Ingredient stirring device for brake pad production and use method of ingredient stirring device

A technology of stirring device and brake pad, which is applied to mixers with rotary stirring devices, accessories of mixers, chemical instruments and methods, etc., can solve the problems of insufficient mixing, low efficiency, poor stirring effect, etc., and improve the stirring effect. , High stirring efficiency, the effect of reducing stirring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

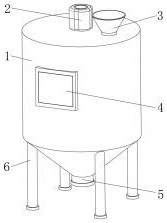

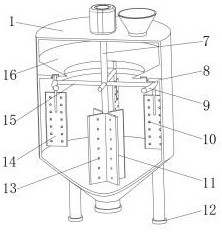

[0038] An ingredient mixing device for brake pad production, such as Figure 1-4As shown, it includes a main body 1, the top outer wall of the main body 1 is fixed with a stirring motor 2 by screws, and the top outer wall of the main body 1 is welded with a feed hopper 3, the bottom outer wall of the main body 1 is provided with a discharge port 5, and the stirring motor 2 The output end is rotatably connected with a stirring main shaft 7 through a coupling, and the outer wall of the stirring main shaft 7 is welded with the same annular support frame 9 through four support rods 15, and the inner wall of the annular support frame 9 is respectively rotatably connected with four circular support frames. Distributed first stirring mechanism, the bottom of the stirring main shaft 7 is also provided with a second stirring mechanism; the first stirring mechanism includes a first stirring blade 14 and a stirring secondary shaft 17, and the stirring secondary shaft 17 passes through a c...

Embodiment 2

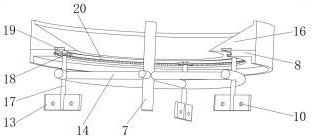

[0044] An ingredient mixing device for brake pad production, such as Figure 5 , Image 6 As shown, in order to fully stir the material at the bottom of the main body 1; this embodiment makes the following improvements on the basis of embodiment 1: the second stirring mechanism is specifically a circumferentially distributed elastic plate 25, and one end of the elastic plate 25 is Welded to the peripheral outer wall of the bottom end of the stirring spindle 7, the elastic plate 25 has a whirlwind structure as a whole; by setting the elastic plate 25 with a whirlwind structure, it can better match the shape of the bottom of the main body 1, thereby improving the stirring of the bottom material of the main body 1 The effect is to strengthen the overall mixing degree and ensure the mixing efficiency.

[0045] In order to improve the stirring effect of the elastic plate 25, such as Image 6 As shown, the outer wall of one side of the elastic plate 25 is integrally provided with ...

Embodiment 3

[0049] A method of using the ingredient stirring device for brake pad production described in embodiment 1 or 2, such as Figure 1-6 shown, including the following steps:

[0050] S1: The user puts the material to be stirred into the main body 1 from the hopper 3, and ensures that the height of the material is lower than the height of the first guide seat 8;

[0051] S2: Set the rotation speed and working time of the stirring motor 2 through the control panel 4, and control the stirring motor 2 to stir;

[0052] S3: Take out the mixed material through the discharge port 5 after the stirring is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com