Experimental apparatus for curing and proportioning depositing silt in channel

An experimental device and waterway technology, applied in the field of waterway engineering, can solve problems such as low work efficiency and failure to meet engineering requirements, and achieve economic cost savings and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

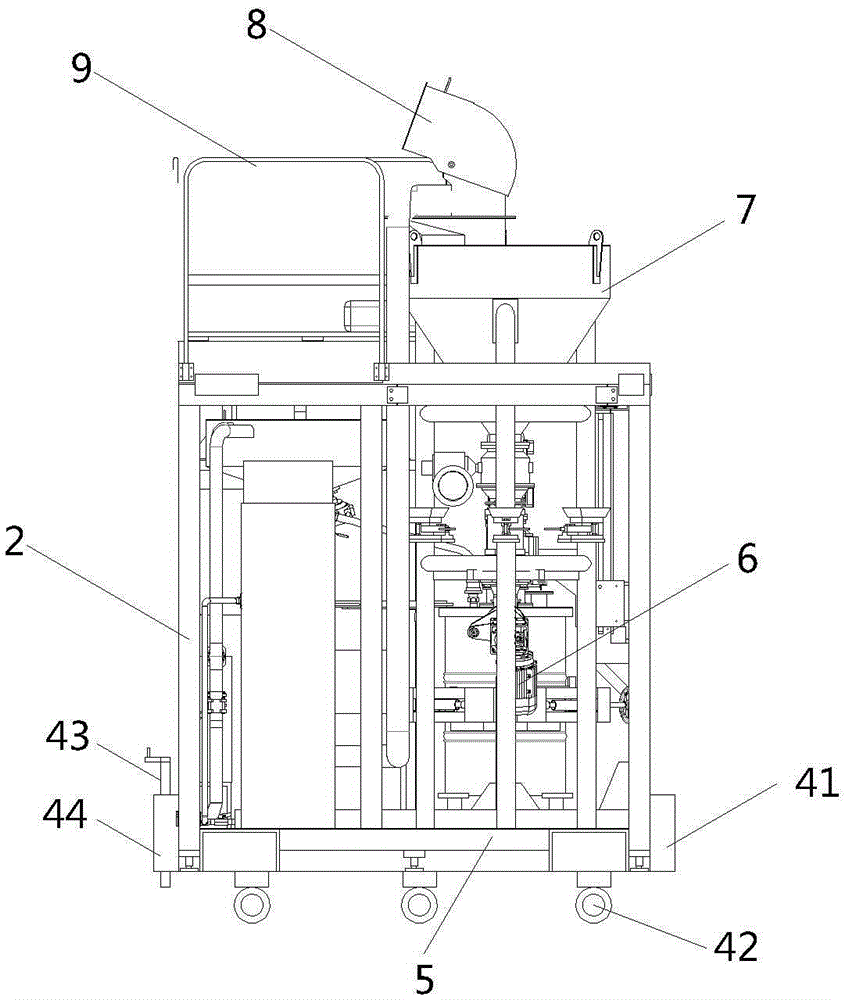

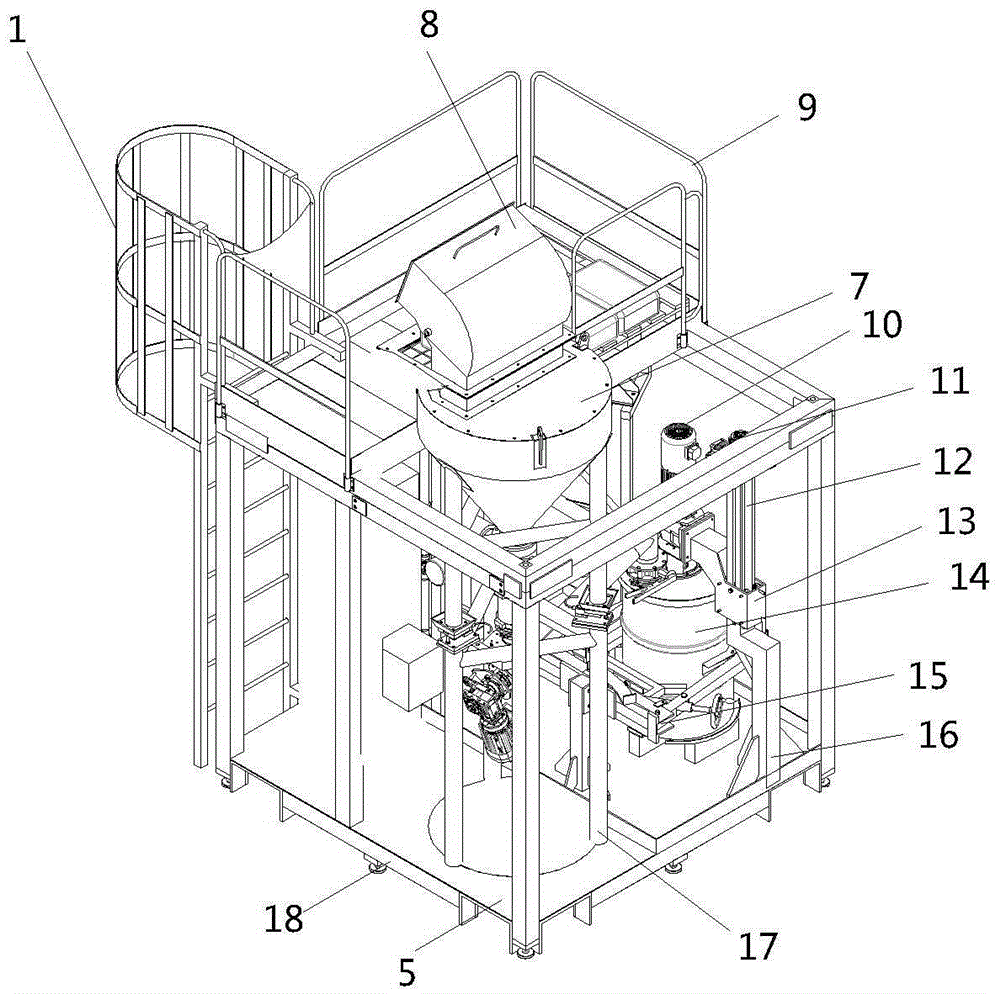

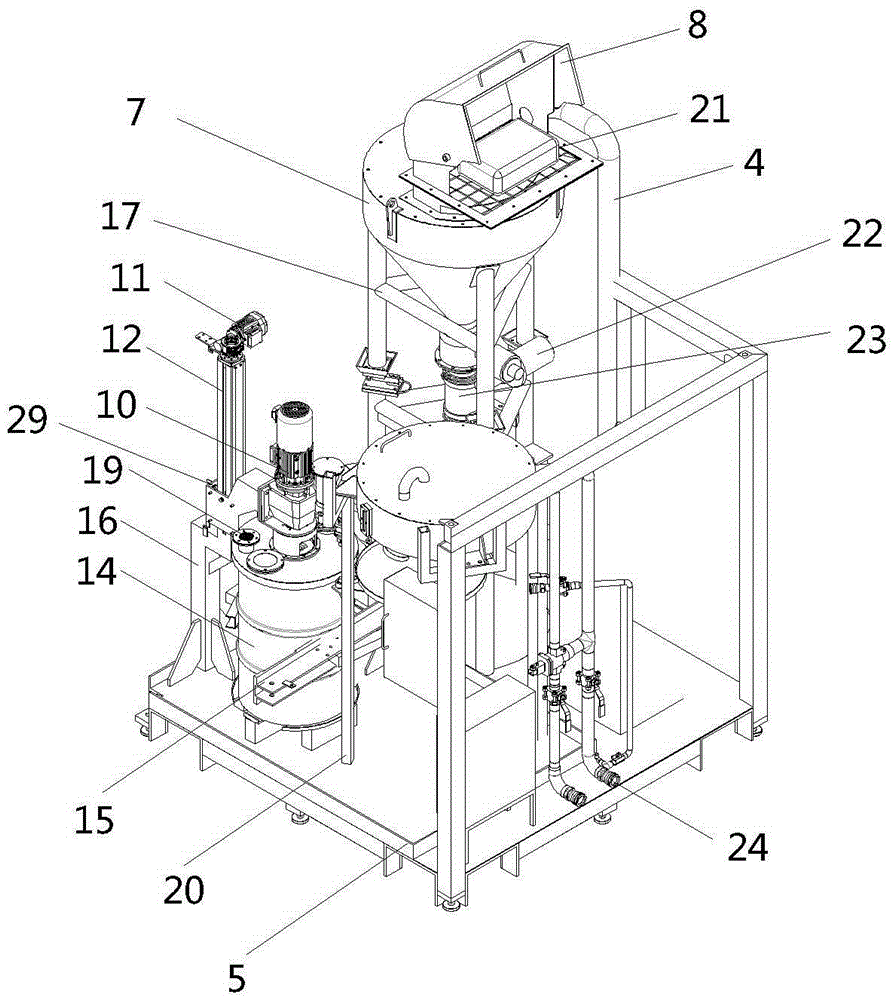

[0028] As shown in the figure, the waterway deposition silt solidification proportioning experimental device of the present invention includes a frame 2, a bottom plate 5 is installed at the bottom of the frame 2, and a vertical support 17 is provided in the frame 2 for the mud box 7 to be installed in a vertical position. On the bracket 17, there is a crushing bin 23 connected below it, and a locking buckle 26 is provided on the mud box 7 to lock and seal the mud box 7. Movable cover 8 is installed. The vertical support 17 is a telescopic support, and a bearing platform 30 is arranged in the middle of it, and a spring pad is installed in the bearing platform 30 . The vertical support 17 is a triangular support, which is welded by three circular pipes, and a filter screen 21 is also provided for the feed port of the mud box 7 .

[0029] The mixing and stirring box 14 is installed on the bottom plate 5, and a feeding pipe 28 is obliquely connected between the mixing and stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com