A Selective Inflow Control Device Based on Swirl Adding Resistance Effect

An inflow control, selective technology, used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of unstable performance, low fluid identification accuracy, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

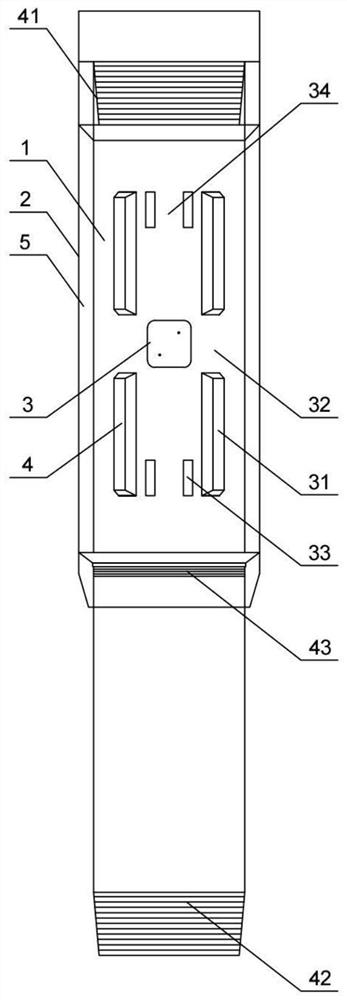

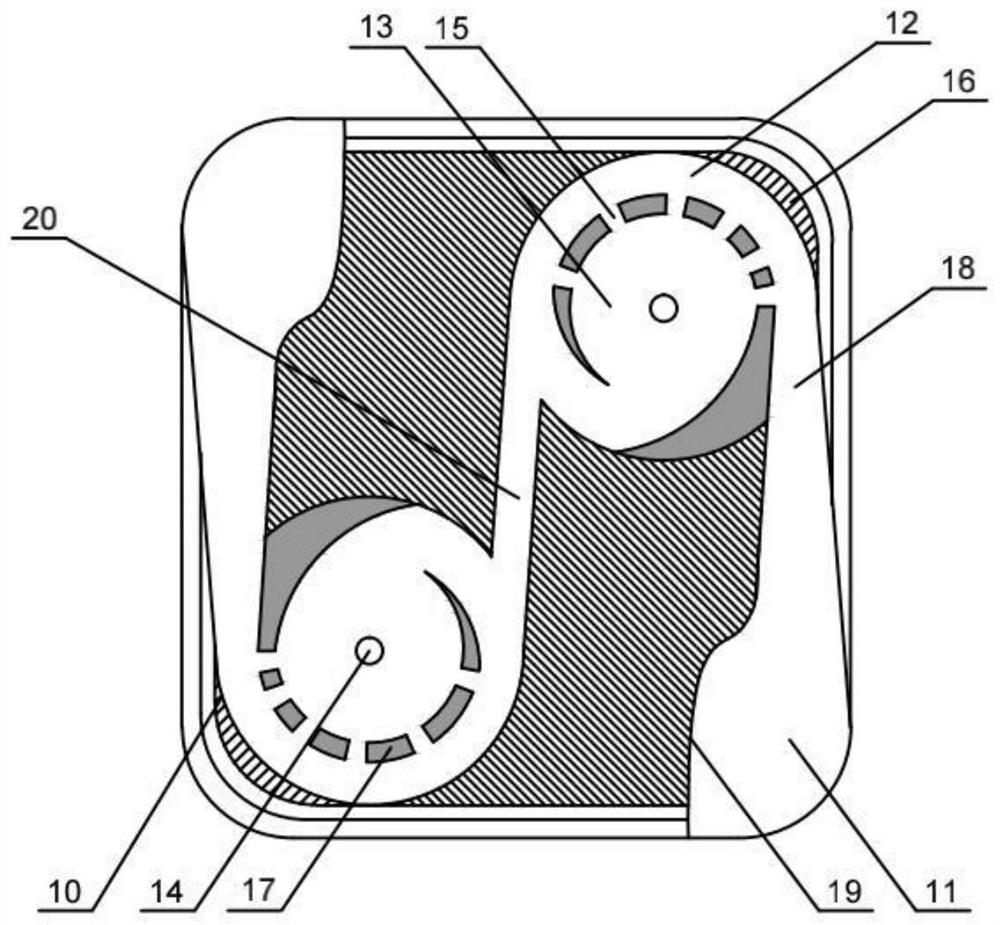

[0029] figure 1 Schematically shows a selective inflow control device based on swirling resistance increasing effect according to an embodiment of the present invention. According to the selective inflow control device based on the swirling resistance increasing effect of the present invention, it can automatically control water and stabilize oil.

[0030] Such as figure 1 As shown, the selective inflow control device based on the swirling resistance increasing effect described in this embodiment includes a central pipe 1 . The central pipe 1 is connected with a special precision sand control screen or other completion strings through a coupling. The device described in this embodiment also includes an outer cylinder 2 . The outer cylinder 2 is sheathed outside the central pipe 1 , and the lower end of the outer cylinder 2 is sealingly connected to the middle of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com