High-concentration waste liquid treatment evaporating reactor

A waste liquid treatment and evaporator technology, applied in the field of evaporators, can solve the problems of airtight opacity, inaccurate liquid level display, large fluctuations, etc., and achieve the effects of reducing stirring resistance, improving stirring effect, and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

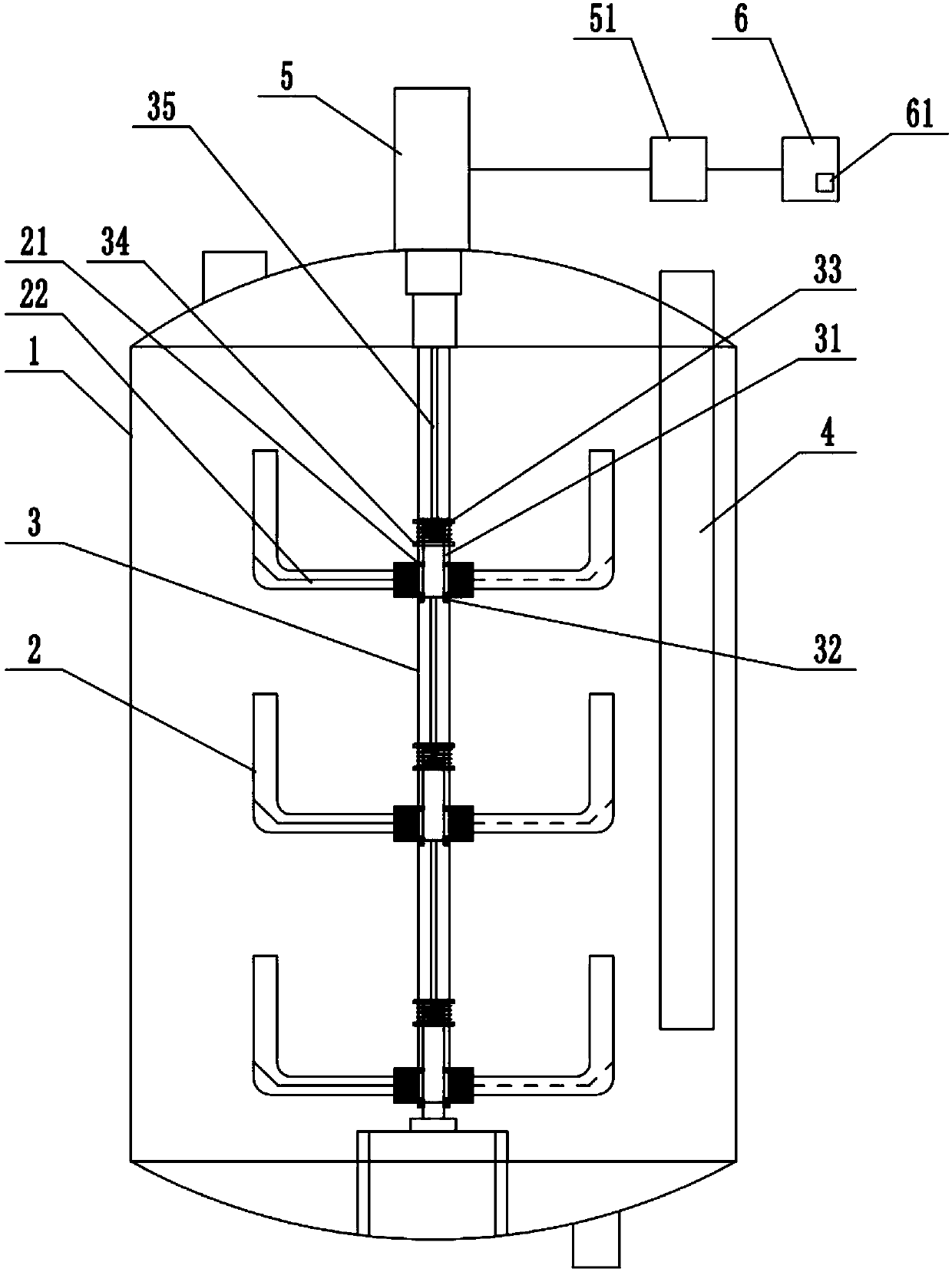

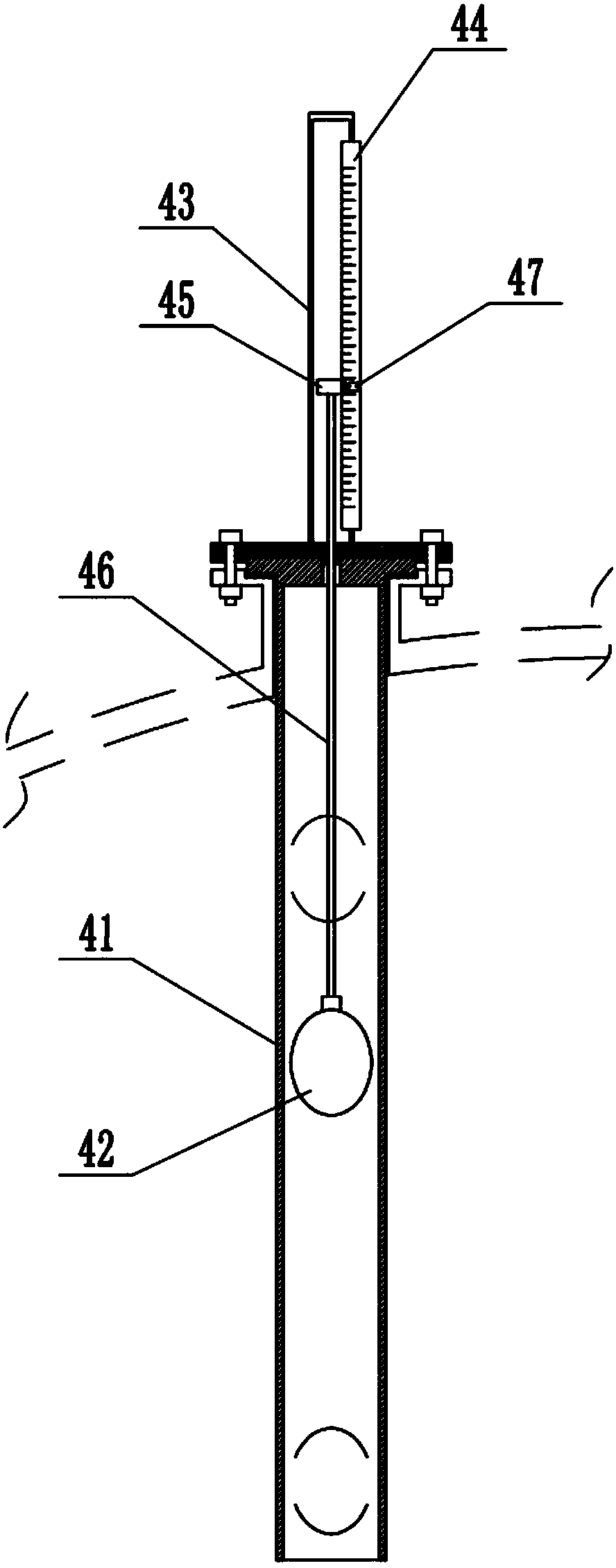

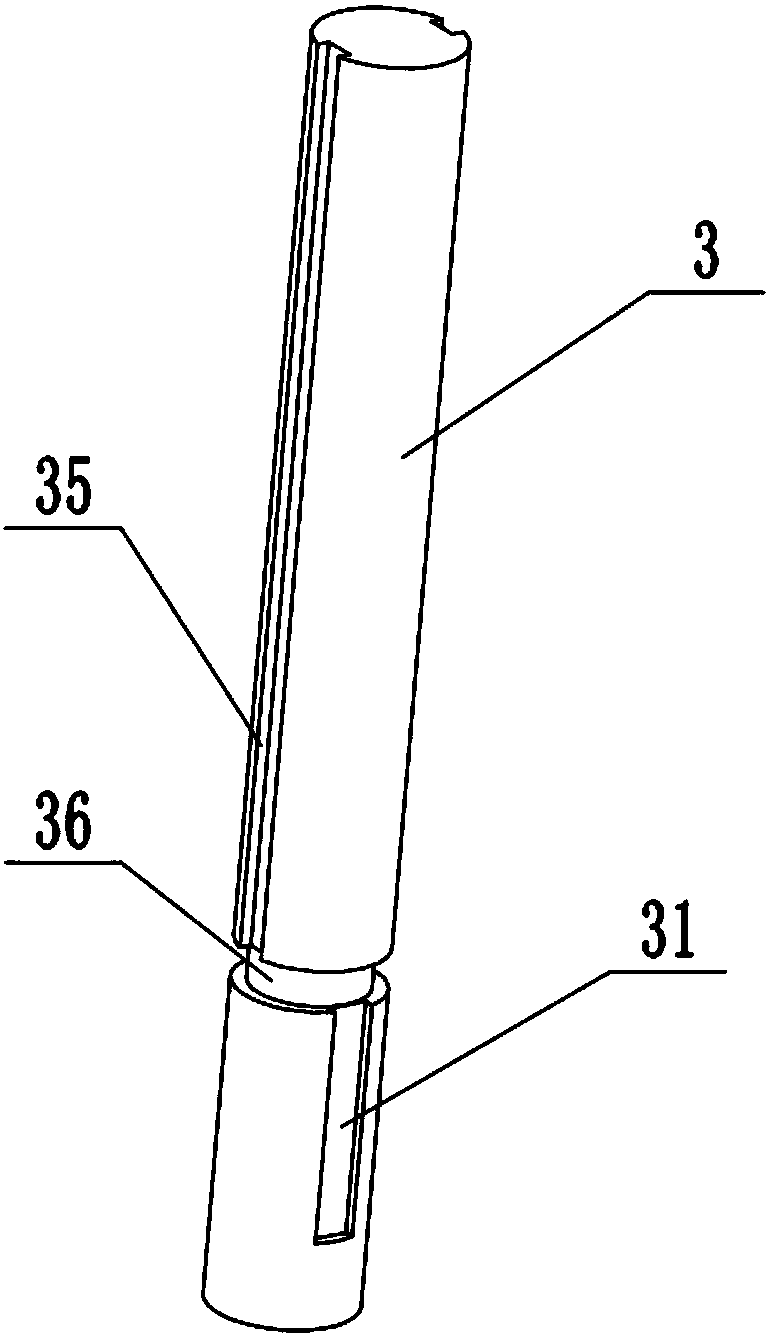

[0030] like figure 1 , figure 2 As shown, the high-concentration waste liquid treatment evaporator in this embodiment includes a tank body 1, in which a stirring shaft 3 with stirring blades 2 is installed and a liquid level detection device 4 is installed, and the stirring shaft 3 passes through the tank body 1 Driven by the stirring motor 5 at the top, the liquid level detection device 4 includes a float tube 41 inserted in the tank body 1, a float ball 42 floating in the float tube 41, installed on the top of the float tube 41 and placed in the tank body 1 outside the scale tube 43, the magnetic induction scale 44 installed on the outside of the scale tube 43, the scale tube 43 is provided with a magnetic block 45 that can move up and down, and the magnetic block 45 is connected to the floating ball 42 through a connecting rod 46; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com