Lubricating device of rolling bearing

A technology of rolling bearing and lubricating device, applied in rolling contact bearing, rotating bearing, bearing, etc., can solve the problems of increased power loss and increased stirring resistance of cooling oil, and achieve the effect of reducing stirring resistance and good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

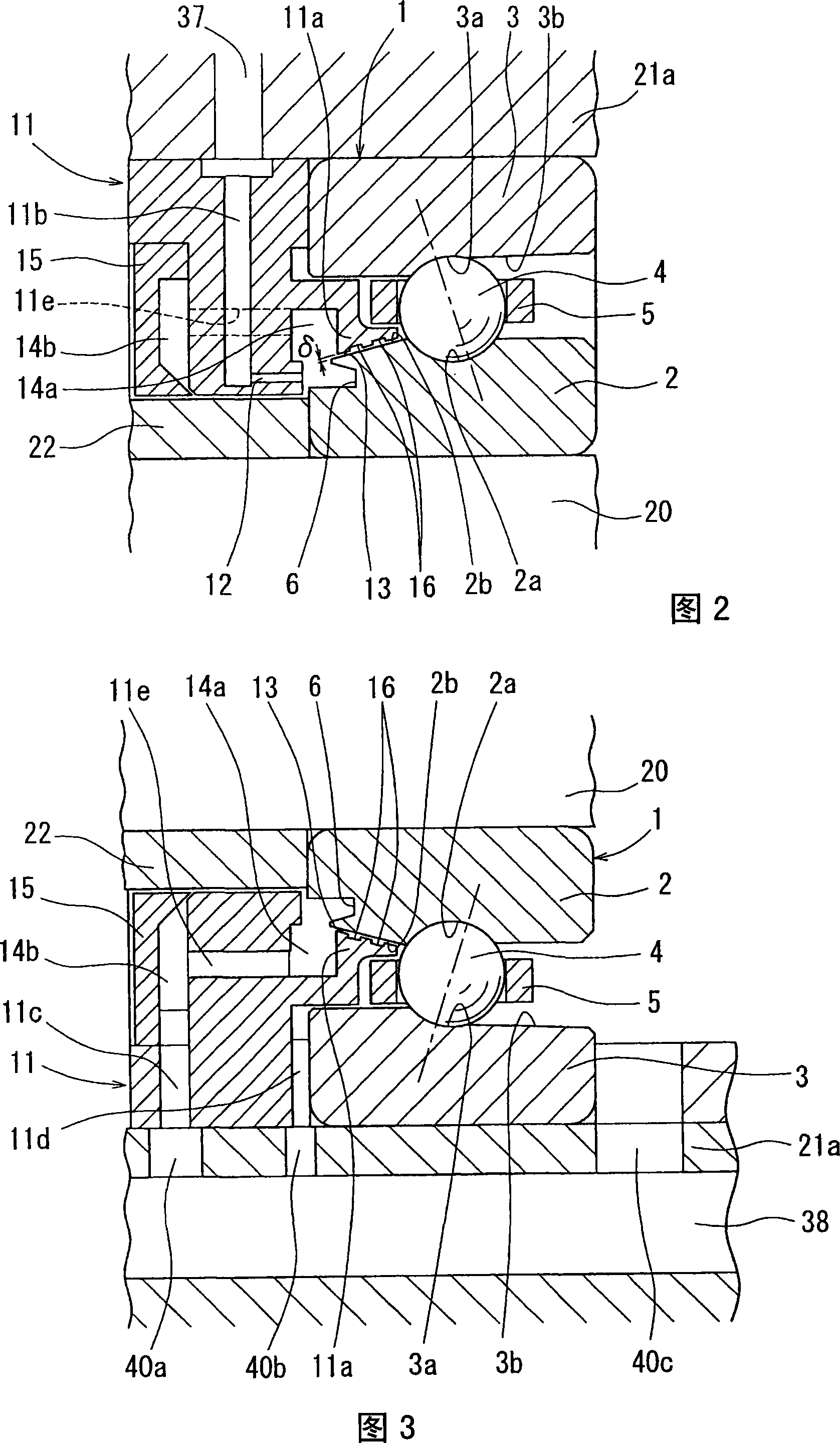

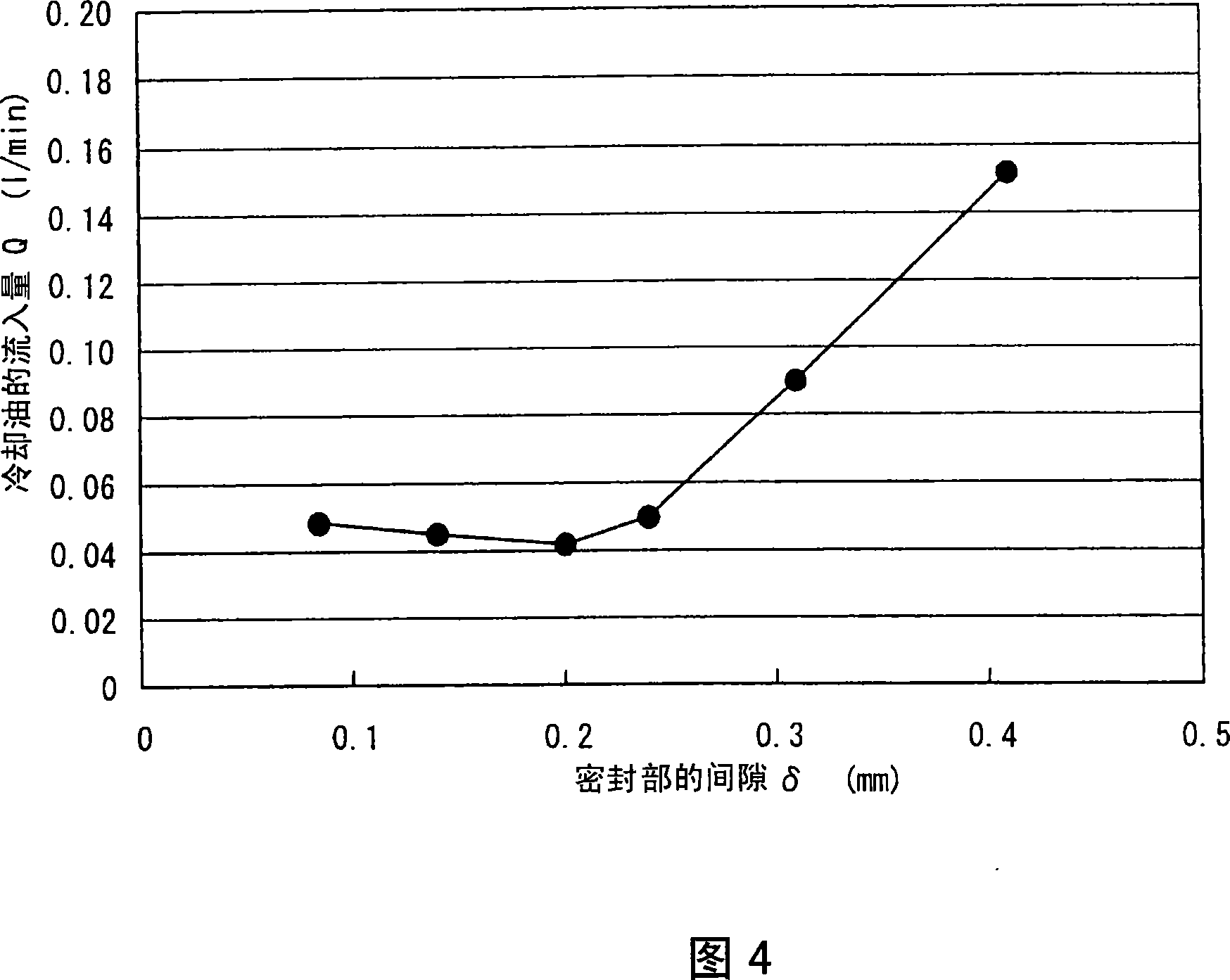

[0069] The gap δ of the sealing portion 13 as shown in FIG. 2 was changed, and the inflow amount Q of the cooling oil sprayed from the nozzle 12 into the inside of the bearing from the sealing portion 13 as lubricating oil was measured. The diameter of the main shaft 20 (inner diameter of the angular contact ball bearing 1 ) was set to 70 mm, the rotational speed thereof was set to 30000 rpm, and the discharge rate of the cooling oil from the nozzle 12 was set to 0.6 liter / minute.

[0070] FIG. 4 shows the measurement results of the inflow amount Q of the above-mentioned cooling oil. From the measurement results, it can be seen that the inflow amount Q of the cooling oil tends to become a horizontal line because the amount is small when the gap is 0.2 mm or less, and it increases rapidly when the gap exceeds 0.2 mm. Therefore, by setting the gap δ of the seal part to 0.2mm or less, the inflow quantity Q of the cooling oil flowing into the bearing can be stably controlled to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com