Grease composition

A technology of lubricating grease composition and urea compound, applied in lubricating composition, mechanical equipment, thickener and other directions, can solve the problems of oil film destruction, limited base oil, inability to meet sufficient service life, etc. The effect of suppressing the occurrence of oil film breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of test grease

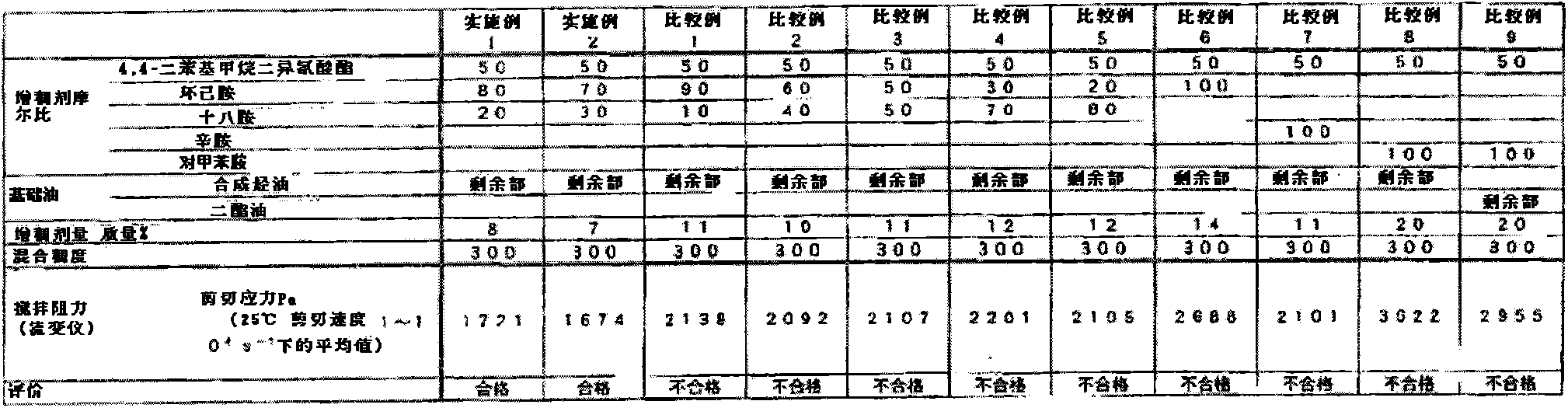

[0045] The thickeners and base oils shown in Table 1 were used to prepare grease compositions of Examples and Comparative Examples. Specifically, 4,4-diphenylmethane diisocyanate and a predetermined amine were reacted in a base oil, heated and cooled, and then kneaded with a 3-roll mill to obtain Examples 1 and 2 and Comparative Examples 1-9 The grease composition. As the base oil, the kinematic viscosity at 40°C measured in accordance with JIS K222023 is used, which is 70.2mm 2 / s synthetic hydrocarbon oil, namely poly-α-olefin oil, or its kinematic viscosity at 40℃ is 11.6mm 2 / s diester oil is dioctyl sebacate. The amount of thickener was adjusted so that the blending consistency (test method JIS K22207.) of the grease composition was 300.

[0046] The composition prepared above was evaluated by the following test method. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com