Automatic dried beancurd stick frying machine

A yuba machine and automatic technology, applied in the direction of oil/fat baking, etc., can solve the problems affecting the fried quality of yuba, over-frying, and the production of carcinogens, etc., to achieve a high degree of automation in the production of structures, a high degree of structure automation, Easy cleaning and replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

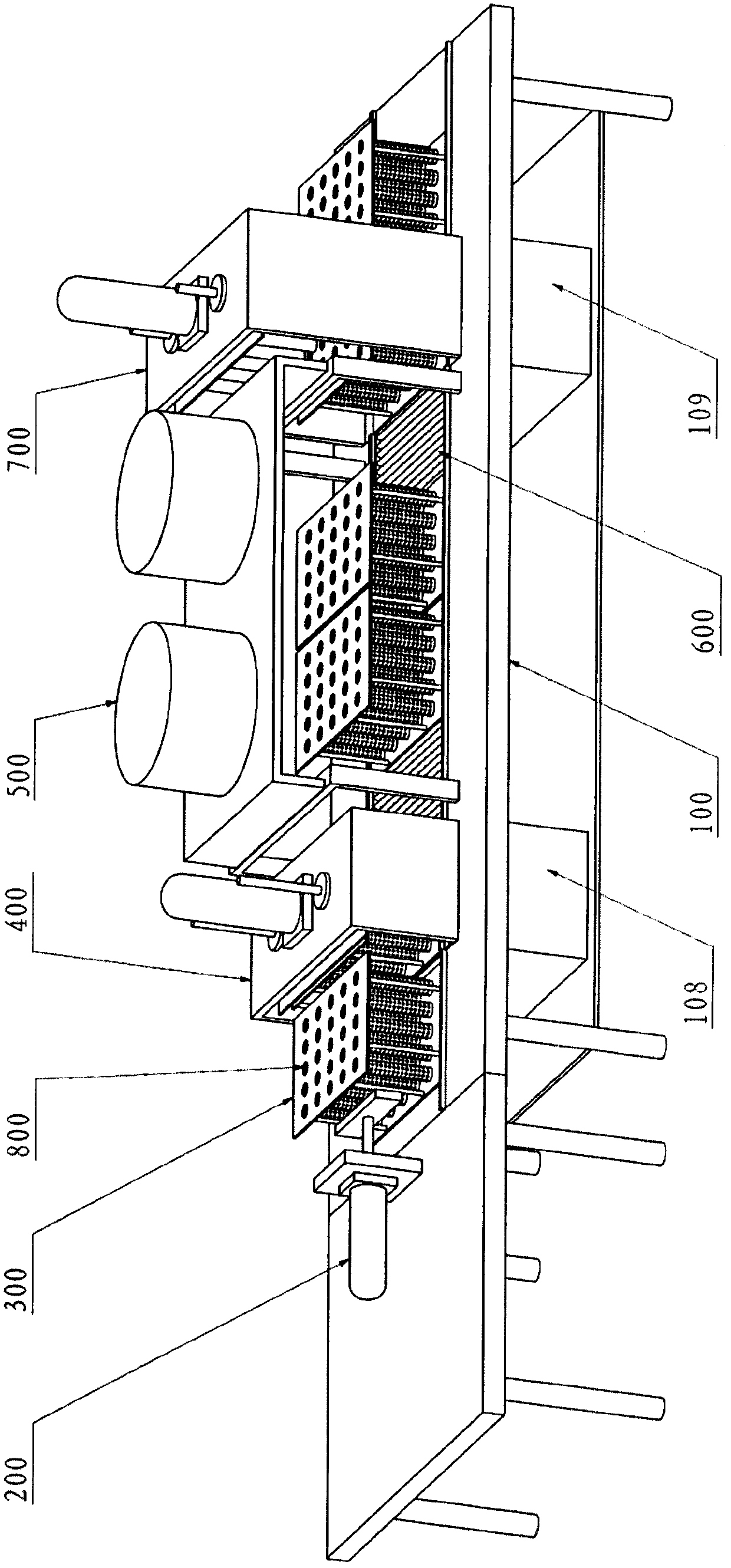

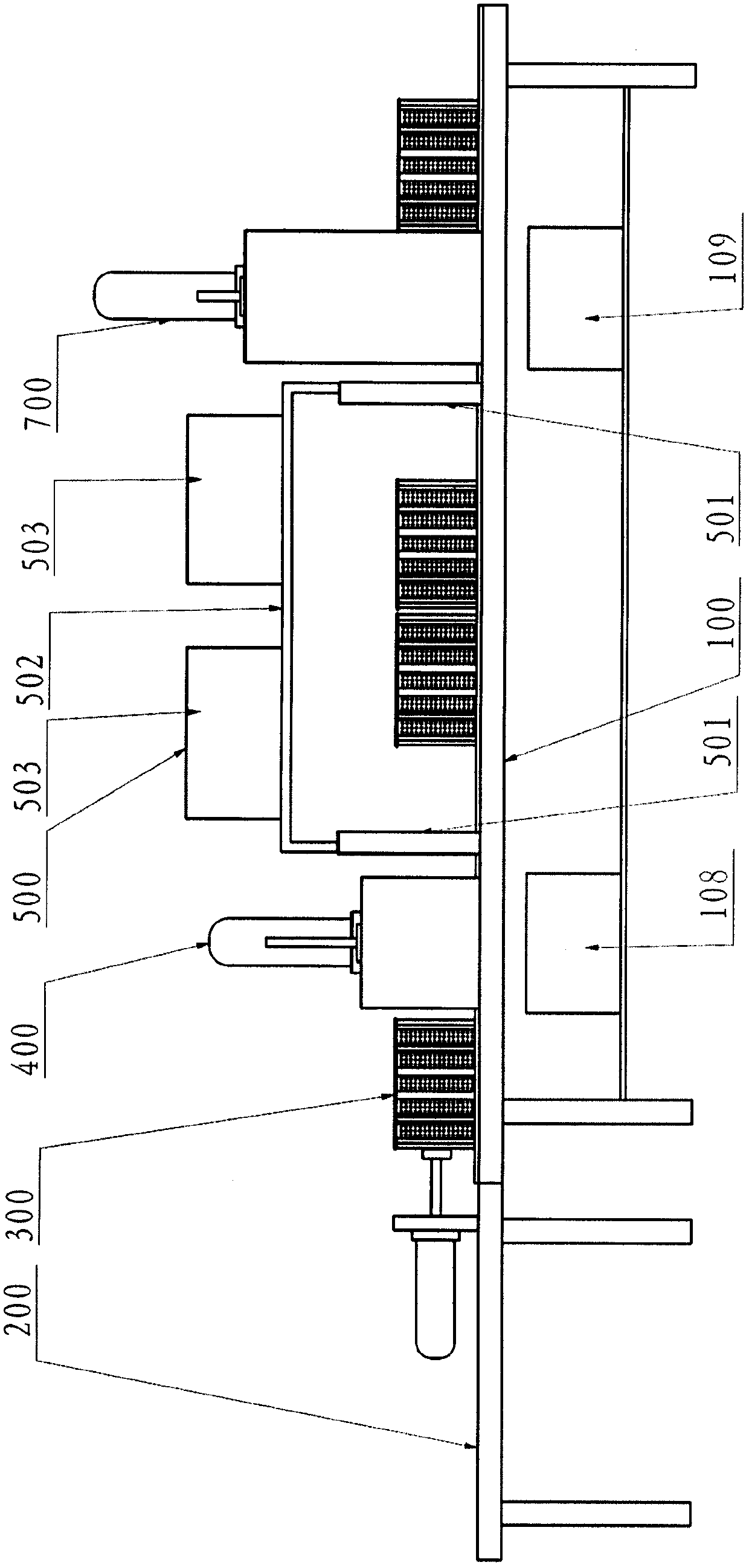

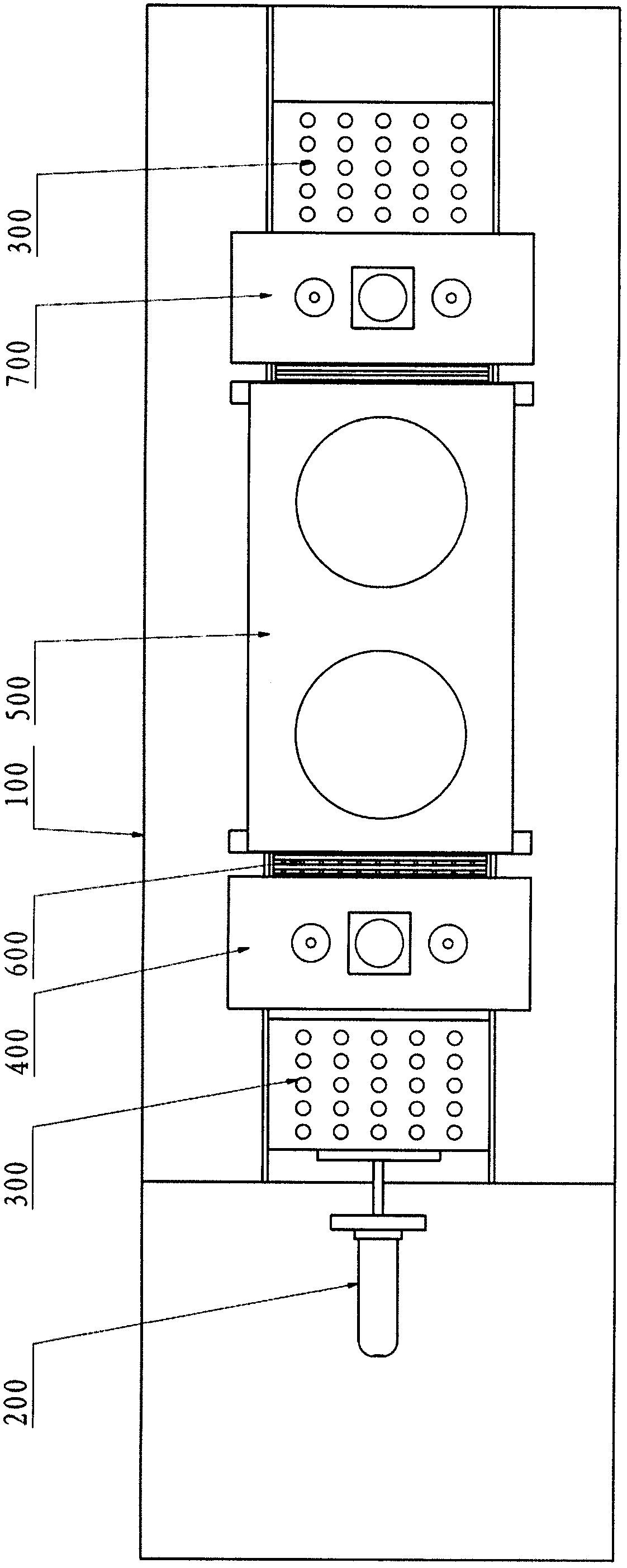

[0046] Example 1: The following combination Figure 1-Figure 21 The present invention is described in detail.

[0047] The bracket assembly 100 includes a frame body 101, an upper table board 102, a lower table board 103, a frying hole 104, a walking hole 105, a discharge hole 106, a limit bar 107, a hot oil tank 108, a receiving box 109, a chute 110, Draw ring 111, stay cord 112.

[0048] Frame body 101 is the desktop type of four sides with pin, and the center of upper table plate 102 is " H " type empty hole, and " H " type empty hole comprises frying hole 104, walking hole 105 and discharge hole 106 (as Figure 7 shown). Hot oil tank 108 and receiving box 109 are placed on the lower table board 103, and hot oil tank 108 is used for providing the hot oil needed for frying, and receiving box 109 is used for collecting fried bean curd sticks after frying (see figure 1 , figure 2 ). Limit bar 107 is set on the both sides of walking hole 105, and limit bar 107 is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com