Double-shaft type stirring debubbler used for vacuum box

A stirring and defoaming, double-shaft technology is applied in the field of double-shaft stirring and defoaming, which can solve the problems of limited operation time and reduced fluidity, and achieve the effects of reducing stirring resistance, high defoaming efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

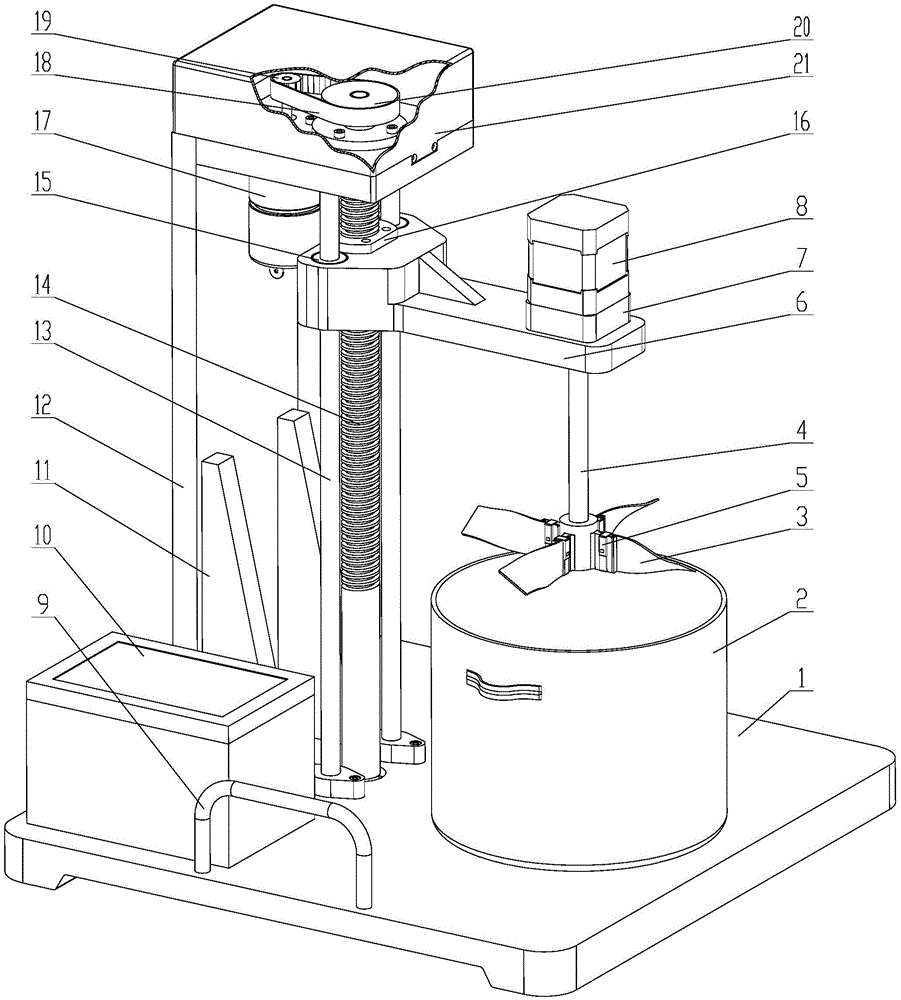

[0030] combined with Figures 1 to 3 The specific embodiment of the present invention is described further:

[0031] The double-shaft stirring degasser used in the vacuum box includes a base, a barrel for holding materials, a lifting device and a stirring device. The lifting device is fixed on the base through a bracket, the stirring device is connected to the lifting device through a cantilever slide, and the stirring device is suspended directly above the material cylinder, and the material cylinder is fixed on the base; the driving lifting device drives the stirring device to lift vertically, The stirring device rotates and stirs the raw materials in the barrel.

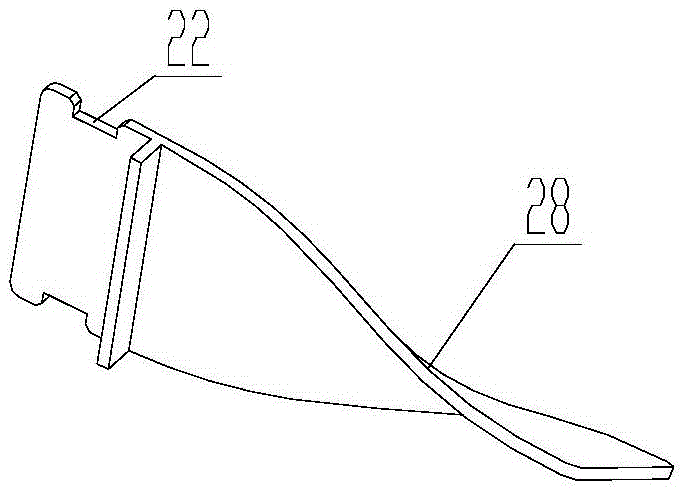

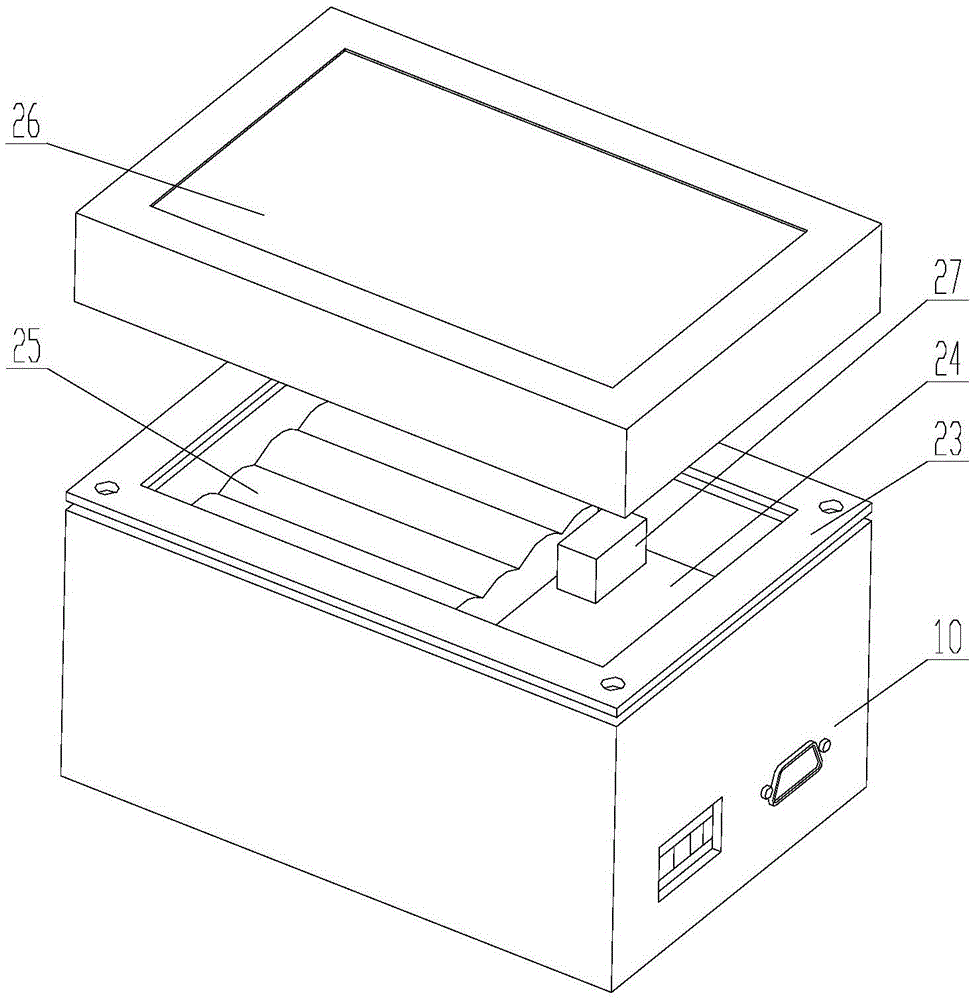

[0032] see figure 1 , the double-shaft stirring degasser for the vacuum box includes a base 1, a barrel 2, a cantilever slide 6 and a stirring rod 4. The cartridge 2 is placed on the base 1 . The top of the barrel 2 is provided with a stirring rod 4, the top of the stirring rod 4 is connected with a stirring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com