Ball bearing and supporting construction

A technology of ball bearings and balls, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reduced rotational performance, increased friction torque, small radial clearance, etc., and achieves improved transmission efficiency and low loss torque Effect of reducing and reducing dynamic friction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

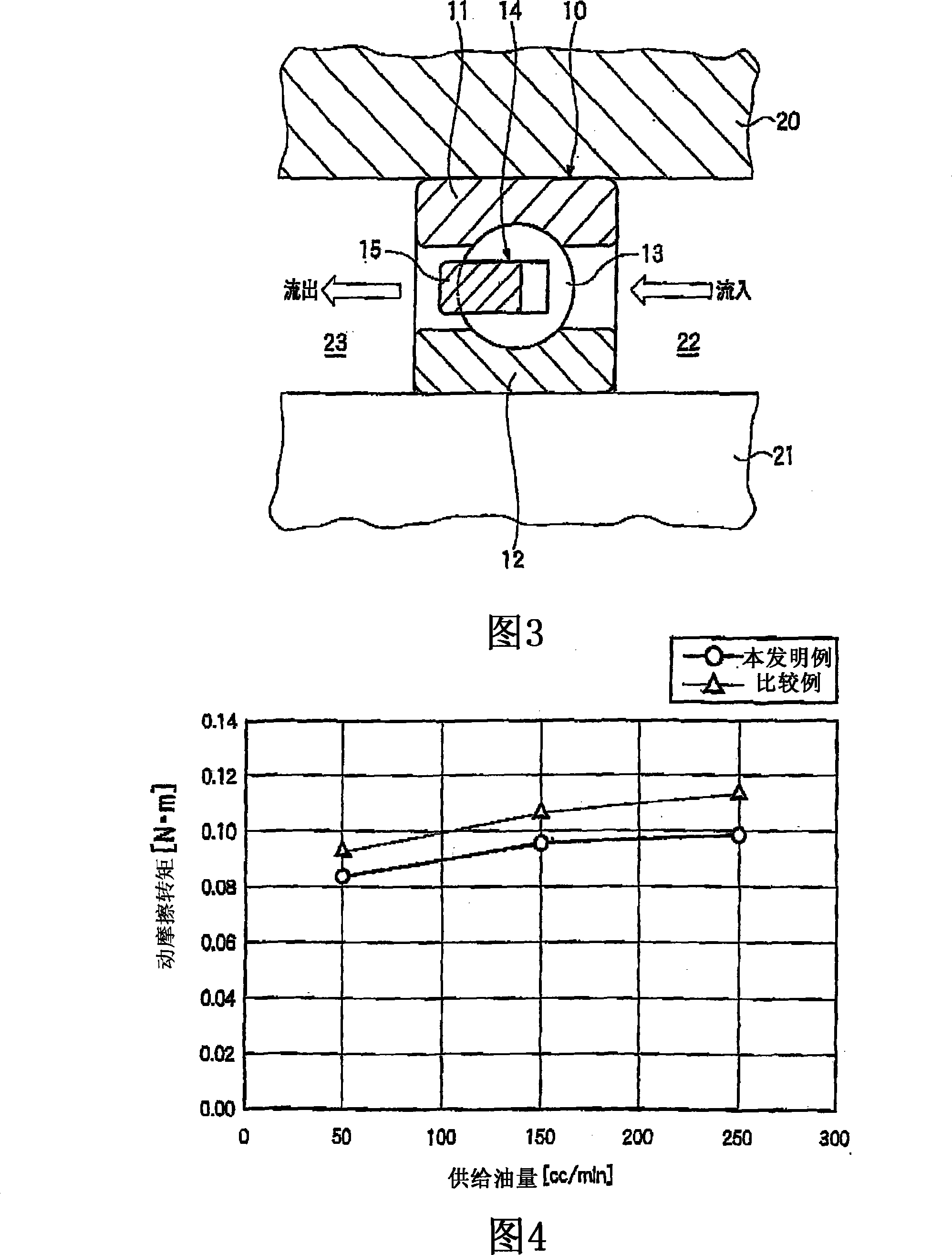

[0115] Hereinafter, a rotation test performed for confirming the function and effect of the ball bearing 10 (example of the present invention) of the present invention will be described.

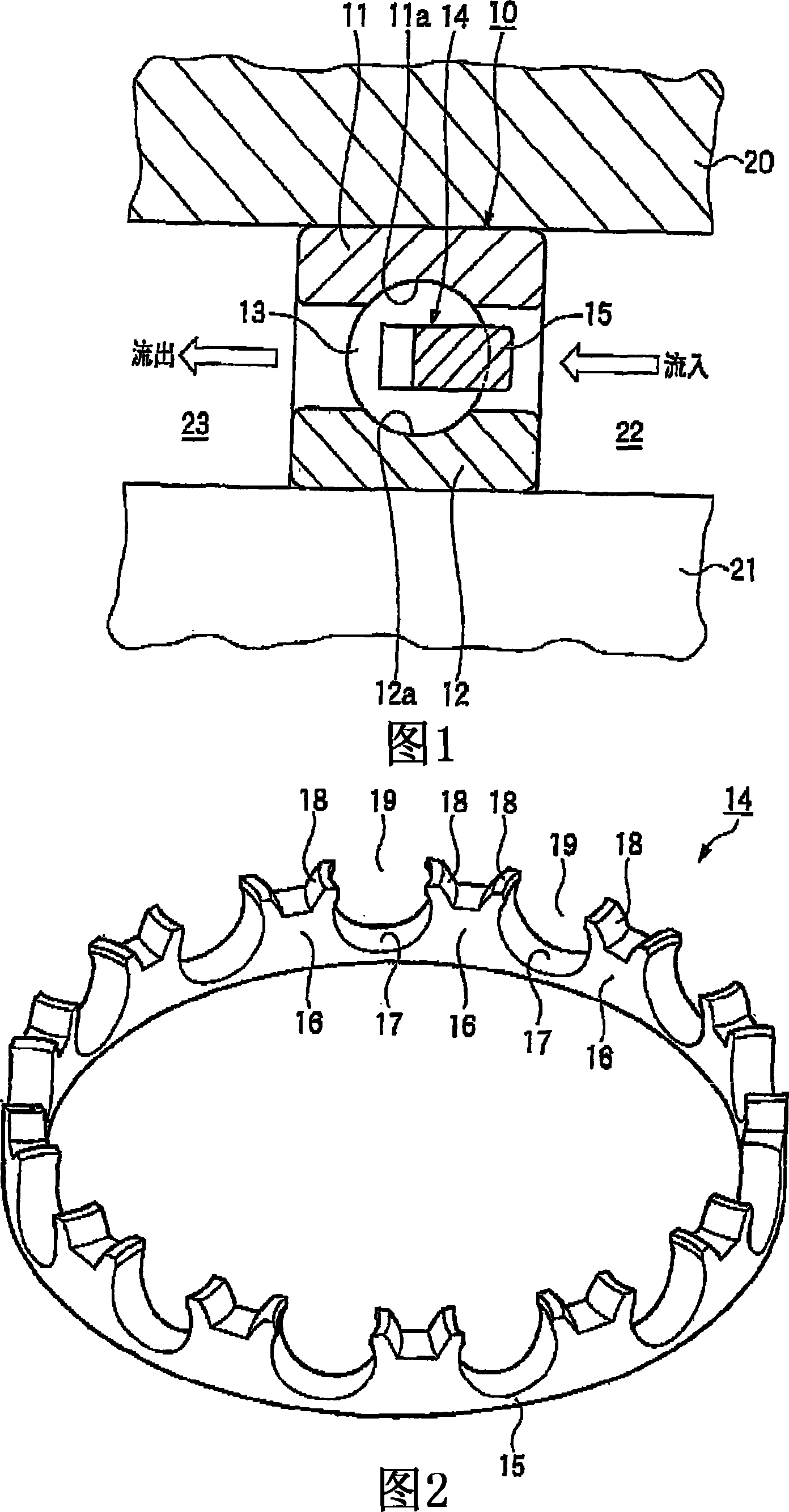

[0116] The ball bearings used in the examples of the present invention and comparative examples used in this test all adopt deep groove ball bearings of standard design (it is said that the JIS number is 6826, inner diameter φ130mm×outer diameter 18mm, PCD147.5mm), as shown in the example of the present invention 1, the rim portion 15 of the crown-shaped cage 14 is arranged on the lubricating oil inflow side, and in the comparative example, as shown in FIG. 3 , the rim portion 15 is arranged on the lubricating oil outflow side.

[0117] In this test, an example of the present invention and a comparative example were prepared, and they were rotated under the following test conditions to measure the relationship between the amount of oil supplied and the dynamic friction torque. Fig. 4 shows th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com