Vertical stirring and mixing equipment with bidirectional stirring devices

A stirring mixing and two-way stirring technology, which is applied in the field of stirring machinery, can solve the problems of large resistance of stirring blades, low stirring efficiency, and influence on stirring effect, and achieve the effects of reducing stirring resistance, improving mixing quality, and improving stirring and mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

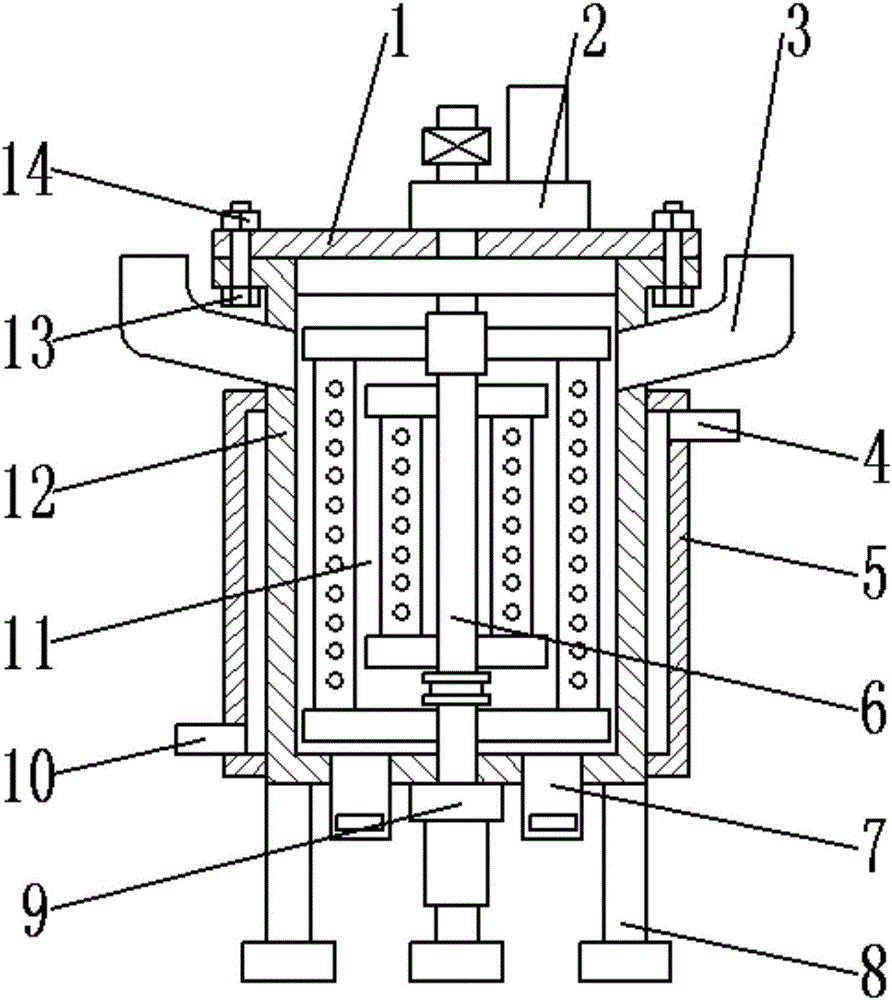

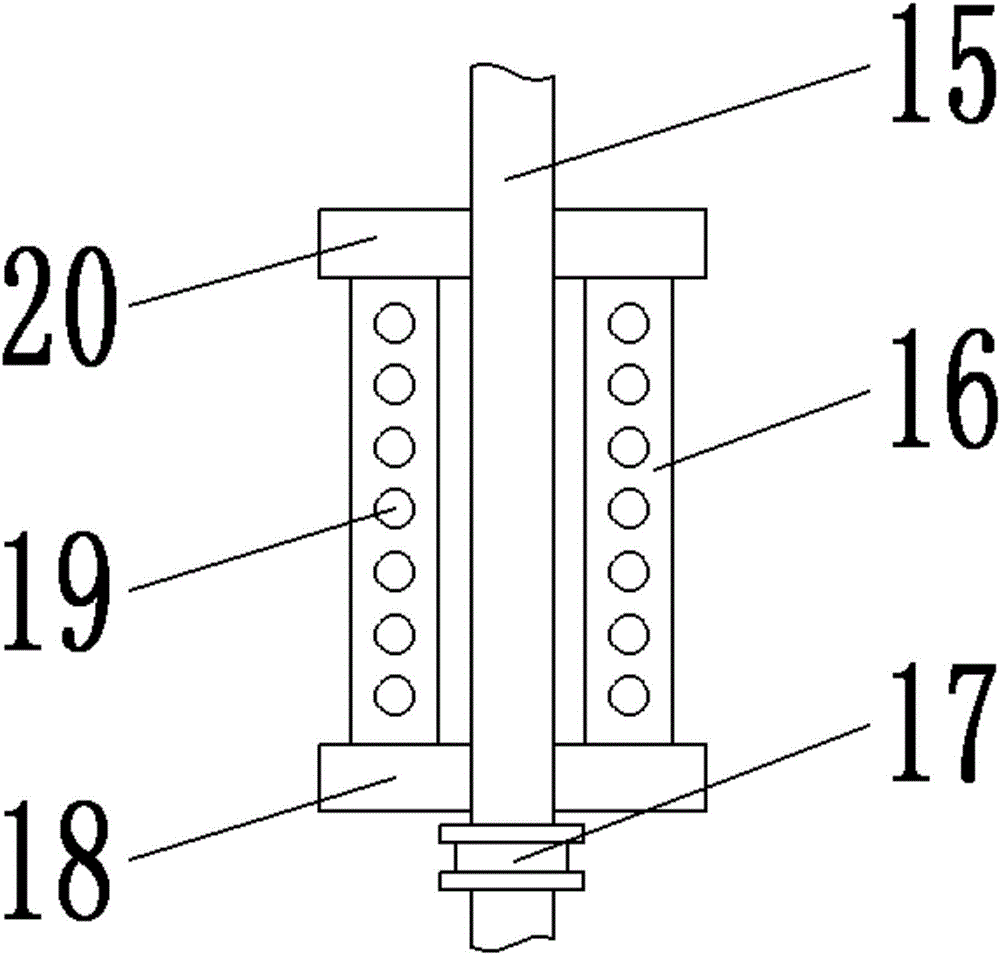

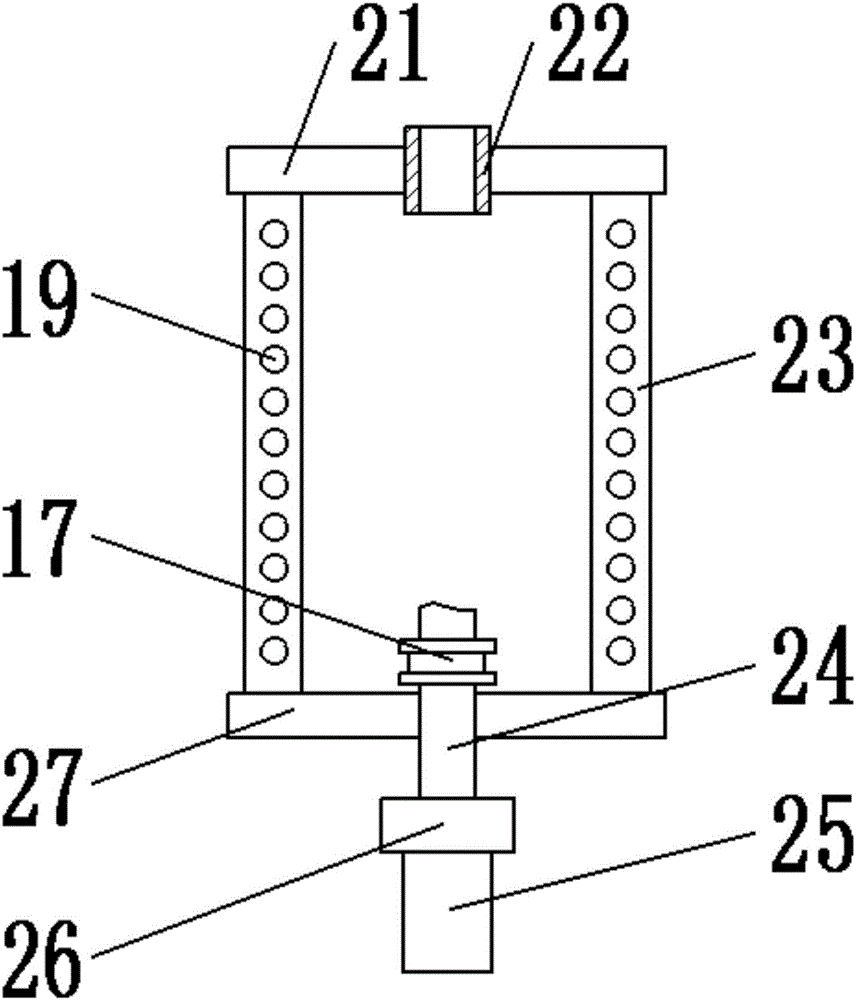

[0018] see Figure 1-4 , a vertical stirring and mixing device with a two-way stirring device, comprising a tank body 12 and a top cover 1; the tank body 12 is set as a hollow cylinder, the inside of which is set as a stirring chamber 11, and the top opening is provided with a top cover 1; The upper cover 1 is connected with the tank body 12 through the mutual screwing of the bolt 13 and the nut 14, and the upper cover 1 and the tank body 12 are made of stainless steel; the upper cover 1 is provided with a liquid inlet and a driving device 2; The liquid inlet and driving device 2 is composed of a transmission box 29, a first motor 28, a liquid inlet pipe 37 and a rotating spray plate 33; the transmission box 29 is fixed on the upper surface of the upper cover 1, and the first gear 30 and the second Two gears 35; the first gear 30 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com