Patents

Literature

193results about How to "Reduce stirring resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

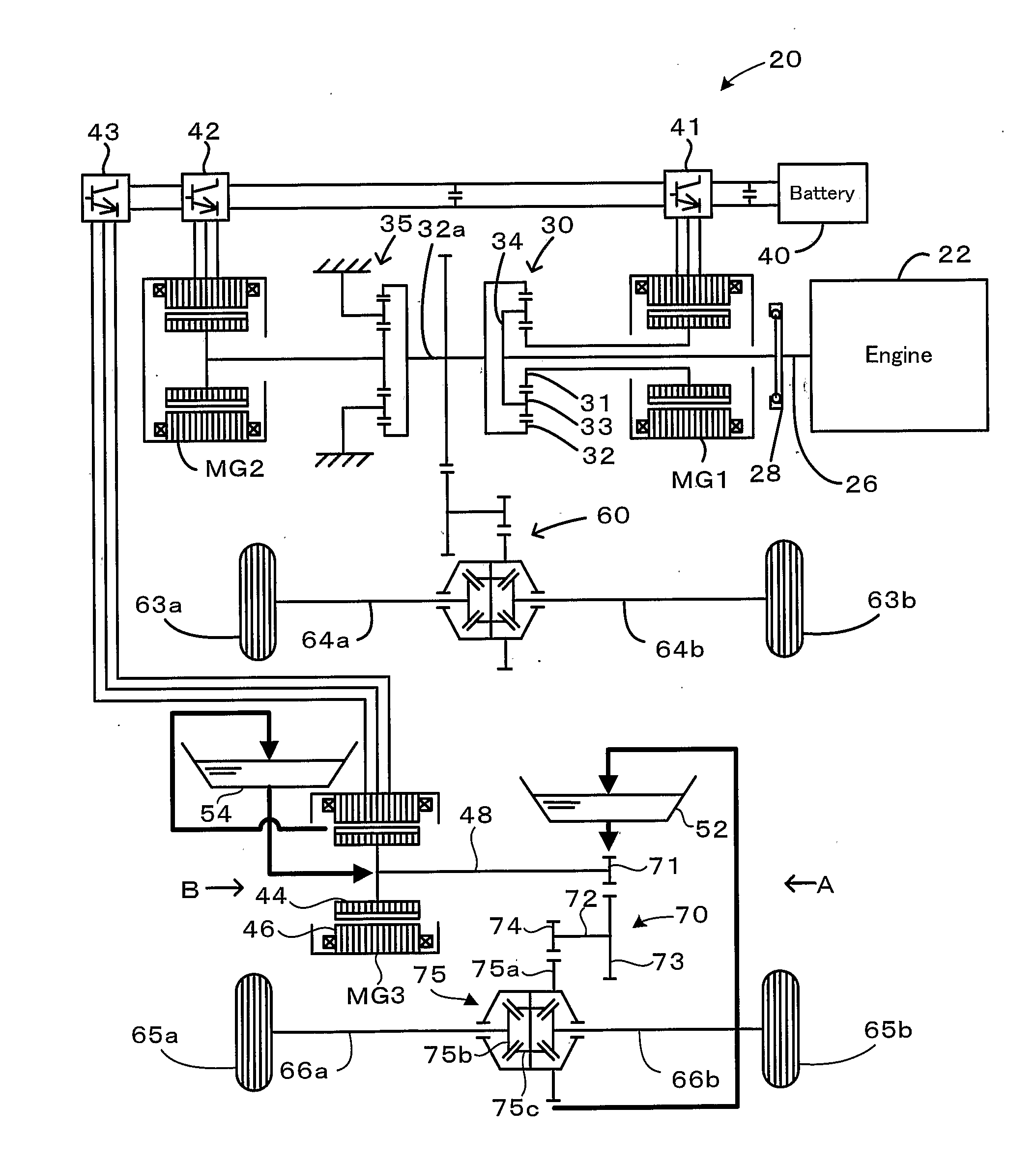

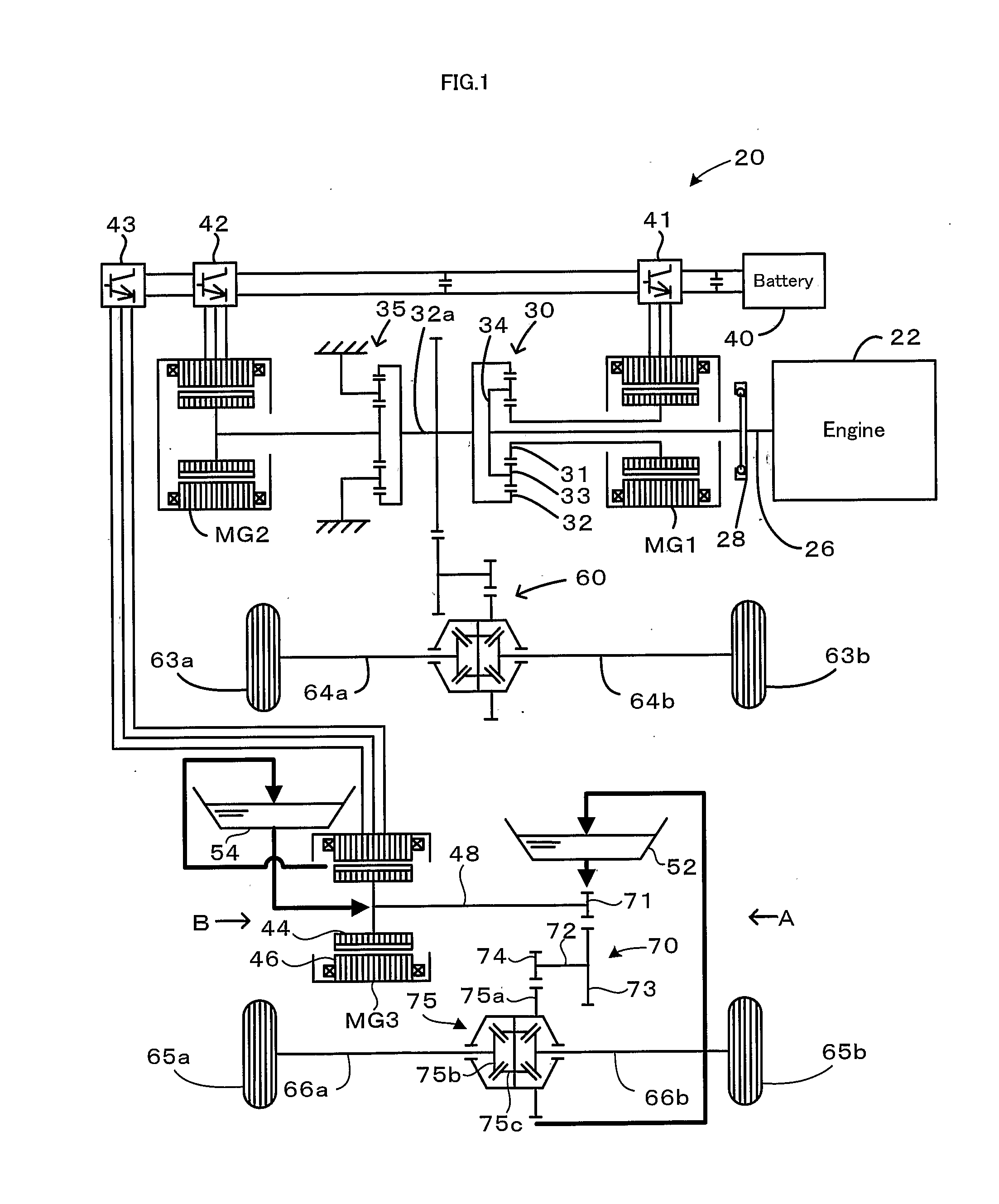

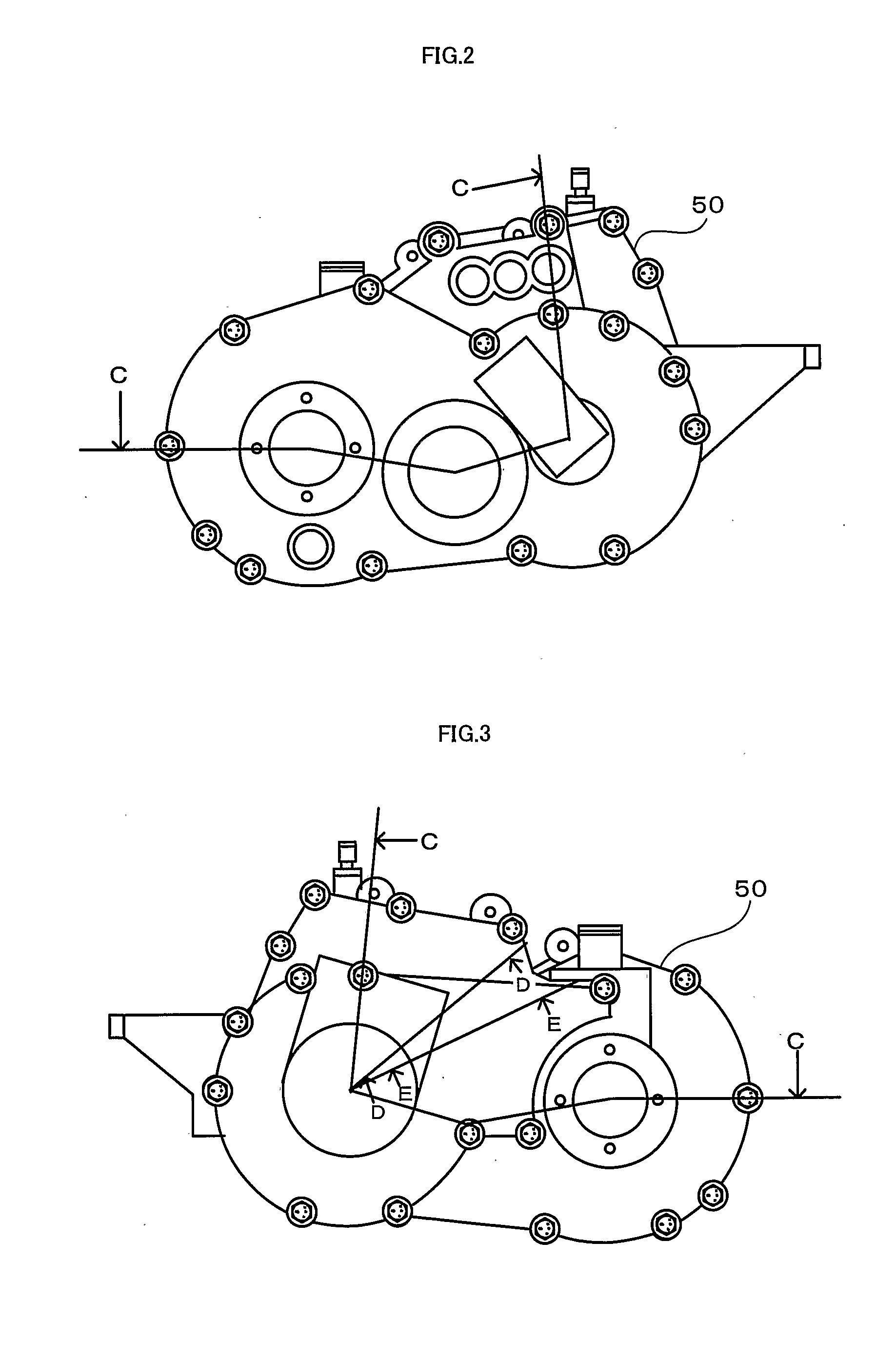

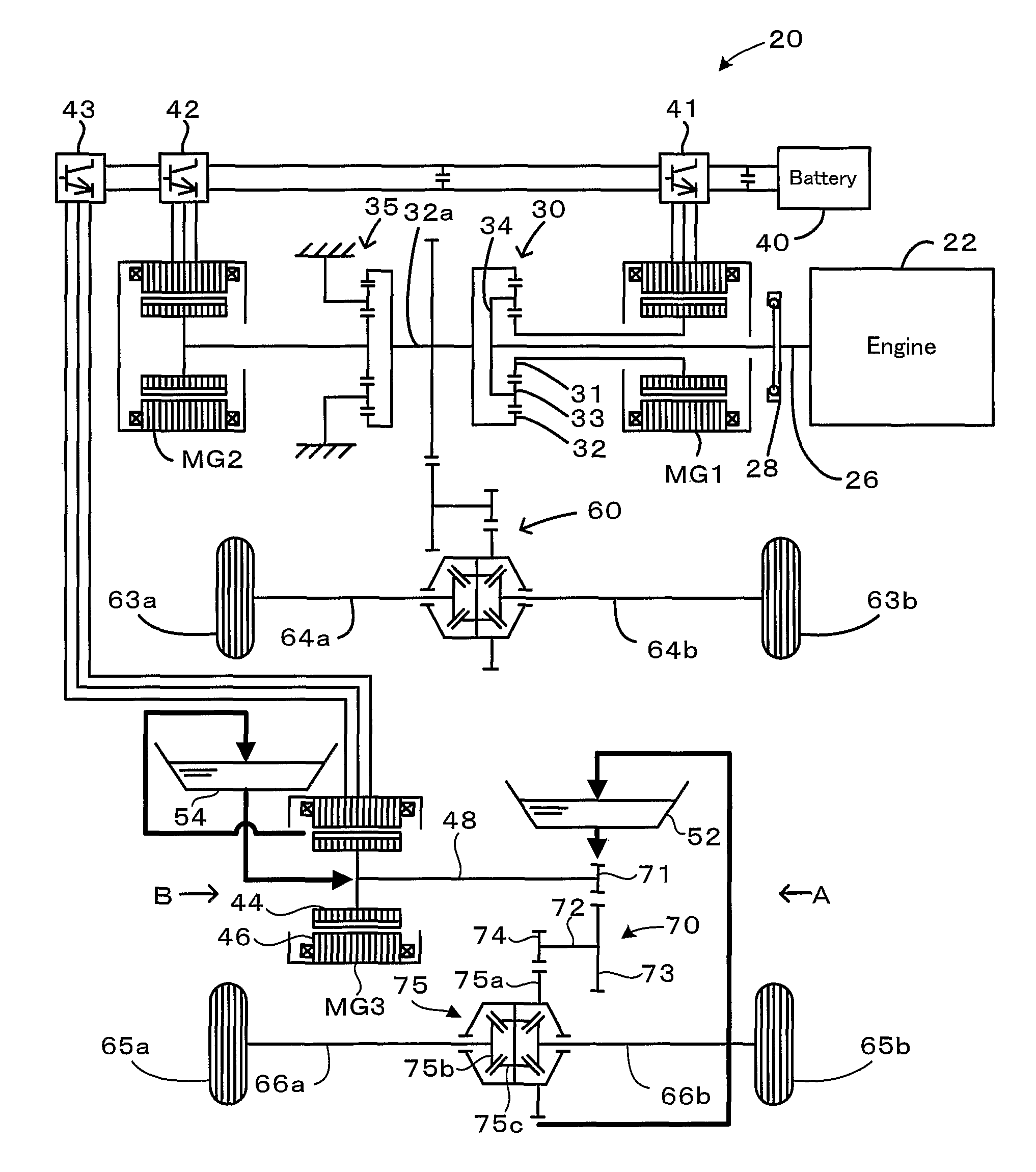

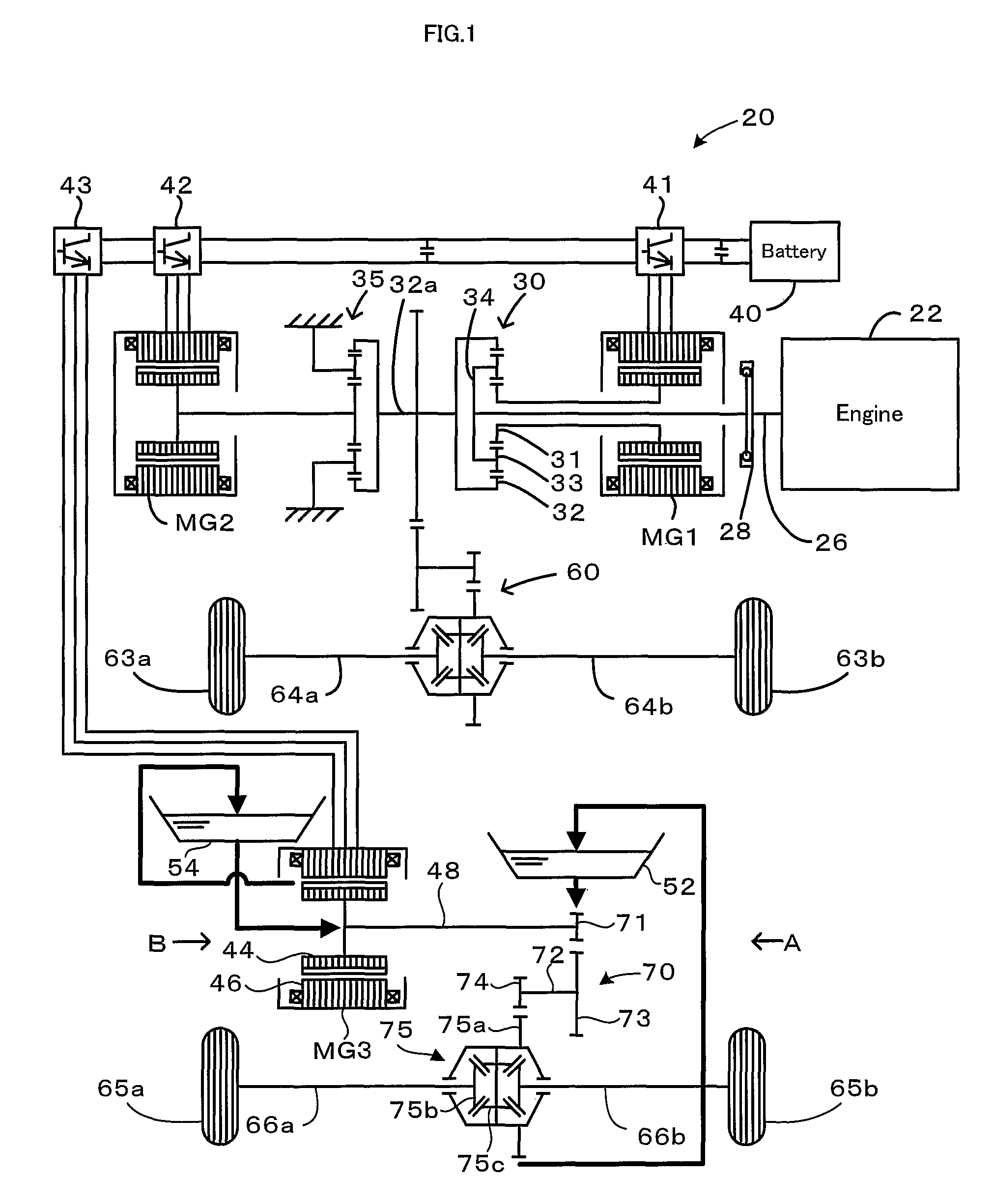

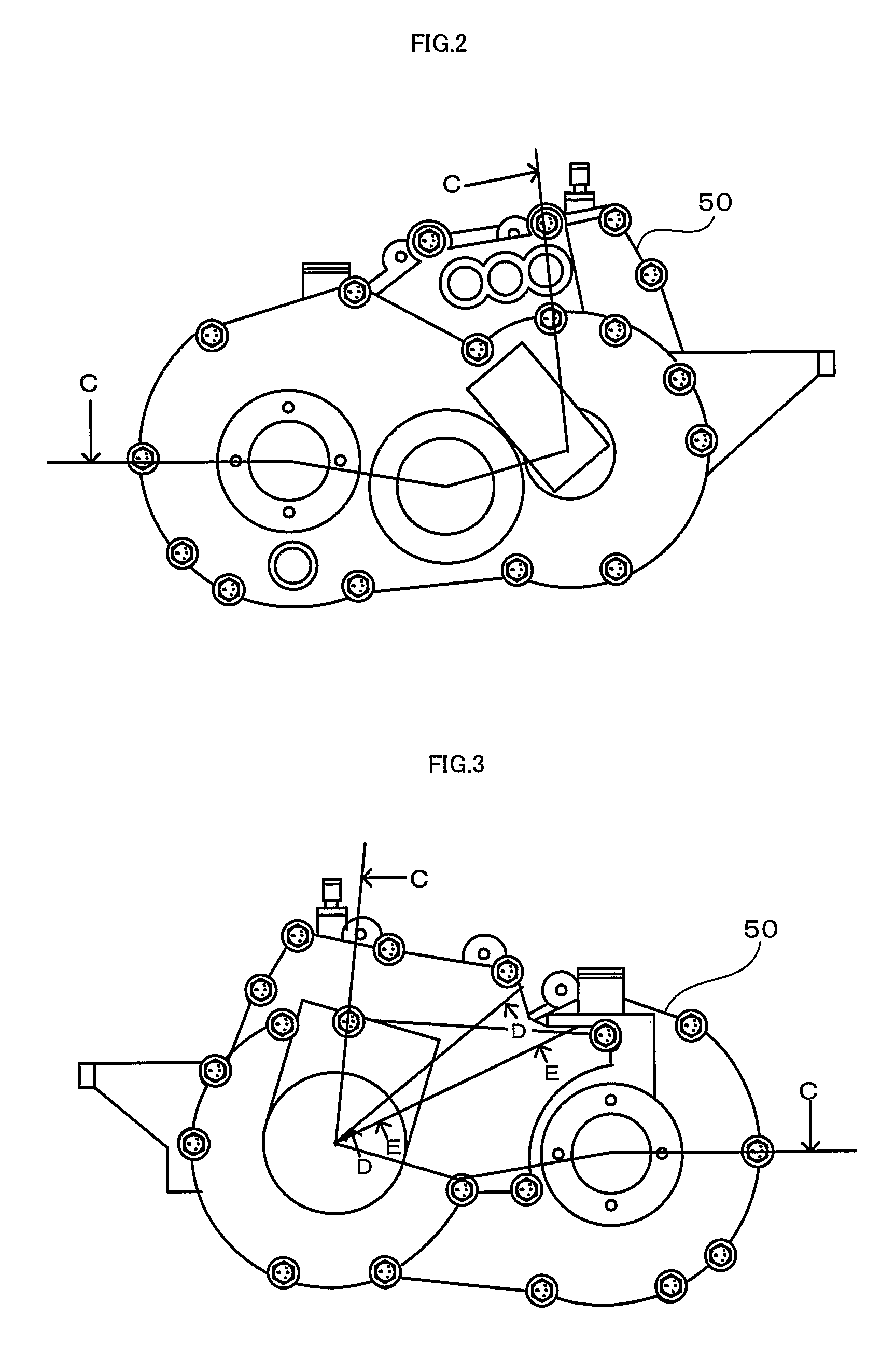

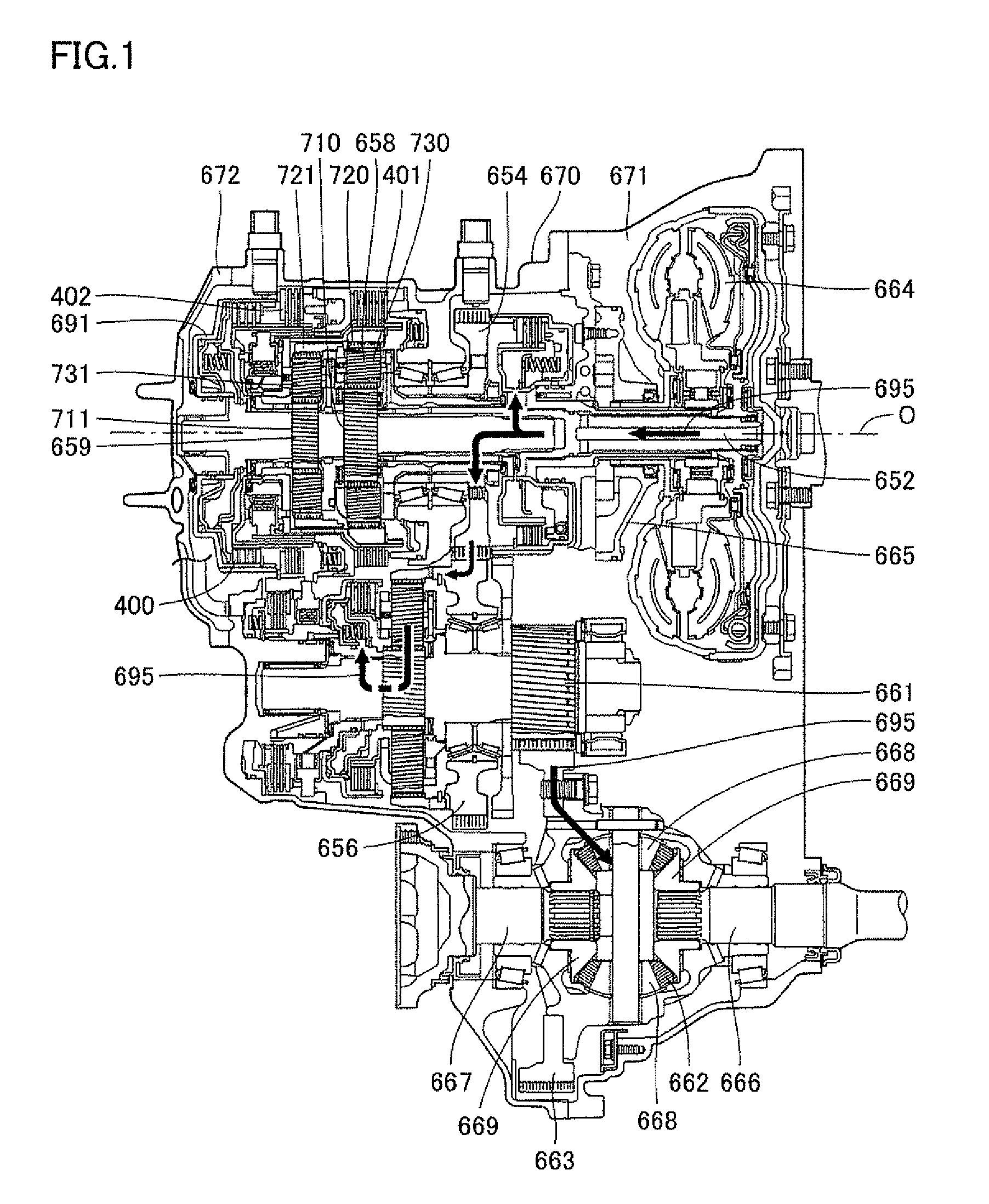

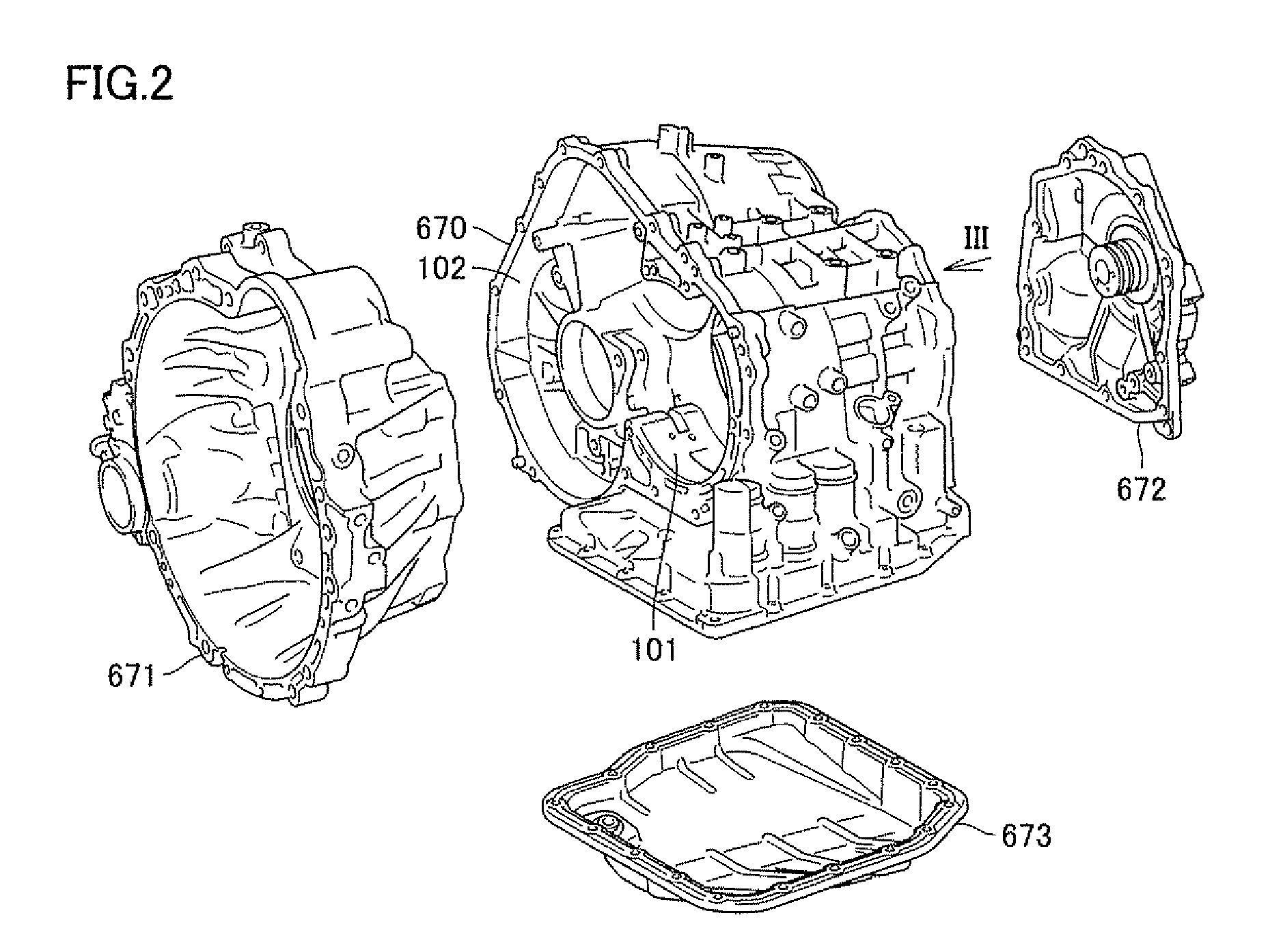

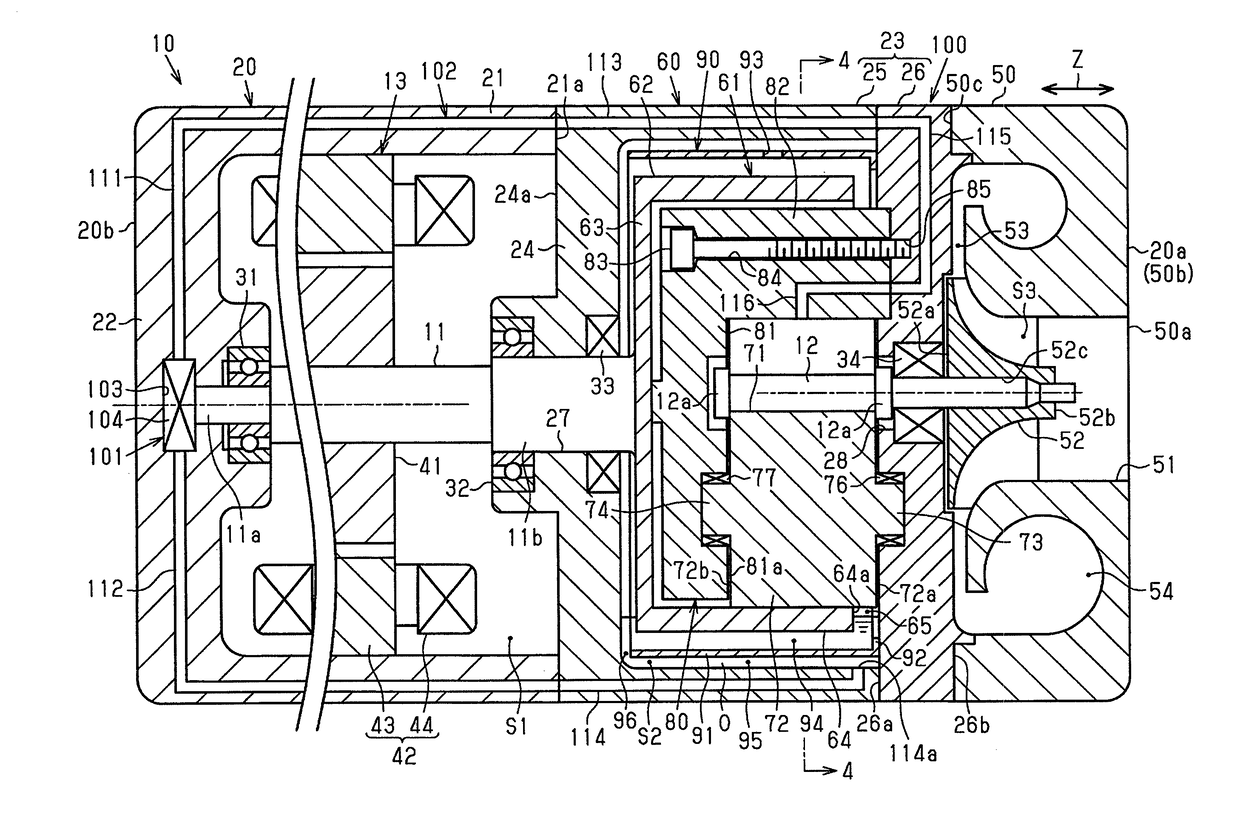

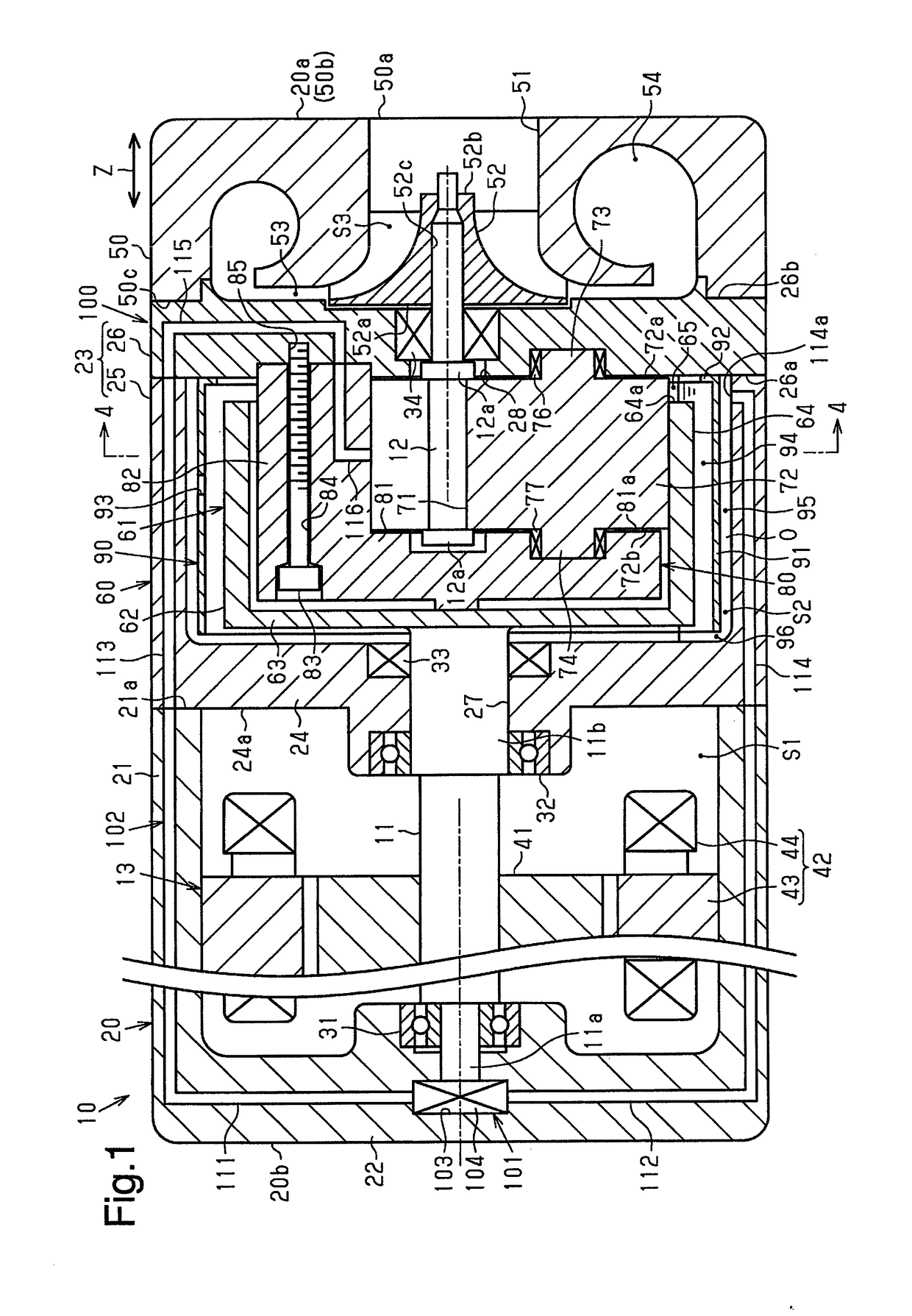

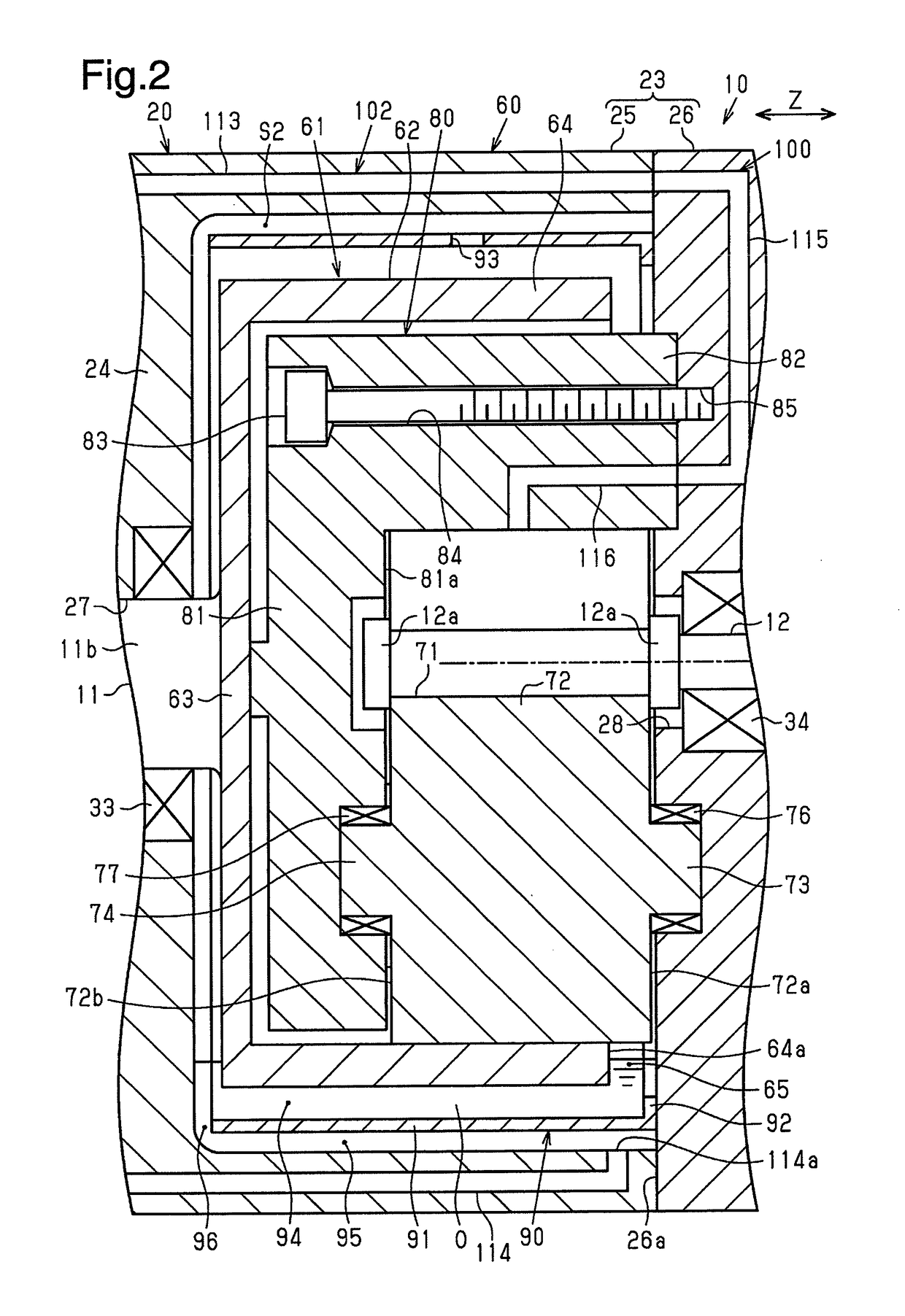

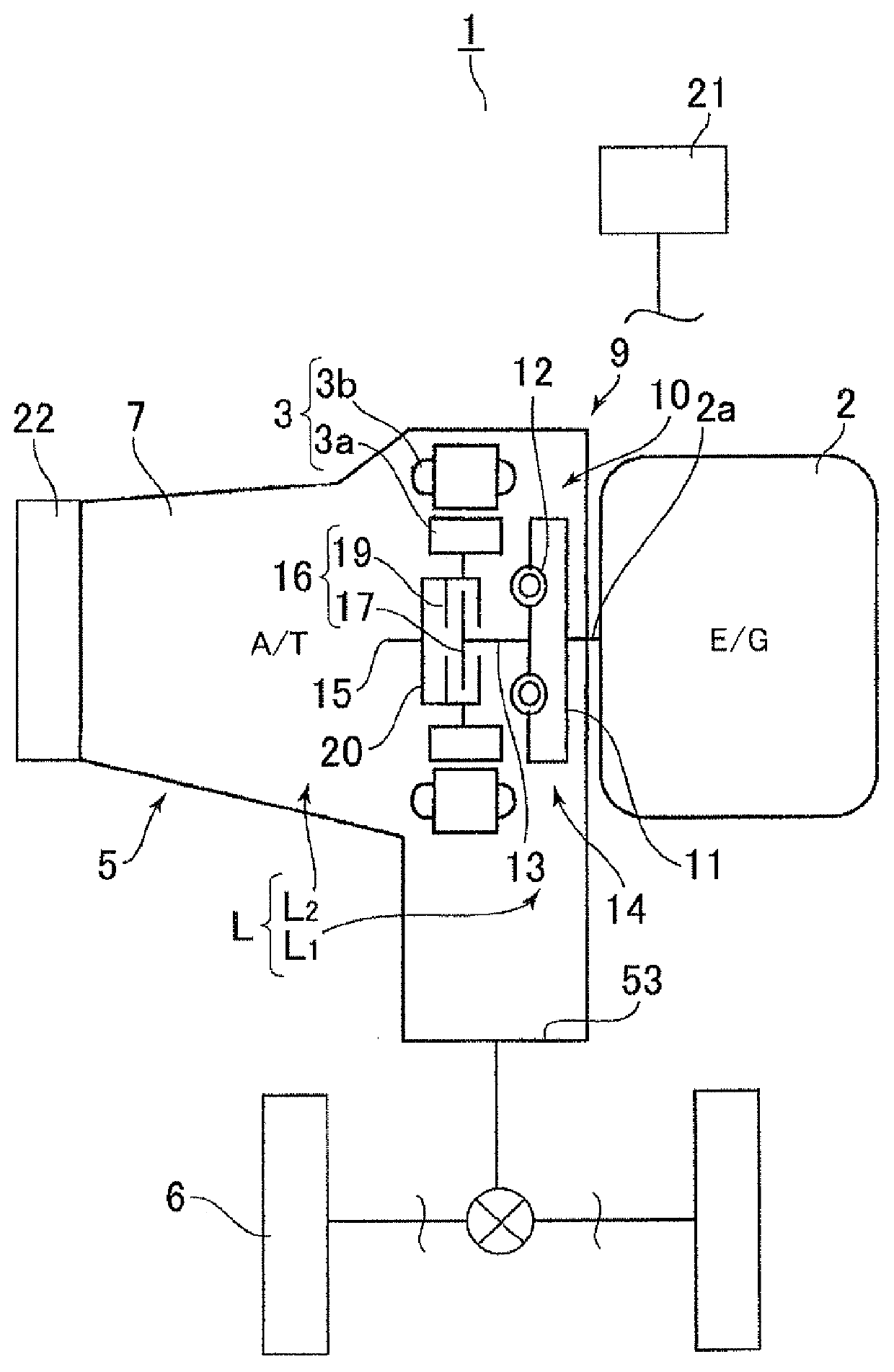

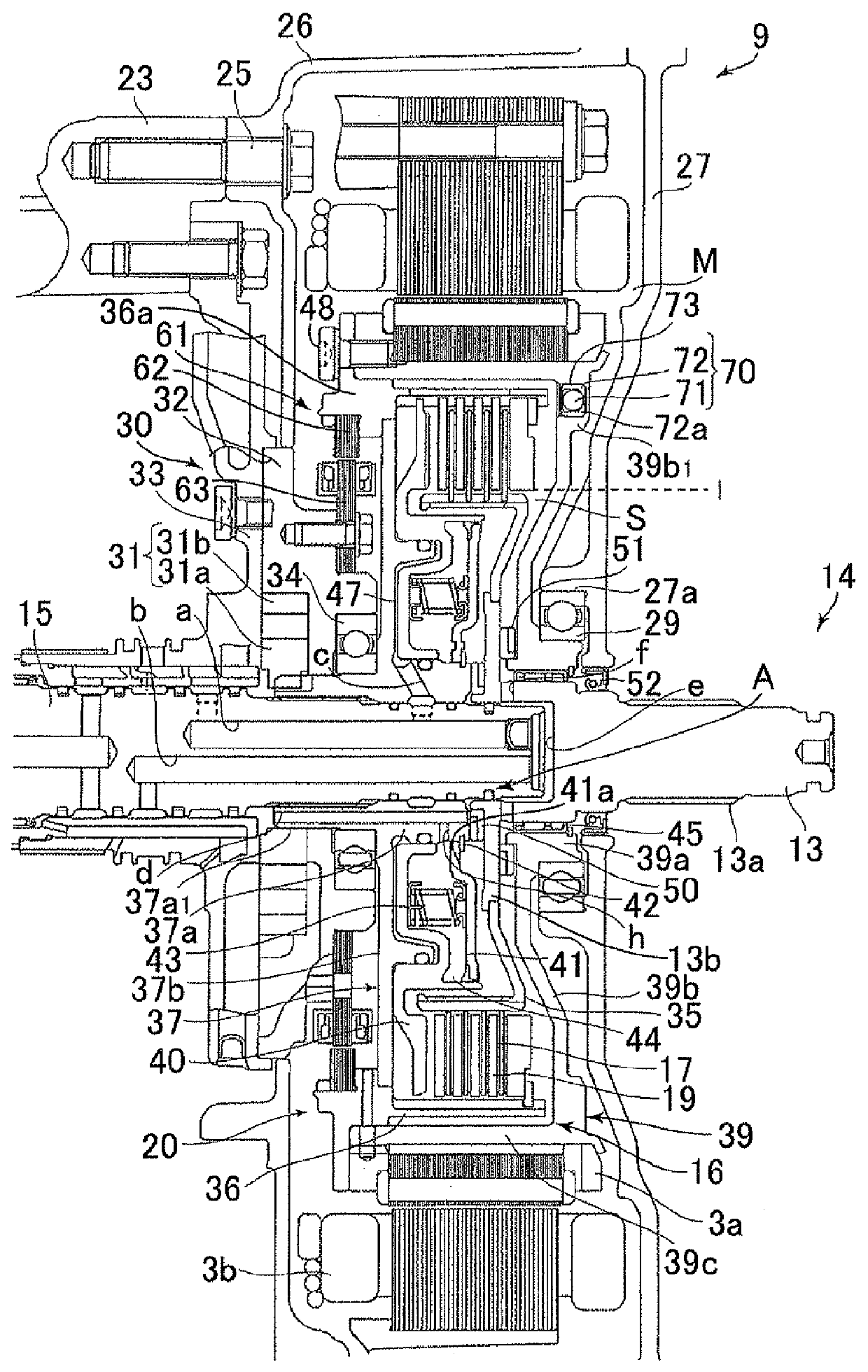

Drive Assembly and Motor Vehicle Equipped with Drive Assembly

ActiveUS20080128208A1Solve insufficient storage spaceSmooth supplyHybrid vehiclesSpeed controllerMobile vehicleEngineering

In a drive assembly of the invention, a first catch tank is provided above a casing that keeps lubricating oil accumulated in a bottom thereof for immersion of part of a rotor of a motor MG3 and of part of a differential ring gear of a differential gear. The first catch tank temporarily keeps the lubricating oil scooped up from the bottom of the casing by the rotation of the differential ring gear. The lubricating oil kept in the first catch tank is flowed down by the force of gravity and is fed to peripheral bearings. A second catch tank is arranged to temporarily keep the lubricating oil scooped up from the bottom of the casing by the rotation of the rotor of the motor MG3. The lubricating oil kept in the second catch tank is flowed down by the force of gravity and is fed to peripheral bearings. This arrangement desirably shortens oil paths connecting the respective catch tanks to the peripheral bearings and ensures smooth supply of the lubricating oil to all the peripheral bearings and other oil-requiring sites.

Owner:TOYOTA JIDOSHA KK

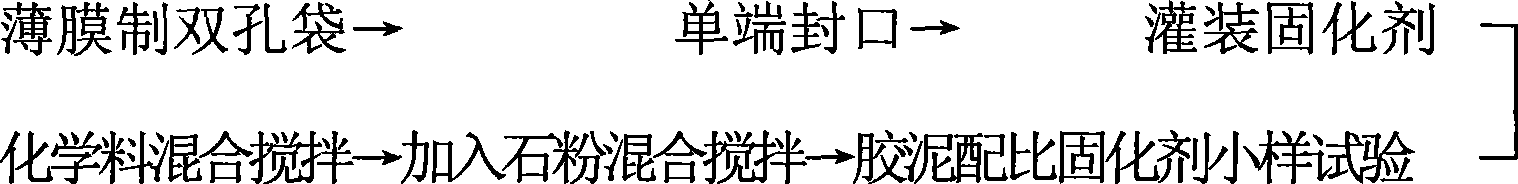

Resin mastic cement for anchorage agent and anchorage agent thereof

InactiveCN101508540AReduce consistencyHigh compressive strengthAnchoring boltsDimethylaniline N-oxideCompressive strength

The invention relates to an anchoring agent, which is resin mortar for an anchoring agent and the anchoring agent, and is used for anchoring large-diameter anchor cables used in the construction of the support of coal mine roadways and the protection of underground engineering. The resin mortar comprises the following compositions in portion by mass: 800 to 1,200 portions of MG unsaturated polyester resin, 4,000 to 6,000 portions of limestone powder, 3 to 10 portions of dimethylaniline, and 6 to 12 portions of white carbon black, wherein the particle size of the limestone powder is between 80 and 120 meshes. The resin mortar and a curing agent form a bi-component anchoring agent. The anchoring agent can effectively reduce the consistency of the resin mortar, and improve the compressive strength after the solidification of the anchoring agent, thereby realizing the effects during the use such as high adhesive force, low stirring resistance and the like; and the anchoring agent meets the requirement of using large-diameter and high-strength anchor cables in the support of the coal mine roadways, reduces anchoring length, construction time and construction personnel, and improves the production efficiency.

Owner:晋城宏圣科威矿用材料有限公司

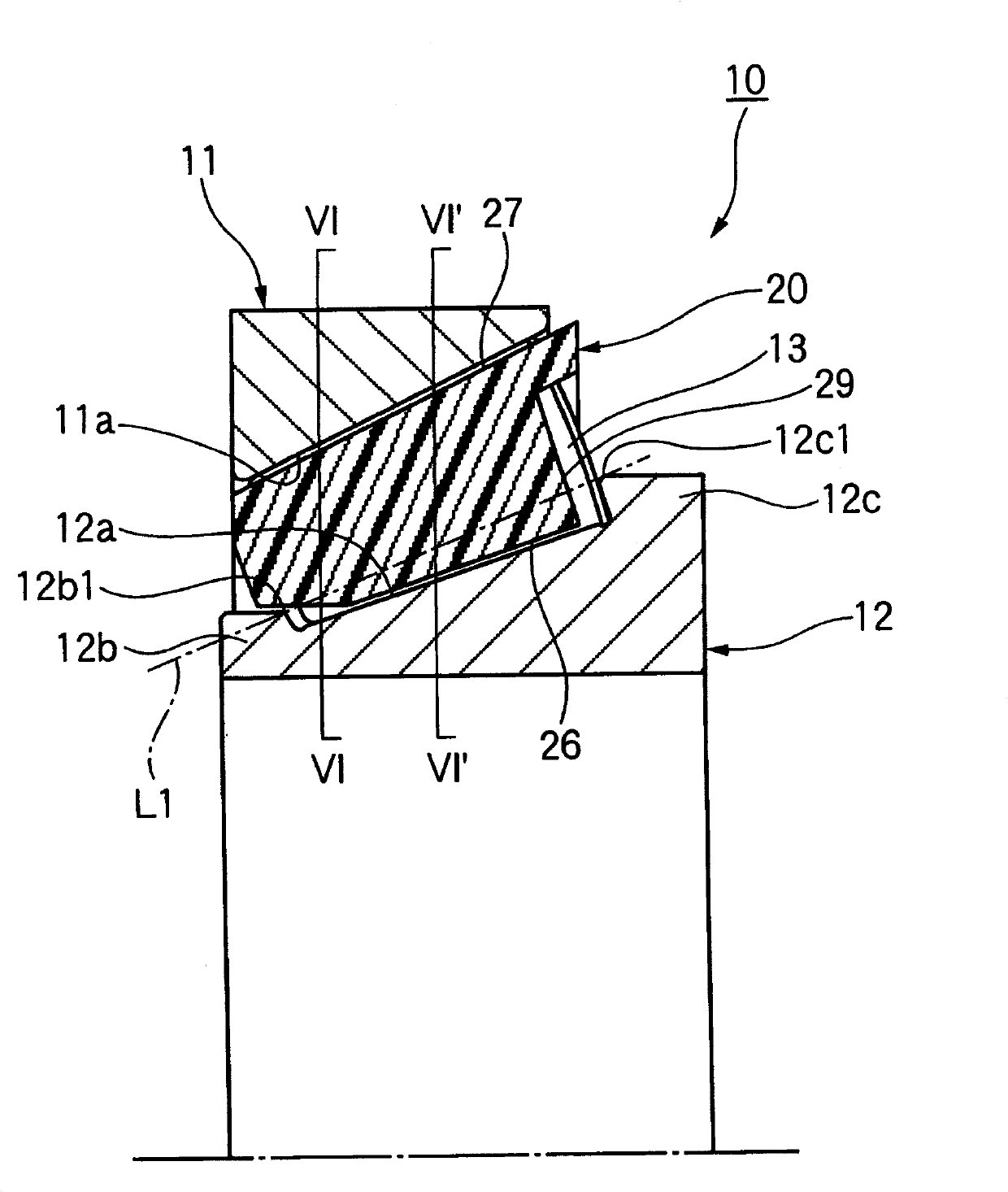

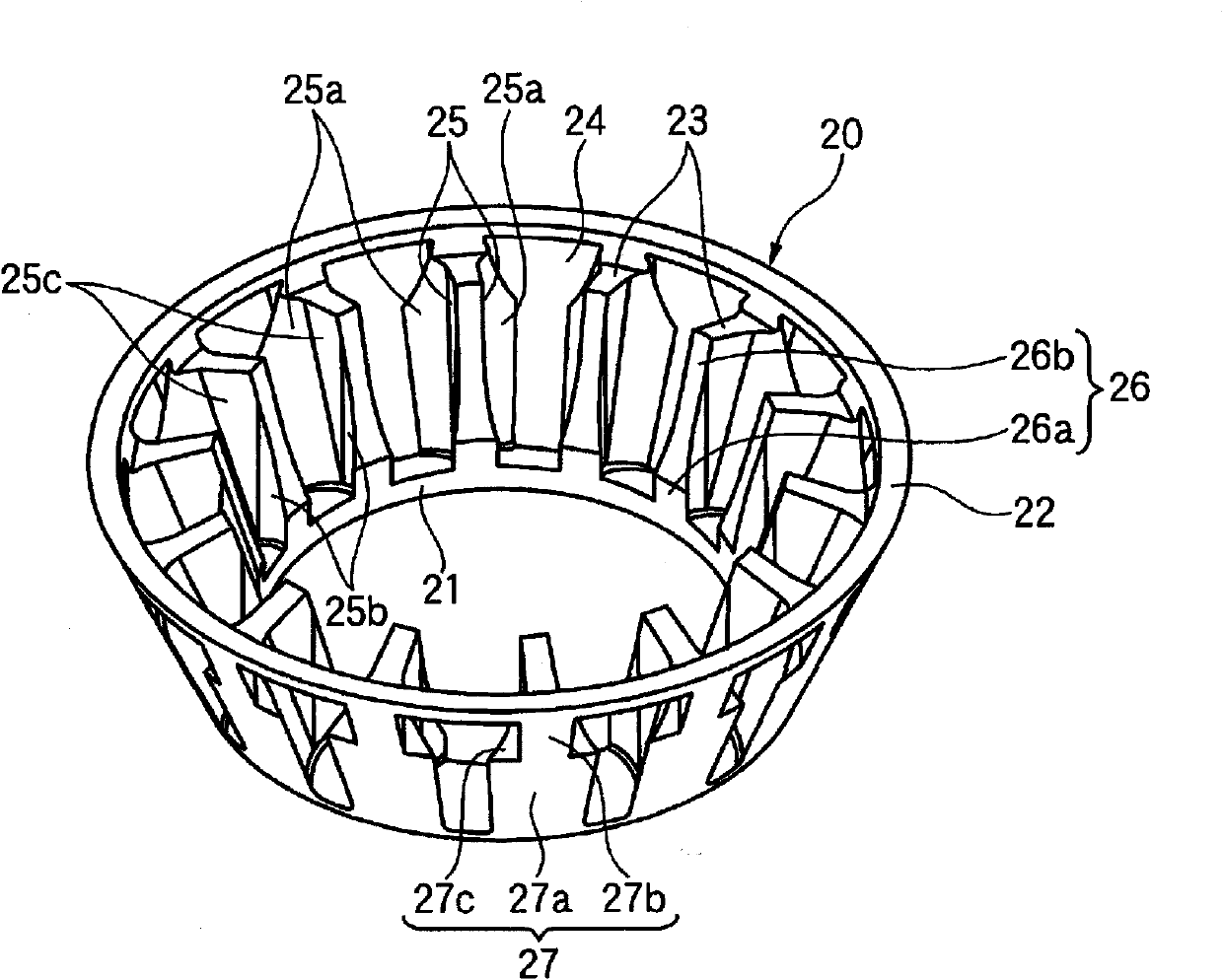

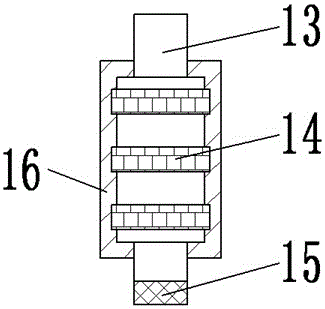

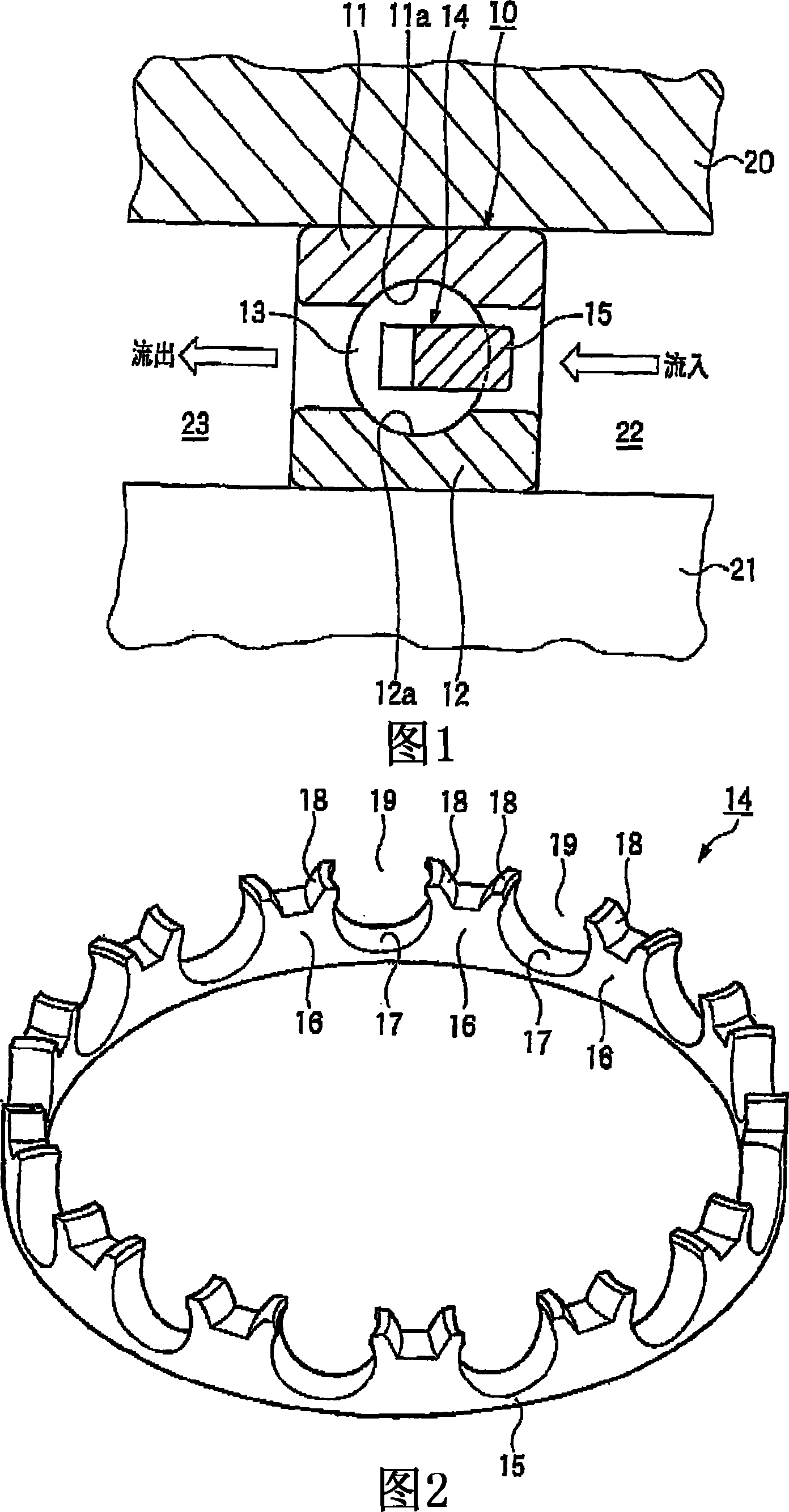

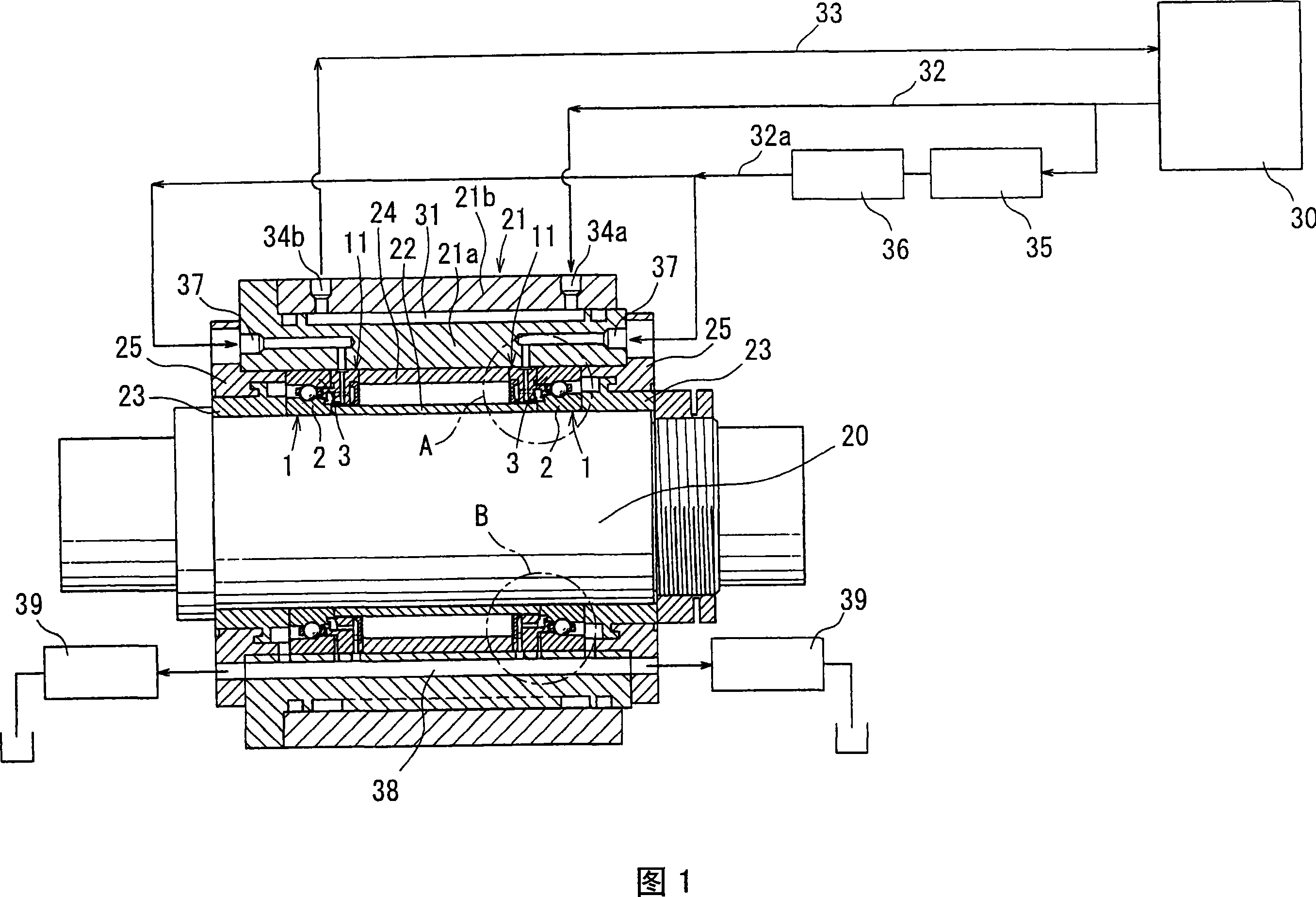

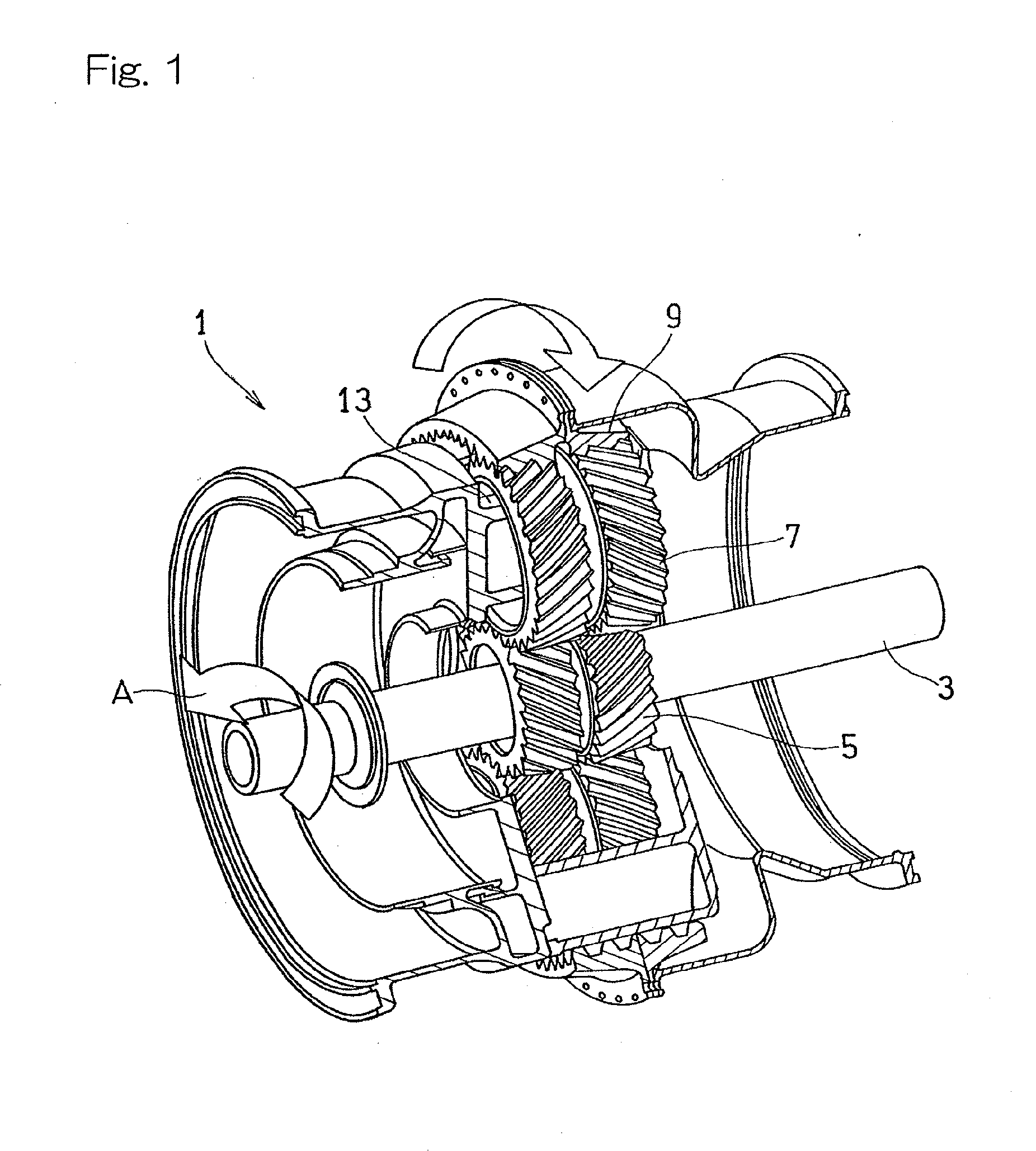

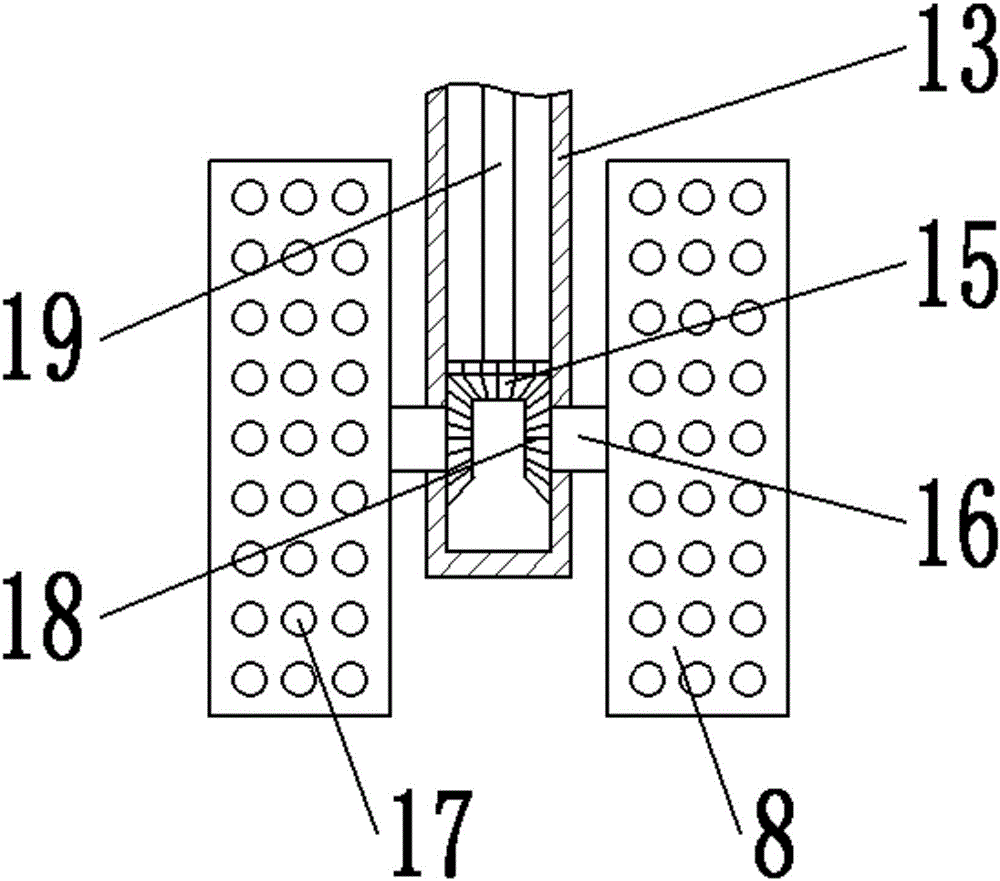

Resin retainer for tapered roller bearing, and tapered roller bearing

ActiveCN102089541AReduce stirring resistanceImproves ease of installationRoller bearingsShaftsEngineeringMechanical engineering

A resin retainer for a tapered roller bearing and the tapered roller bearing which are configured such that a space in the tapered roller bearing is reduced, stir resistance of lubricating oil contained in the bearing is reduced, and easiness of mounting of tapered rollers into the bearing is enhanced. A resin retainer (20) for a tapered roller bearing is provided with a small-diameter annular section (21), a large-diameter annular section (22), and struts (23) for interconnecting both the annular sections (21, 22). The struts (23) are each provided with a pair of circumferential side surfaces (25) respectively having roller guide surfaces (27), and also each provided with an inner peripheral surface (26) having a circumferential width smaller on the large-diameter annular section (22) side than on the small-diameter annular section (21) side. Between adjacent struts (23) is provided a retaining region (Ar) having, between the opposed circumferential side surfaces (25) of the adjacent struts (23), an outer-diameter-side pocket width (W1) and an inner-diameter-side pocket width (W2) which are set less than a diameter (D) of the tapered rollers.

Owner:NSK LTD

Lube base oil, lubricating oil composition for internal combustion engine, and lubricating oil composition for drive transmission device

InactiveCN101379171AExcellent viscosity-temperature characteristicsReduce energy lossBase-materialsMeth-Chemical composition

A lube base oil satisfying at least one of the following requirements (a) and (b). A lubricating oil composition for internal combustion engines is provided which comprises the lube base oil, an ash-free antioxidant containing no sulfur as a constituent element, and at least one member selected among ash-free antioxidants containing sulfur as a constituent element and organ omolybdenum compounds. Also provided is a lubricating oil composition for drive transmission devices which comprises the lube base oil, a poly(meth)acrylate-type viscosity index modifier, and a phosphorus compound. (a) The content of saturated matters is 90 mass% or higher and the proportion of cyclic saturated matters in those saturated matters is 10-40 mass%. (b) The lube base oil satisfies the relationship represented by the following expression (1). 1.440=n20-0.002OEv100=1.453 (1) [In the expression, n20 indicates the refractive index at 20 DEG C of the lube base oil and kv100 indicates the dynamic viscosity (mm2 / s) at 100 DEG C of the lube base oil].

Owner:NIPPON OIL CO LTD +1

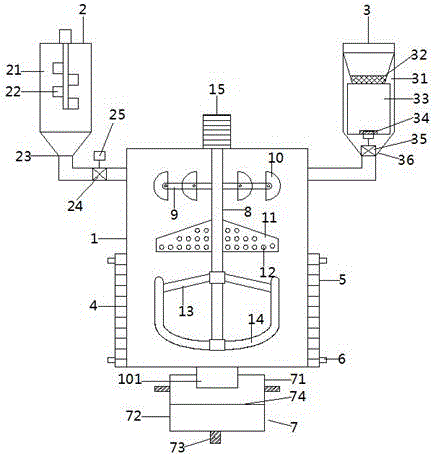

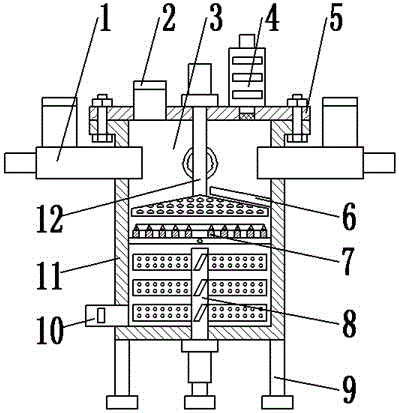

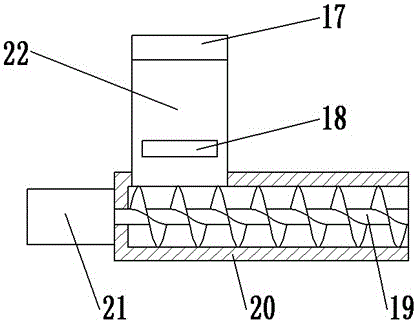

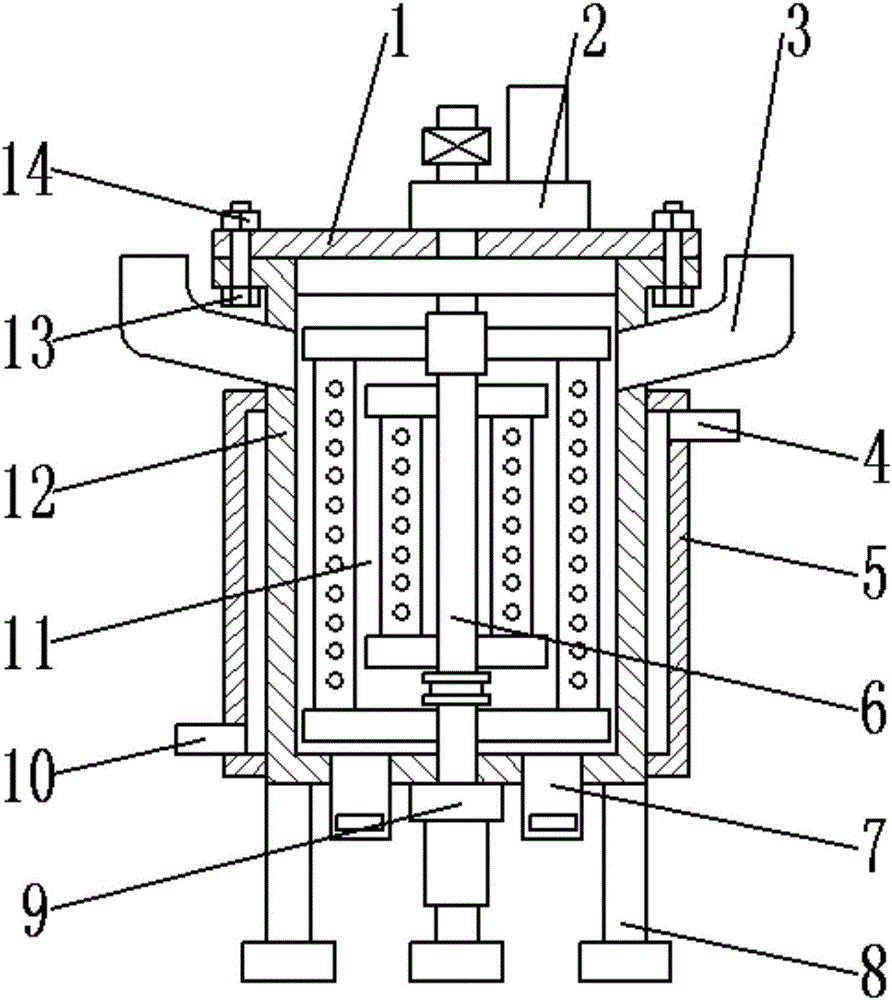

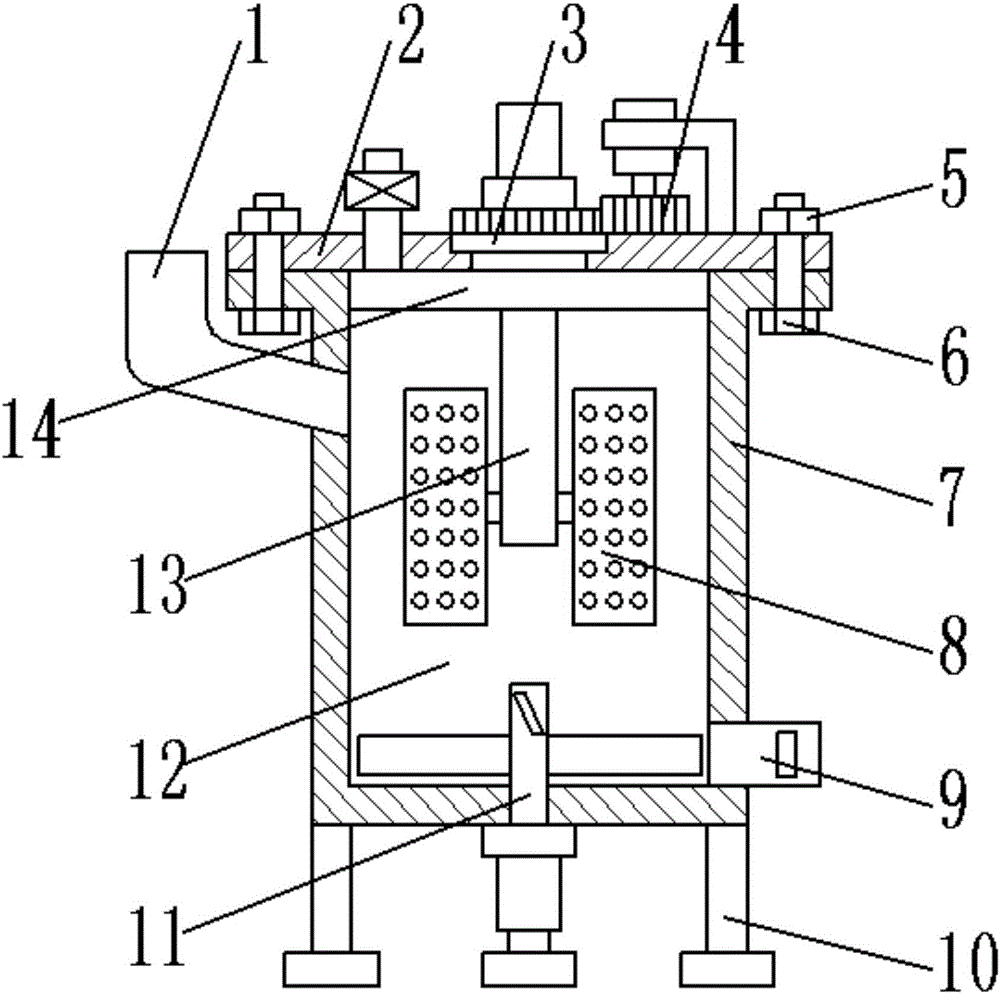

High-performance reactor with quantitative feeding mechanism

InactiveCN106040156ASave human resourcesIncrease productivityRotary stirring mixersTransportation and packagingEngineeringRaw material

The invention discloses a high-performance reactor with a quantitative feeding mechanism, comprising a body. The top end of the left outer wall of the body is provided with a particles feeding port, the upper left and right of the body are provided with a particles feeding device and a powder feeding device respectively, the particles feeding device comprises a particles storage bucket, a stirring device mounted in the particles storage bucket, a particles discharge tank and an intelligent meter. The high-performance reactor with a quantitative feeding mechanism can automatically finish a feeding process and enables raw materials to be automatically and intelligently rationed and weighed, production efficiency is effectively improved, production cost is reduced, material in the body is stirred by using three stirring mechanisms arranged from top to bottom, stirring efficiency is greatly improved, and stirring effect is guaranteed; a collection pit and a screen arranged at the bottom of the body can separate the material and impurities, the quality of the material is guaranteed, and in addition, a heat transfer coefficient of a reactor stirrer can be promoted.

Owner:李明波

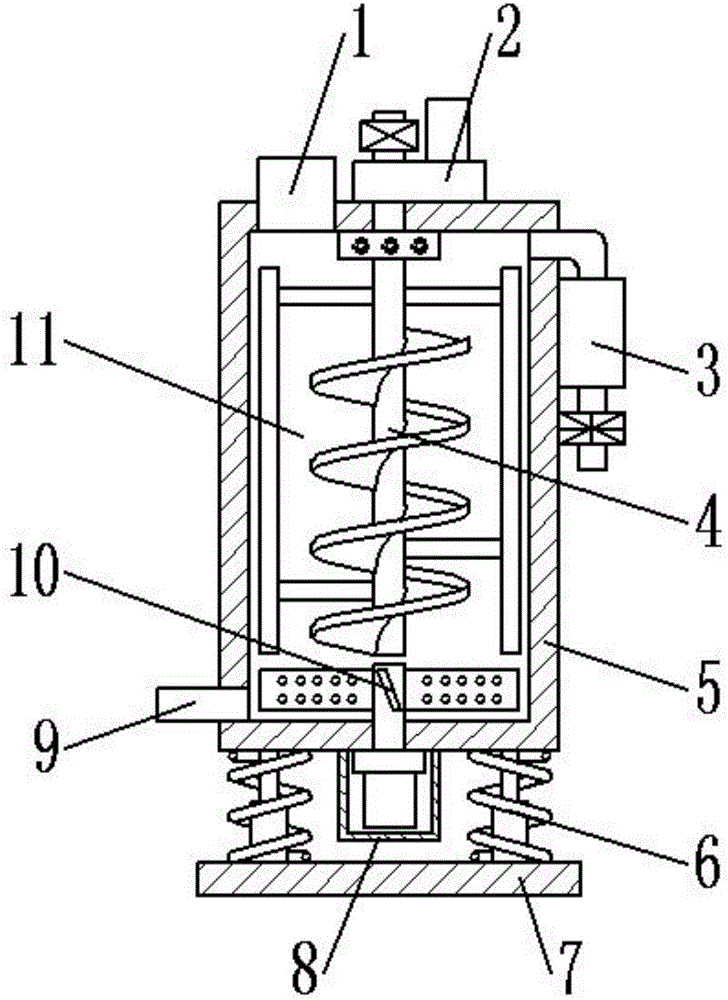

Vibration damping type dust-removing and high-efficiency bidirectional stirring equipment

InactiveCN106345342AWell mixedQuality improvementRotary stirring mixersTransportation and packagingBiochemical engineeringWater pipe

The invention provides vibration damping type dust-removing and high-efficiency bidirectional stirring equipment. The vibration damping type dust-removing and high-efficiency bidirectional stirring equipment comprises a tank body, wherein a stirring cavity is formed inside the tank body; a feeding pipe and a water adding and driving device are arranged at the top of the tank body; the water adding and driving device consists of a driving box, a rotating motor, a water inlet pipe and a rotational spraying tray; a first stirring device and a second stirring device are arranged in the stirring cavity; the first stirring device consists of a first stirring shaft, spiral stirring blades and a scraper plate; the second stirring device is arranged at the bottom of the tank body and consists of a stirring motor, a second stirring shaft and stirring blades; a dust remover is arranged on the side wall of the top of the tank body; a discharging pipe is arranged on the side wall of the bottom of the tank body; the bottom surface of the tank body is connected with a base plate through a vibration damping device. According to the vibration damping type dust-removing and high-efficiency bidirectional stirring equipment provided by the invention, the water adding and driving device facilitates the mixing of materials; in addition, after use, the tank body is cleaned; by means of the first stirring device and the second stirring device, sufficient mixing of the materials is facilitated, and the quality of a product is improved.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

Lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities

InactiveCN106732040AAvoid pollutionAvoid non-conformitiesDispersed particle filtrationTransportation and packagingEngineeringScrew conveyor

The invention provides lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities. The equipment comprises a tank body and an upper cover, a mixing cavity is formed inside the tank body, an auxiliary feeding pipe and a filtering device are arranged on the upper cover, the filtering device is composed of an exhausting pipe and a filtering tank, and a feeding device is arranged on the side wall of the top of the tank body and composed of a feeding pipe, a feeding screw conveyor, a feeding motor and a material storing tank; a material guiding device, an impurity removing device and a stirring device, the material guiding device is composed of a material guiding motor, a rotating shaft and a material guiding disc, the impurity removing device is composed of multiple concentric electromagnetic rings, and the stirring device is composed of a stirring motor, a stirring shaft and stirring pieces. Raw material dust is prevented from directly causing dust pollution through the filtering device, and recycling of the raw material dust is facilitated, so that unqualified products caused by unbalanced proportion is prevented; mixing degree of raw materials is increased through the stirring device, so that the raw materials are mixed more uniformly.

Owner:SHENZHEN JUOCAN TECH CO LTD

Ball bearing and supporting construction

InactiveCN101235851AReduce resistanceReduce stirring resistanceBearing componentsEngineeringRadial clearance

A ball bearing has an inner ring fitted on a rotational shaft and including an inner ring raceway on an outer circumferential surface thereof, an outer ring including an outer ring raceway on an inner circumferential surface thereof, a plurality of balls rotatably provided between the inner ring raceway and the outer ring raceway and a crown resin cage for retaining the balls at equal intervals in a circumferential direction. A bore diameter of the inner ring is 100 mm or more, and a radial clearance resulting in a state that the inner ring is assembled to the rotational shaft is 20 mu m or more.

Owner:NSK LTD

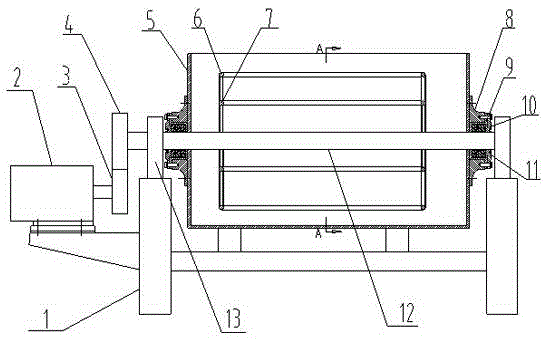

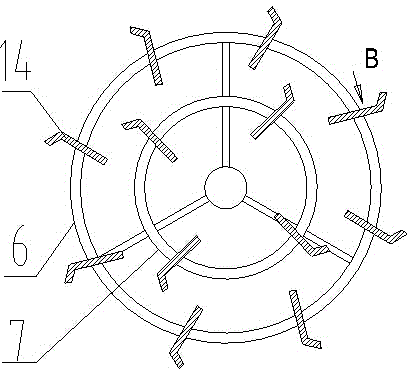

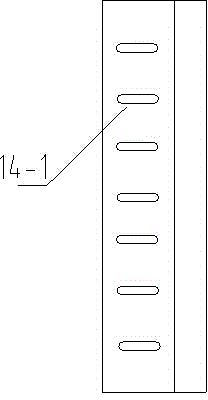

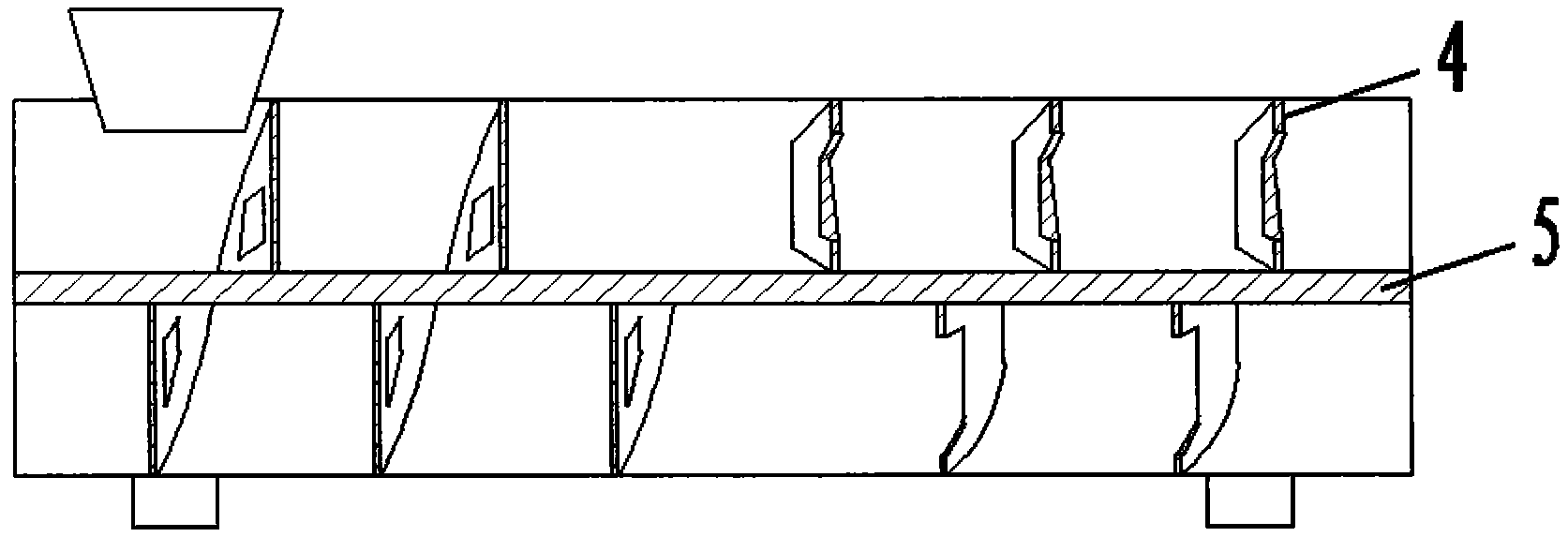

Horizontal mortar mixer

InactiveCN104827568AStir wellImprove mixing uniformityCement mixing apparatusEngineeringMechanical engineering

The invention relates to a horizontal mortar mixer, which comprises a rack, a stirring box, a stirring shaft and a driving device. The stirring shaft runs through the stirring box rotatably, two ends of the stirring shaft extend out of the stirring box and supports a corresponding bearing therein, the bearing is supported by the rack, and the extension ends of the stirring shaft both and the stirring box are installed in seal fit through a sealing device. One end of the stirring shaft is driven by the driving device, the positions close to both ends on the stirring shaft are respectively provided with a large and a small concentric ring, the two large rings have a same diameter, the two small rings have a same diameter, the two large rings are connected by eight stirring blades, and the two small rings are connected by four stirring blades, the stirring blades are all angular bending plates with obtuse included angle, the opening direction of the included angle and the rotating direction of the stirring shaft are the same, the length direction of the stirring blades is parallel to the stirring shaft, and the stirring blades are provided with a plurality of waist type holes. The horizontal mortar mixer provided by the invention has the advantages of uniform stirring and energy saving.

Owner:LUOYANG INST OF SCI & TECH

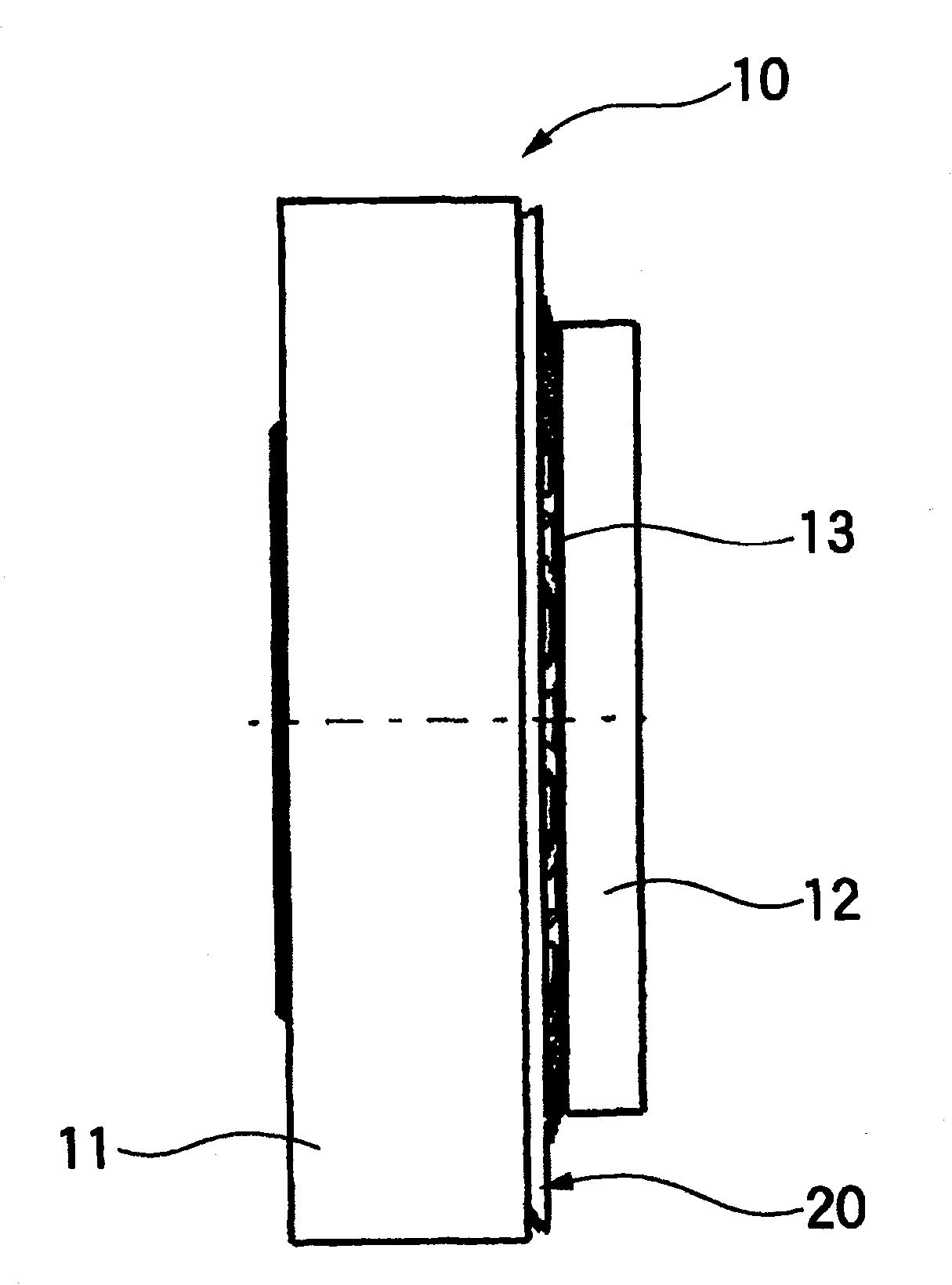

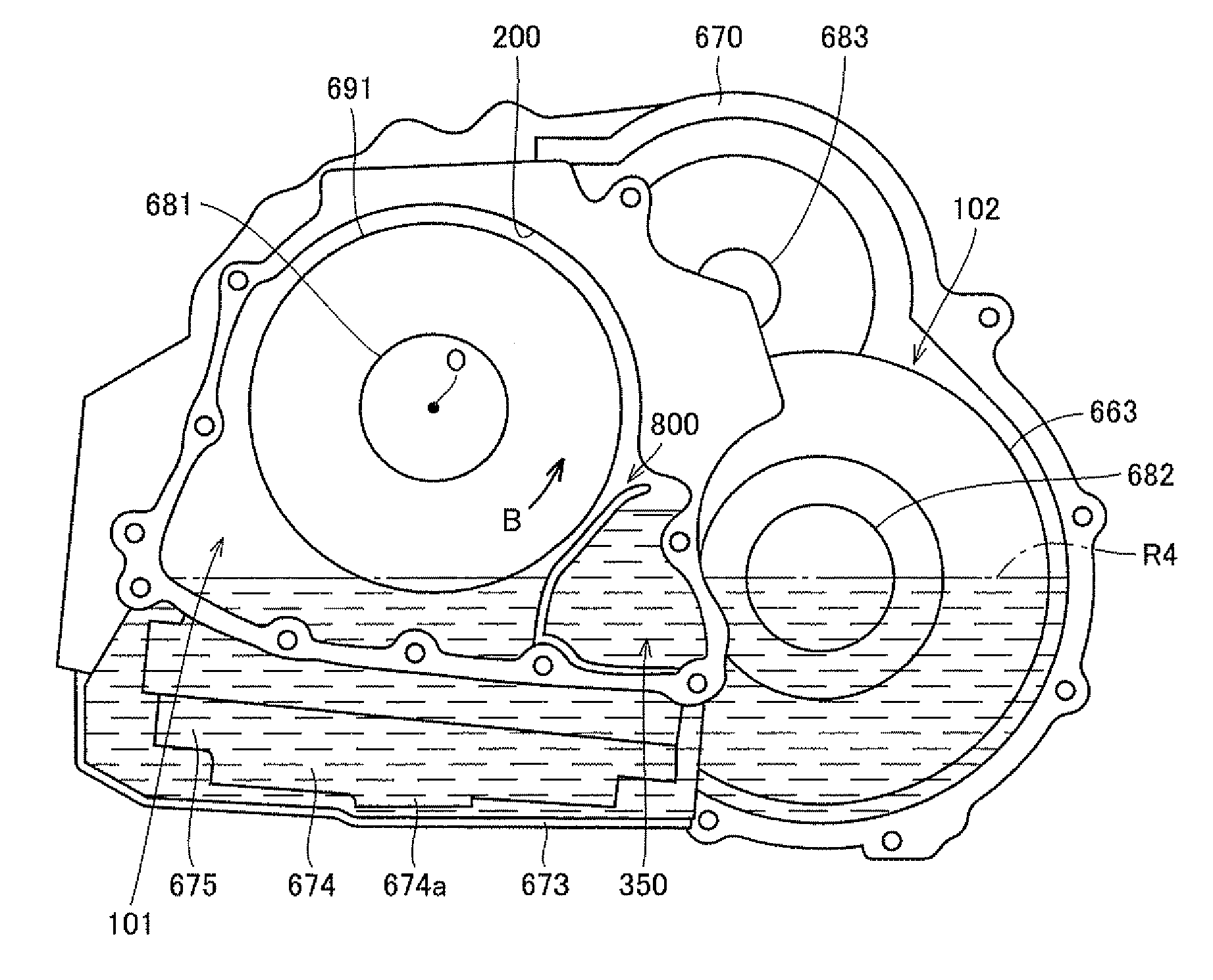

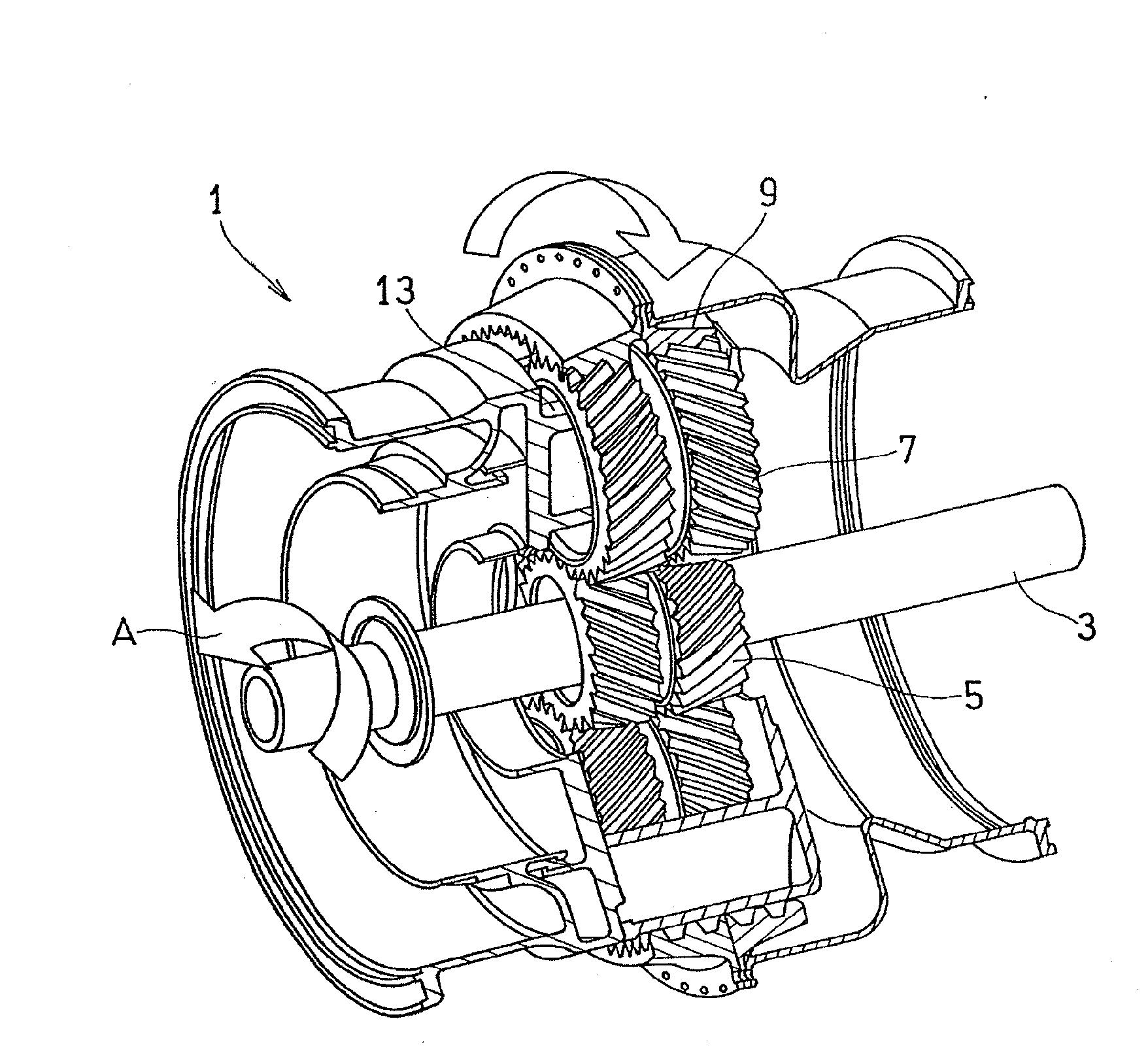

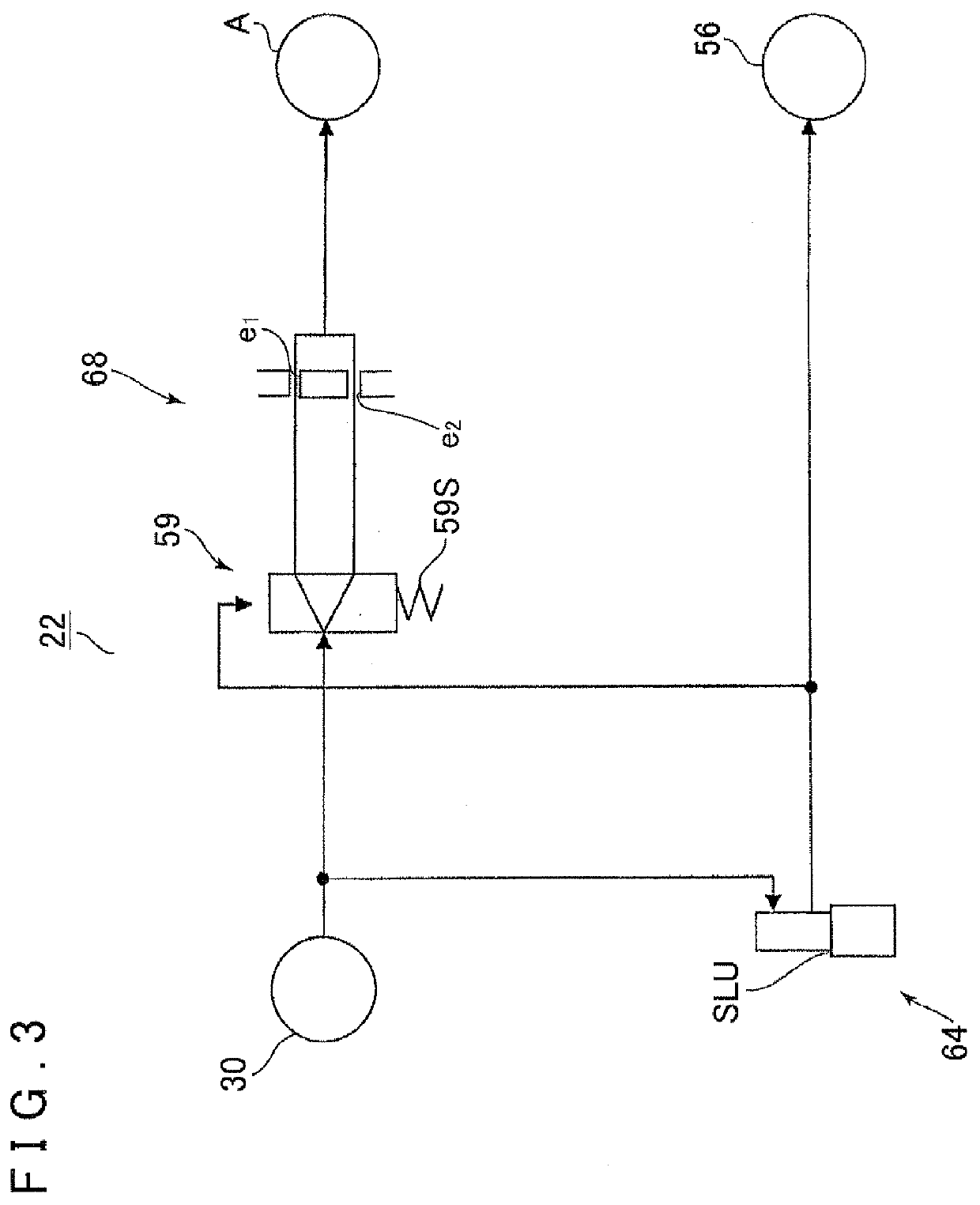

Drive assembly and motor vehicle equipped with drive assembly

ActiveUS8267223B2Restricts size and shapeImprove the level ofHybrid vehiclesSpeed controllerEngineeringElectric motor

In a drive assembly of the invention, a first catch tank is provided above a casing that keeps lubricating oil accumulated in a bottom thereof for immersion of part of a rotor of a motor MG3 and of part of a differential ring gear of a differential gear. The first catch tank temporarily keeps the lubricating oil scooped up from the bottom of the casing by the rotation of the differential ring gear. The lubricating oil kept in the first catch tank is flowed down by the force of gravity and is fed to peripheral bearings. A second catch tank is arranged to temporarily keep the lubricating oil scooped up from the bottom of the casing by the rotation of the rotor of the motor MG3. The lubricating oil kept in the second catch tank is flowed down by the force of gravity and is fed to peripheral bearings. This arrangement desirably shortens oil paths connecting the respective catch tanks to the peripheral bearings and ensures smooth supply of the lubricating oil to all the peripheral bearings and other oil-requiring sites.

Owner:TOYOTA JIDOSHA KK

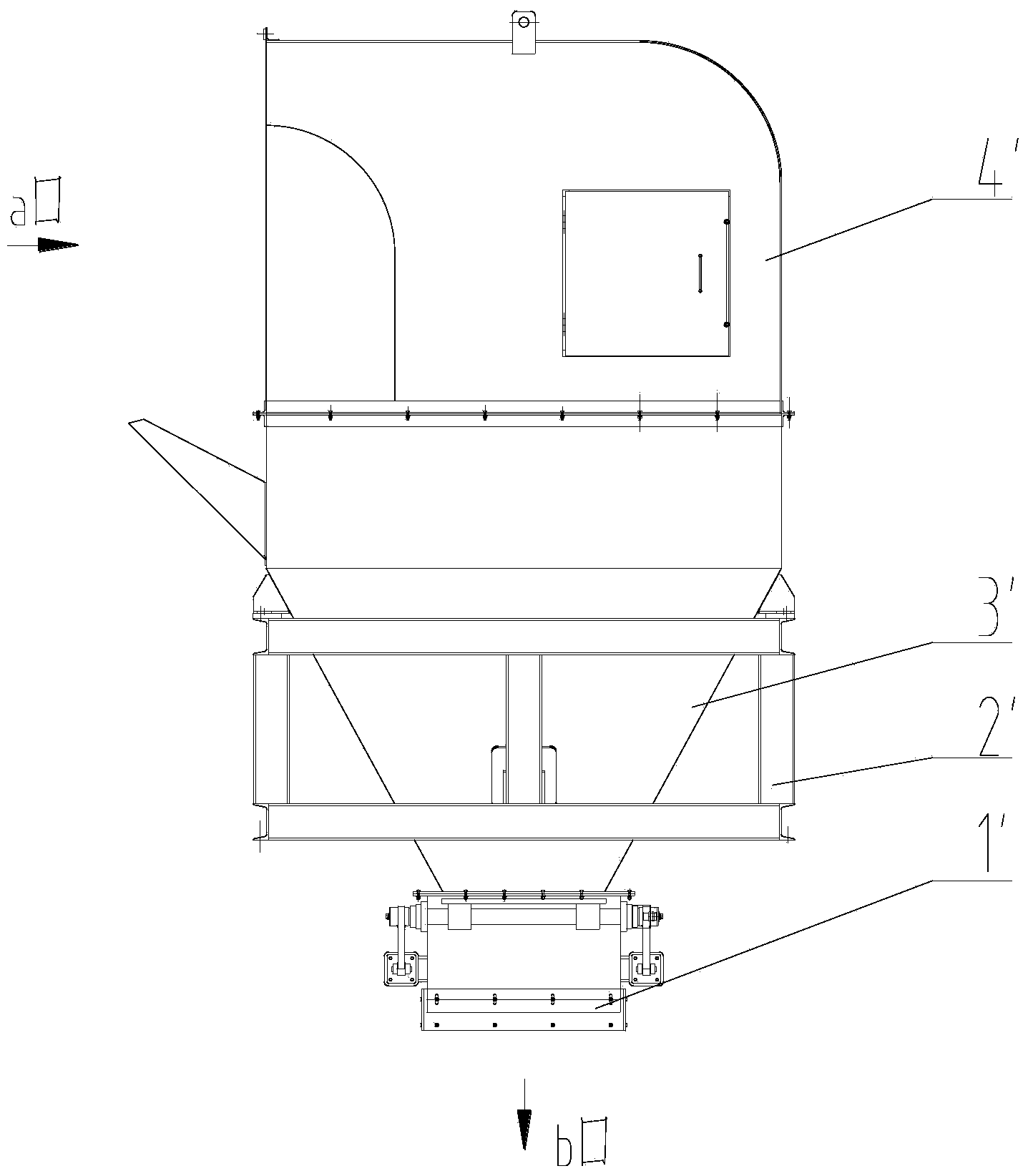

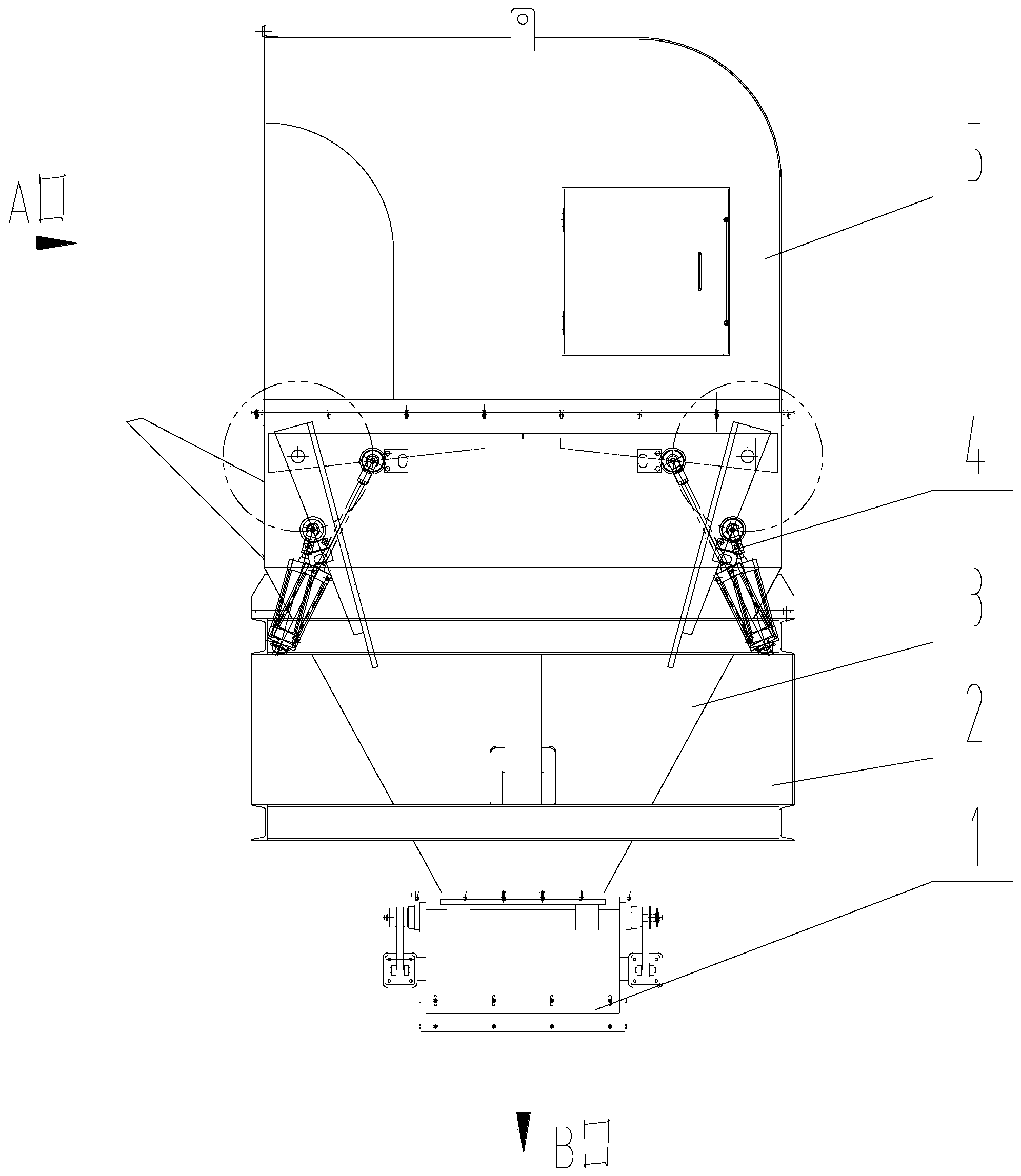

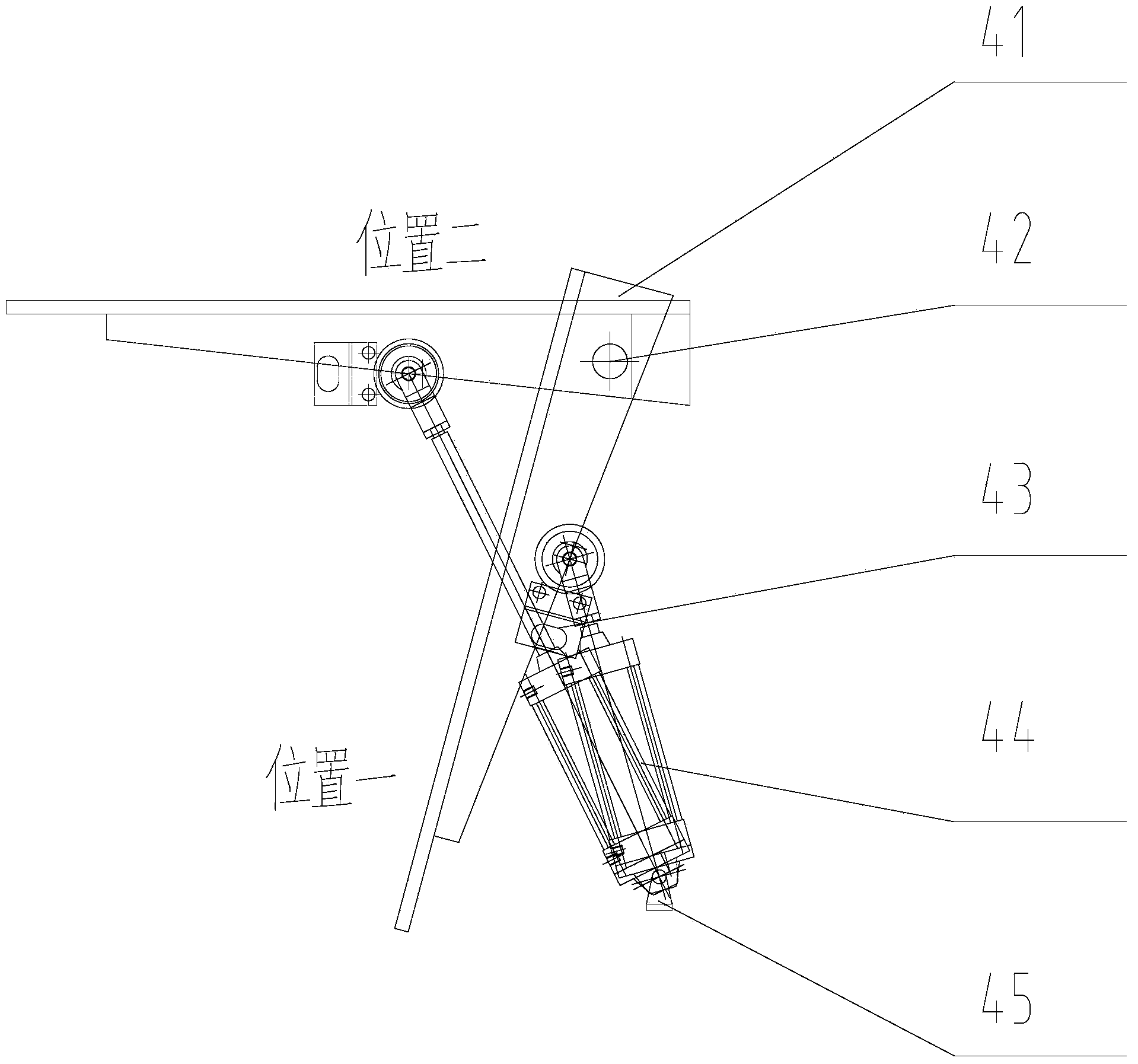

Aggregate holding hopper, concrete stirring station and aggregate distributing control method

ActiveCN104385464AHigh strengthReduce stirring resistanceIngredients storageControl apparatusEngineeringMechanical engineering

The invention discloses an aggregate holding hopper, a concrete stirring station and an aggregate distributing control method. The aggregate holding hopper comprises a hopper body and a hopper valve, the hopper valve is arranged at the lower end of the hopper body, and the hopper is inside provided with a material discharge channel; and the aggregate holding hopper also comprises a material distributing device arranged on the hopper body; and the material distributing device comprises a revolving door mechanism and a driving mechanism, the driving mechanism is used to drive the revolving door mechanism to switch the close state and the open state, the close state of the revolving door mechanism is a state that the material discharge channel is closed, and the open state of the revolving door mechanism is a state that the material discharge channel is opened. The provided aggregate holding hopper is capable of realizing batch-wise pouring of two materials, avoids overlarge stirring resistance in a main machine, and improves the stirring efficiency and the stirring effect.

Owner:三一西北重工有限公司

Flue gas dust removal device with stirring and cleaning mechanism

InactiveCN103405986AEasy to rollTo ensure that it is not blockedCombination devicesFlue gasDust control

The invention relates to a device for separating dispersed particles by using liquid as a separating agent after gas passes through a liquid bath, and in particular relates to a flue gas dust removal device with a stirring and cleaning mechanism. The invention adopts the technical scheme that the flue gas dust removal device comprises a shell (1), a smoke inlet (9), a smoke outlet (3), a flue gas channel (6), a flue gas pretreatment device (10), an impeller dust removal device (2), a dust removal and spraying device (7), a separation plate (17), a filter screen (4), a cleaning and spraying device (5), a liquid groove (11), a liquid supply device (8) and a filler adsorption device (15) above the flue gas channel (6), and is characterized in that a stirring impeller (12) is arranged in the filler adsorption device (15) and is connected with a motor (14) through a stirring wheel shaft (13). The flue gas dust removal device with the stirring and cleaning mechanism has the beneficial effect that effects of automatically cleaning fillers and protecting the filler adsorption device from being blocked are achieved.

Owner:李钻水

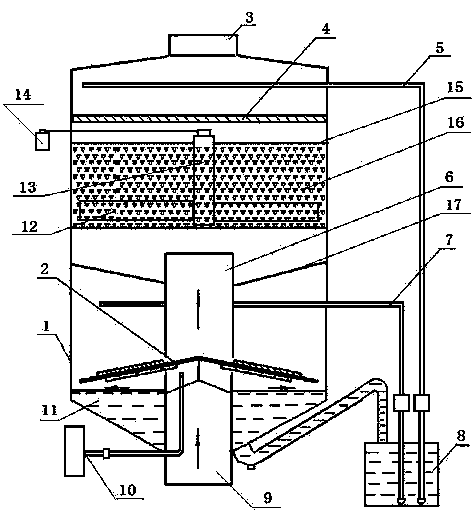

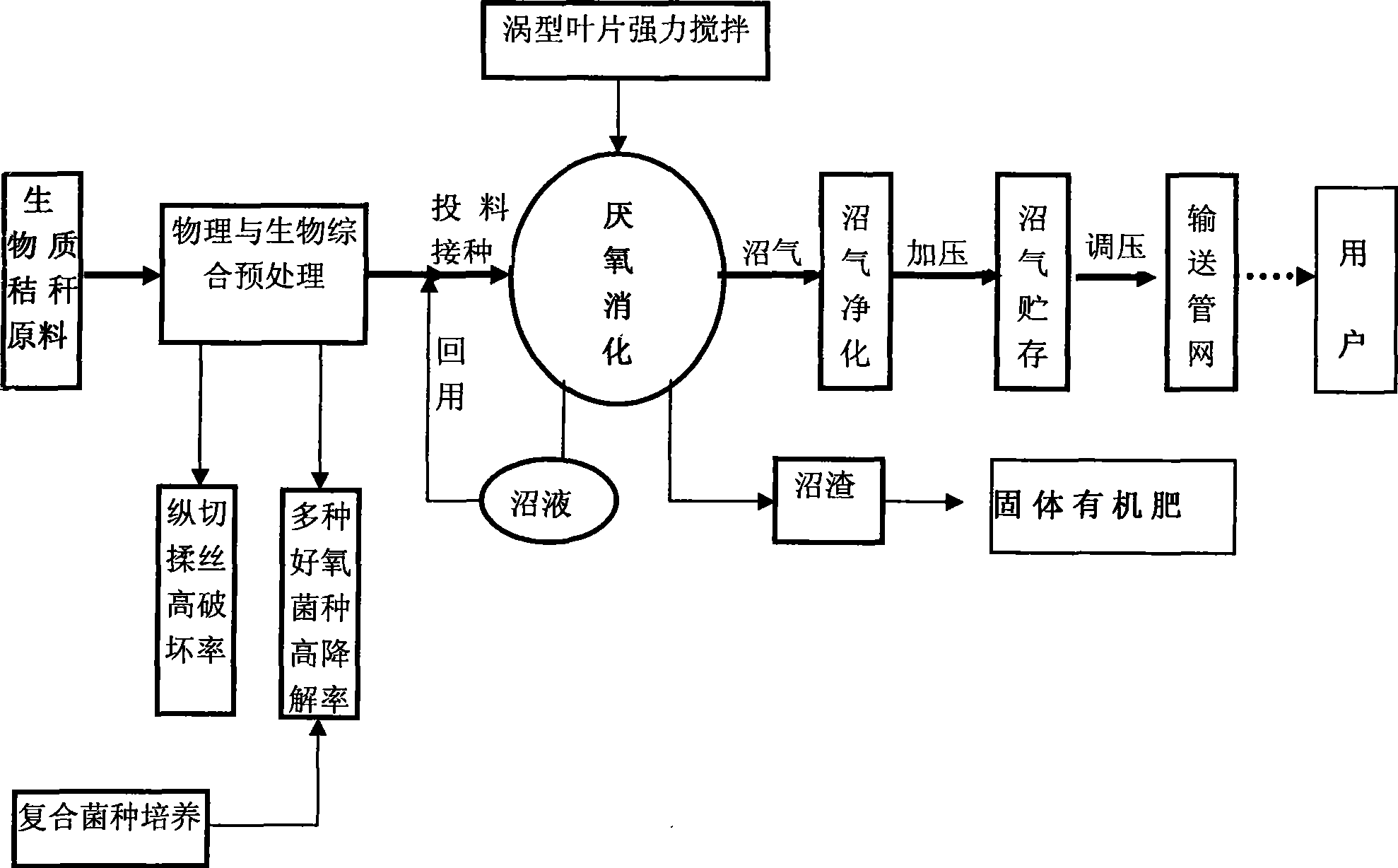

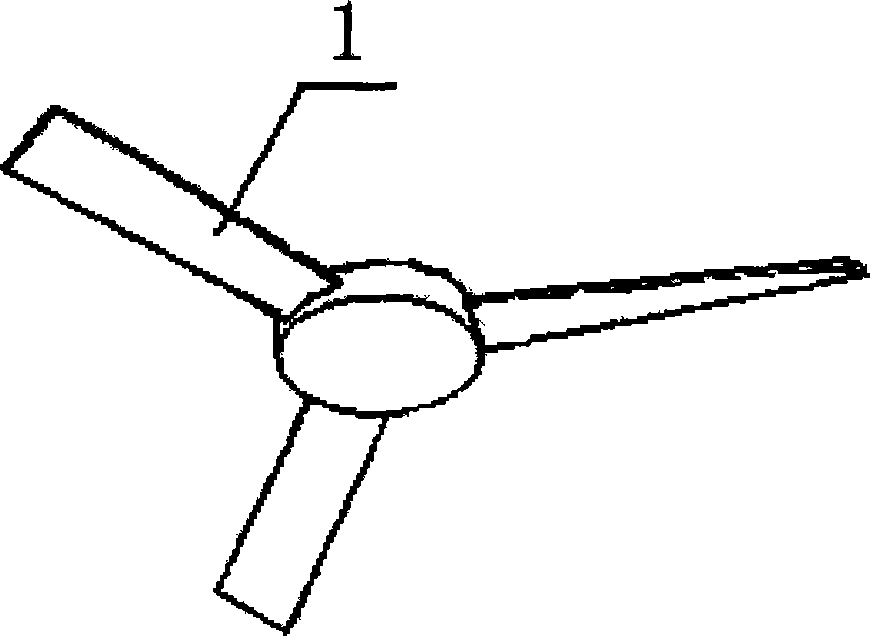

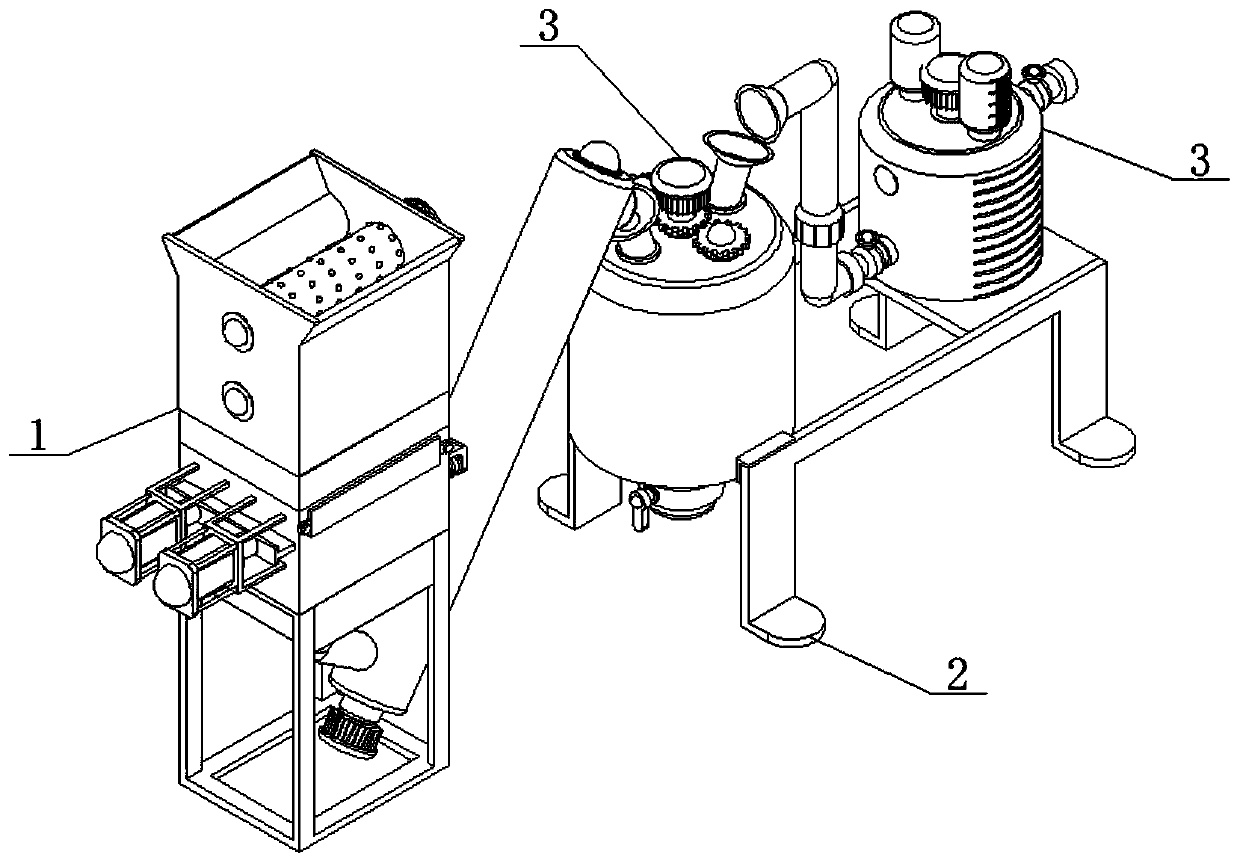

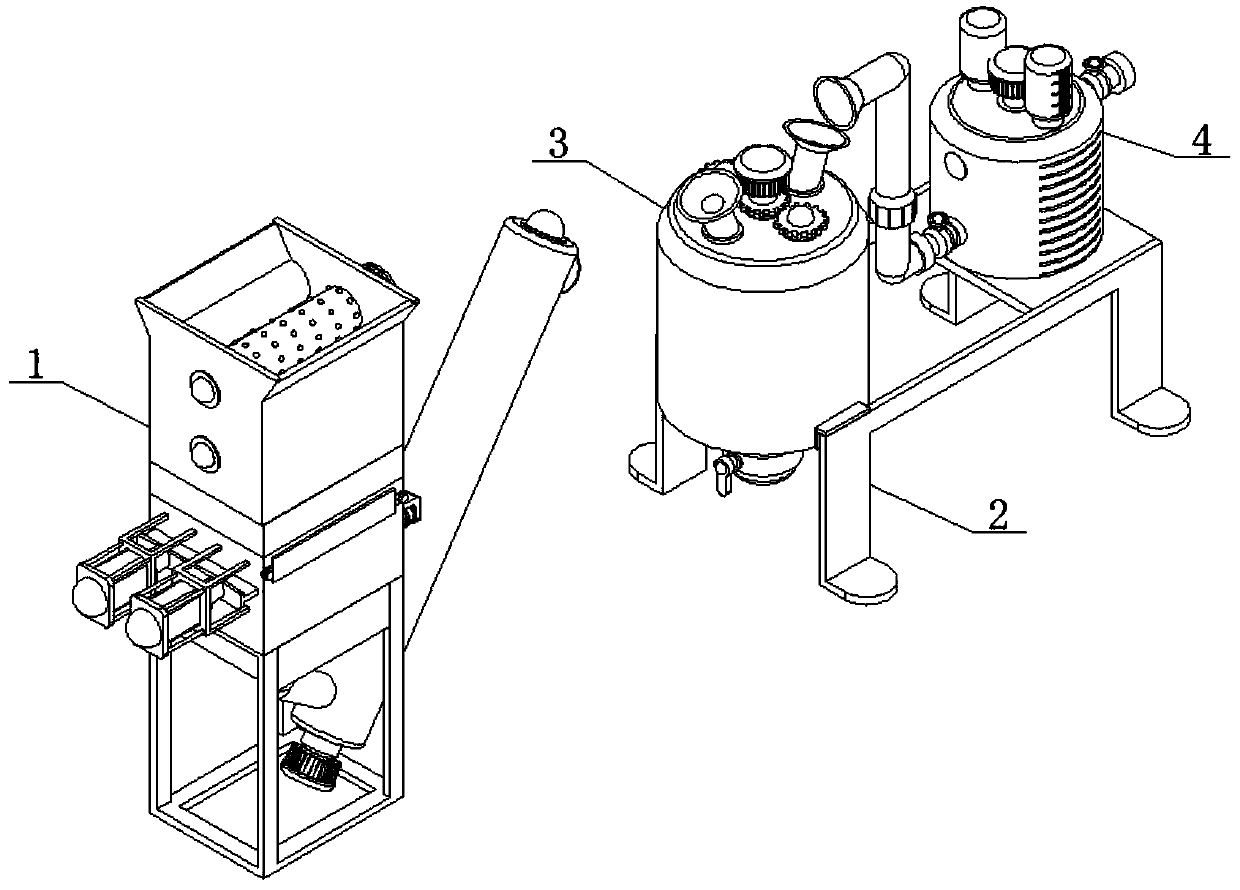

Pure stalk fermentation biogas preparation process and apparatus based on composite strain degradation

InactiveCN101497893AEasy to useEasy to transportBio-organic fraction processingClimate change adaptationMicroorganismPhysical separation

The invention relates to a technique for preparing methane through straw stalks fermentation only based on multi-microorganism degradation, which comprises the following steps: A. physical and biologic comprehensive pretreatment is carried out on biomass straw stalk raw materials; B. the biomass straw stalk raw materials which are comprehensively pretreated are thoroughly degraded and thrown into an anaerobic fermentation reactor together with fermentation inoculation strains for anaerobic reaction and methane preparation; C. the output methane of the step B is desulfurized, enters into a gas-storing device and is delivered to users through a transmission pipeline network; D. methane residues and methane liquid of the step B after the anaerobic reaction are discharged, the methane residues can be used as solid organic fertilizer through physical separation, and the methane liquid refluxes to the anaerobic fermentation reactor for reutilization. The invention also discloses a device for preparing the methane through straw stalks fermentation only based on multi-microorganism degradation. The time of traditional technique for straw stalks pretreatment is 10-15 days; however, the time of the technique for straw stalks pretreatment is only 5 days and the degradation efficiency of the technique is 1.3-1.5 times as high as that of the traditional technique.

Owner:SHANDONG UNIV

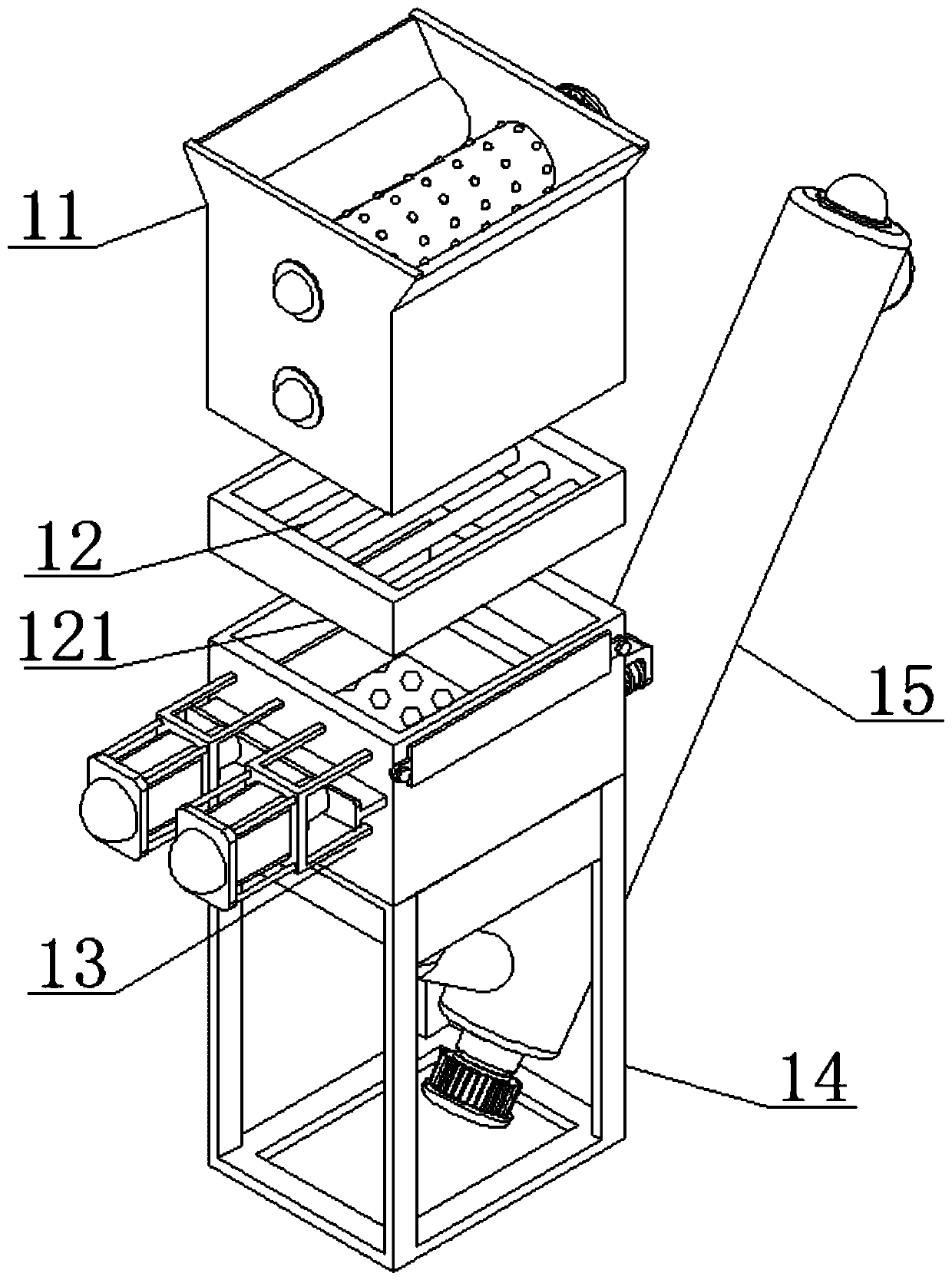

Automatic mechanical equipment for feed stirring

InactiveCN111068566AWell mixedPromote absorptionFeeding-stuffTransportation and packagingAgricultural engineeringStructural engineering

The invention discloses automatic mechanical equipment for feed stirring. The automatic mechanical equipment comprises a crushing structure, a bracket, a mixing structure and a batching structure, thecrushing structure is composed of a crushing frame, a magnetic separation frame, a screening frame, a material guiding structure and a conveying structure. The crushing frame, the magnetic separationframe, the screening frame and the material guiding structure are sequentially connected in a through a welding mode from top to bottom. The conveying structure is obliquely fixed to the bottom end of the material guiding structure, the conveying structure is connected with the material guiding structure in a penetrating mode, the bracket is arranged on one side of the crushing frame, the mixingstructure and the batching structure are arranged on the bracket, and the crushing structure and the batching structure are arranged on the two sides of the mixing structure respectively. The equipment is convenient for automatic mixing of a feed and traditional manually treated fresh forage, so that the use amount of workers is reduced, the labor intensity is reduced, the discharge efficiency isimproved, the labor cost in feed processing is reduced, the feed stirring treatment efficiency is improved, accurate matching between the feed and additives is facilitated, and the feed mixing and proportioning precision is improved.

Owner:白沚玄

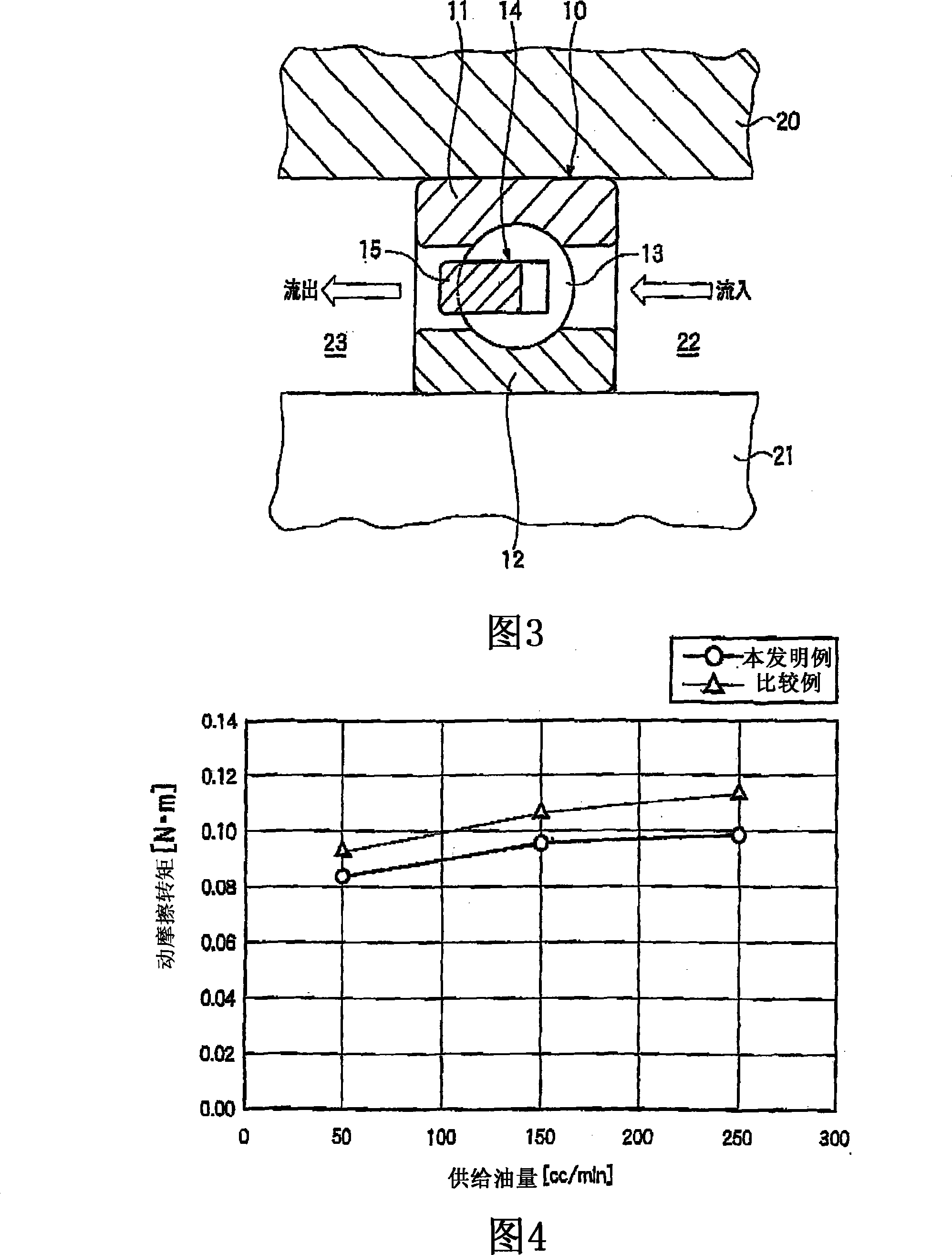

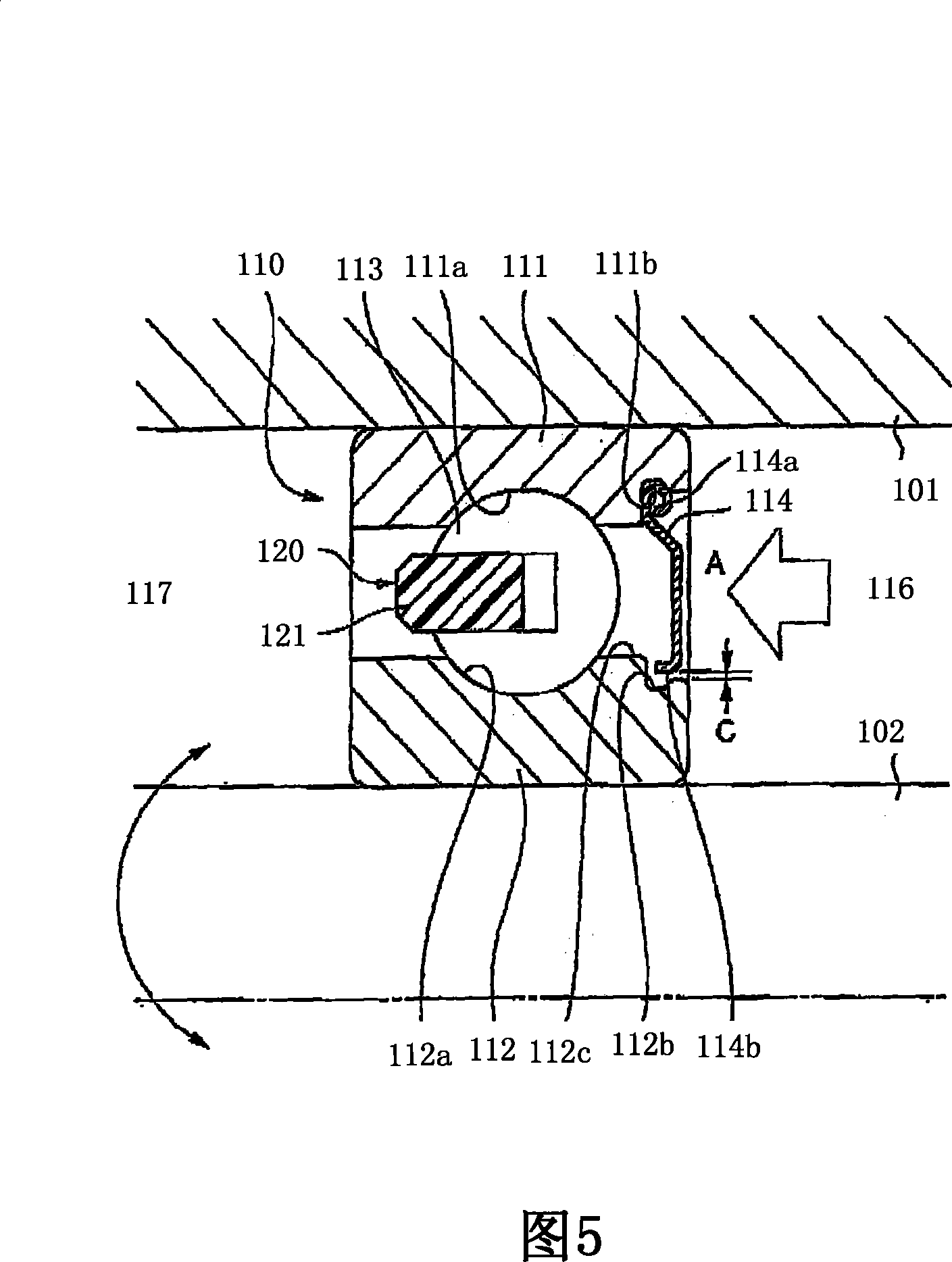

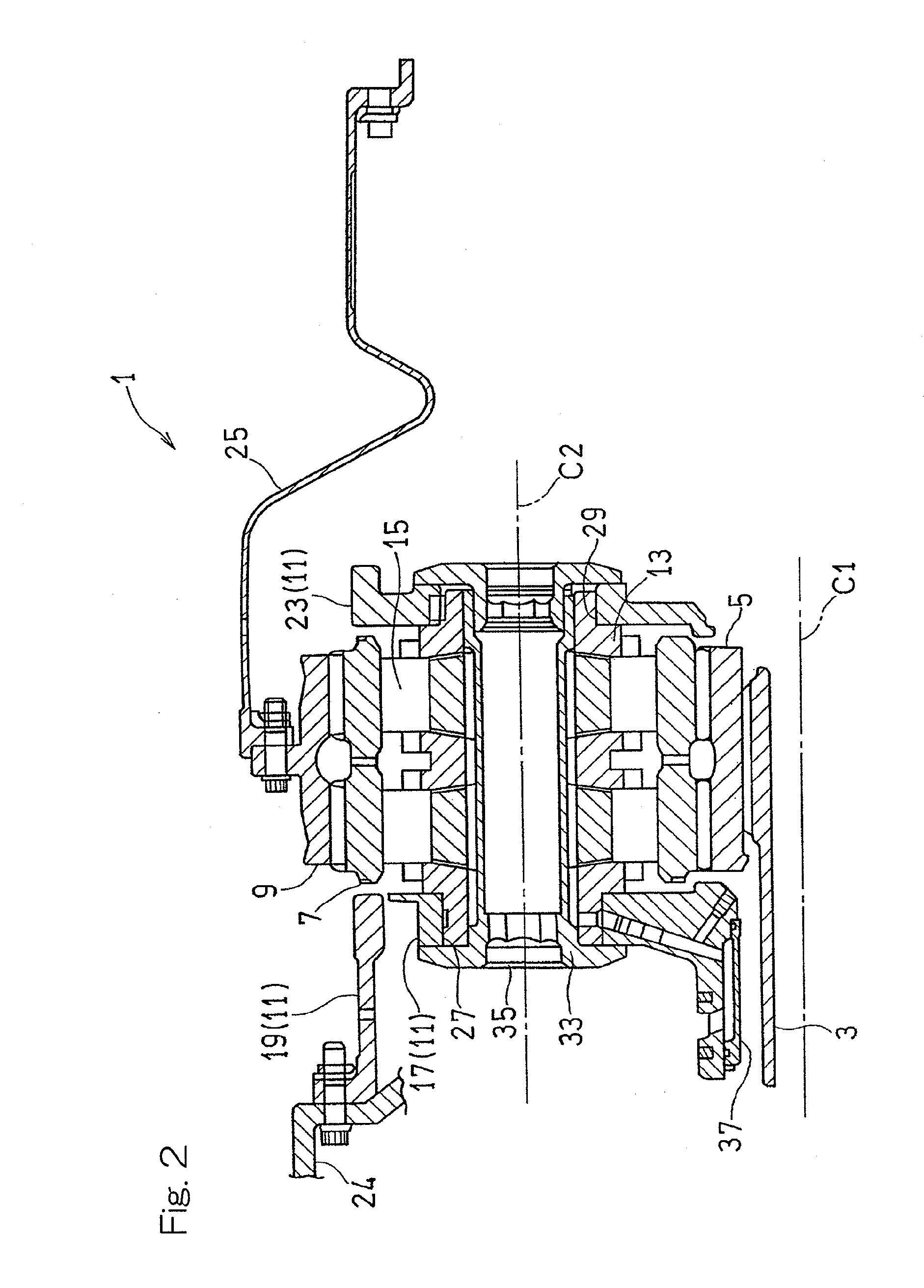

Lubricating device of rolling bearing

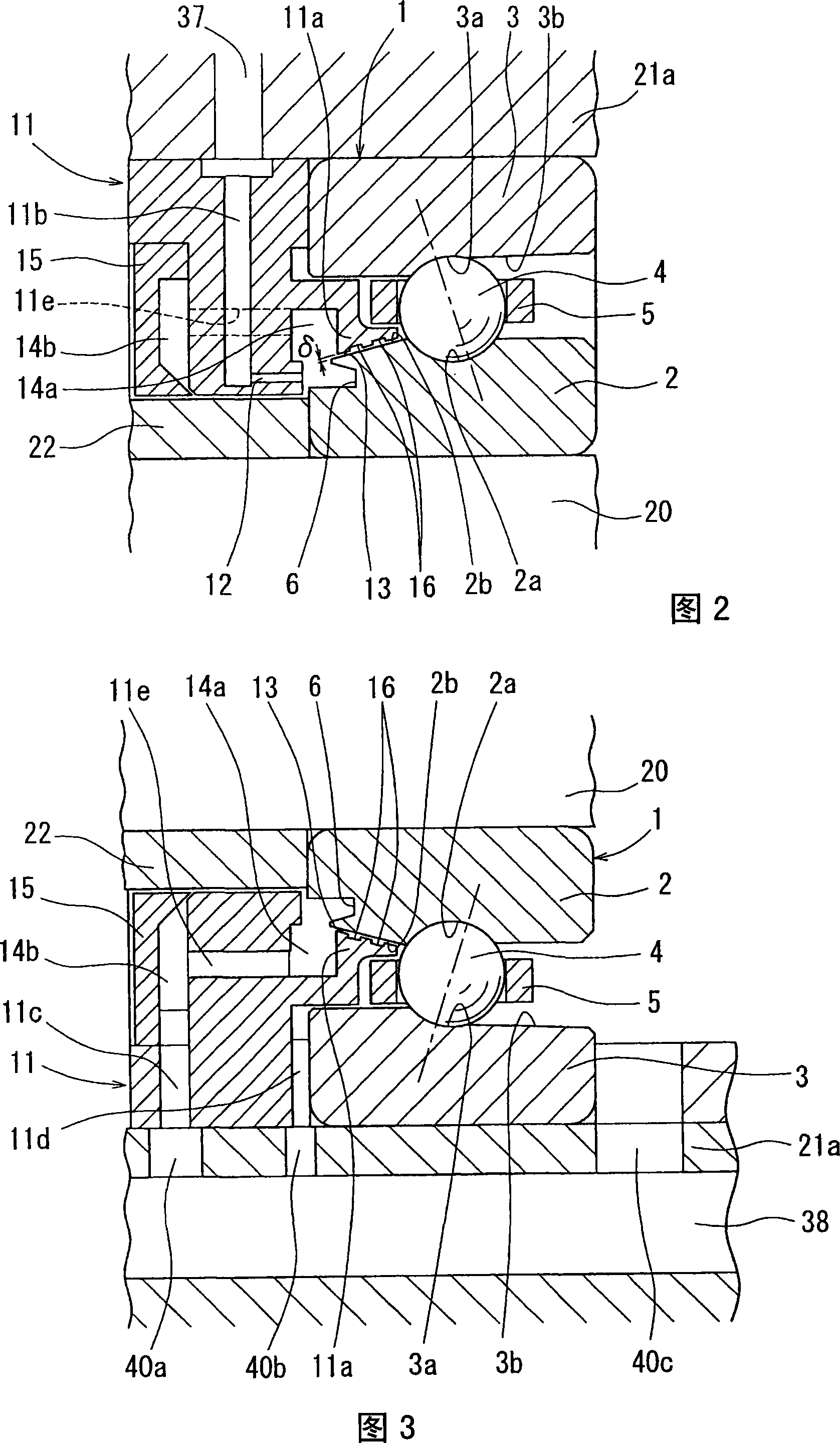

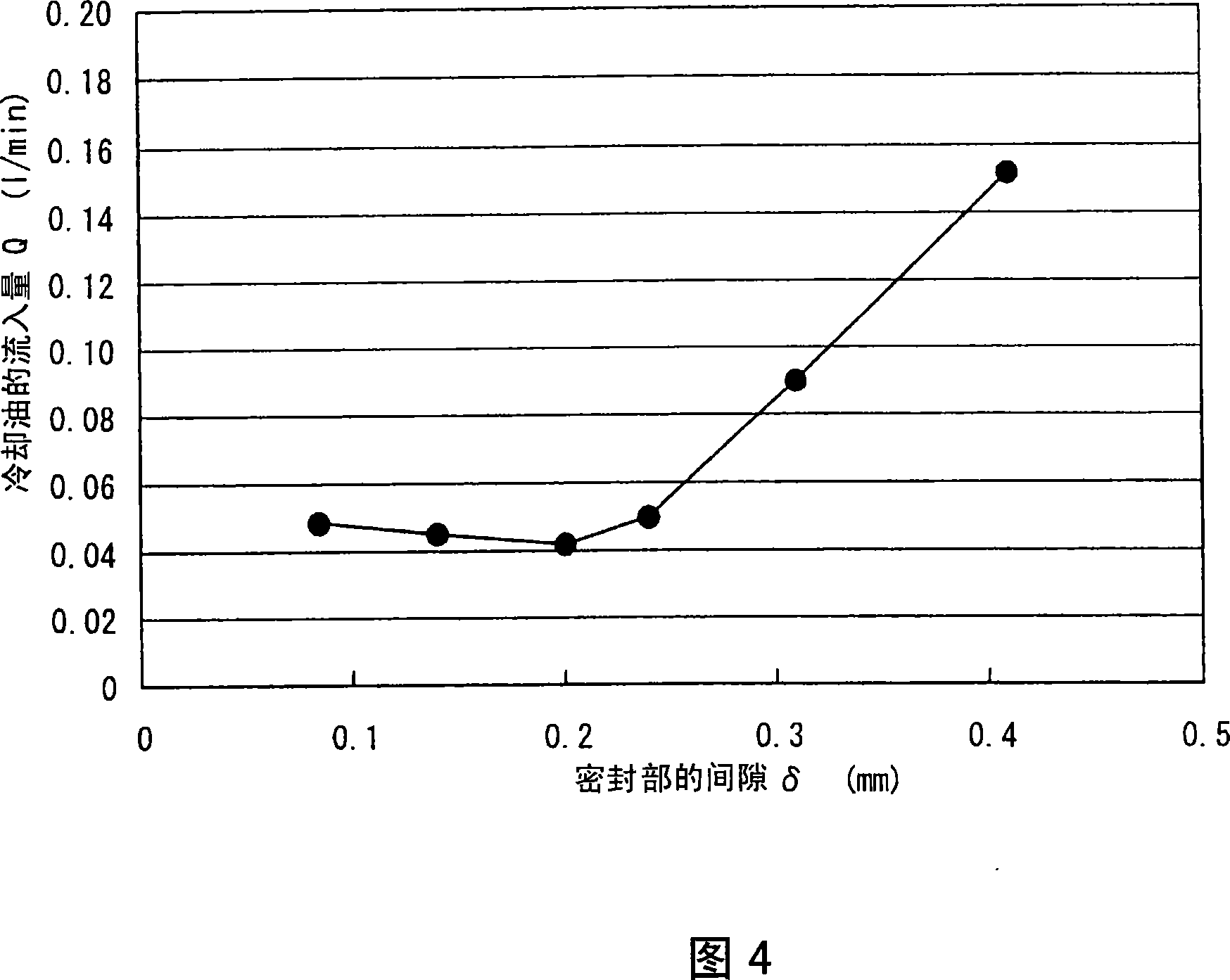

InactiveCN101203686AInflow suppressionReduce stirring resistanceRolling contact bearingsBearing unit rigid supportBall bearingRolling-element bearing

A lubricating device of a rolling bearing with an inner ring cooling function capable of reducing a coolant agitating resistance due to the high-speed rotation of the rolling bearing. A coolant introducing member (11) in which a nozzle (12) discharging a coolant to a circular groove (6) at the end face of the inner ring (2) is formed is disposed on the rear face side of an angular ball bearing (1), and a seal part (13) facing the tapered surface (2b) of the angular ball bearing (1) through a clearance is formed at the extension part (11a) of the coolant introducing member (11). The inflow amount of the coolant from the seal part (13) into the bearing is suppressed by setting the clearance d at the seal part (13) to 0.2 mm or less so that the coolant agitating resistance due to the high-speed rotation of the angular ball bearing (1) can be reduced.

Owner:NTN CORP

Heat-conduction filling material for heat dissipation of electronic components, and preparation method thereof

InactiveCN107501936AIncrease the degree of mixingReduce stirring resistanceRotary stirring mixersTransportation and packagingCarbon nanotubeElectron

The present invention relates to the technical field of materials, and provides a heat-conduction filling material for the heat dissipation of electronic components, wherein the heat-conduction filling material comprises, by mass, 14-20% of a silicon rubber, 20-40% of a graphene / carbon nano-tube composite material, 30-60% of a metal oxide, 0.1-1% of a coupling agent, and 1-2% of a liquid state metal. According to the present invention, the graphene / carbon nano-tube composite material is selected as the raw material and has the three-dimensional network structure, and through the synergistic effect between the graphene and the carbon nano-tubes, the excellent performances are provided compared to the single use of any one material, wherein the excellent performances comprise good isotropic thermal conductivity, good isotropic electric conductivity, good three-dimensional space micro-pore network and the like; and the limitation problem of the thermal conduction direction due to the single use of the two materials such as graphene and carbon nano-tubes in the prior art is solved.

Owner:SHANGHAI ALLIED PLASTIC IND

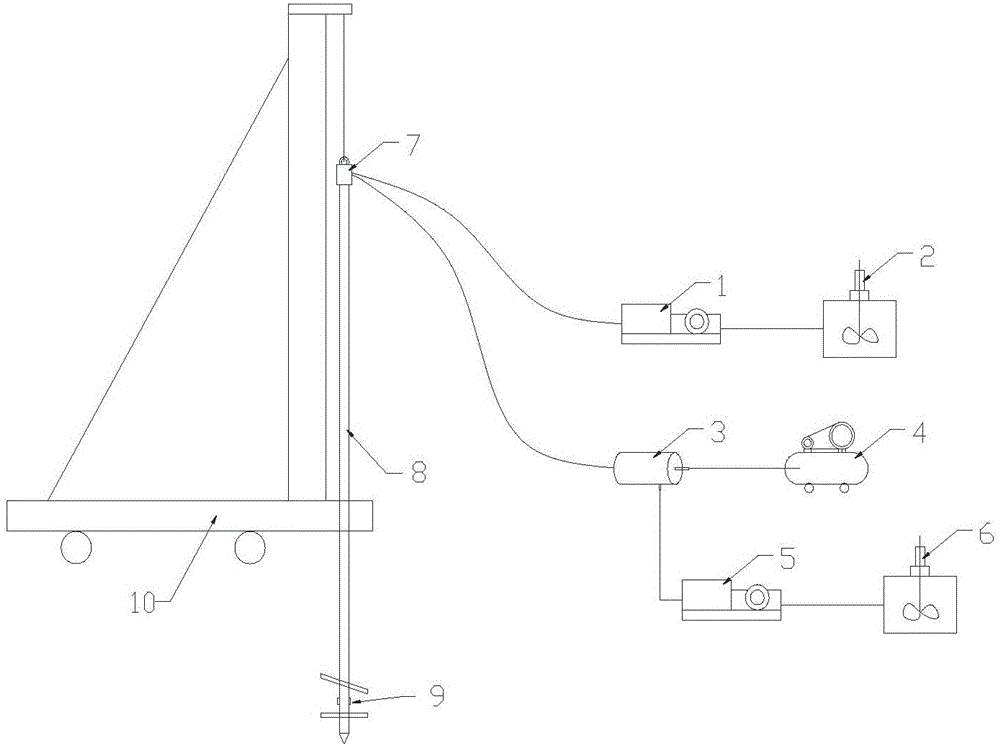

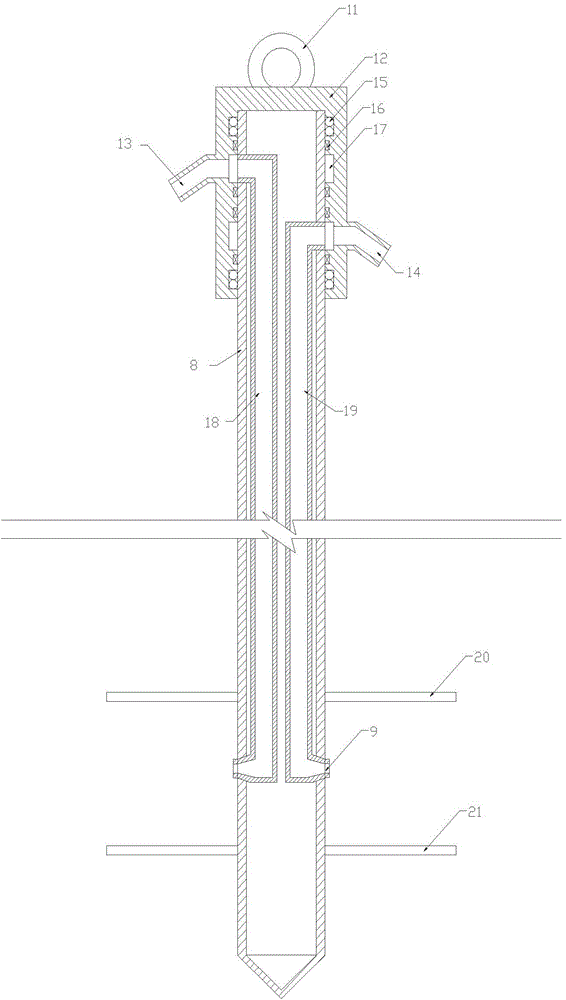

Technical method for improving quality of deep cement soil mixing piles using compressed air foam

InactiveCN104631446AImprove construction qualityImprove construction efficiencyBulkheads/pilesSoil mixingCement grout

The invention provides a technical method for improving quality of deep cement soil mixing piles using compressed air foam, and on the basis of a 'guniting-stirring' technology in conventional deep cement soil mixing pile machine, a foam injection system is added. Cement grout and the compressed air foam pass through a double-channel rotating joint and a double-channel drill stem and are finally ejected into soil simultaneously through a nozzle in the side face of a drill. The compressed air foam assists the guniting and the stirring of the cement mixing drill, on one hand stirring resistance of the drill in a sand soil layer is reduced, on the other hand, drill adhesion in cohesive soil is reduced. According to the technical method, cement adding amount and uniformity of the stirring can be guaranteed, so that the quality of the cement soil mixing piles is improved.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

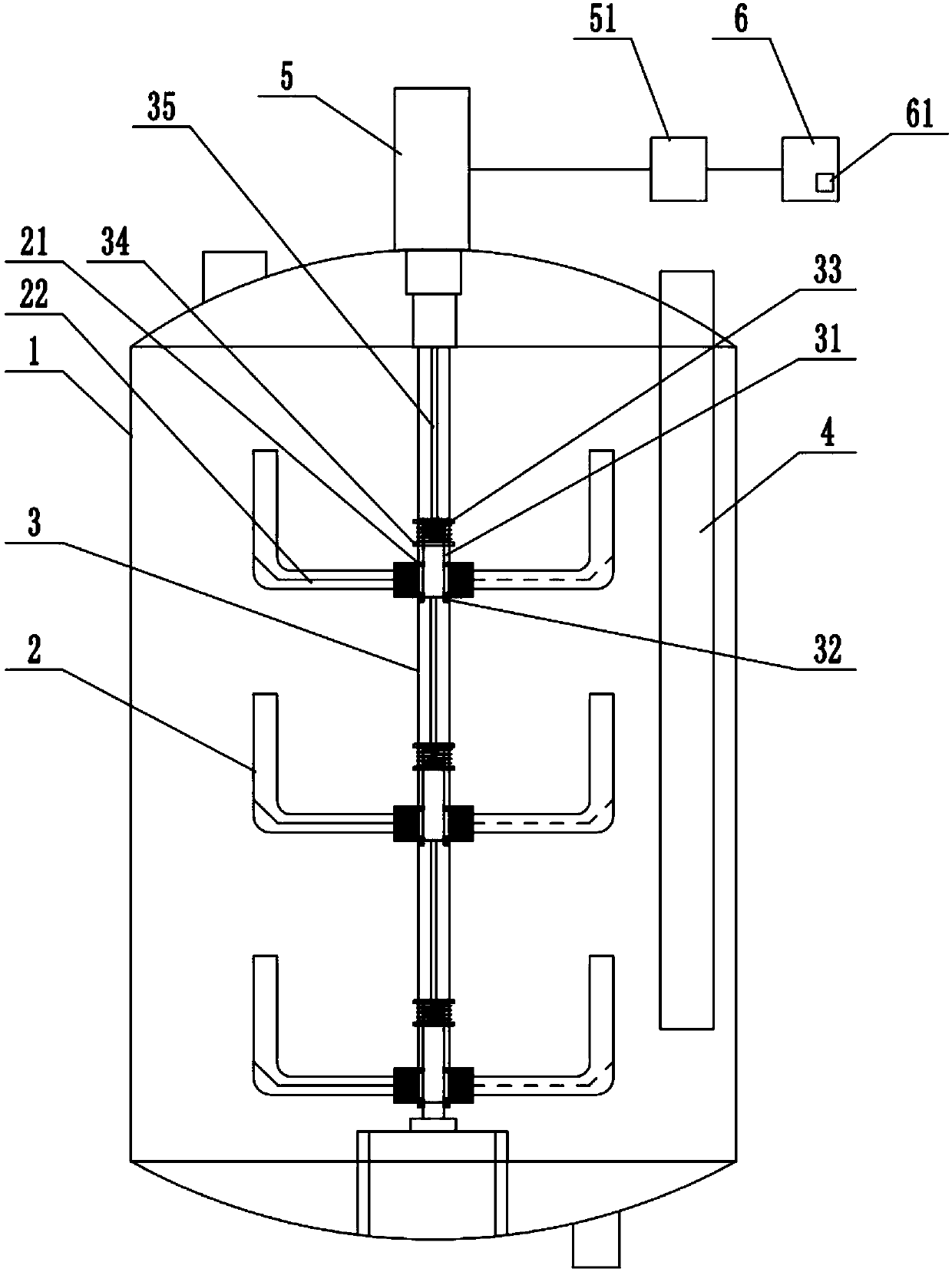

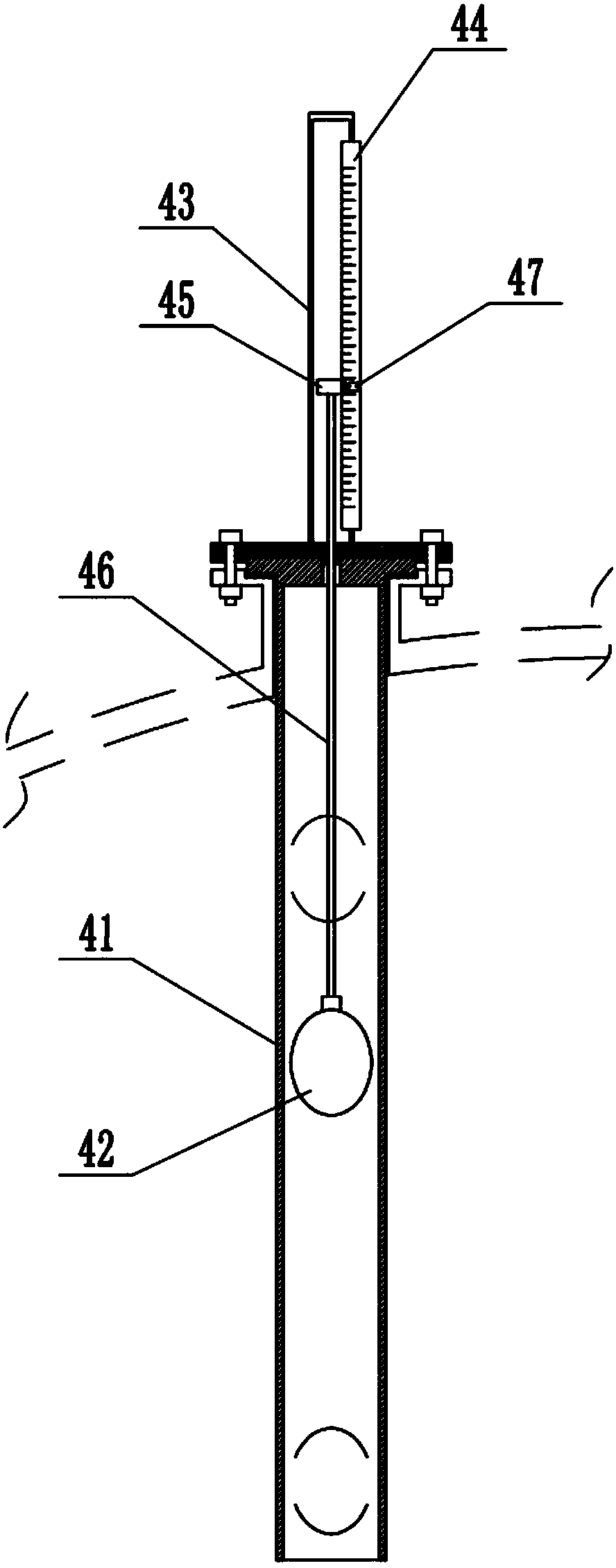

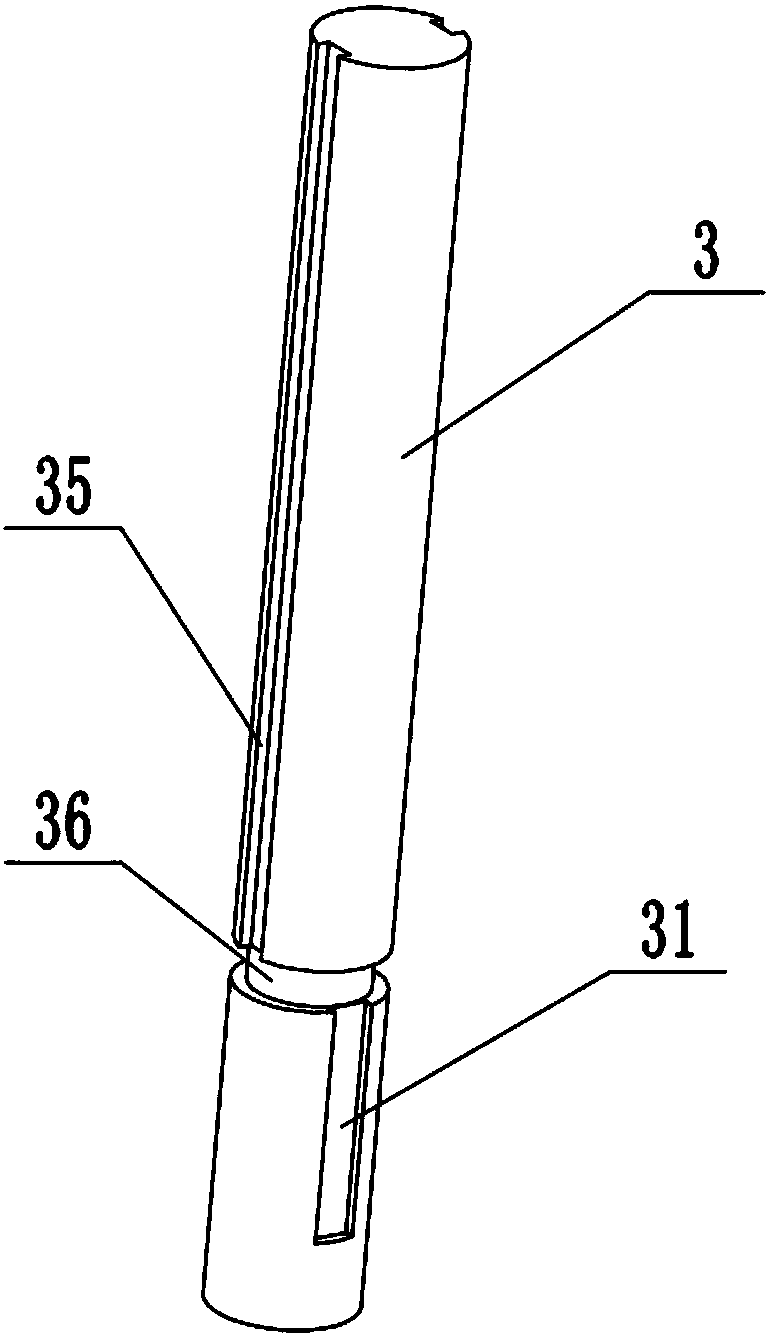

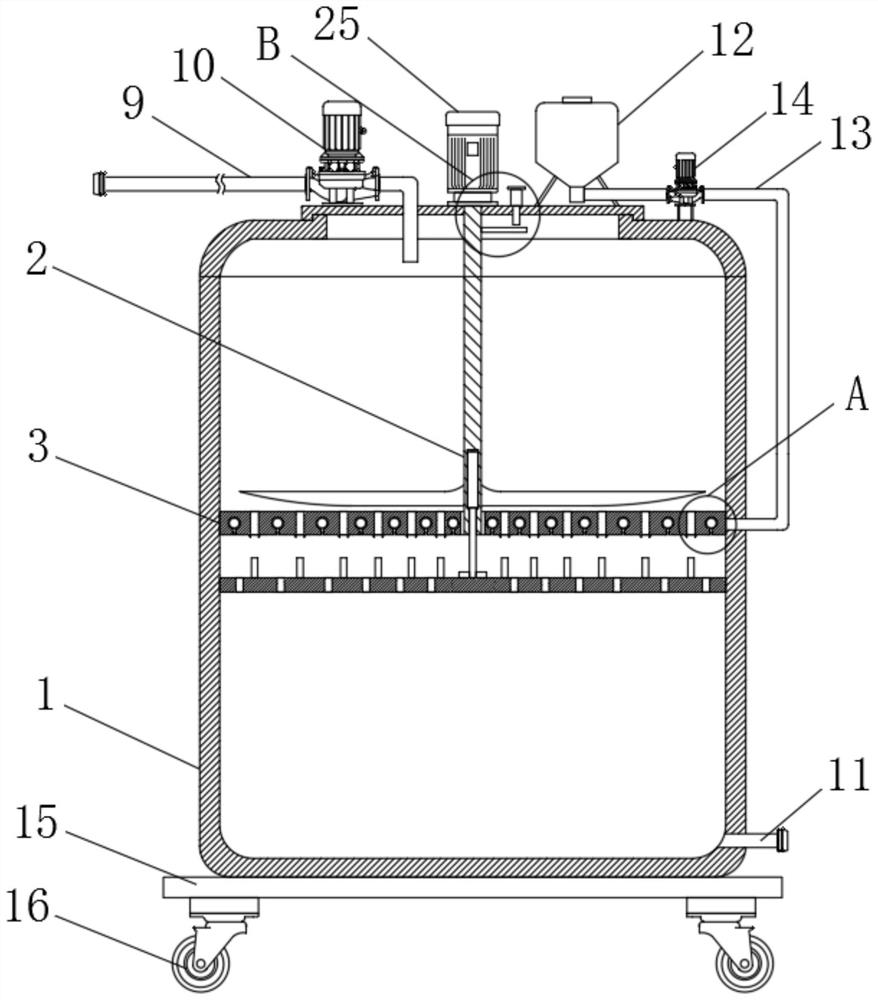

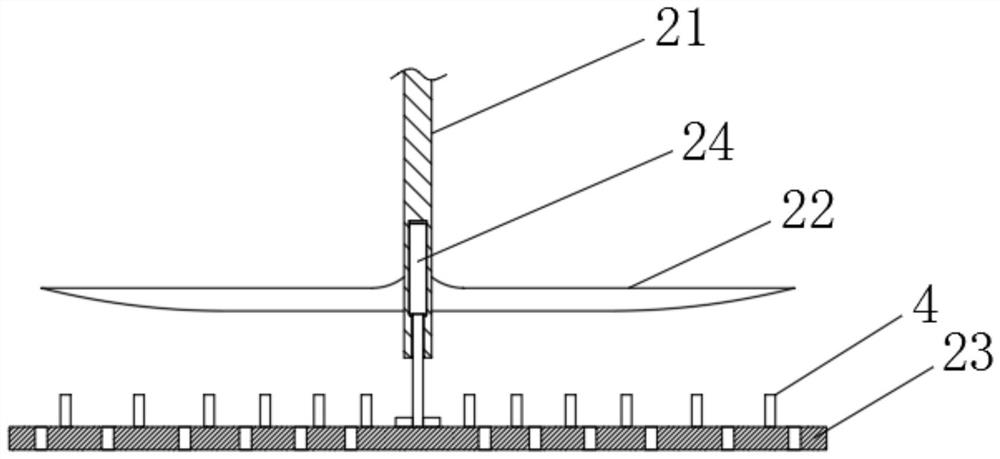

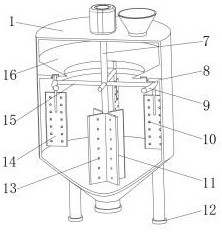

High-concentration waste liquid treatment evaporating reactor

PendingCN107899527AAvoid detecting inaccurate defectsHeight adjustableSolution crystallizationCrystallization by component evaporationElectric machineryProcess engineering

The invention relates to a high-concentration waste liquid treatment evaporator, which comprises a tank body, wherein a stirring shaft with stirring blades, and a liquid level detection device are arranged in the tank body; the stirring shaft is driven by a stirring motor at the top of the tank body; the liquid level detection device comprises a floating ball tube inserted into the tank body, a floating ball floating in the floating ball tube, a ruler tube which is mounted at the top end of the floating ball tube and is arranged outside the tank body, and a magnetic induction ruler mounted onthe outer side of the ruler tube; a magnetic block capable of moving up and down is arranged in the ruler tube; the magnetic block is connected with the floating ball through a connection rod; multiple groups of stirring blades are arranged up and down in a spacing manner; the stirring blades and the stirring shaft are mounted in an axial sliding manner. According to the high-concentration waste liquid treatment evaporator, by the adoption of a magnetic flap type liquid level detection device, the shortcomings that detection cannot be realized due to crystallization and a conventional ultrasonic liquidometer is inaccurate in detection due to stirring of internal liquid can be overcome; by the adoption of the stirring blades capable of floating up and down, the stirring resistance can be reduced in time, and the stirring effect is enhanced.

Owner:苏州浩长空环保科技有限公司

Power transmission device

InactiveUS8302506B2Reduce resistanceLevel avoidGearboxesGear lubrication/coolingVertical planeMechanical engineering

A power transmission device includes: a main case having an inside storing an oil; a drum carrying up the oil; and a partition wall partitioning the inside of the main case into a transmission gear housing containing the drum and a catch tank. An inner wall of the main case includes a down-extending portion extending down toward a feed opening of the catch tank, and extending toward the drum rather than along a vertical plane extending in the vertical direction as the down-extending portion extends downward, and a receding portion bordering on the down-extending portion and extending away from the drum from a bordering point where the receding portion borders on the down-extending portion.

Owner:TOYOTA JIDOSHA KK

Wastewater treatment device for garment fabric disinfection

ActiveCN113023938AReduce cloggingFully mix and restoreSpecific water treatment objectivesTreatment involving filtrationFiltrationProcess engineering

The invention relates to a wastewater treatment device for garment fabric disinfection. The wastewater treatment device comprises a tank body, a crushing and mixing assembly and a dosing and shunting assembly, wherein the crushing and mixing assembly and the dosing and shunting assembly are mounted in the tank body. The crushing and mixing assembly comprises a stirring shaft, crushing blades, a lower filter plate and a first electric push rod, the crushing blades and the lower filter plate are distributed on the stirring shaft up and down and rotate along with the stirring shaft, and the first electric push rod is embedded in the bottom of the stirring shaft and drives the lower filter plate to move up and down. The dosing and shunting assembly comprises an upper filter plate arranged between the crushing blade and the lower filter plate, and a spraying mechanism embedded in the lower surface of the upper filter plate and used for adding a reducing agent. The upper filter plate with the pesticide spraying mechanism is arranged between the crushing blade and the lower filter plate, crushed waste liquid can form multiple waste liquid flows through preliminary filtration, a reducing agent forms multiple reducing agent flows through the pesticide spraying mechanism, the reducing agent flows are scattered and wrap the waste liquid flows, full mixing reduction can be achieved, and the conditions of impurity blockage and the like are reduced.

Owner:ANHUI GUIGU E COMMERCE

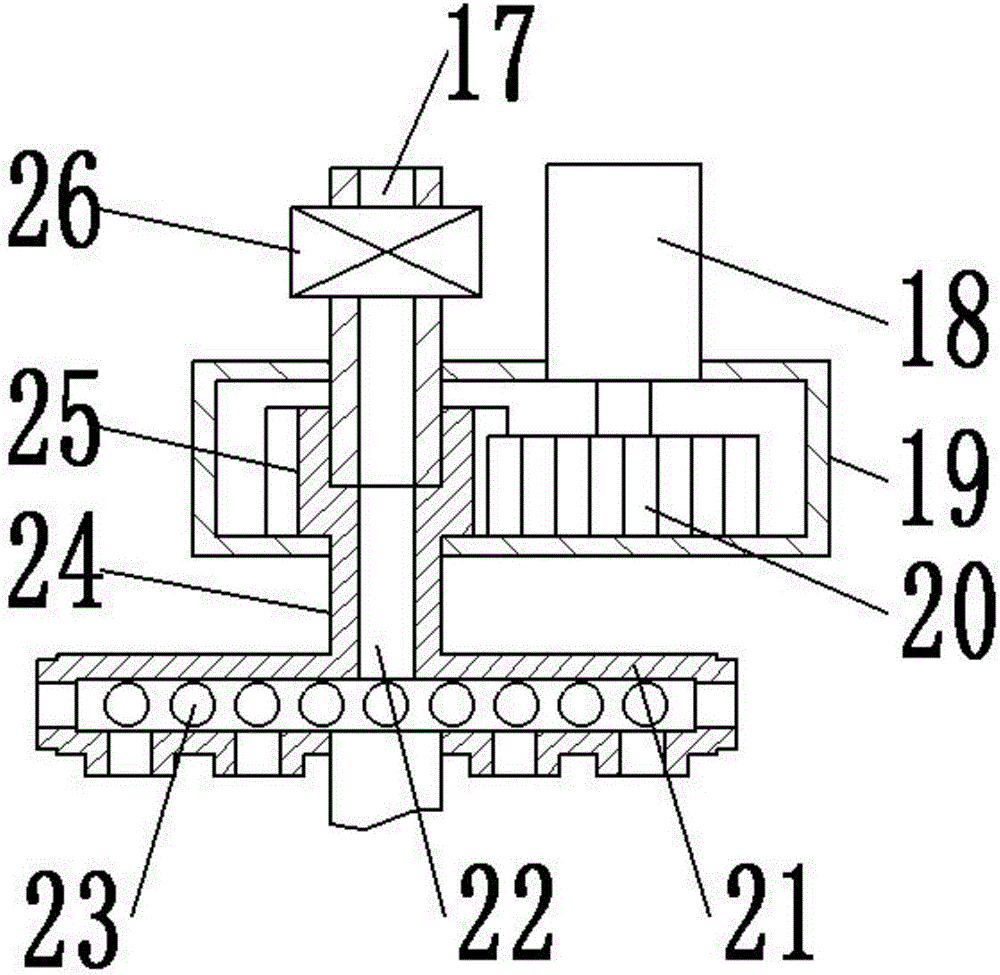

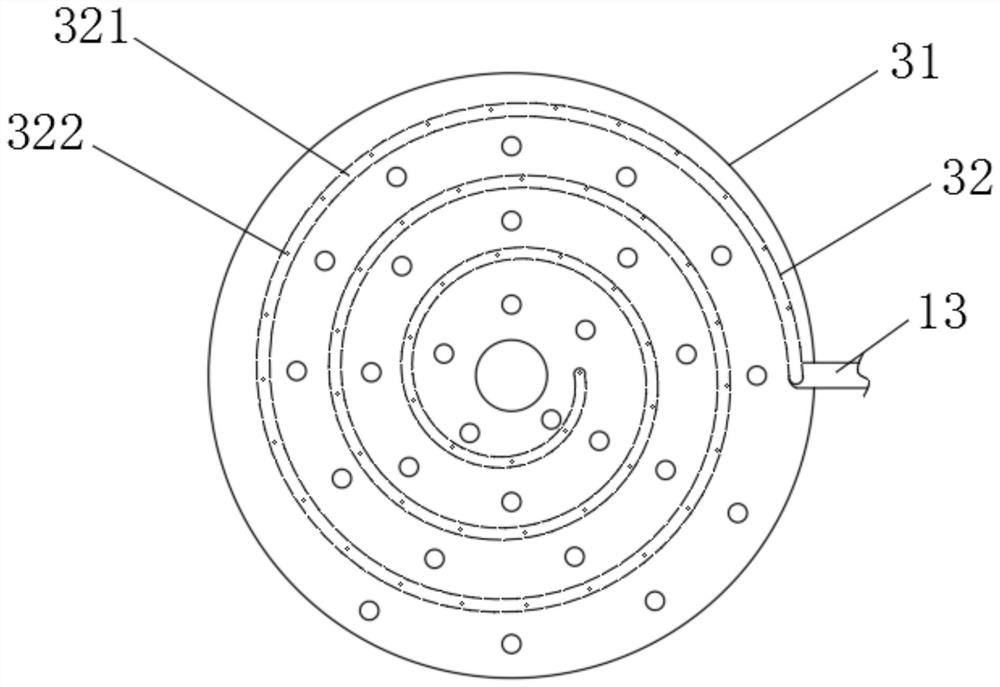

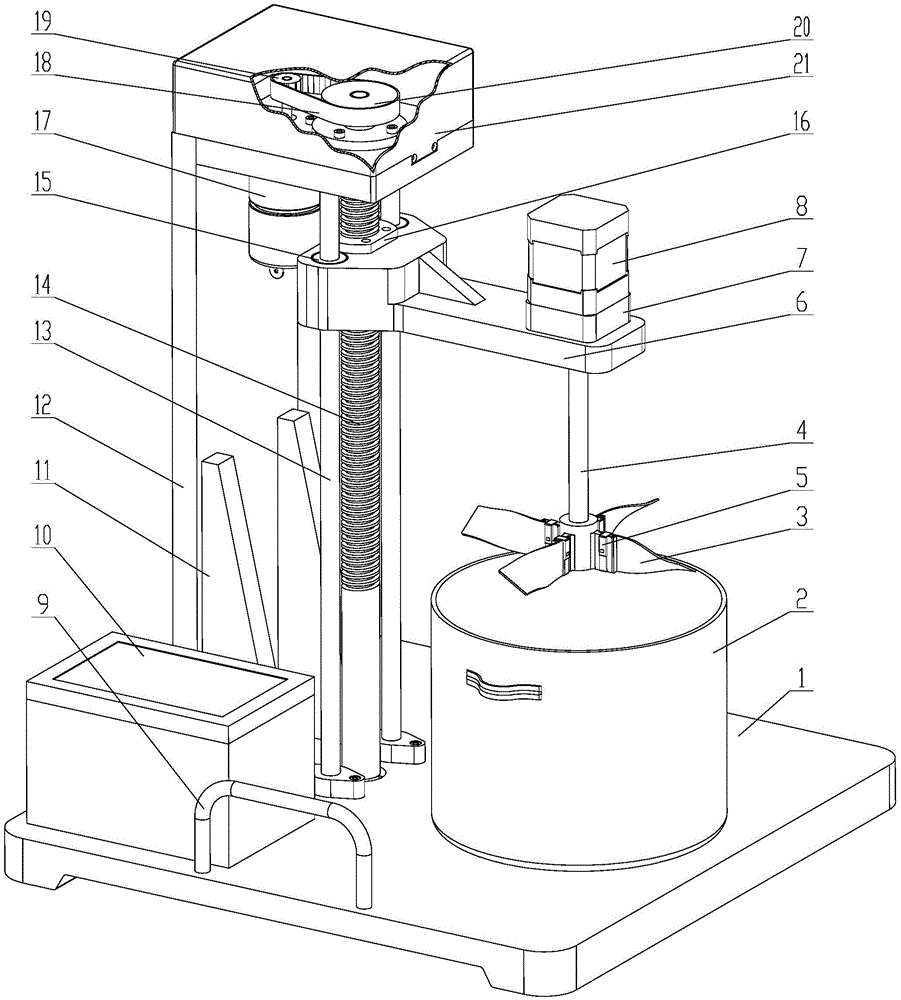

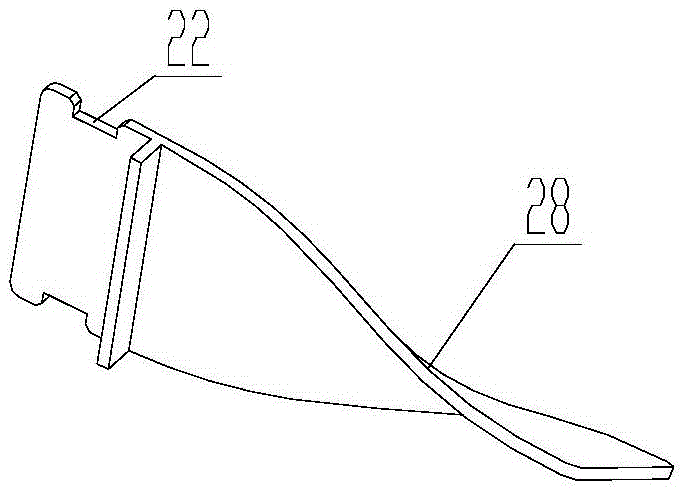

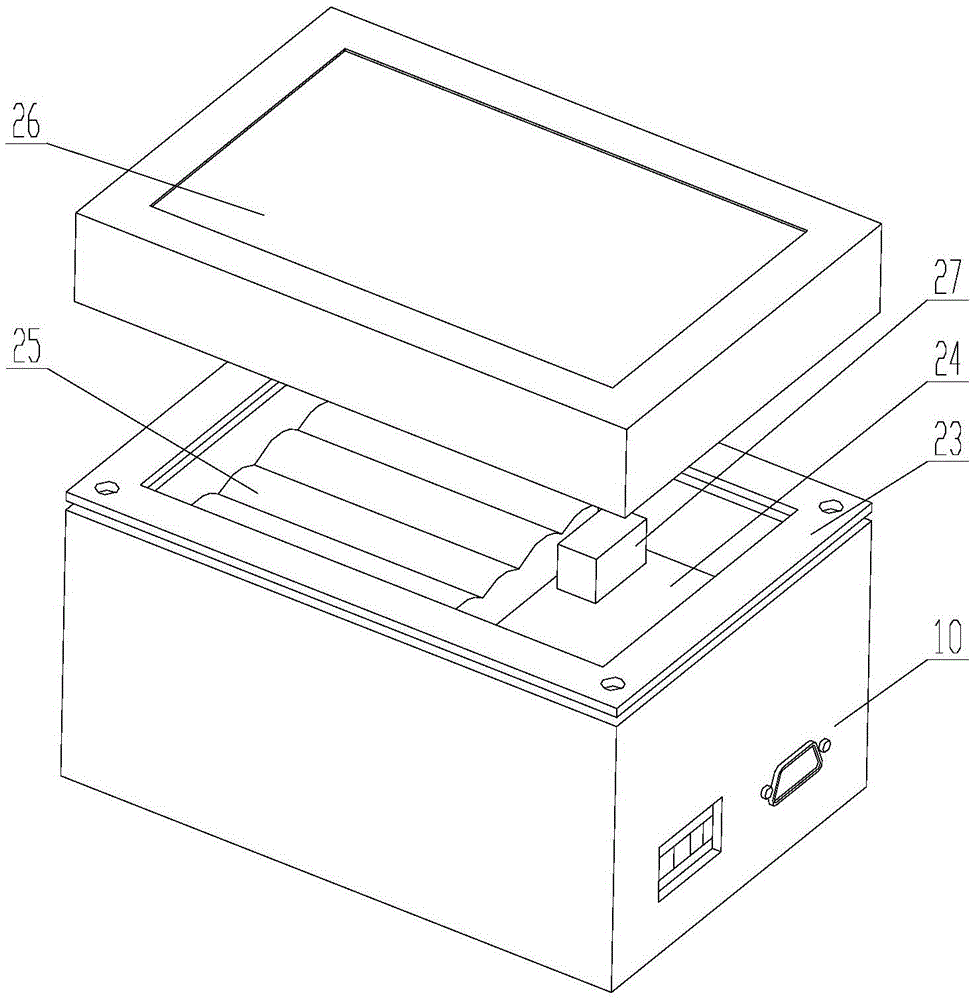

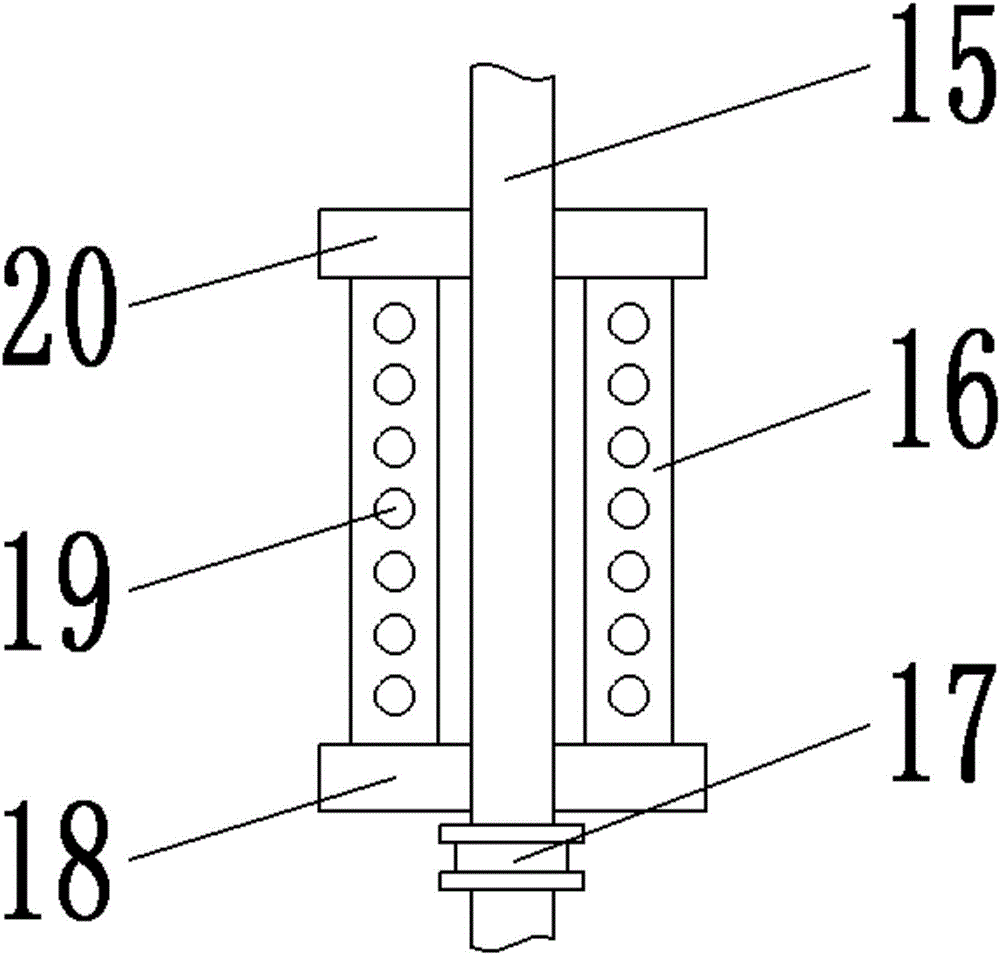

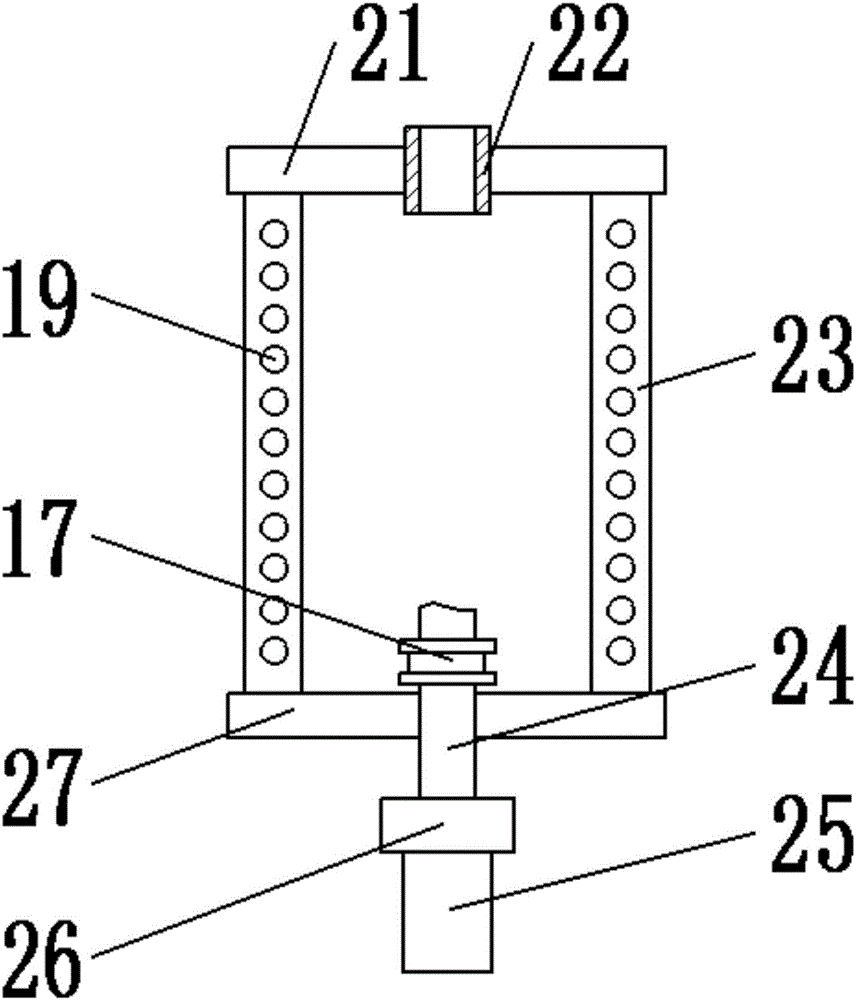

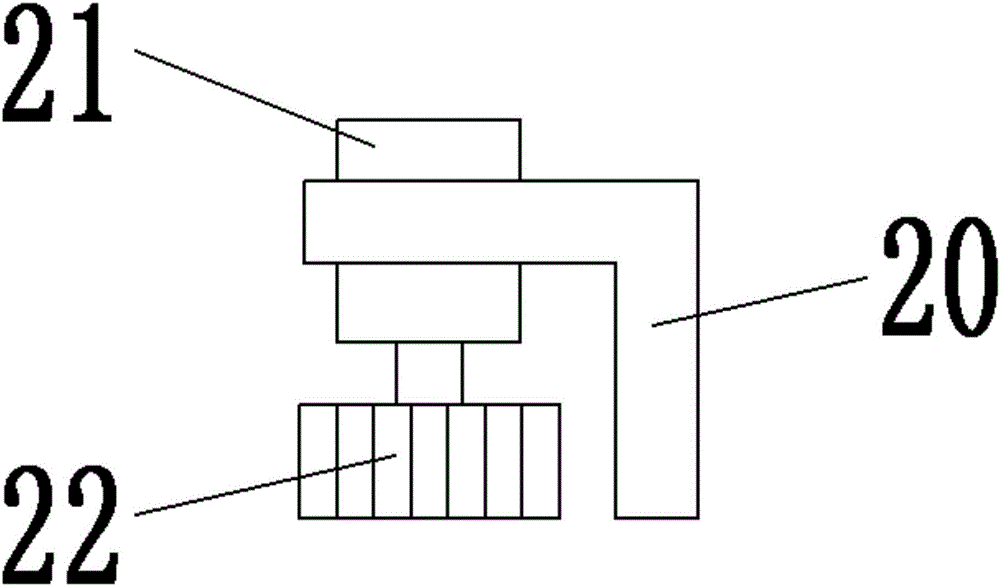

Double-shaft type stirring debubbler used for vacuum box

ActiveCN105536298AReduce stirring resistanceSimple structureLiquid degasificationCantileverCombined use

The invention discloses a double-shaft type stirring debubbler used for a vacuum box. The double-shaft type stirring debubbler comprises a pedestal, a material barrel for holding materials, a lifting device and a stirring device. The lifting device is fixed on the pedestal through a bracket, the stirring device is connected to the lifting device through a cantilever sliding table, and is suspended right above the material barrel, and the material barrel is fixed on the pedestal. The lifting device is driven to drive the stirring device to lift vertically, and the stirring device performs rotary stirring of the raw materials in the material barrel. The double-shaft type stirring debubbler provided by the invention can be placed in a vacuum environment overall, an operator starts stirring procedure by remote control outside, a stirring shaft drives stirring paddles to mix materials, while the stirring shaft performs stirring, a lifting shaft drives the stirring shaft to do up-and-down reciprocating motion to bring the bottom liquid to the surface, so that bubbles in the materials rapidly rupture on the surface and escape. The double-shaft type stirring debubbler provided by the invention can be used in combination with a vacuum box, and has the advantages of simple structure, convenient use, good mixing uniformity, and high debubbling efficiency.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

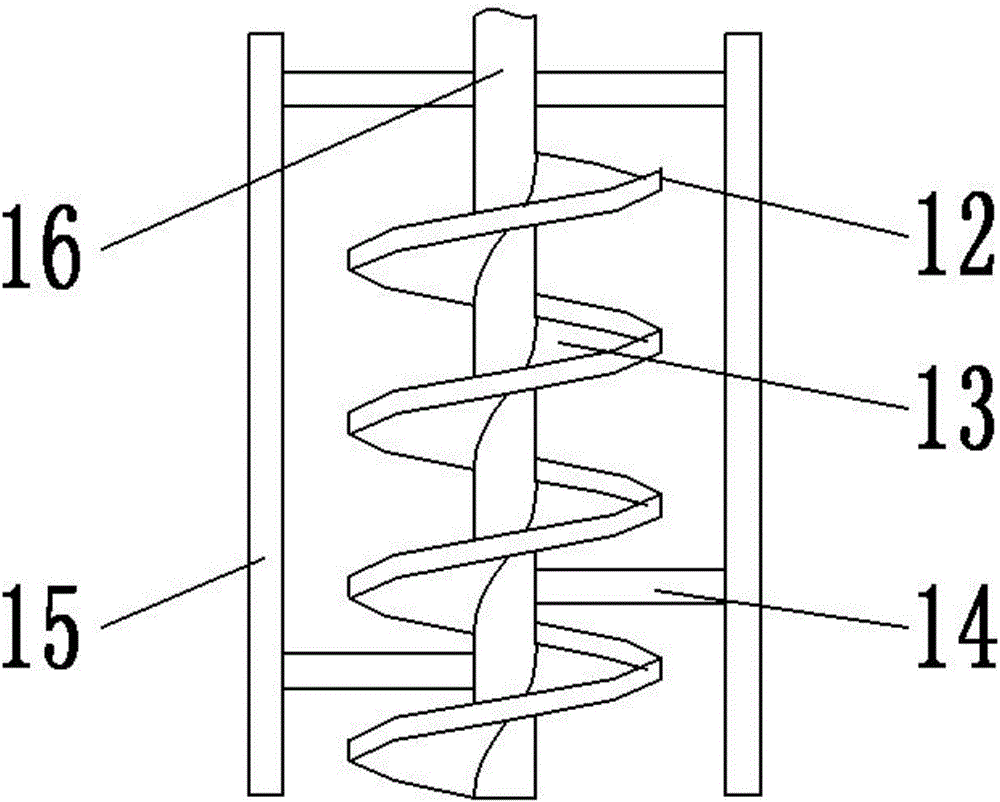

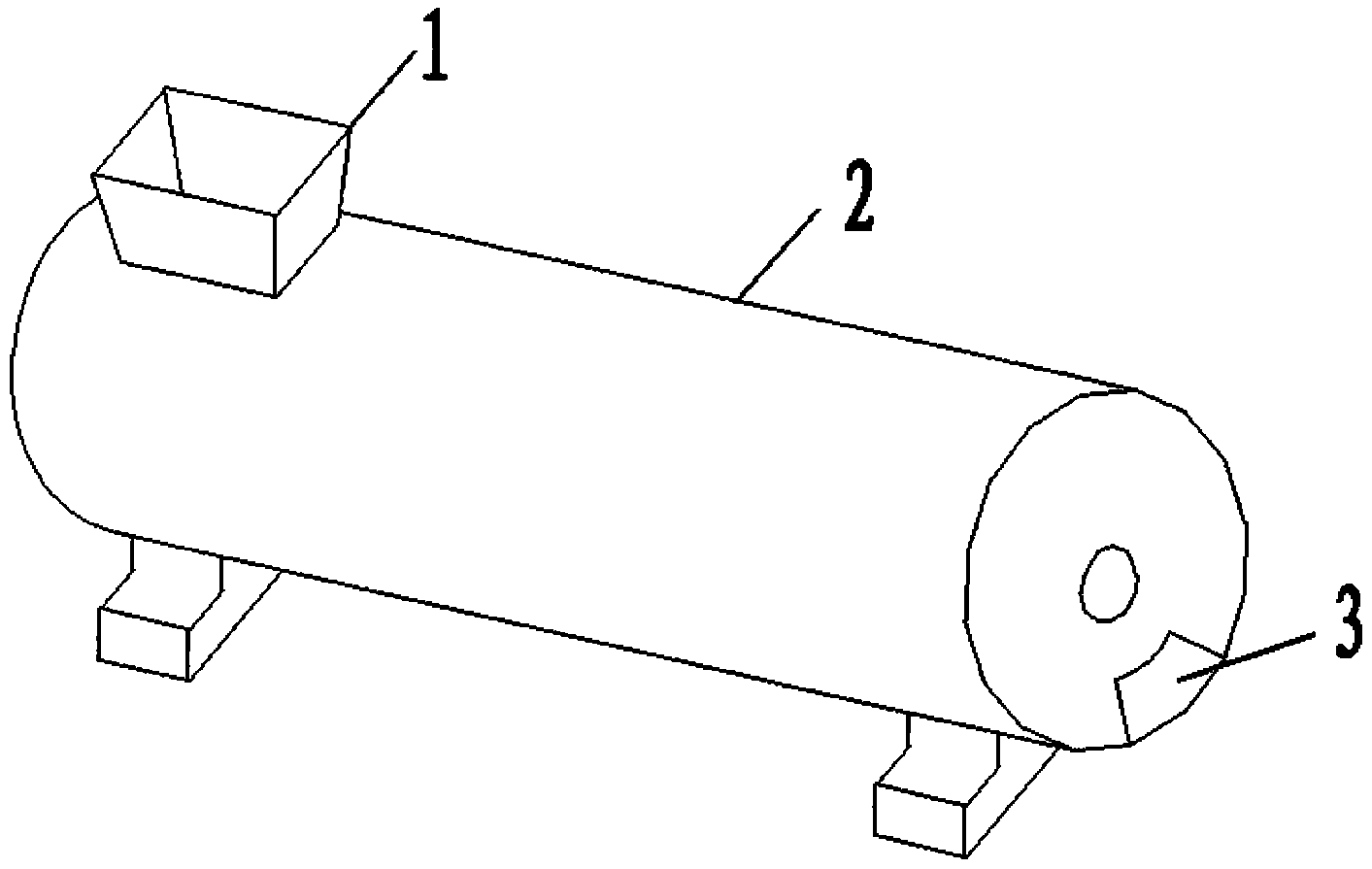

Organic fertilizer fermentation machine

InactiveCN103626540AImprove mixing uniformityReduce stirring resistanceBio-organic fraction processingOrganic fertiliser preparationBarrel ShapedOrganic manure

The invention discloses an organic fertilizer fermentation machine which comprises a material inlet, a material storehouse, a material outlet, a rotating shaft and stirring wheels, wherein the material storehouse is barrel-shaped; the material inlet is formed in the upper part of the material storehouse; the material outlet is formed in the end face of one end, which is far away from the material inlet, of the barrel-shaped material storehouse; the rotating shaft is arranged in the material storehouse; the stirring wheels are spirally mounted on the rotating shaft. The stirring wheels of the organic fertilizer fermentation machine are sections and are provided with windows, so that the stirring resistance and the material discharging resistance are reduced; the uniformity of fertilizer stirring is improved; due to the conical material outlet, materials are more convenient to discharge; a heat preservation layer on the outer layer of the material storehouse can effectively guarantee the fermentation temperature in winter.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Ingredient stirring device for brake pad production and use method of ingredient stirring device

InactiveCN111974276AImprove fluencyImprove the mixing effectTransportation and packagingRotary stirring mixersElectric machineCoupling

The invention discloses an ingredient stirring device for brake pad production and a use method of the ingredient stirring device, relates to the technical field of ingredient stirring devices for brake pad production and aims to improve the stirring effect. The device comprises a main body, wherein a stirring motor is fixed on the outer wall of the top of the main body through screws, a feeding hopper is welded on the outer wall of the top of the main body, a discharging port is formed in the outer wall of the bottom of the main body, an output end of the stirring motor is rotationally connected with a stirring spindle through a coupling, and the same annular support frame is welded on the circumferential outer wall of the stirring spindle through four support rods. The use method of thedevice comprises the following steps: a user puts a to-be-stirred material into the main body from the feeding hopper, and the height of the material is lower than that of a first guide seat. Multi-directional stirring is realized, the device is different from a common central rotating mechanism, the stirring effect of a second discharge hole is better, and the stirring efficiency is higher; and besides, by means of structures such as balls and the like, the rotating smoothness of a stirring countershaft is improved.

Owner:HENGYANG MAITE BRAKE SYST CO LTD

Planetary gear device

ActiveUS20150167819A1Reduce resistanceEasy to changeGear lubrication/coolingToothed gearingsGear wheelSpur gear

A planetary gear device includes: a sun gear having external teeth; a plurality of planet gears having external teeth and meshed with the sun gear; a ring gear having internal teeth and meshed with the planet gears; and a baffle unit disposed between the planet gears adjacent to each other and configured to collect lubricant oil into a collection chamber. The baffle unit includes: a discharge outlet to discharge a portion of the lubricant oil collected in the collection chamber in an axial direction; and a ring gear oil supply hole to discharge another portion of the lubricant oil in a radially outward direction and supplied to the ring gear, and a weir member separable from the baffle unit and configured to cover a portion of the discharge outlet to reserve the lubricant oil to be discharged through the ring gear oil supply hole.

Owner:KAWASAKI HEAVY IND LTD

Centrifugal compressor

ActiveUS20180283387A1Reduce stirring resistancePump componentsPump installationsCentrifugal compressorElectric motor

A centrifugal compressor includes an electric motor coupled to a low-speed shaft, an impeller, and a speed increaser. The speed increaser includes a ring member, a high-speed shaft, rollers, a speed increaser housing member, a discharge passage, and a partition. The ring member includes a circumferential wall and is rotated when the low-speed shaft rotates. The high-speed shaft is coupled to the impeller. The rollers are located between the circumferential wall and the high-speed shaft. The speed increaser housing member stores oil. The discharge passage discharges oil out of the ring member. The partition is located between the speed increaser housing member and the circumferential wall in the radial direction. Power is transmitted from the low-speed shaft to the high-speed shaft by the ring member and the rollers.

Owner:TOYOTA IND CORP

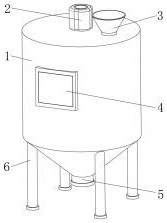

Vertical stirring and mixing equipment with bidirectional stirring devices

InactiveCN106512800AExpand the spraying areaSpraying speed is fastRotary stirring mixersTransportation and packagingEngineeringSolid material

The invention provides vertical stirring and mixing equipment with bidirectional stirring devices. The vertical stirring and mixing equipment comprises a tank and an upper cover. A stirring cavity is arranged inside the tank; a liquid inlet and driving device is arranged on the upper cover; the liquid inlet and driving device comprises a transmission box, a first motor, a liquid inlet pipe and a rotary spray disc; the forward stirring device and the reverse stirring device are arranged in the stirring cavity; the forward stirring device comprises a forward stirring shaft and forward stirring blades; the reverse stirring device comprises a second motor, a reverse stirring shaft and reverse stirring blades; feed hoppers are arranged on the side walls of the top of the tank; a jacket is arranged on the outer wall of the tank. The vertical stirring and mixing equipment has the advantages that the spray areas and the spray speed can be increased for liquid materials by the liquid inlet and driving device, accordingly, the liquid materials and solid materials can be conveniently in sufficient contact with one another, and the mixing quality can be improved; the materials in the tank can be bidirectionally stirred by the forward stirring device and the reverse stirring device, accordingly, the stirring and mixing quality can be improved, and stirring dead spaces in the tank can be avoided.

Owner:郑州吉音动漫科技有限公司

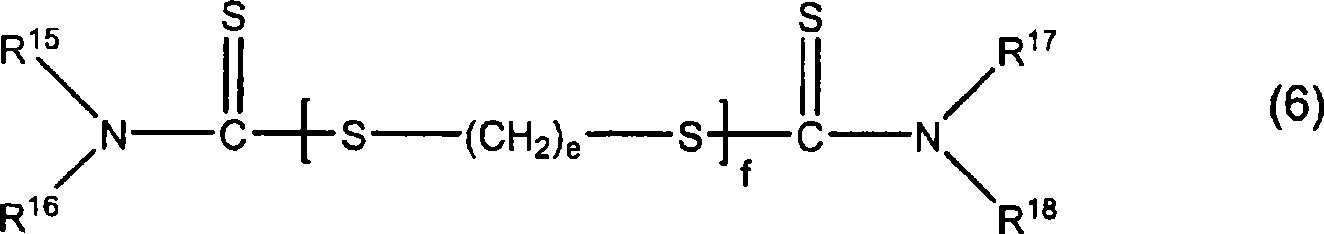

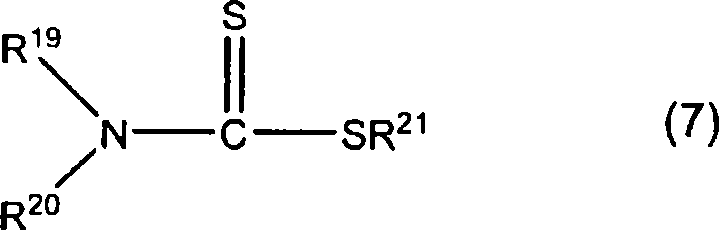

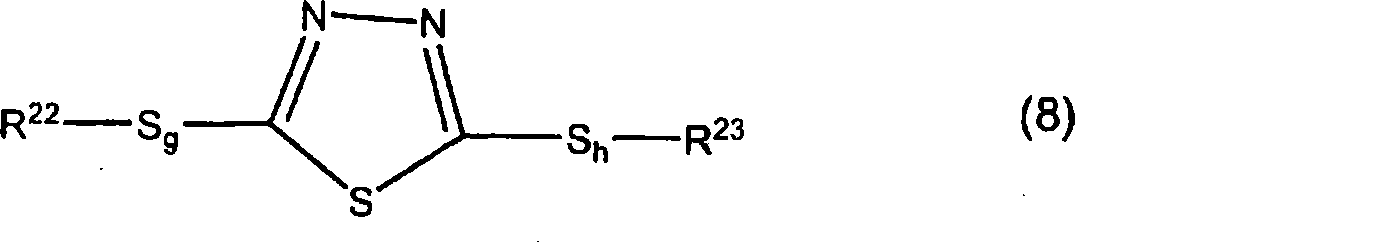

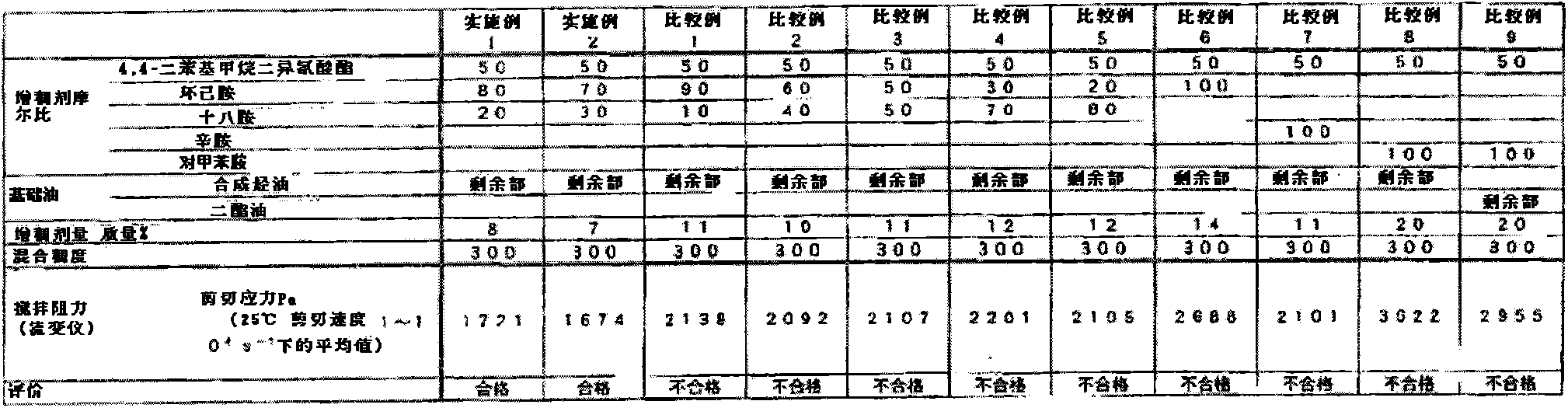

Grease composition

ActiveCN103415603AReduce stirring resistanceDoes not reduce kinematic viscosityRolling contact bearingsBearing componentsBase oilCarbon atom

The invention provides a grease composition which contains a base oil and a thickener, where the thickener is a diurea compound represented by formula (1), and the thickener is contained in an amount of 3 to 20 mass % in the grease composition: wherein R2 is diphenylmethane group; and R1 and R3, which may be the same or different represent cyclohexyl group or a straight-chain or branched alkyl group having 8 to 22 carbon atoms, with the ratio of the number of moles of the cyclohexyl group to the total number of moles of the cyclohexyl group and the alkyl group, expressed as [((the number of the cyclohexyl group) / (the number of the cyclohexyl group+the number of the alkyl group))×100] being 70 to 80 mol %.

Owner:KYODO YUSHI CO LTD

Chemical material stirring and mixing equipment with high stirring force

InactiveCN106693764AEfficient mixingReduce stirring resistanceRotary stirring mixersTransportation and packagingEngineeringSolid material

The invention provides chemical material stirring and mixing equipment with high stirring force. The chemical material stirring and mixing equipment comprises a tank body and an upper lid; the inside of the tank body is provided with a stirring cavity; the upper surface of the upper lid is provided with a driving device and a transmission device, and the lower surface of the upper lid is provided with a liquid entering device; the transmission device is arranged in a turntable mounting groove; the transmission device is composed of a first motor and a first straight gear; the transmission device is composed of a turntable, a second straight gear, a second gear and a sleeve; the liquid entering device is composed of a spraying dish and a liquid entering pipe; the bottom of the stirring cavity is provided with a stirring device; the stirring device is composed of a third motor, a stirring shaft and a stirring plate. According to the chemical material stirring and mixing equipment with the high stirring force, the driving device and the transmission device drive a stirring piece to conduct the rotation in the horizontal direction and the rotation in the vertical direction, which is beneficial to conducting efficient stirring on materials in the tank body; the spraying area and the spraying speed of liquid materials are increased through the liquid entering device, which brings convenience to sufficient contact with solid materials, and is beneficial to fast stirring and mixing among the materials.

Owner:郑州吉音动漫科技有限公司

Hybrid drive apparatus

InactiveUS20120217121A1Reduce stirring resistanceImprove cooling effectFluid actuated clutchesFriction clutchesEngineeringElectrical and Electronics engineering

A hybrid drive apparatus includes a case with first and second friction plates that can be soaked with oil. A communication mechanism allows or cuts off the communication between an internal space of the case and outside, and discharges the to the outside when the internal space communicates with the outside. A controller controls an engagement pressure to obtain a disengaged state in which the first and second friction plates are disengaged and a slipping state in which the first and second friction plates slip and rotate. An oil adjustment portion adjusts an oil amount supplied to the internal space, based on a control state of the friction engagement device, and adjusts the oil amount to a first amount when the friction engagement device is disengaged, and adjusts the oil amount to a second amount larger than the first amount when the friction engagement device starts to slip.

Owner:AISIN AW CO LTD

Custard cream and production method thereof

ActiveCN107047804AIncrease the degree of mixingReduce stirring resistanceEdible oils/fats ingredientsTransportation and packagingHydroxypropylmethyl celluloseChemistry

The invention discloses custard cream and production method thereof and relates to cream and production methods thereof. The custard cream comprises, by mass percentage, 4-8% of palm oil, 1-6% of anhydrous butter, 2-10% of non-hydrogenated vegetable oil, 5-20% of syrup, 5-20% of single cream, 0.1-1% of yolk powder, 0.5-5% of whole milk powder, 0.5-5% of sweet whey powder, 1-5% of white granulated sugar, 2-8% of glucose, 0.2-2% of hydroxypropyl distarch phosphate, 0.1-1% of hydroxypropyl methyl cellulose, 0.01-0.1% of carrageenan, 0.01-0.1% of locust bean gum, 0.2-2% of xanthan gum, 0.05-0.5% of microcrystalline cellulose, 0.02-0.2% of sorbitan monostearate and the like.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com