Three-dimensional multilayer pneumatic picking loom

A three-dimensional multi-layer and weft insertion technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of low weaving efficiency and low degree of automation, and achieve the effect of improving weaving efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

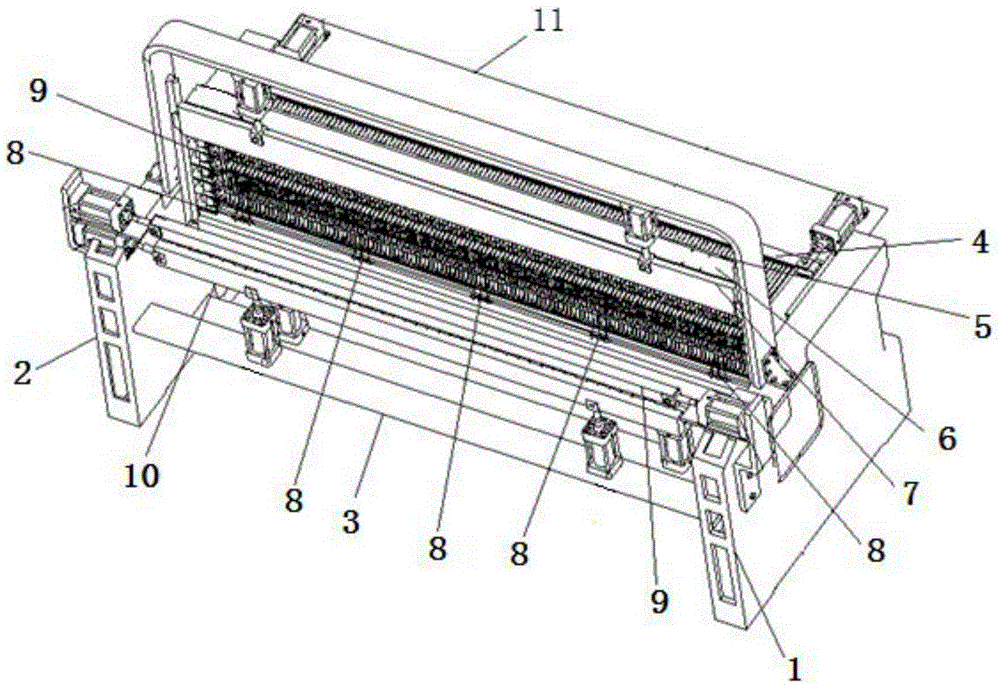

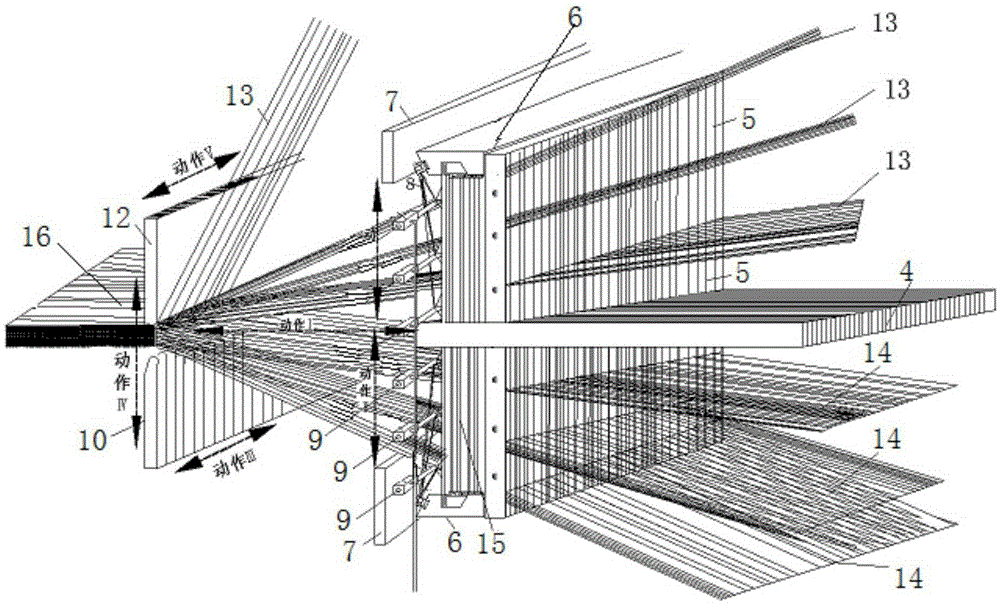

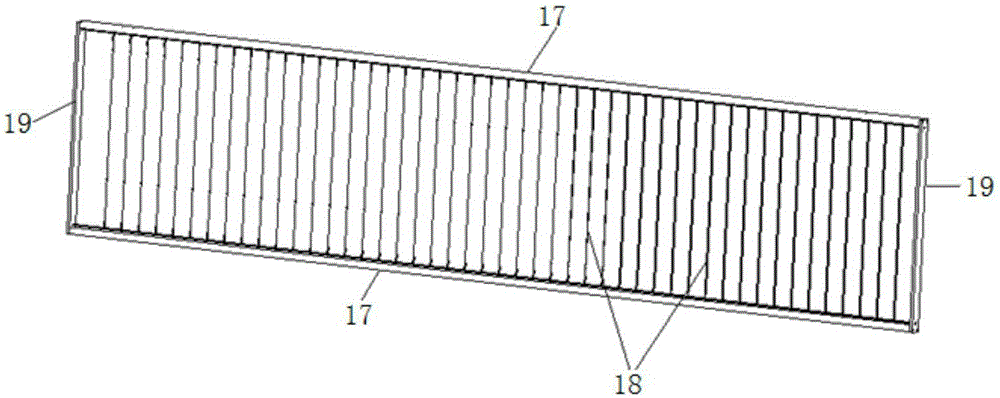

[0025] The present invention is a kind of three-dimensional multilayer air-jet weft insertion loom, the structure is as follows figure 1 , 2 As shown, it includes wallboard a1 and wallboard b2 arranged in parallel, a frame beam 3 for supporting is horizontally arranged between wallboard a1 and wallboard b2, and a horizontally arranged beating-up is supported on wallboard a1 and wallboard b2 Mechanism 4, an open heald frame 5, a weft insertion slay 6 and a closing mechanism 7 are sequentially arranged between the wallboard a1 and the wallboard b2 along the horizontal movement direction of the warp yarn 14, the open heald frame 5, the weft insertion slay 6 and the The closing mechanism 7 is arranged along the vertical direction and the three are parallel to each other. The open heald frame 5 is arranged close to the beating mechanism 4. A yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com