Horizontal mortar mixer

A technology for mixers and mortars, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as stirring up, uneven mixing, and component ratios far from expected, so as to improve mixing uniformity and reduce stirring resistance , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

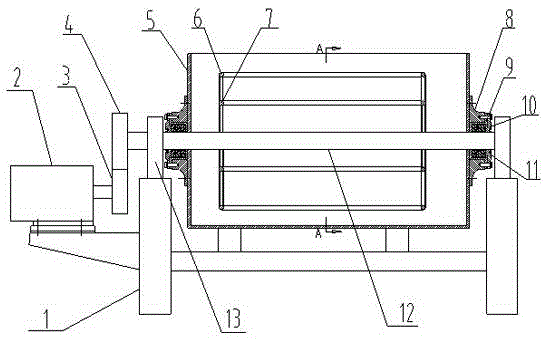

[0015] A horizontal mortar mixer, comprising a frame 1, a stirring box 5, a stirring shaft 12 and a driving device, the stirring shaft 12 is rotatably installed in the stirring box 5, and both ends of the stirring shaft 12 extend out of the stirring box 5, supported in corresponding bearings.

[0016] The bearings are supported on the frame 1 through the corresponding bearing housings 13, and the protruding ends of the stirring shafts 12 are sealed and fitted with the stirring box 5 through sealing devices.

[0017] The sealing device includes a connecting seat 8 with a central hole, a stuffing box 9 with an inner flange at one end and an outer flange at the other end, a packing 10 and a gland 11. The connecting seat 8 is connected to the stirring On the box 5, the connecting seat 8 is set on the end of the stirring shaft 12 through the central hole, and a gap for nesting the stuffing box 9 is formed between the central hole and the stirring shaft 12, and one end of the stuffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com