Wastewater treatment device for garment fabric disinfection

A waste water treatment and fabric technology, applied in the field of clothing processing, can solve the problems of affecting the mixing reduction effect and clogging pipelines, and achieve the effects of good impurity crushing effect, reduction of impurity clogging, and lower stirring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

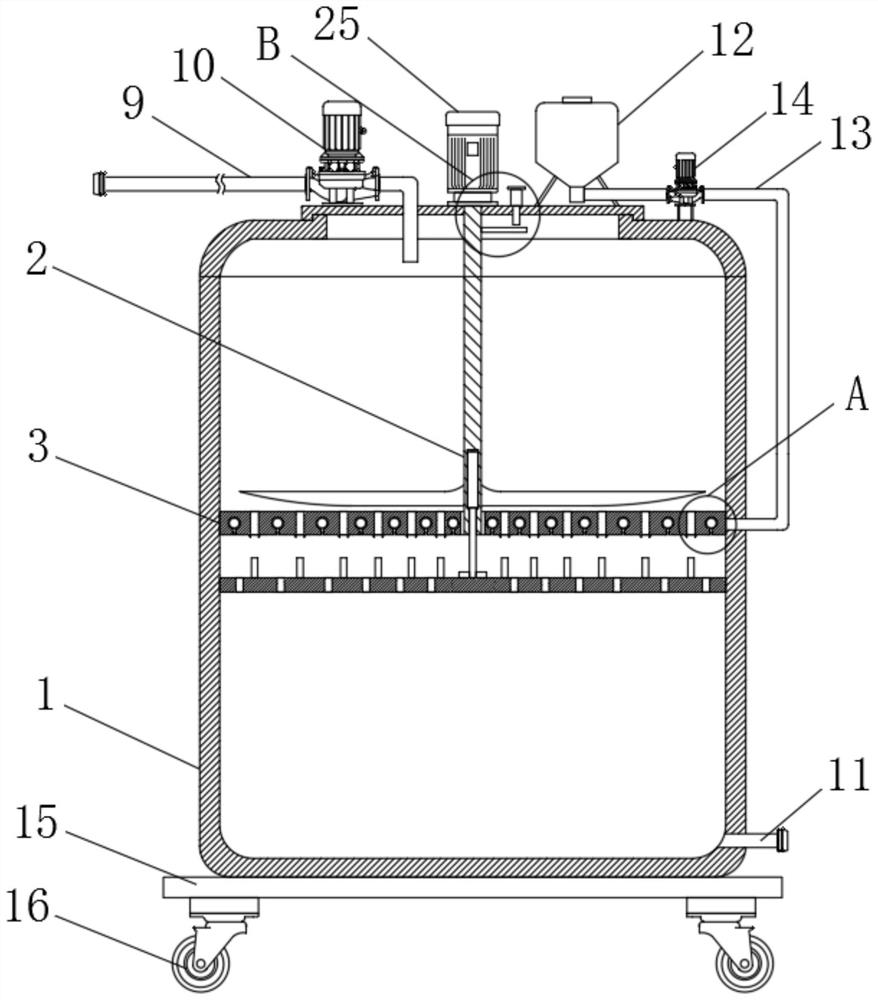

[0032] Such as Figure 1-4 As shown, a waste water treatment device for disinfection of clothing fabrics includes a tank body 1, a crushing and mixing assembly 2 installed in the tank body 1, and a drug feeding and diverting assembly 3.

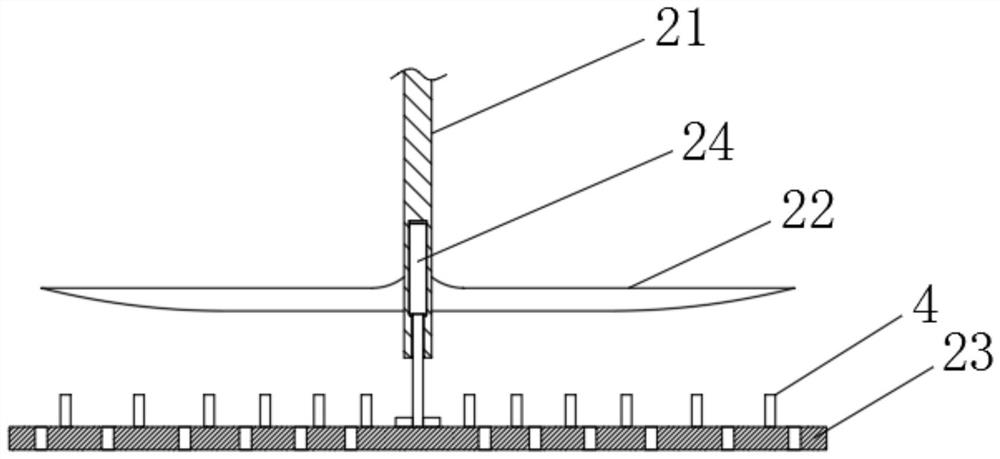

[0033] The crushing and mixing assembly 2 includes a stirring shaft 21, a crushing blade 22, a lower filter plate 23 and a No. 1 electric push rod 24, and the crushing blade 22 and the lower filter plate 23 are distributed up and down on the stirring shaft 21 and follow the rotation of the stirring shaft 21 , the No. 1 electric push rod 24 is embedded in the bottom of the stirring shaft 21 and drives the lower filter plate 23 to move up and down.

[0034] The top end of the stirring shaft 21 passes through the tank body 1 and is connected to a servo motor 25 , and the servo motor 25 is fixed on the top of the tank body 1 .

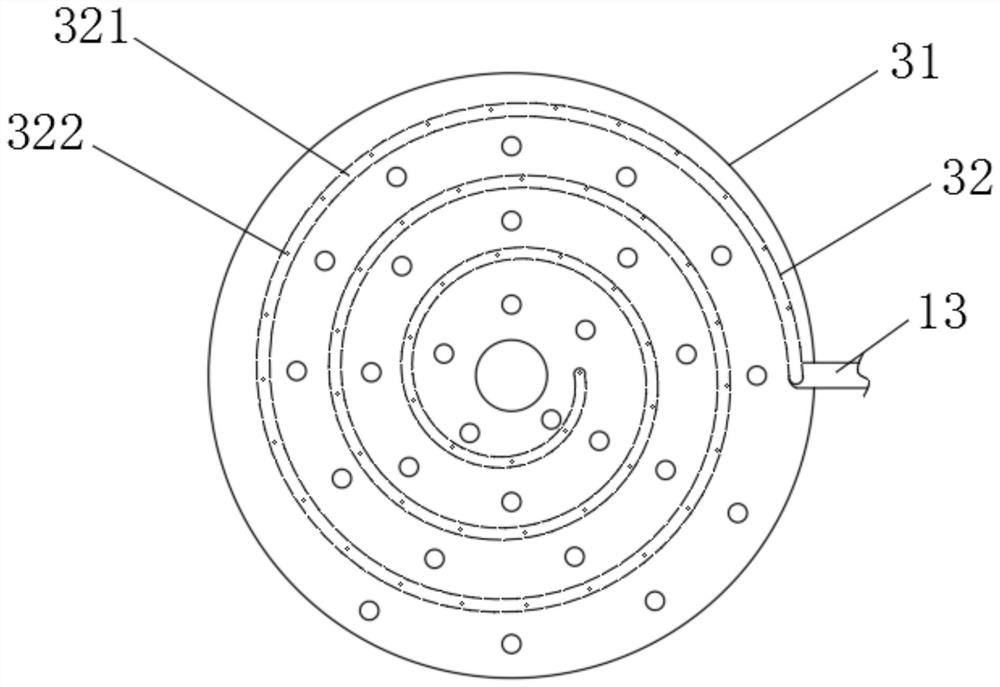

[0035] The dosing and splitting assembly 3 includes an upper filter plate 31 arranged between the crushing blade 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com