Flue gas dust removal device with stirring and cleaning mechanism

A technology of dust removal device and cleaning mechanism, which is applied in the direction of combination device, dispersed particle separation, chemical instrument and method, etc. It can solve the problems of reduced dust removal effect of equipment, dust blockage, poor working environment of filler adsorption device, etc., and achieves the convenience of filler sliding and rolling , to ensure that it is not blocked, and the cleaning effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

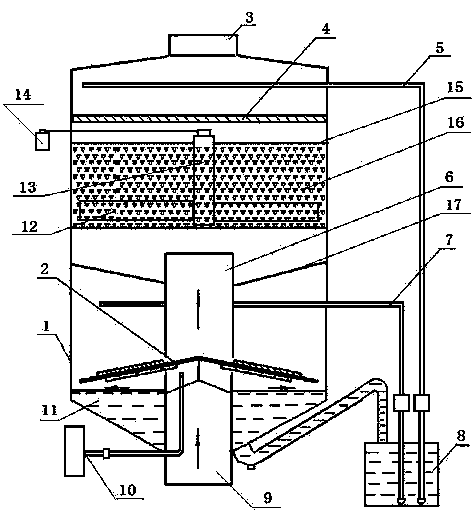

[0010] Such as figure 1 Shown is a schematic diagram of the present invention, which includes a housing (1), a smoke inlet (9), a smoke exhaust port (3), a flue gas duct (6), a flue gas pretreatment device (10), and an impeller dust removal device ( 2), dust removal spray device (7), clapboard (17), filter screen (4), cleaning spray device (5), liquid tank (11), liquid supply device (8), and in the flue gas duct ( 6) The filler adsorption device (15) above is characterized in that: the filler adsorption device (15) is equipped with a stirring impeller (12), and the stirring impeller (12) passes through the stirring wheel shaft (13) and the motor ( 14) Connected.

[0011] The filler adsorption device (15) described in the present invention contains fillers (16), and the fillers (16) refer to granules with a certain geometric shape and size, such as round granules, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com