. Compared with the prior art, the fish skinremoving device is high in structural automation degree, can replace manual work, improves the operation environment of workers, reduces the labor intensity, saves time and labor and improves the fish skin removing efficiency. Due to the arrangement of the scanning device, a fish body is accurately positioned, accurate clamping of the clamping device on the two sides of the fish body is guaranteed, subsequent fish skin removing operation is facilitated, and the fish body is prevented from sliding out of the conveying belt device. Due to the arrangement of the rotating device, the cutter device can adapt to different fish body appearance radians, and the torque borne by a rotating shaft is reduced through the arrangement of a bearing seat.

Owner:JIANGNAN UNIV

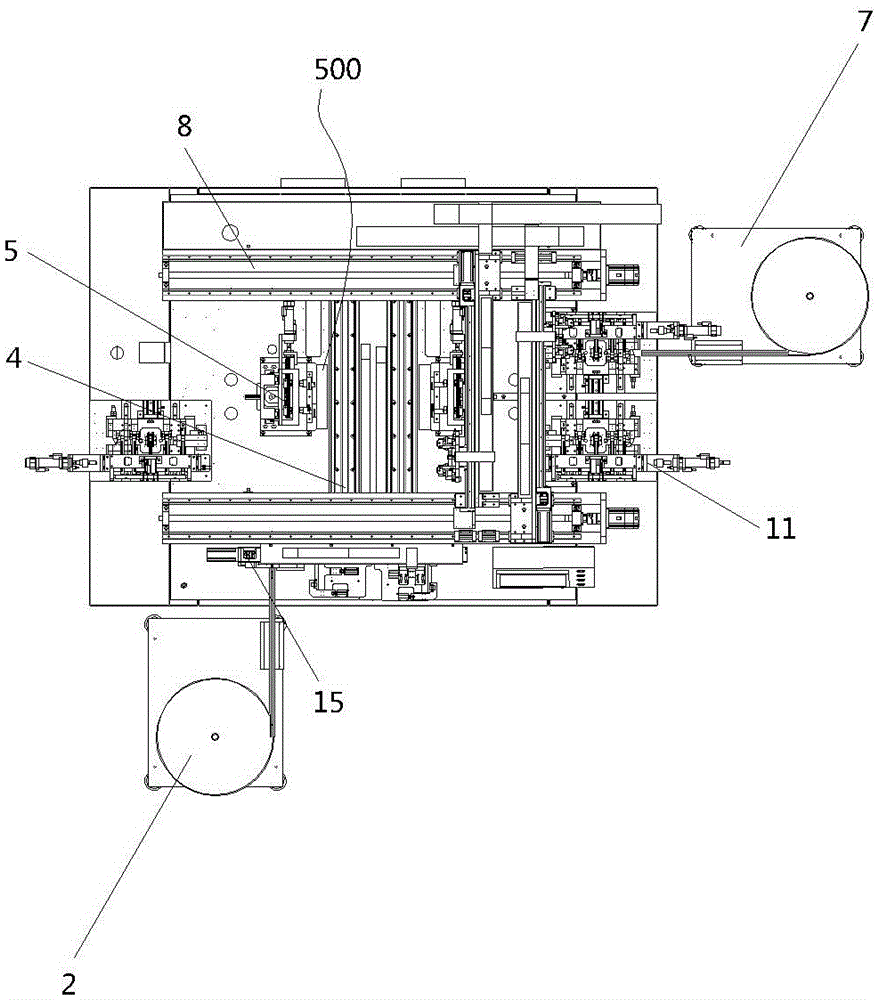

LED lamp bead assembly equipment

ActiveCN105149940BHigh degree of structural automationHigh speedAssembly machinesEngineeringLED lamp

The invention discloses an LED lamp bead assembling device. The LED lamp bead assembling device comprises a working table, and is characterized in that a first transverse rail and a second transverse rail are arranged on the two sides of the working table respectively, a lamp bead feed device is installed on the first transverse rail and the second transverse rail, a lamp holder feed device is vertically installed below the first transverse rail and the second transverse rail, and assembling device bodies are arranged on the two sides of the lamp holder feed device; a lamp bead taking device is installed on one side of the working table, a lamp holder taking device is installed on the other side of the working table, and a lamp holder assembling device is installed on the second transverse rail. The LED lamp bead assembling device has the advantages of being high in structure automation degree, capable of automatically conveying diode lamp beads into lamp holders, high in speed, capable of saving labor and suitable for being used and popularized.

Owner:YANGZHOU GUOGUANG LIGHTING GRP CO LTD

Double-piece color box automatic nail box machine

ActiveCN105216374BConvenient adsorption and flipAchieve precise positioningBox making operationsPaper-makingPulp and paper industryIn degree

The invention relates to a double-plate type automatic box nailing machine for a color box. The double-plate type automatic box nailing machine comprises a movable assembly which can slip on a paper feeding guide rod, wherein a fixed nailing head is further arranged below the paper feeding guide rod; the two ends of the movable assembly are respectively connected with a left suction nozzle supporting base and a right suction nozzle supporting base; a plurality of suction nozzles for adsorbing corrugated paper boards are respectively distributed on the left suction nozzle supporting base and the right suction nozzle supporting base; in a slip direction of the movable assembly, one side of the paper feeding guide rod is further provided with a plate placing table for bearing spliced corrugated paper boards; one side of the plate placing table is provided with a paper turnover swing rod capable of turning over; a swing end of the paper turnover swing rod is symmetrically provided with a plurality of suction nozzles; a pair of conveying platforms is further arranged in a turnover direction of the paper turnover swing rod; and the two ends of the conveying platform are provided with a left folding arm and a right folding arm. The double-plate type automatic box nailing machine for the color box is high in degree of automation of an integral structure, capable of releasing original labor personnel from complex double-plate type nailing operation and time-saving and labor-saving, thereby not only saving investment cost of manpower resource of enterprises, but also improving production efficiency.

Owner:泰州市华驰不锈钢制品有限公司

Automatic dried beancurd stick frying machine

PendingCN110881488AQuality assuranceHigh degree of structural automationOil/fat bakingReciprocating motionProcess engineering

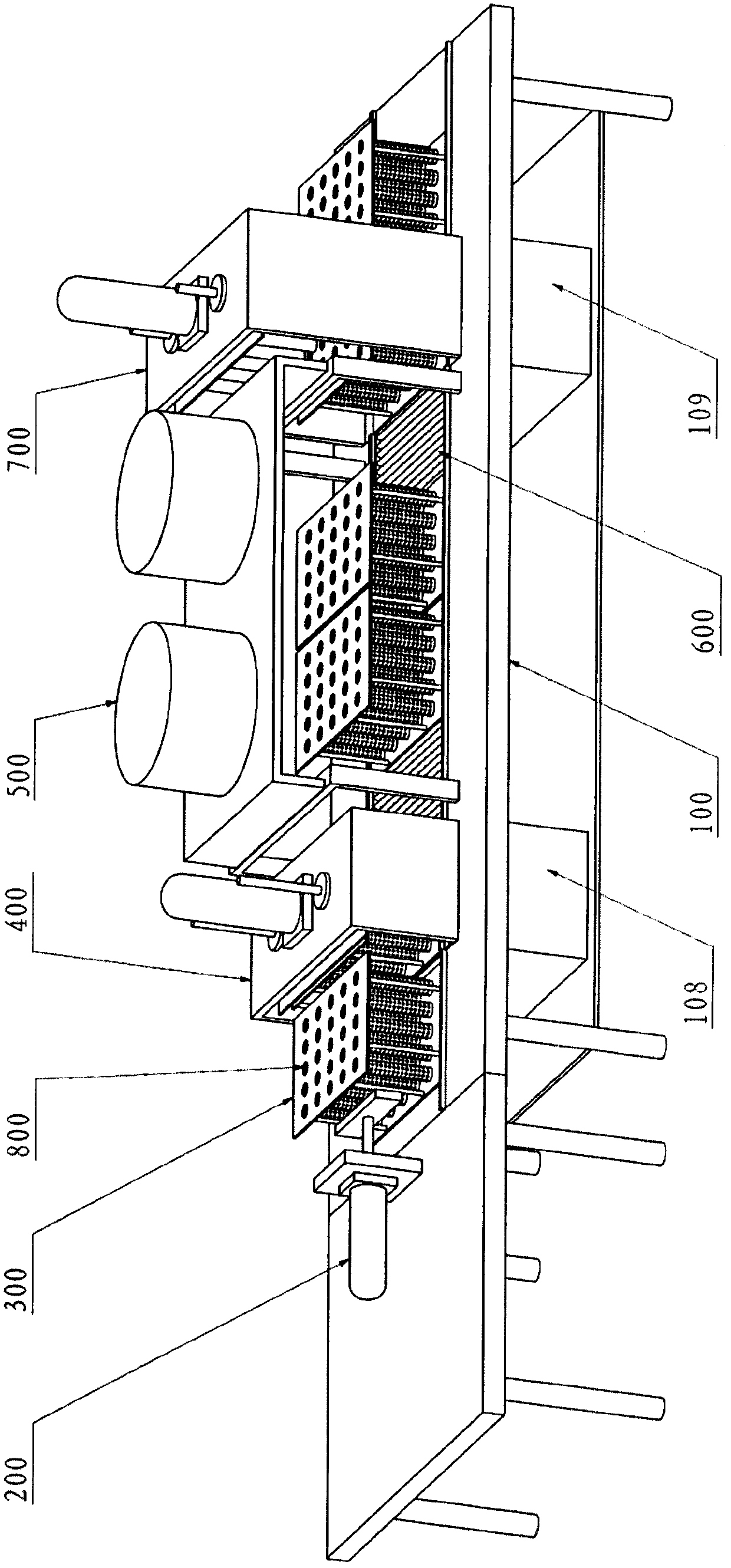

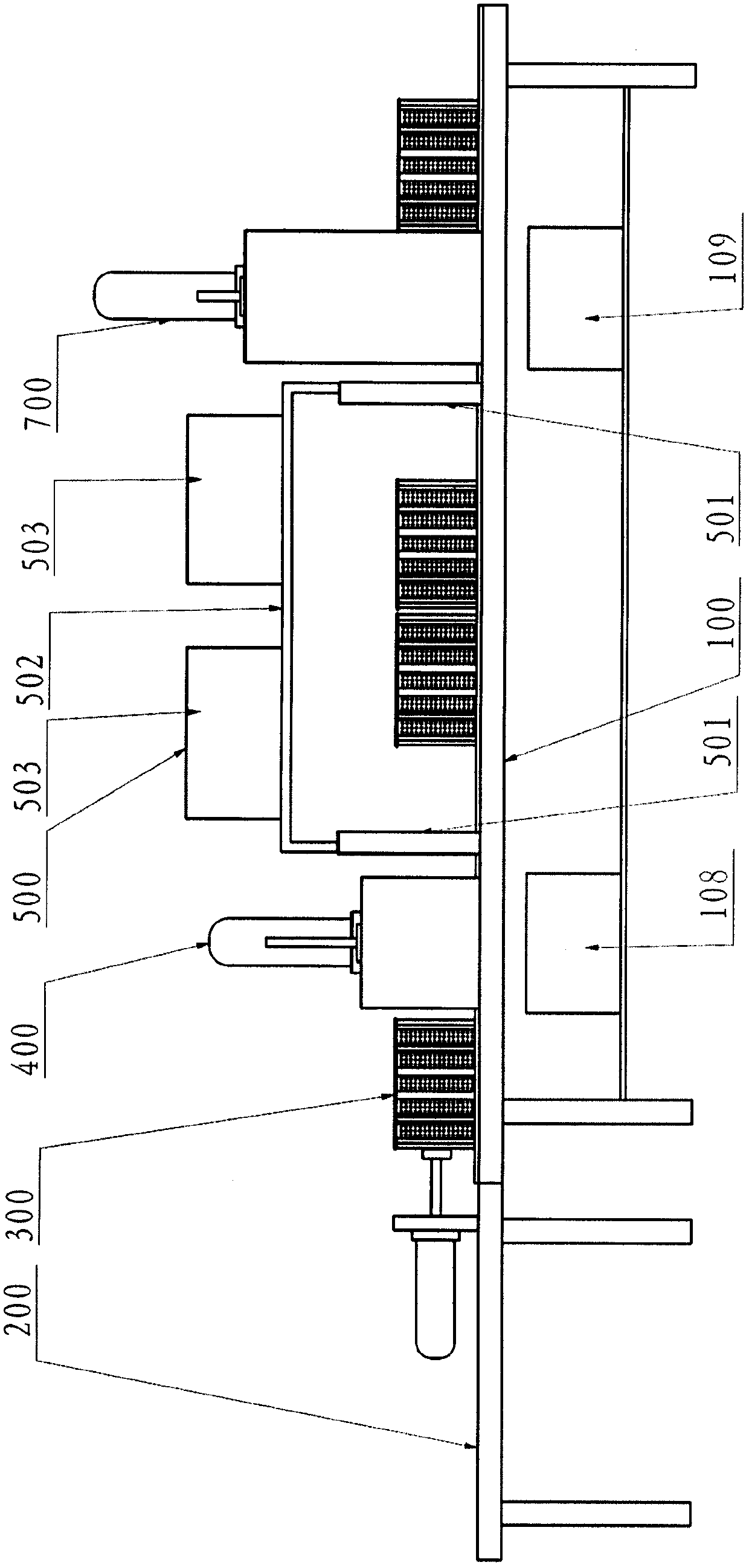

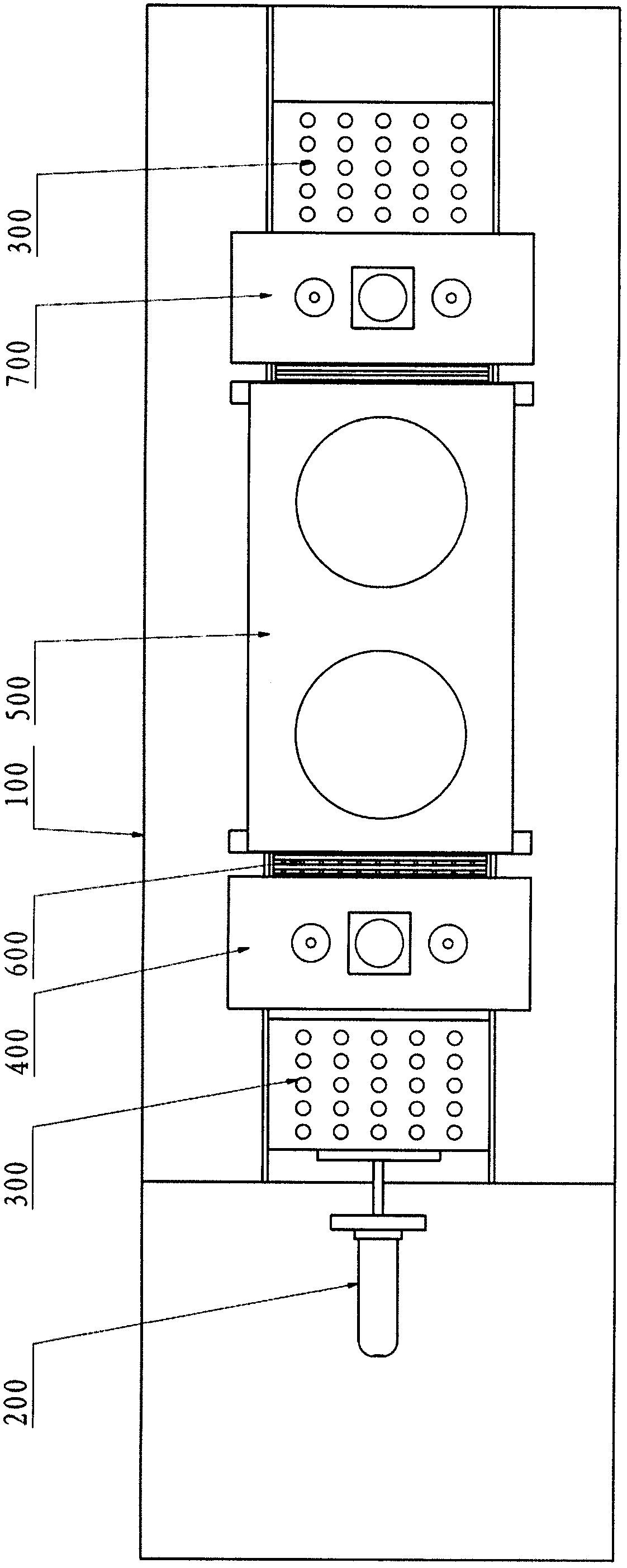

The invention belongs to the field of food production and processing equipment, and particularly relates to an automatic dried beancurd stick frying machine. The automatic dried beancurd stick fryingmachine comprises a support assembly 100, a pushing assembly 200, a frying hanging tool assembly 300, an up-down frying assembly 400, an air inlet assembly 500, an oil return assembly 600, an up-downstripping assembly 700 and dried beancurd sticks 800. The machine is characterized in that the oil return assembly 600 is installed at the position of a through hole in the middle of a frame body 101of the support assembly 100, and the oil return assembly 600 is divided into three layers, namely an upper layer waved plate 601, a middle layer precipitation plate 605 and a bottom layer inclined plate 618; the upper-layer waved plate 601 and the middle-layer precipitation plate 605 are fixed together and can do reciprocating motion together; and a bottom-layer inclined plate 618 is detachably mounted on the frame body 101 of the support assembly 100 and is positioned below the middle-layer precipitation plate 605, so that hot oil flows back to a hot oil tank 108. The machine has the beneficial effects that filtering can be completed efficiently in time, the automation degree of the manufacturing structure is high, cleaning and replacement are easy, and the service life is long.

Owner:广西天天食品科技有限公司

Driving device for taking off and entering last machine for shoe body

The invention provides a driving device for a machine for taking off the last and inserting the last into the last as a shoe body, which belongs to the field of shoemaking equipment and includes a fixed frame on which an inverted shoe last is fixed, and a flattening assembly is arranged above the shoe last. The left and right sides are equipped with clamping components, and the rear end of the shoe tree is provided with a stripping component. The stripping component includes a rising cam, a rising driving rod and a lifting frame. The rising cam is rotatably connected to the fixed frame. Drive groove, the first drive groove drives the lifting frame to move up and down through the rising drive rod. The upper end of the lifting frame is provided with a translation cam, a translation driving rod and a last block. The translation cam is arranged horizontally and is connected to the lifting frame in rotation. The second drive slot drives the last block to move left and right through the translation drive rod. The power drive of the present invention makes the operation of the whole structure more stable and reliable, greatly reduces the failure rate, and reduces energy consumption, saves energy and is more environmentally friendly.

Owner:JIHUA LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com