Patents

Literature

94results about How to "Realize automatic stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shoemaking device and operating method

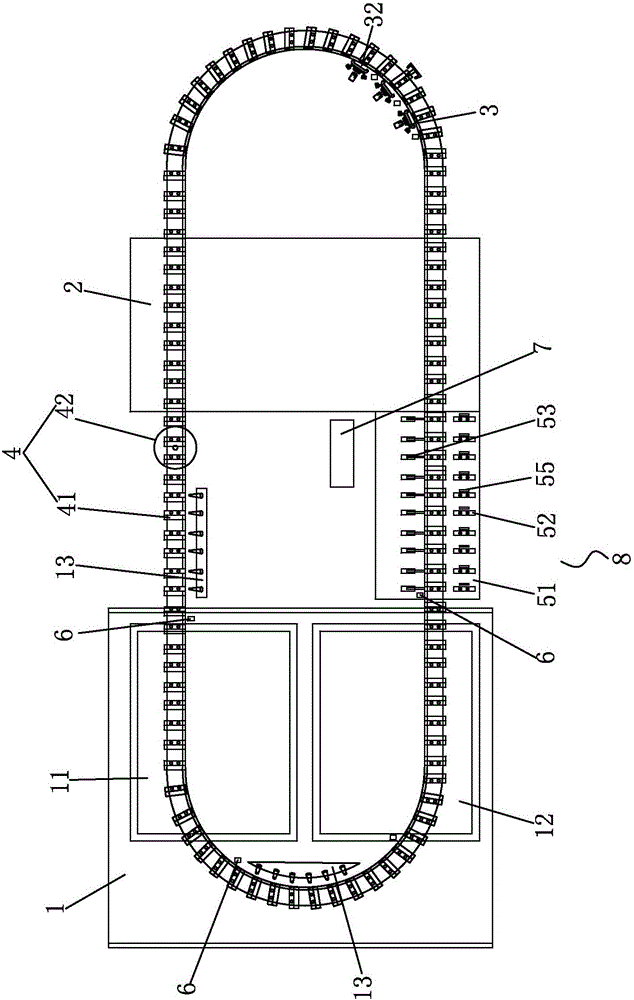

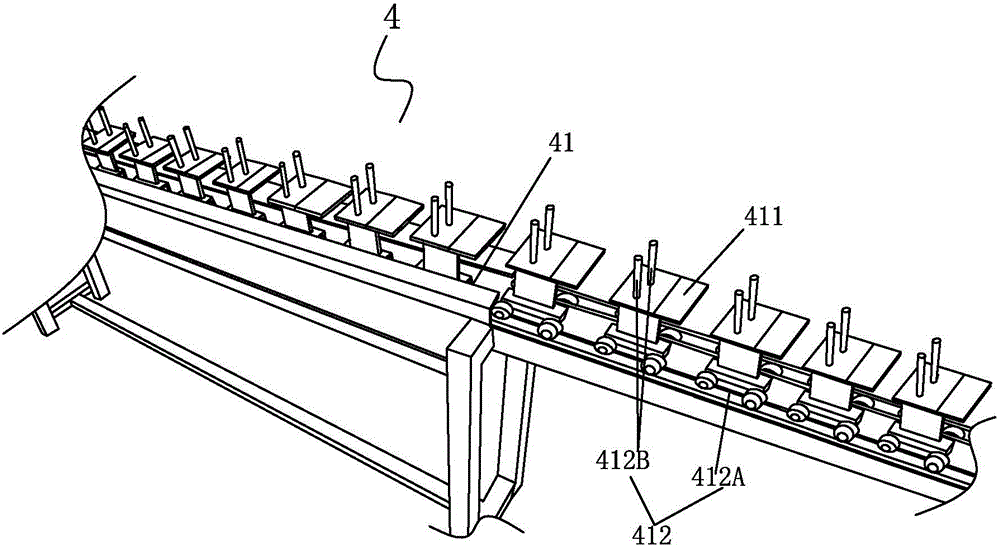

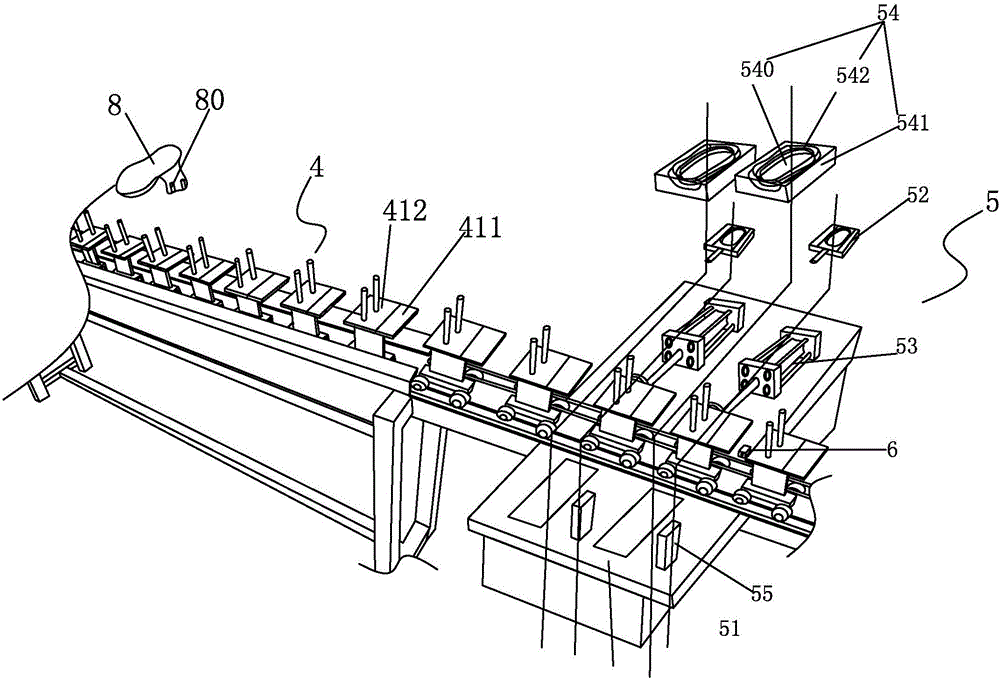

The invention discloses a shoemaking device.The shoemaking device comprises a drying device, a cooling device and a delasting mechanism.The shoemaking device further comprises a conveying mechanism, a press fitting mechanism, an induction unit and a control unit.The conveying mechanism is arranged on the drying device, the press fitting mechanism, the cooling device and the delasting mechanism in a penetrating mode to define an annular conveying mechanism.The conveying mechanism comprises an upper track, a lower track and a driving motor used for driving the upper track and the lower track to generate horizontal annular displacement, wherein the upper track is used for carrying soles, and supports used for positioning and supporting lasts are formed on the lower track.The press fitting mechanism is arranged between the drying device and the cooling device and comprises pressure bearing tables, auxiliary clamping components, driving air cylinders and pressure applying units, wherein the pressure bearing tables are arranged on one or two sides of the conveying mechanism and used for supporting the lasts.According to the shoemaking device, various devices needed in the shoemaking process are combined into a whole, automatic operation is achieved under driving of the control unit, and thus manual cost is substantially lowered.

Owner:ANTA CHINA

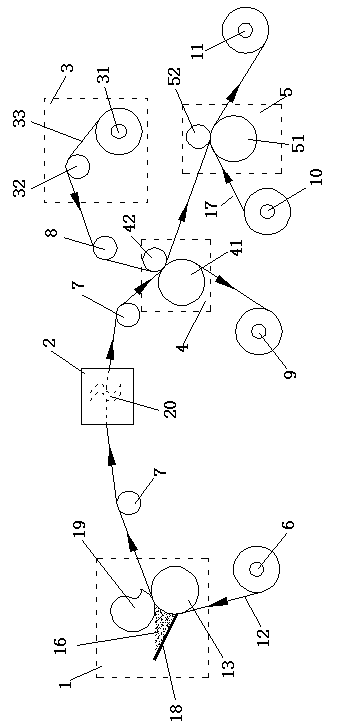

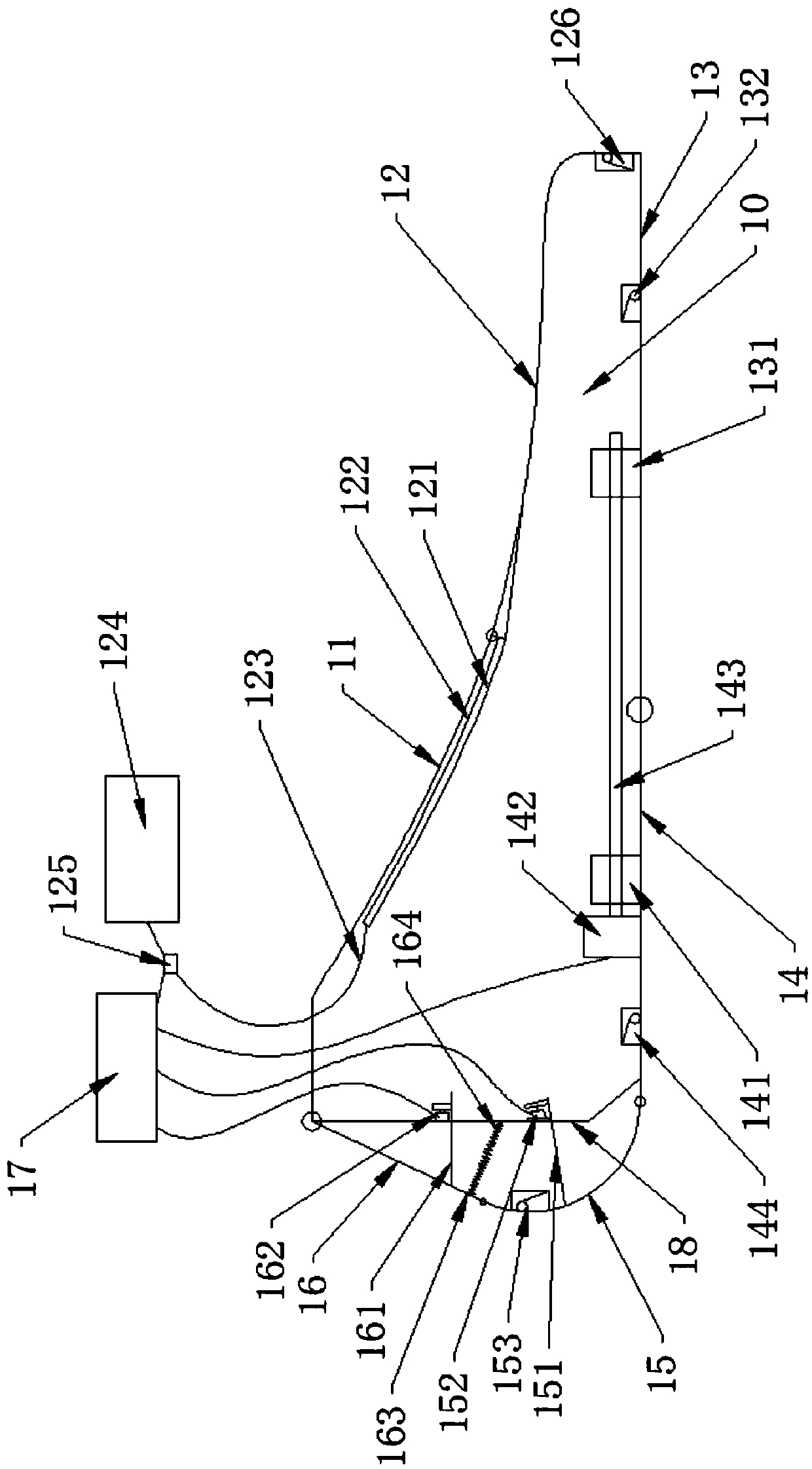

Production process of reflective thermal attachment film and special production line thereof

ActiveCN103529504ASimple processing technologyReduce processing costsLayered productsReflex reflectorsMachining processAdhesive

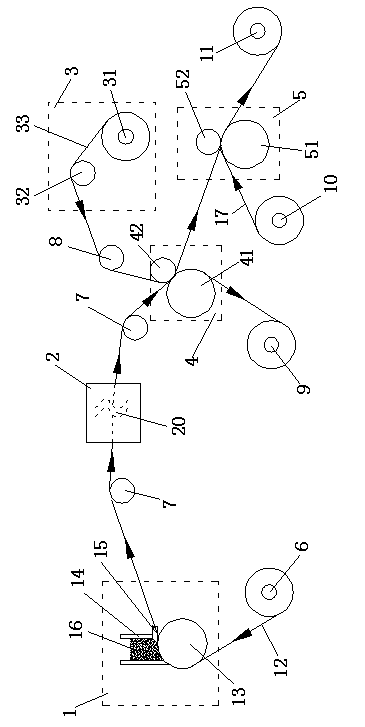

The invention relates to a production process of a reflective thermal attachment film. The production process comprises the following steps: firstly coating a composite adhesive on an anti-adhesion film through a composite adhesive coating mechanism and then feeding into a drying tunnel for drying; performing first compounding with a bead implanted film through a rubber roll and a steel roll; performing second compounding on the composite bead implanted film and the adhesive film through a rubber roll and a steel roll; coiling after the two compounding steps to obtain a finished product. According to the production line, automatic feeding of the anti-adhesion film, the composite bead implanted film and the like is realized by using mechanisms such as each bottom roll and guide roll, and continuous automatic machining is realized on the same production line. By using the production process and the production line of the reflective thermal attachment film, firstly the machining process is simplified and the machining cost is effectively reduced, secondly the machining efficiency and the machining quality are also effectively improved while automatic machining is realized and a large amount of cost such as labor cost is saved, and thirdly automatic stripping and recovery of the anti-adhesion film are realized, the recycling is facilitated, a large amount of material cost is saved, and considerable economic profit is brought to manufacturers.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

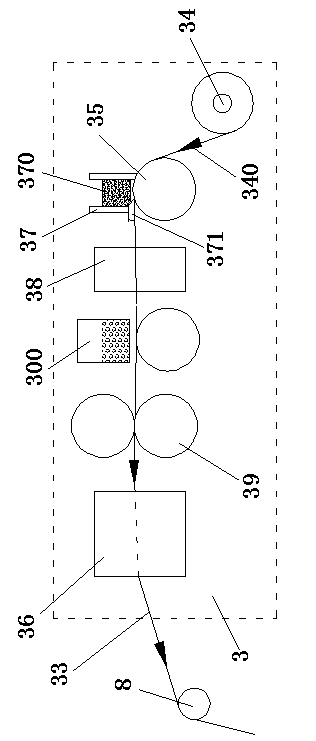

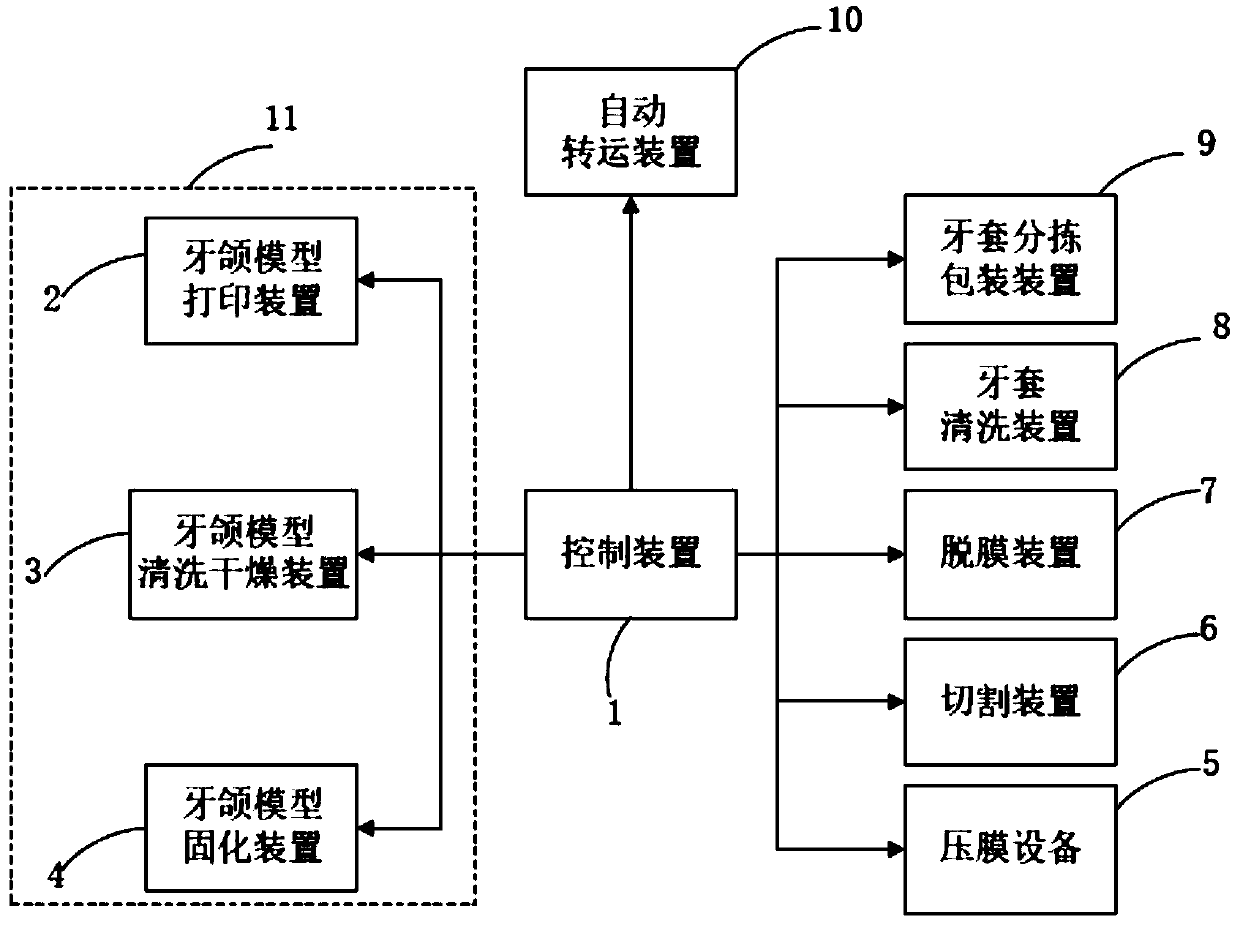

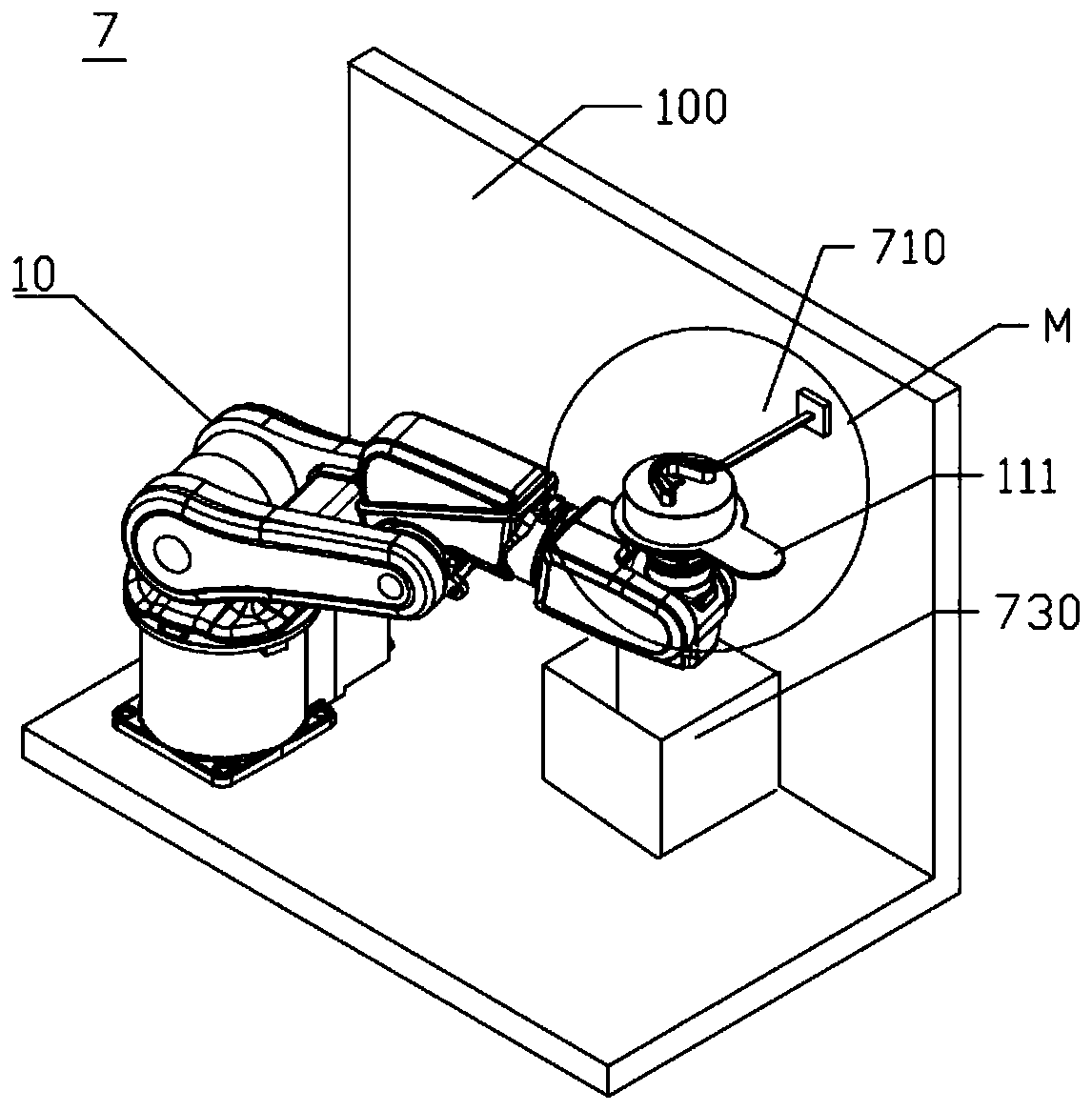

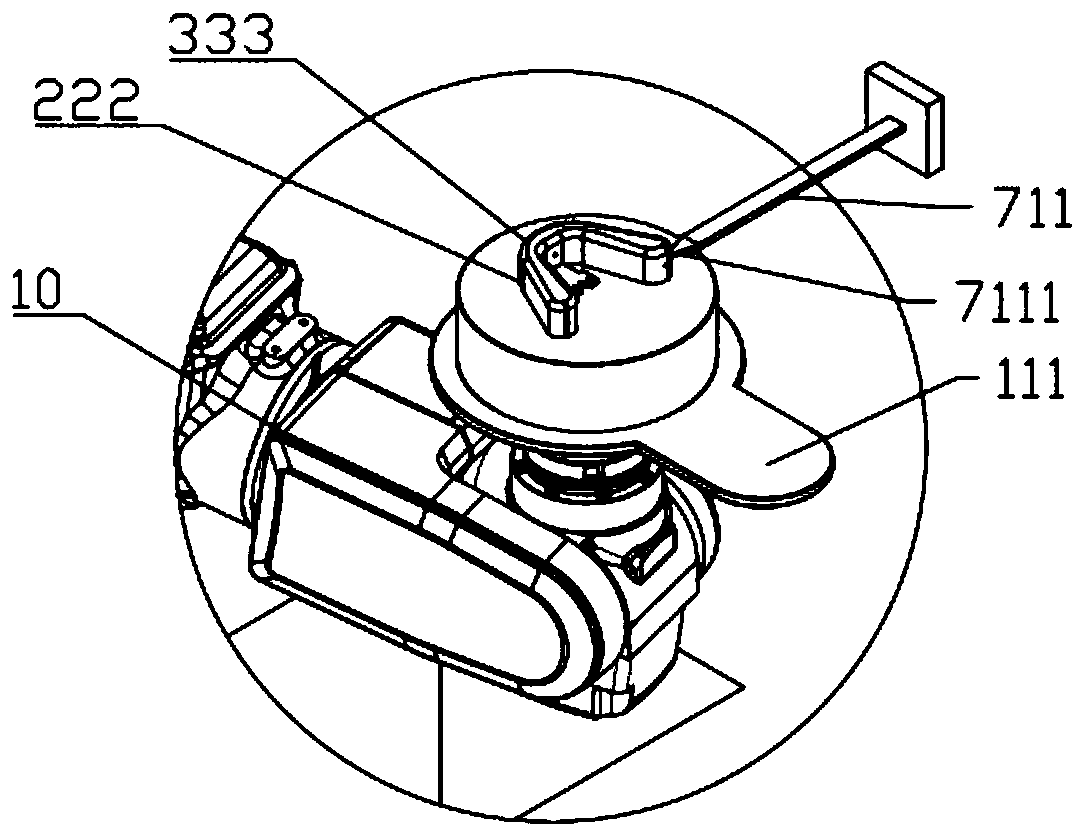

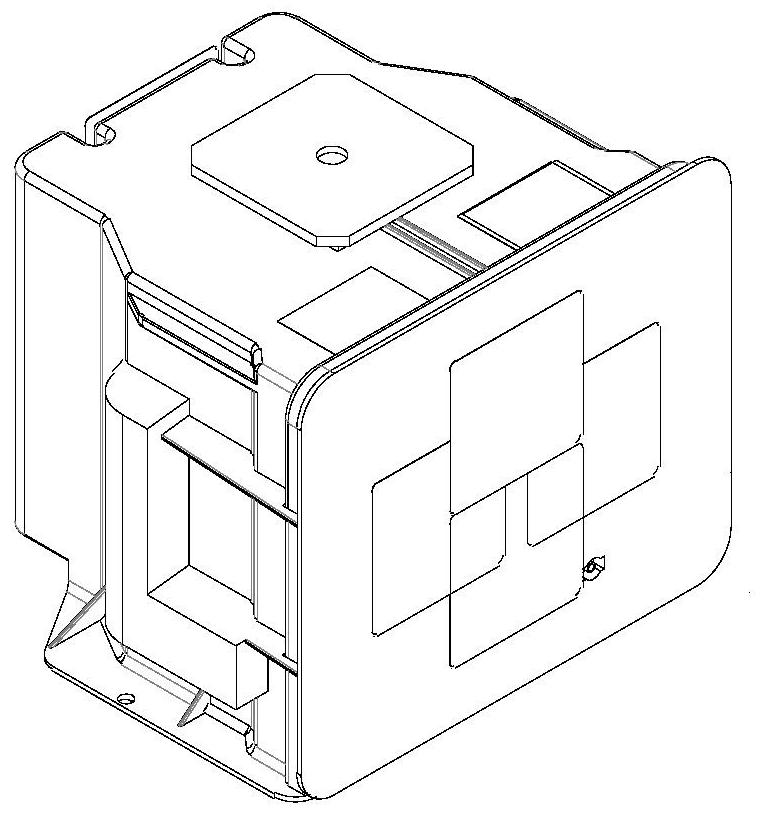

Membrane stripping device, membrane stripping method and one-stop tooth socket production system

PendingCN109808157AQuality assuranceAvoid exposure to contaminationDrying gas arrangementsDental articulatorsEngineeringDental Models

The invention discloses a membrane stripping device which comprises a control device, an automatic transfer device, a transmission tray arranged at the free end of the automatic transfer device and amembrane stripping module. The membrane stripping module is provided with a membrane prying part which is provided with a membrane prying end, the transmission tray can be loaded with a dental model with a tooth socket to be subjected to membrane stripping, the control device controls the automatic transfer device to move to enable the open end of the tooth socket loaded on the automatic transferdevice to make contact with the membrane prying end, the control device controls the automatic transfer device and the membrane prying part to move relatively to produce membrane prying force to pry the tooth socket from the dental model, and automatic stripping of the tooth socket from the dental model is achieved. The invention further discloses an automatic membrane stripping method adopting the membrane stripping device and a one-stop tooth socket production system with the membrane stripping device. The membrane stripping device and the membrane stripping method achieve automatic membranestripping in tooth socket production, and the one-stop tooth socket production system achieves integrated layout of tooth socket production and lays a foundation to chair side manufacturing and immediate delivery.

Owner:浙江正雅齿科股份有限公司

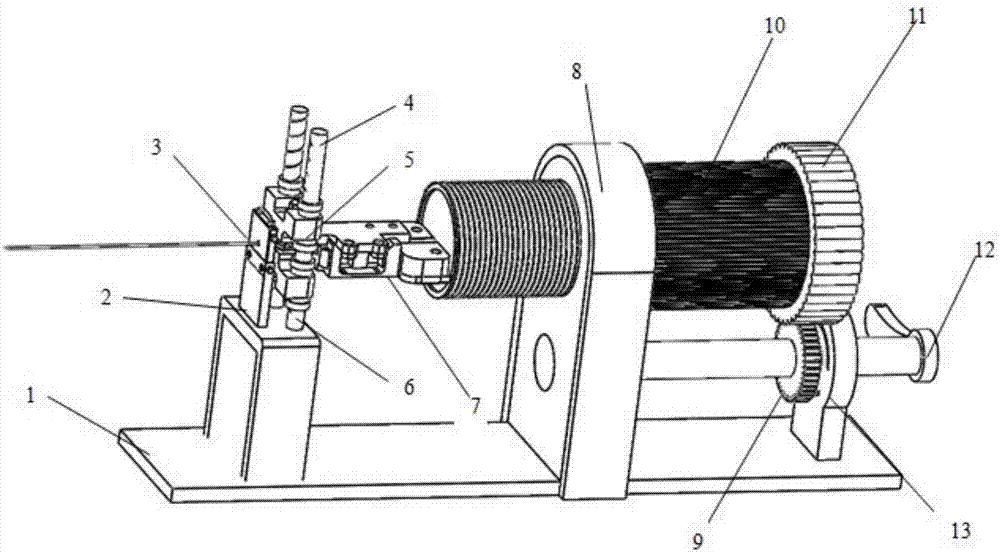

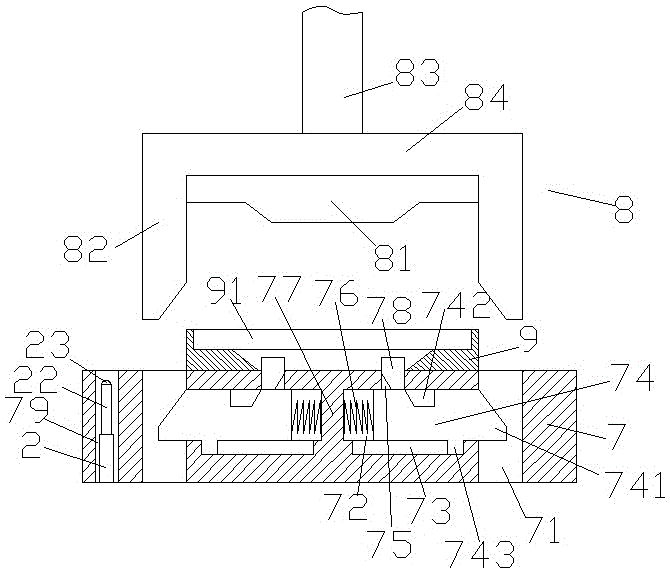

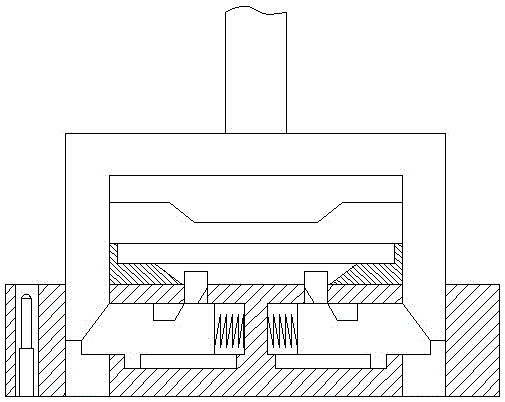

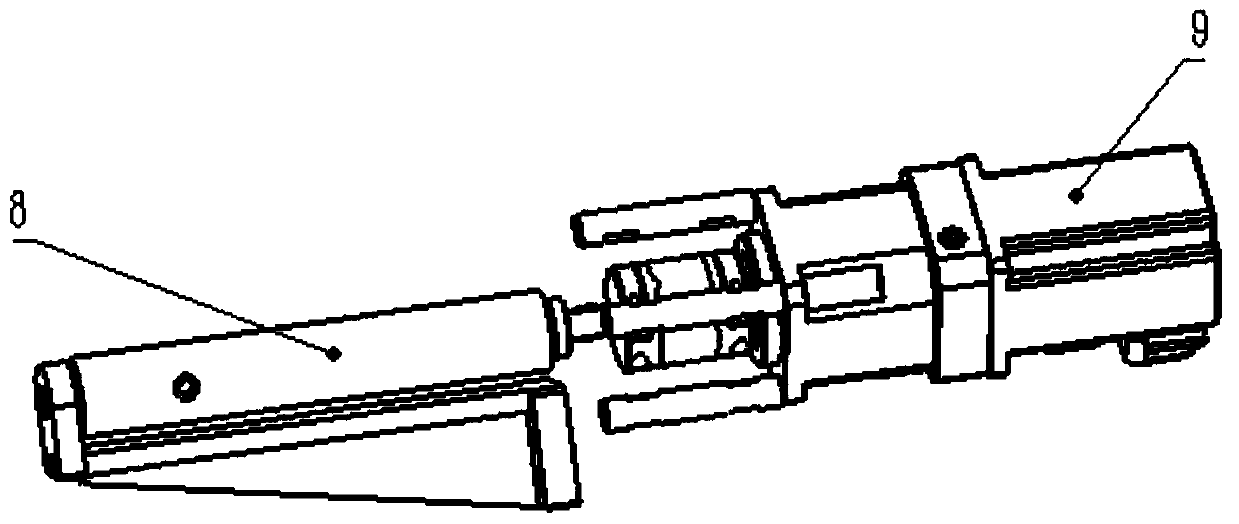

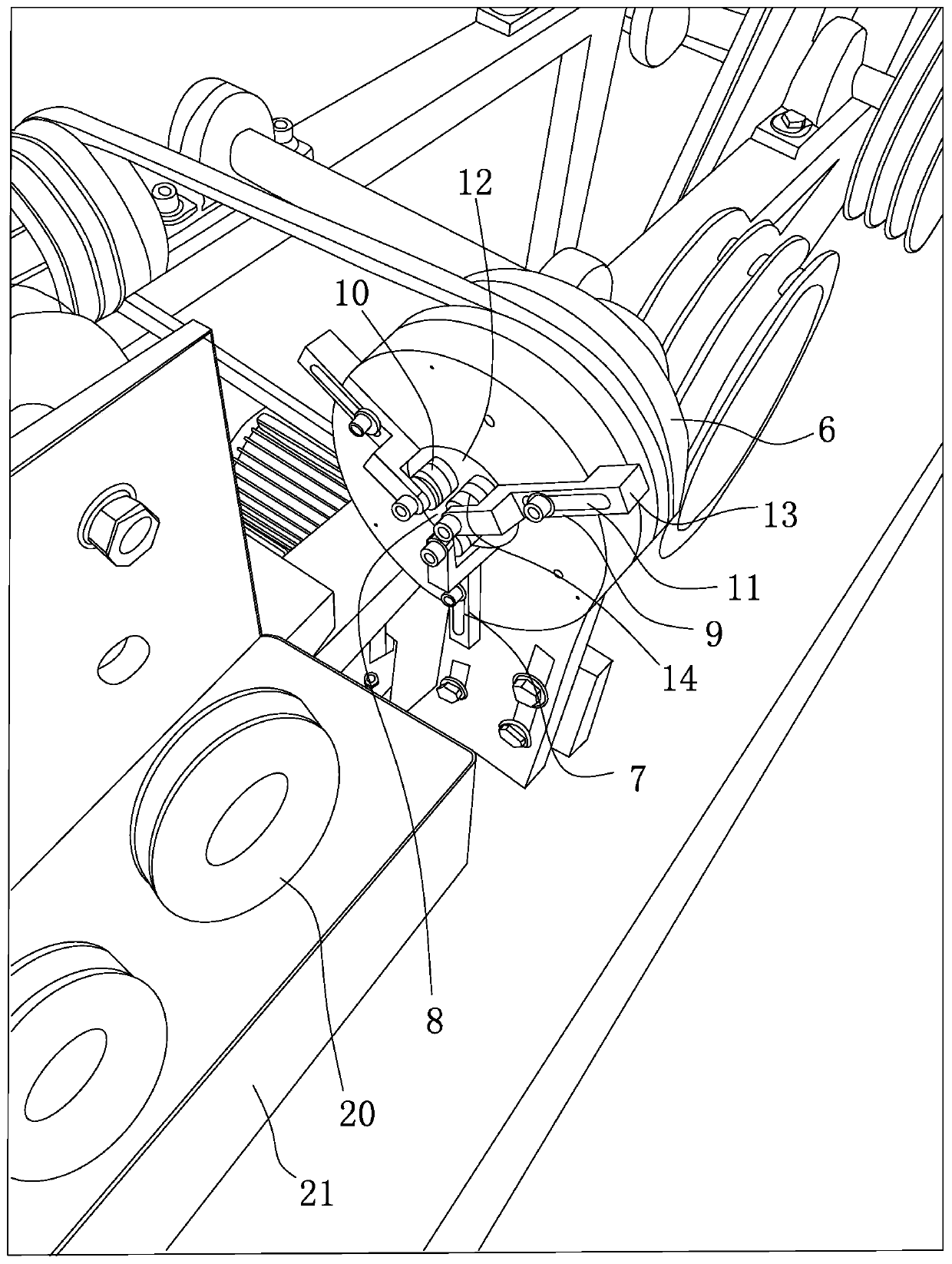

Optical fiber coating layer rotation stripping device

ActiveCN107065071AWon't hurtAchieve continuous strippingOptical light guidesEngineeringPositioning system

The invention discloses an optical fiber coating layer rotation stripping device. The optical fiber coating layer rotation stripping device comprises an optical fiber positioning stripping unit and an optical fiber clamping feeding unit; the optical fiber positioning stripping device comprises a stripping assembly and a positioning assembly; the stripping assembly comprises a pair of blades which are arranged vertically and are inclined relative to a horizontal plane, and the cutting edges of the blades are in different planes; the positioning assembly comprises a pair of positioning clamping blocks which are arranged vertically and are detachable; a distance between the cutting edge of a corresponding blade and an axis can be controlled through the positioning clamping blocks which clamp and position the optical fiber so as to control a cutting depth of the cutting edge; the optical fiber cutting unit comprises an optical clamp and a driving assembly; the optical clamp drives the optical fiber to rotate to feed under the driving of the driving assembly in order to produce a stripping force which is perpendicular to the cutting direction of the blade to realize stripping of the optical fiber coating layer. The optical fiber coating layer rotation stripping device can fast and effectively strip the optical fiber coating layer, and the stripped optical fiber has a good end surface and the internal cladding is not damaged.

Owner:HUAZHONG UNIV OF SCI & TECH

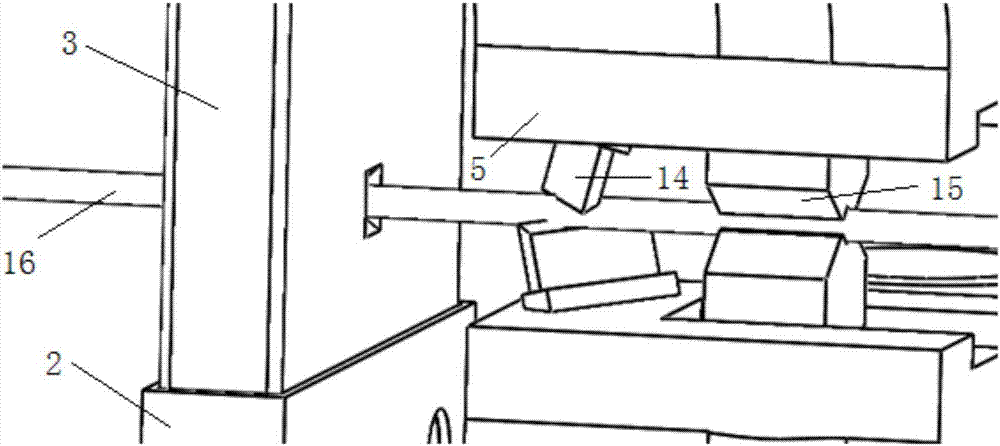

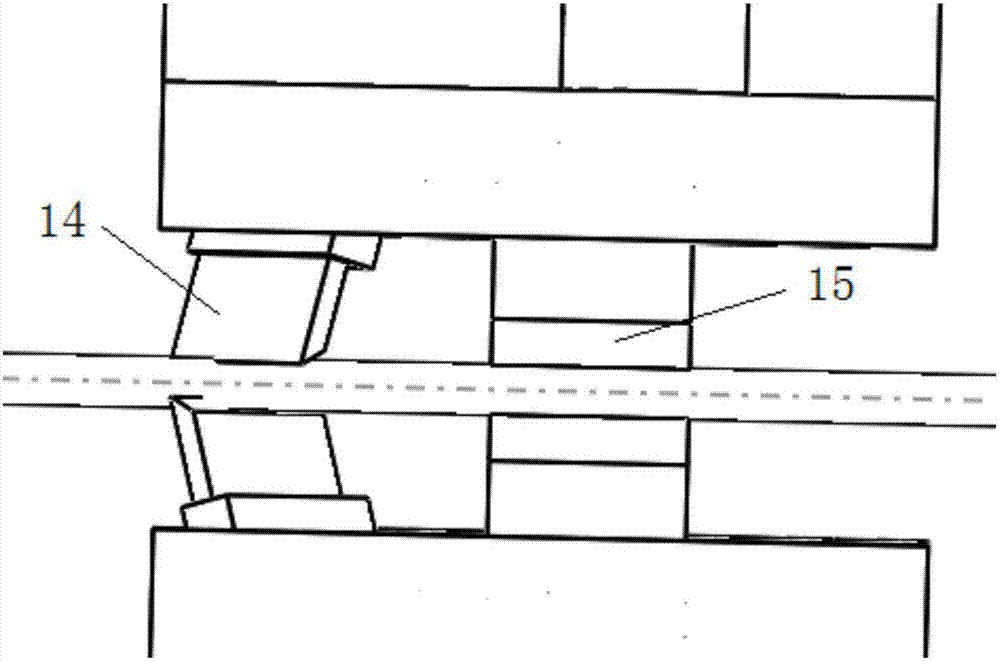

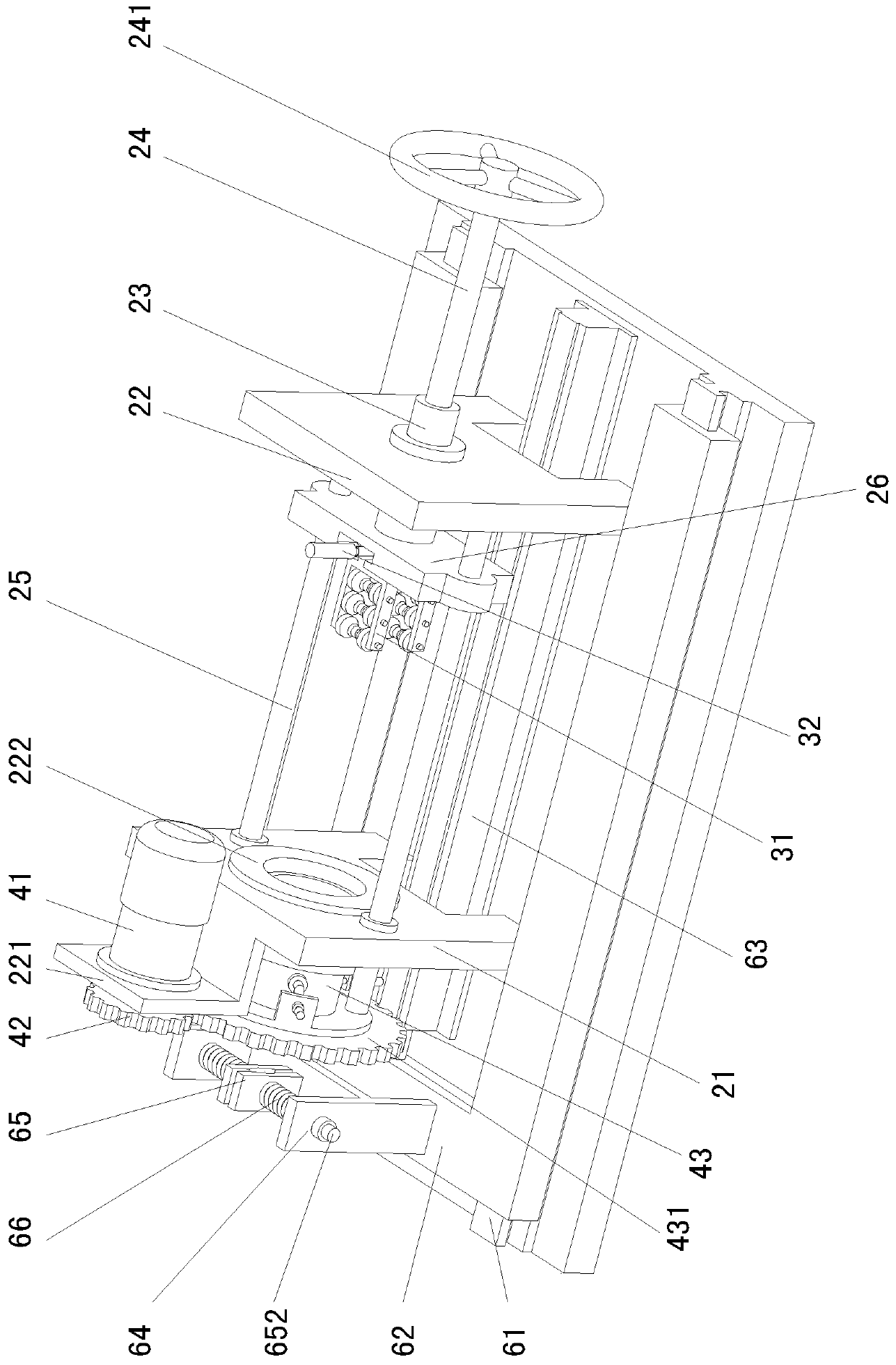

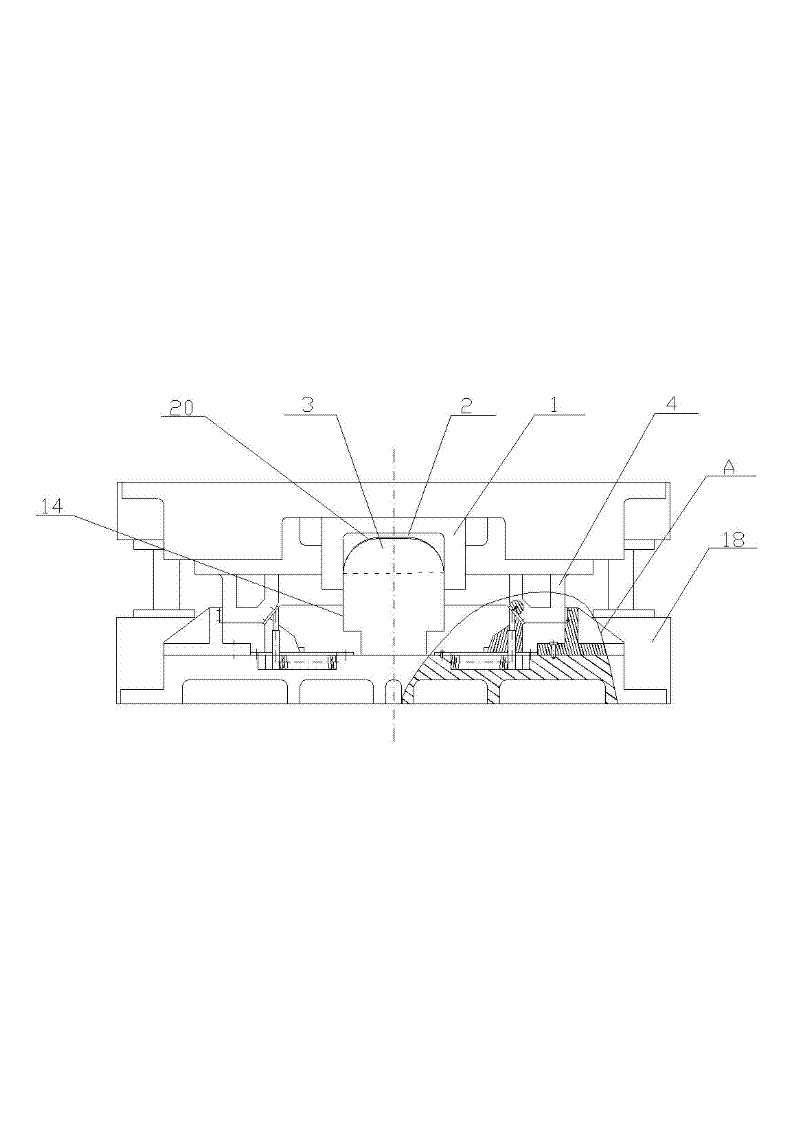

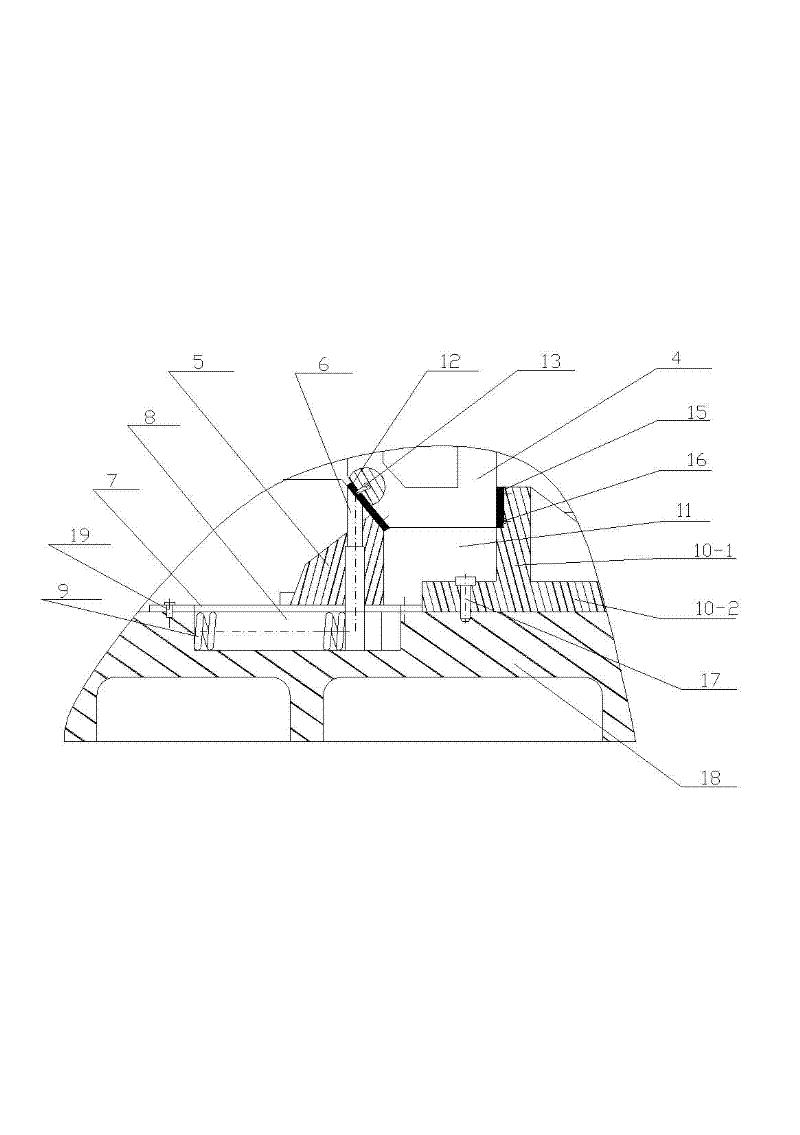

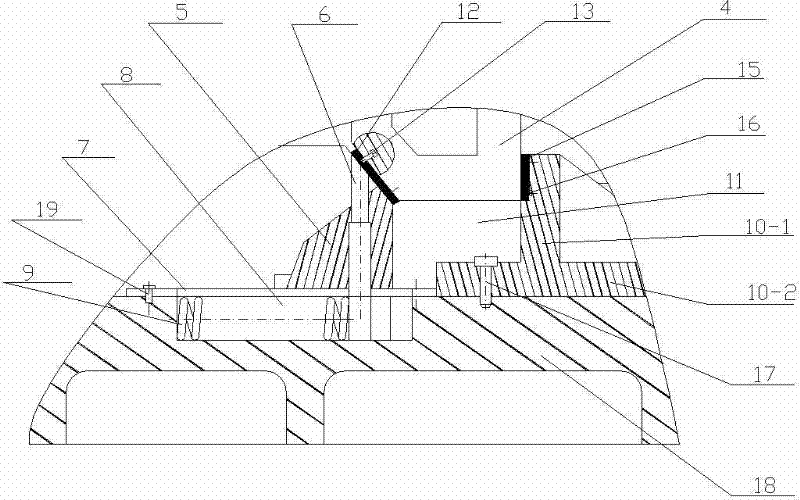

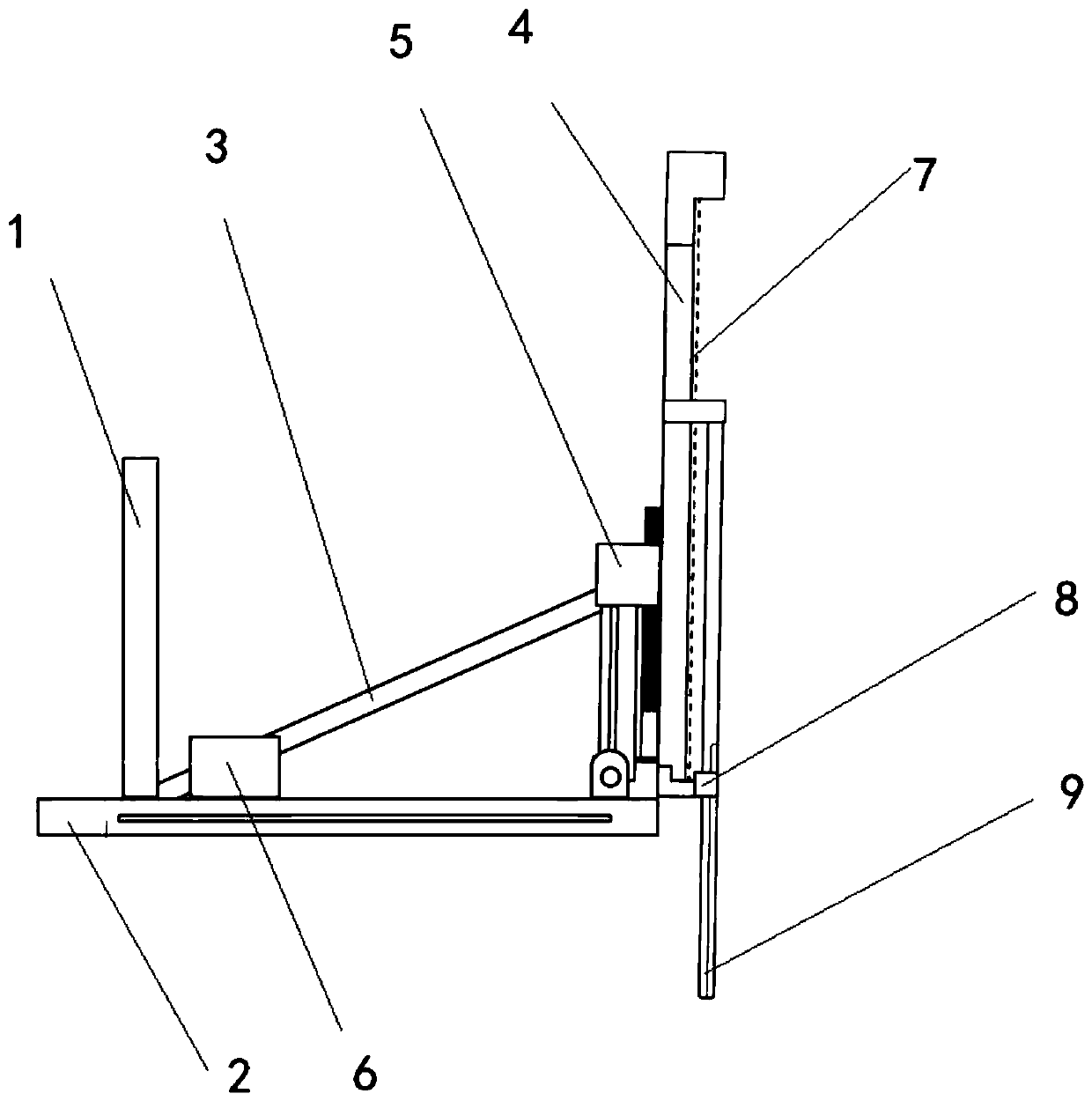

Cam-driven delasting-lasting integrated machine

The invention provides a cam-driven delasting-lasting integrated machine, belonging to the shoemaking equipment field. The integrated machine comprises a fixed frame, wherein an inverted shoe tree isfixedly arranged on the fixed frame, a flat pressing assembly is arranged above the shoe tree, clamping assemblies are arranged on the left and right sides of the shoe tree; and a delasting assembly is arranged at the rear end of the shoe tree and comprises a raising cam, a raising driving rod and a lifting frame, the raising cam is rotatably connected to the fixed frame, a first driving slot is formed in the raising cam and is used for driving the lifting frame to move up and down through the raising driving rod, a translation cam, a translation driving rod and a delasting block are arrangedat the upper end of the lifting frame, the translation cam is horizontally arranged and is rotatably connected with the lifting frame, a second driving slot is formed in the translation cam and is used for driving the block to move leftwards and rightwards through the translation driving rod. The integrated machine is driven by a power supply, so that the operation of the whole structure is relatively stable and reliable, the failure rate is greatly decreased, the energy consumption is reduced, the energy source is saved, and the integrated machine is relatively environment-friendly.

Owner:JIHUA LAB

Insulating jacket fixed-length stripping device and method for insulated wire processing

ActiveCN110854750AEnsure consistencyAvoid harmApparatus for removing/armouring cablesEngineeringStructural engineering

The invention relates to an insulating jacket fixed-length stripping device and method for insulated wire processing. The device comprises a base, a length adjusting mechanism arranged on the base andused for controlling the stripping length of an insulating jacket of an insulated wire, a limiting wheel set guide mechanism arranged on the length adjusting mechanism, a rotary driving mechanism arranged on the length adjusting mechanism, a stripping needle knife assembly arranged on the rotary driving mechanism, and a clamping traction mechanism arranged on the base and used for pulling the insulated wire to move. The limiting wheel set guide mechanism is used for horizontally limiting and guiding the insulated wire, and the rotary driving mechanism is used for driving the stripping needleknife assembly to rotate. The device provided by the invention is applicable to a wide range of sizes of insulated wires, can realize fixed-length automatic stripping of an insulating jacket, and is convenient and rapid in stripping.

Owner:HENGYANG NORMAL UNIV

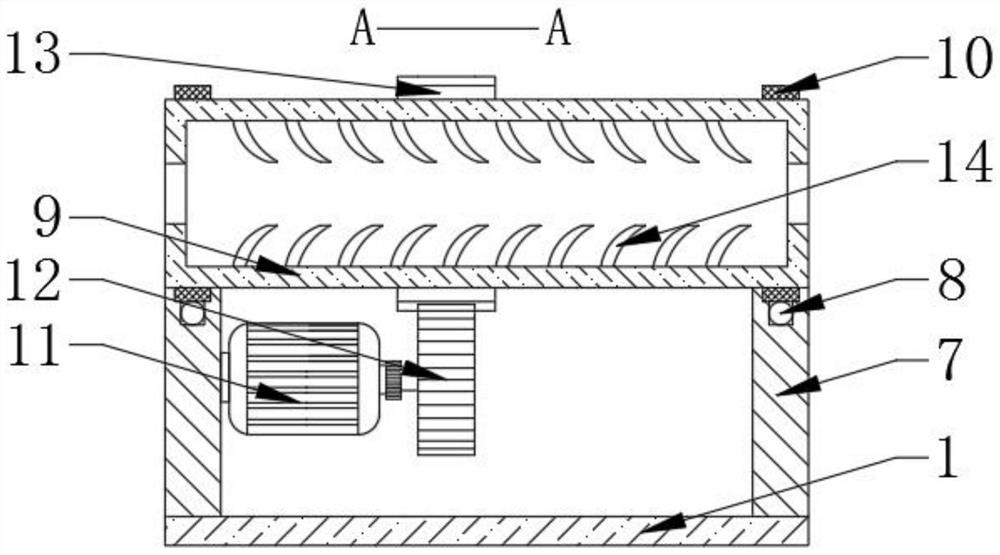

An automatic device for sleeving O-shaped ring

The invention relates to an automatic device for sleeving an O-shaped ring. The device comprises a fixed main body, a shell, a O-shaped ring sleeving mechanism and a driving mechanism; the O-shaped ring sleeving mechanism comprise a material stripping sleeve, an elastic returning part, a moving rod, a plurality of material taking claws which are positioned in the material stripping sleeve and arein linkage fit with the moving rod and a material stripping rod which corresponds to the position above the material stripping sleeve and is in linkage with the moving rod; and a through hole allowingone ends of the plurality of material taking claws to penetrate through is formed in the material stripping sleeve, the plurality of material taking claws are distributed in an annular array and aremovably arranged on the moving rod, returning components are arranged between the moving rod and the plurality of material taking claws, one ends of the plurality of material taking claws act along with the moving rod and can penetrate through the through hole of the material stripping sleeve and are mutually supported to be opened, and the material stripping rod moves along with the moving rod and can be used for driving one end of the material stripping sleeve to extend out of the shell. The device has the advantages of being simple in structure, stable and reliable in performance, high in efficiency and capable of saving manpower.

Owner:ZHEJIANG BLCH PNEUMATIC SCI & TECH

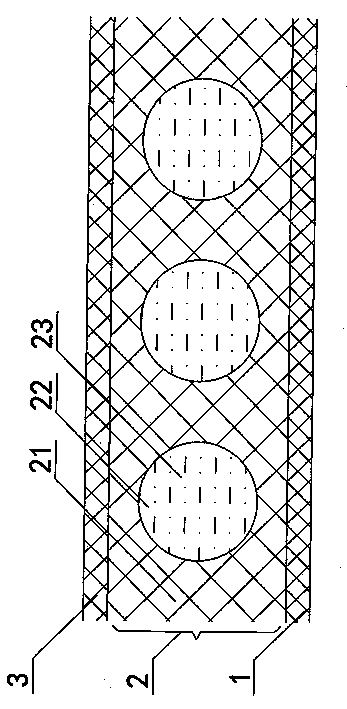

Anti-icing laminating membrane

InactiveCN104191682ARealize automatic strippingEasy to cleanLayered productsSurface stressBasal lamina

The invention discloses an anti-icing laminating membrane. The anti-icing laminating membrane is formed by a base layer, a middle solution bubble cap layer and an outer skin surface layer through bonding, wherein the middle solution bubble cap layer is composed of a middle layer filling material, a low-freezing-point solution and bubble caps, a plurality of bubble caps are embedded in the middle layer filling material, the low-freezing-point solution fills the bubble caps, and the outer skin surface layer and the middle layer filling material are bonded together; the freezing point of the solution in the bubble caps is slightly lower than that of water, stress strain caused by phase change expansion of the low-freezing-point solution in the bubble caps acts on the outer skin, as the expansion stress of the bubble caps to the skin is not uniform and continuous surface stress, non-uniform stress caused by the skin acts on an external icing freezing interface until a defect of the interface is caused, ice is fractured or the adhesion strength of ice is reduced due to the unstability of the freezing interface, then the ice cracks and falls off or is convenient to remove, and therefore, the ice can be conveniently cleaned.

Owner:JILIN UNIV

Thermal wire stripping apparatus

InactiveCN106981844ARealize automatic strippingSimple designApparatus for removing/armouring cablesFiberEngineering

The invention relates to a thermal wire stripping apparatus which includes a supporting pedestal which is provided with a wire mechanism and a wire scalding mechanism. The wire mechanism is intended for transporting an electrical wire. The wire scalding mechanism is disposed at a position corresponding to the head end of the wire mechanism, and is intended for clamping a wire sheath of the electrical wire and conducting thermal scalding. The tail end of the wire mechanism is connected to a rotating apparatus which drives the wire mechanism to rotate the electrical wire back and forth. The head end of the wire mechanism is an electrical wire output end, and the tail end is and an electrical wire input end. When the head end of the wire mechanism outputs an electrical wire, and the wire scalding mechanism clamps the electrical wire and thermally scalds the electrical wire, the rotating apparatus drives the wire mechanism to rotate the electrical wire back and forth, such that the wire sheath of the electrical wire is evenly heated at 360 degrees and is fused. According to the invention, the apparatus herein can rotate the electrical wire in the process of thermal stripping, the wire sheath of the electrical wire can be evenly heated at 360 degrees on the wire scalding mechanism and be fused in real sense, thus realizing automatic wire stripping. The apparatus herein has the characteristics of simple design, scientific structure, high automation and excellent wire stripping effects. The apparatus herein can be designated to strip fiber braided wires, can greatly increase production efficiency and is applicable to promotion for enterprises.

Owner:黄志刚

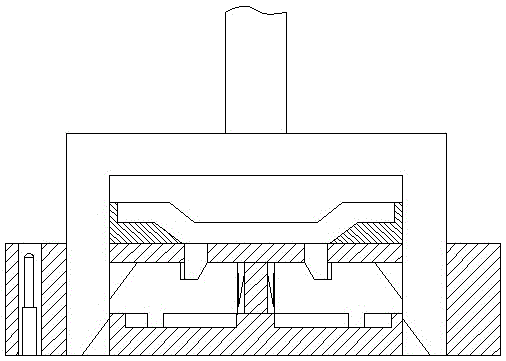

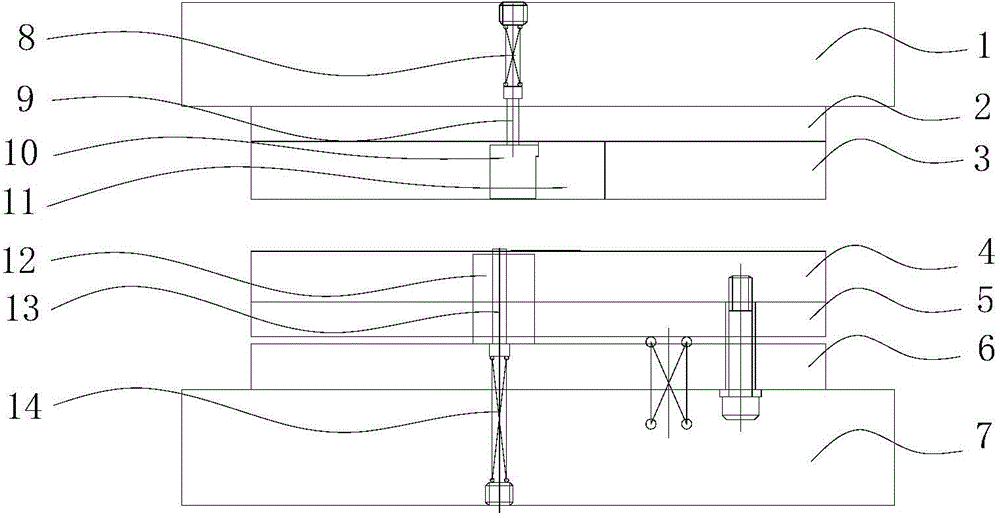

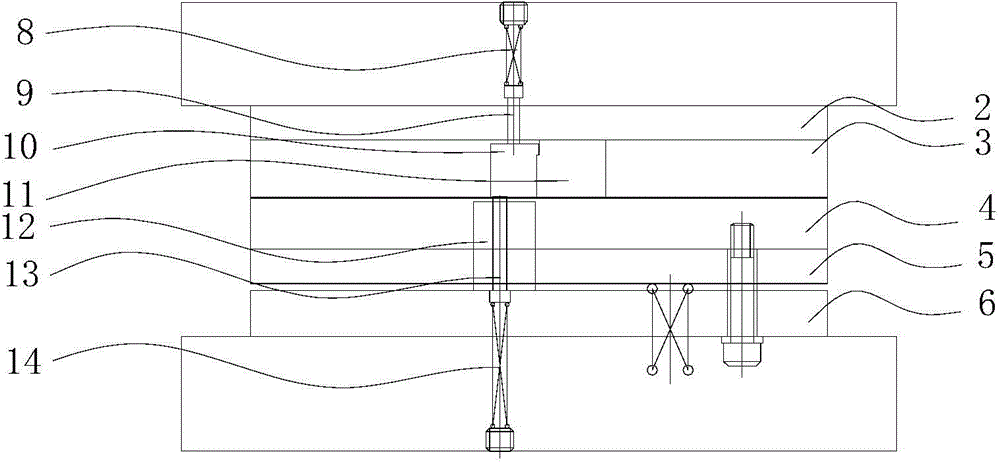

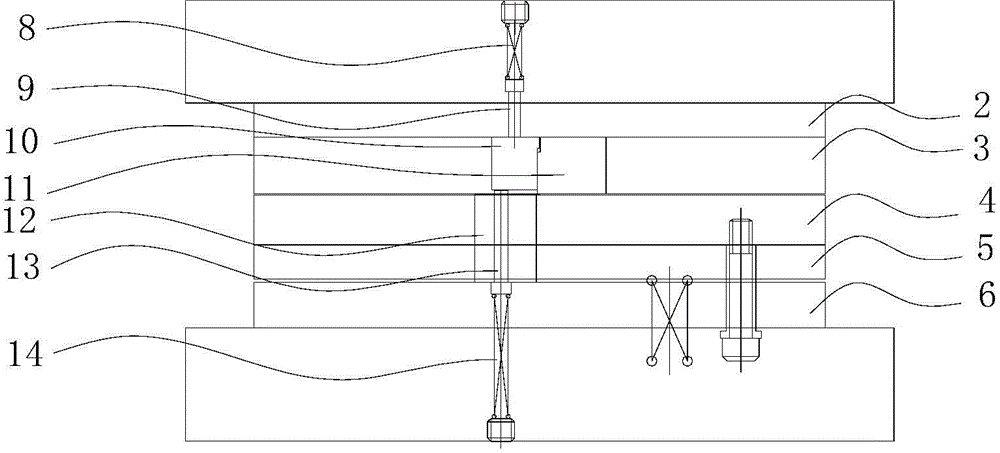

Improved die with automatic stripping function

ActiveCN106623671AImprove performancePrevent shiftingShaping toolsStripping-off devicesEngineeringPunching

The invention discloses an improved die with an automatic stripping function. The improved die with the automatic stripping function comprises an upper frame body and a lower frame body arranged below the upper frame body. A pressing plate, an upper die body and a lifting push rod are arranged in the upper frame body. Oblique-surface pushing and pressing columns which extend downwards are fixedly arranged on the two sides of the pressing plate correspondingly. A lower die body which is opposite to the upper die body is arranged at the top of the lower frame body. Through holes are formed in the positions, opposite to the lower portions of the oblique-surface pushing and pressing columns, in the lower frame body. Sliding grooves are formed in the portion, between the through holes, in the lower frame body in a bilaterally symmetrical mode. A partition plate which is fixedly connected with the lower frame body is arranged between the sliding grooves. A through hole which penetrates through the wall of the lower frame body and communicates with the bottom of the interior of the lower die body is formed in the top of each sliding groove, and an oblique-surface stripping block is arranged in the through hole. A sliding guide groove is formed in the bottom of each sliding groove, a sliding block is slidably arranged in each sliding groove, an ejection spring is arranged between each sliding block and the partition plate, and an oblique-surface sliding groove is formed in the top of each sliding block. The improved die with the automatic stripping function is simple in structure, and automatic stripping can be achieved after punching is completed; and the manufacturing cost is low, and maintenance is convenient.

Owner:顺庭模具科技南通有限公司

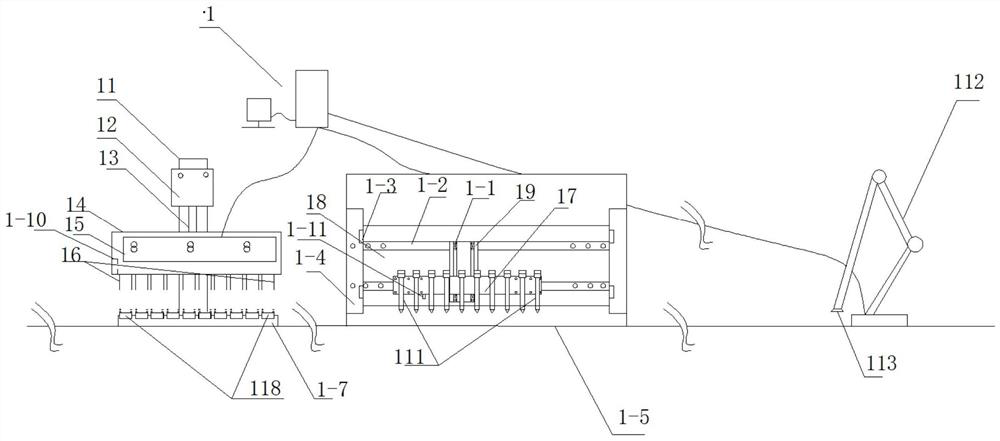

Automatic laser auxiliary heat stripping type insulated cable stripper

PendingCN110198015AWon't bendEasy to straightenApparatus for removing/armouring cablesElectronic waste recyclingElectric controlPre treatment

The utility model provides an automatic laser auxiliary heat stripping type insulated cable stripper, relates to the field of automation equipment. The automatic laser auxiliary heat stripping type insulated cable stripper comprises a cable stripper box body, a cable traction module, a laser pretreatment module, a heating module and a striping module are installed in the cable stripper box body, the cable stripper box body comprises an upper box body and a lower box body, and the upper box body and the lower box body are mutually connected through a box body open-close switch and a box body connection hinge. By combination of ultraviolet laser auxiliary pretreatment and an electric control electrode heating mode, the automatic laser auxiliary heat stripping type insulated cable stripper iscooperated with a direct current motor to drive a cable traction roller to achieve the automatic thermal stripping of the insulated cable protection layer, and the method is reliable in principle andsimple and convenient in operation step, reduces the labor intensity of workers, and has a very wide application prospect.

Owner:INNER MONGOLIA UNIVERSITY

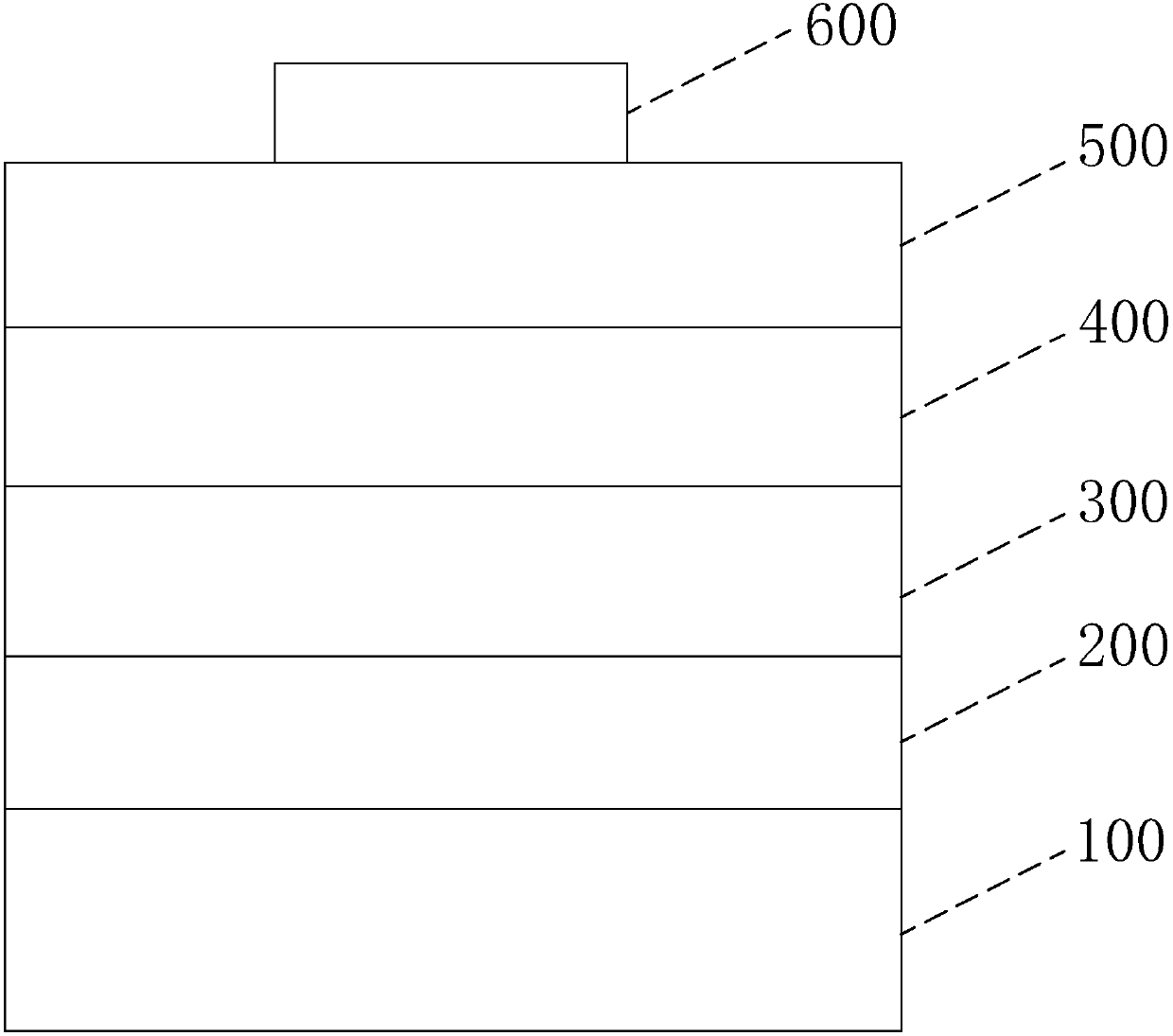

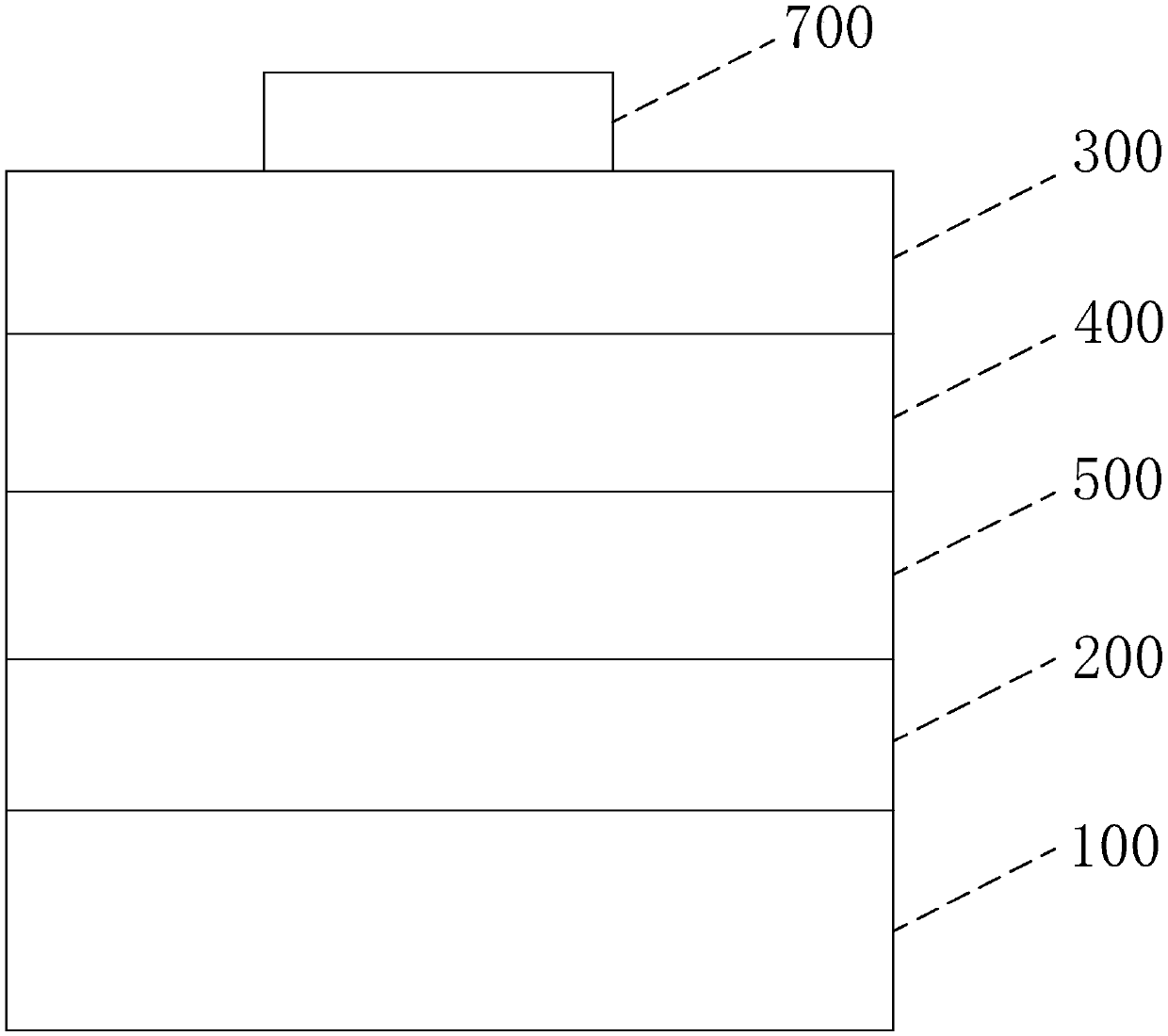

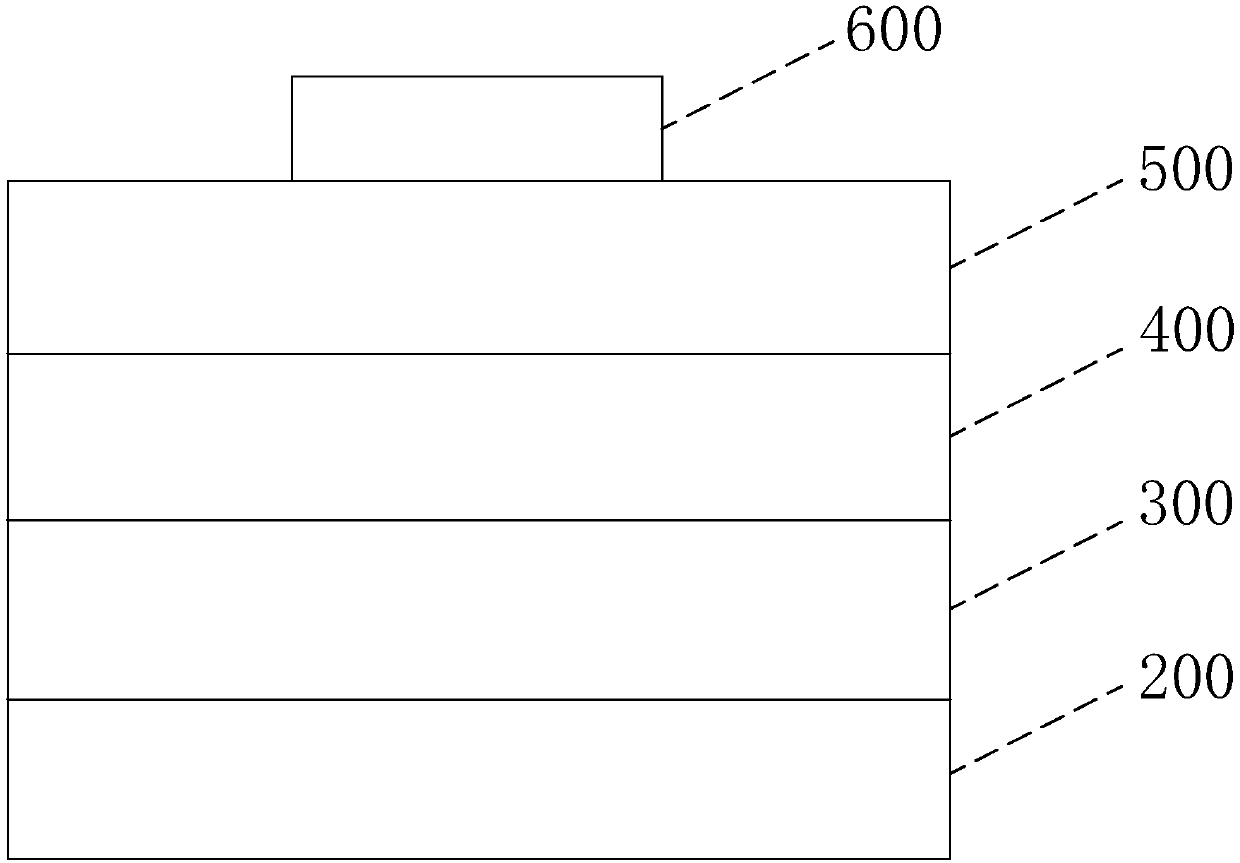

Self-supporting vertical structure LED chip and preparation method thereof

PendingCN107644928ARealize automatic strippingSimple preparation processSemiconductor devicesFinal product manufactureCurrent crowdingThermal shock

The invention discloses a self-supporting vertical structure LED chip and a preparation method thereof. The physical characteristics of a LiGaO2 material are used. During rapid annealing, a LiGaO2 substrate automatically breaks up due to thermal shock to directly separate the LiGaO2 substrate from a metal film, so as to realize automatic stripping of the substrate. The preparation process of the LED chip is simplified. The manufacture cost is reduced. In addition, the metal film is directly used as the supporting substrate of a vertical structure, which can play the role of an electrode. The metal heat dissipation performance is great. Current distribution is even. The problem of current crowding is avoided. The light emitting efficiency is improved. A high power LED can be realized. Lightshielding of the electrode is realized. The light emitting area of the LED chip is improved. The metal film can reflect light, which helps to improve the light extraction efficiency to realize a highluminous efficiency LED.

Owner:江门市奥伦德光电有限公司 +1

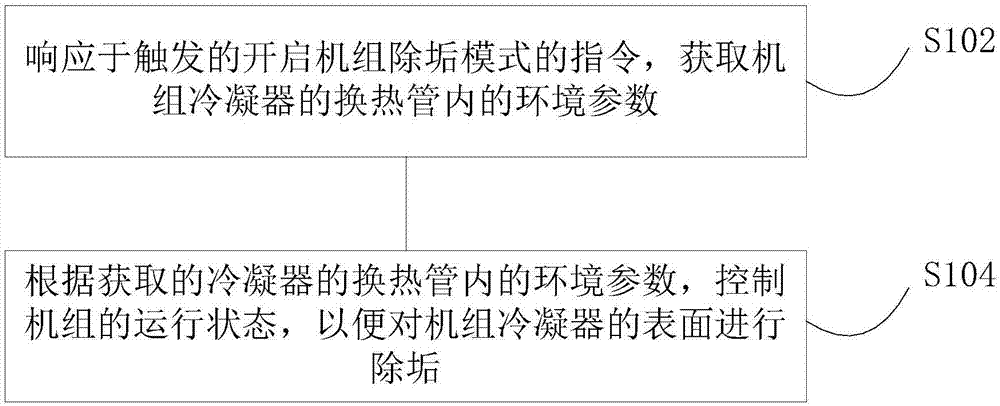

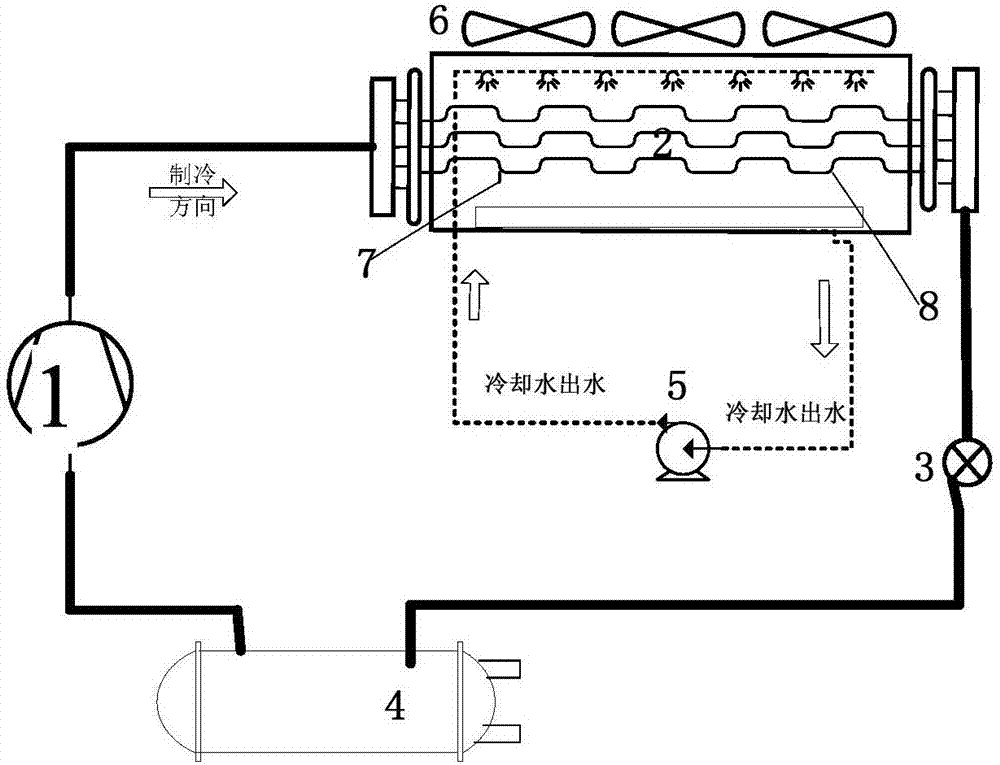

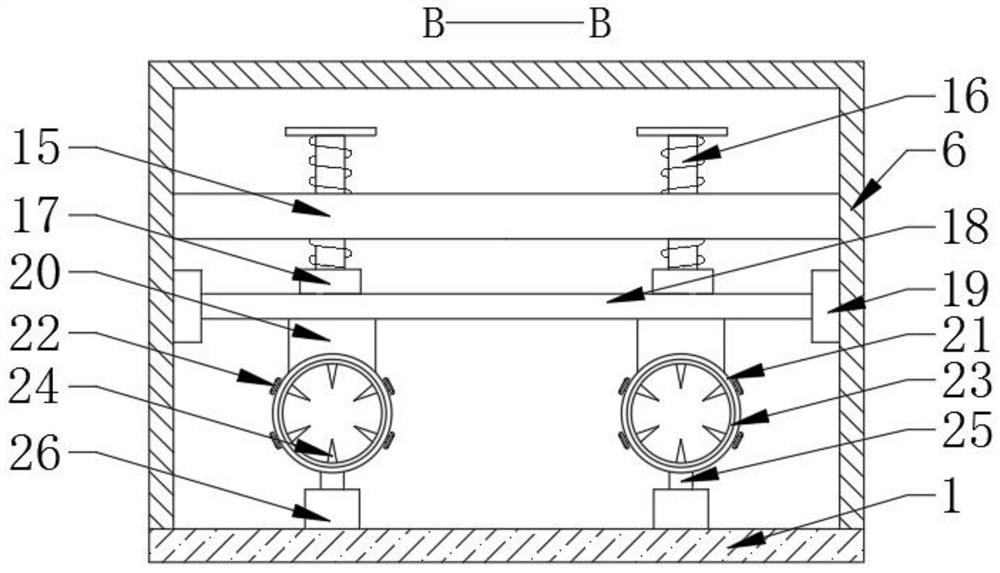

Control method and device of evaporative condensing unit

ActiveCN106958956AImprove cooling effectImprove heat transfer coefficientCompression machines with non-reversible cycleRefrigeration safety arrangementEngineeringExchange coefficient

The invention discloses a control method and a device of an evaporative condensing unit. The method comprises the steps of obtaining environmental parameters in a heat exchange tube of a unit condenser according to a triggered instruction for turning on a unit descaling mode, and controlling the operating state of the unit according to the obtained environmental parameters in the heat exchange tube of the condenser so as to descale the surface of the unit condenser. By using the control method, the problem of influence on the performance of the unit because scale is generated when the evaporative condensing unit is operated for a long time in the prior art is solved, and the heat exchange coefficient of the condenser and the refrigerating effect of the unit are increased.

Owner:GREE ELECTRIC APPLIANCES INC

Flanging die structure of machine cover of crane

The invention provides a flanging die structure of a machine cover of a crane, which enables a pressure-shaped flange of the machine cover of the crane to form once without sectional performing, eliminates the artificial beating process step and enables the forming quality of the flange to be high. The flanging die structure comprises a material pressing device, a female die and a male die, and is characterized by further comprising a flanging structure, wherein the flanging structure comprises oblique wedge drivers and oblique wedge sliding plates, wherein the oblique wedge drivers are respectively arranged on the left side and the right side of the female die, the oblique wedge sliding plates are respectively arranged on the left side and the right side of the male die, the oblique wedge sliding plates are mounted on wear-resistant plates, sliding ports are arranged on the wear-resistant plates, sunk grooves are arranged on a male die base corresponding to the lower parts of the sliding ports, a spring is fixedly arranged in each sunk groove, through holes are formed in the oblique wedge sliding plates, elastic pins are plug-in mounted in the through holes, the elastic pins penetrate through the oblique wedge sliding plates and extend into the sunk grooves, one end of each spring is fixed on the side wall in the sunk groove, the other end of each spring is connected with the elastic pin, reverse side blocks are arranged on the outer sides of the oblique wedge sliding plates and on the male die base, each reverse side block body comprises a baffle plate and a baseplate, and cavities are formed between the baffle plates of the reverse side blocks and the oblique wedge sliding plates.

Owner:无锡泰立特科技有限公司

LCD light-curing 3D printer

InactiveCN112339267AHigh speedIncrease printing speedAdditive manufacturing apparatus3D object support structuresComputer control systemComputer printing

The invention discloses an LCD light-curing 3D printer. The LCD light-curing 3D printer comprises a rack, a stripping system, a molding platform, an LCD display screen, a box body, a light source system, a computer control system, a material slot and a lifting device, wherein the rack is used for mounting a printer assembly; the stripping system is used for stripping a printed product from the molding platform; the molding platform is taken as a molding plane of the printed product; the LCD display screen is used for receiving a 3D component model; the box body is used for mounting a light source system and a computer control system; the light source system is used for generating light, and irradiating a layered picture in the model to the bottom of the molding platform, so that the light-curing material is cured into a corresponding pattern cured layer; the computer control system is used for controlling operation of a printer; the material slot is used for storing the light-curing material; and the lifting device is used for regulating a distance between the stripping system and the material slot. The 3D printer disclosed by the invention has the advantages of being high in printing precision, high in speed, great in printing dimension, long in service life and the like.

Owner:上海幻嘉信息科技有限公司

Forming mold for Z-shaped product

InactiveCN104826930ARealize automatic strippingSmooth strippingShaping toolsStripping-off devicesMaterials science

Owner:昆山电子羽电业制品有限公司

Automatic stripping and sticking device for sponges with release paper

ActiveCN108202890ARealize automatic strippingAchieve pasteArticle unpackingPulp and paper industryRelease liner

The invention discloses an automatic stripping and sticking device for the sponges with release paper. The automatic stripping and sticking device for the sponges with the release paper comprises a stripping module and a sticking module. The stripping module is used for stripping off the release paper on the sponges. The sticking module is used for sticking the sponges without the release paper tothe structures needing the sponges. The sticking module comprises an air blowing plate and an air intake pipe. The air blowing plate is arranged at the material outlet of the stripping module. The air intake pipe which is vertically arranged can move between the air blowing plate and the structures needing the sponges. The air blowing plate can blow air upwards so as to blow the sponges without the release paper upwards while the sponges move from the material outlet of the stripping module to the air blowing plate. With the automatic stripping and sticking device for the sponges with the release paper, it can be realized that the release paper on the sponges is automatically stripped off and the sponges are automatically stuck; and the production efficiency is improved, and manpower is saved.

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

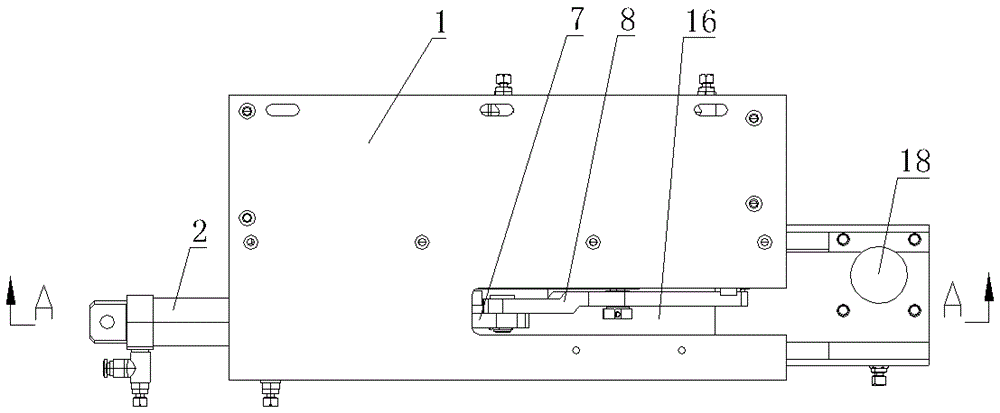

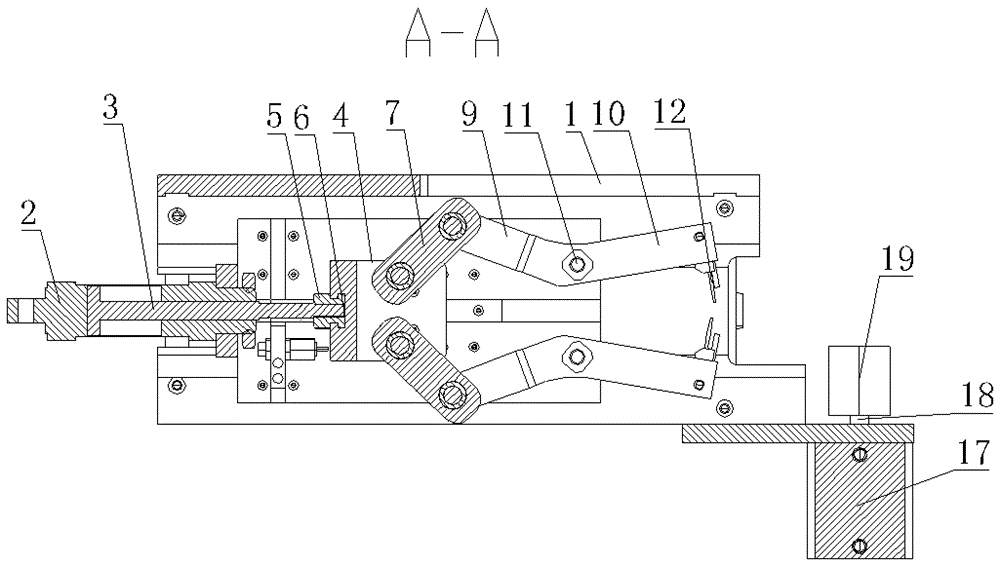

Cable stripping device

ActiveCN106786211AAvoid injuryEasy to operateApparatus for removing/armouring cablesEngineeringPiston rod

The invention provides a cable stripping device which is simple in structure, can strip cables conveniently and quickly, achieve automatic cable stripping, is free of manual operation and high in automation degree, improves production efficiency and reduces labor intensity. The cable stripping device comprises a machine frame, wherein a clamping air cylinder which is horizontally arranged is arranged on one side of the machine frame, a piston rod of the clamping air cylinder extends out forward, the front end of the piston rod of the clamping air cylinder is connected with a connection block, two first connection rods are hinged to the connection block, the two first connection rods are vertically and symmetrically arranged, and the first connection rods are each connected with second connection rods; each second connection rod comprises a first swing arm and a second swing arm, wherein a hinged point is arranged between the first swing arm and the second swing arm; the second connection rods are arranged on the machine frame in a rotatable mode through the hinged points, the first swing arms are in hinged connection with the first connection rods, and cable stripping clamp heads are arranged at the front ends of the second swing arms; a cable stripping air cylinder which is horizontally arranged is arranged on one side of the machine frame, a piston rod of the cable stripping air cylinder extends out backwards, the piston rod of the cable stripping air cylinder is fixedly connected with a connection plate, and the other end of the connection plate is fixedly connected with the clamping air cylinder.

Owner:上海鸣志电工股份有限公司

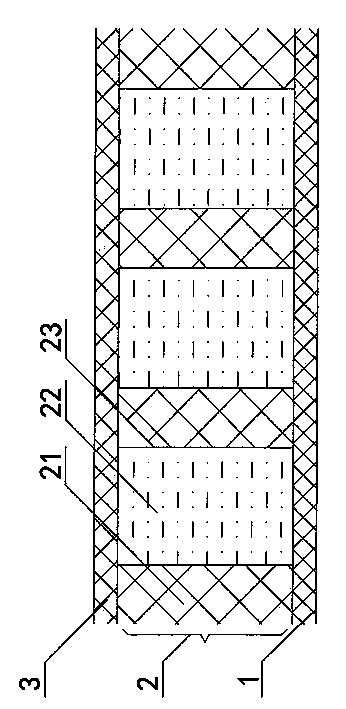

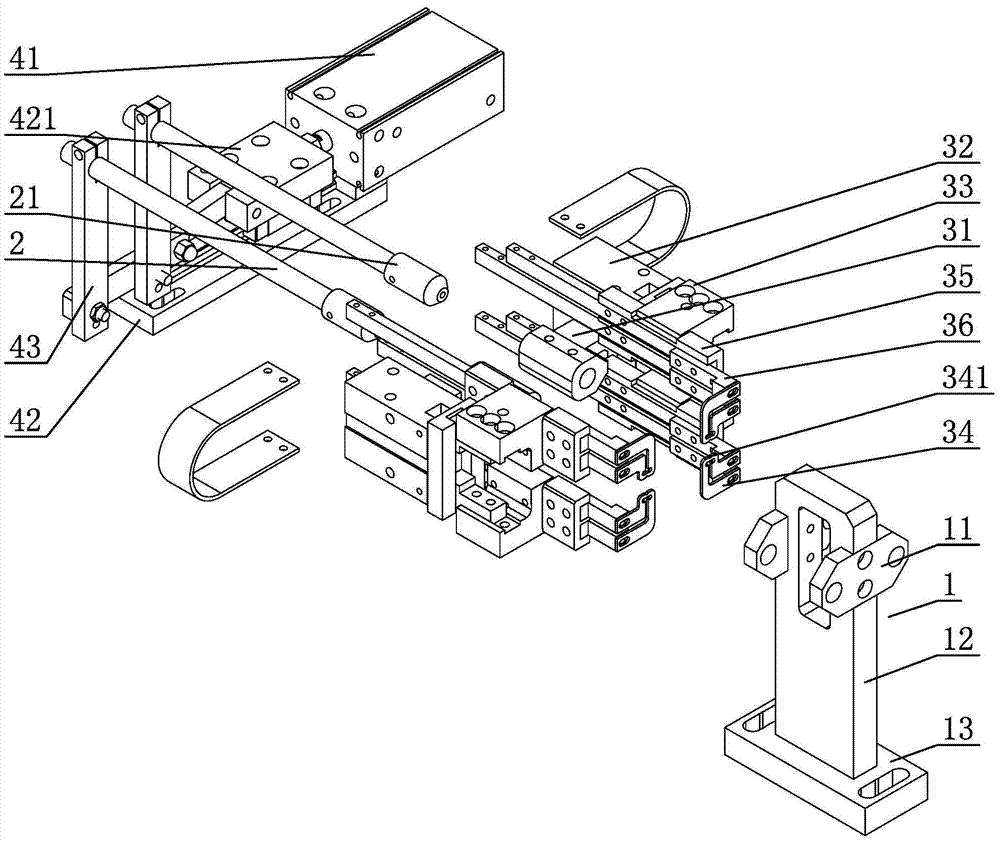

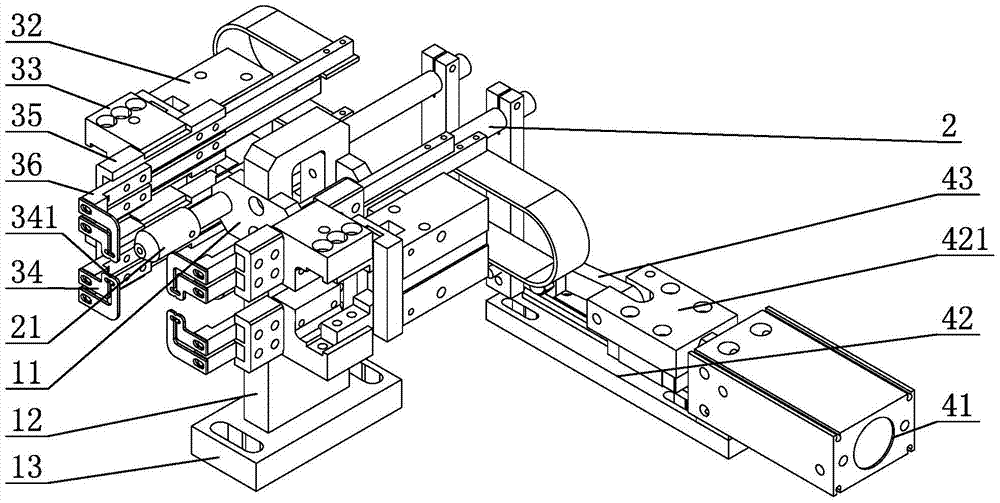

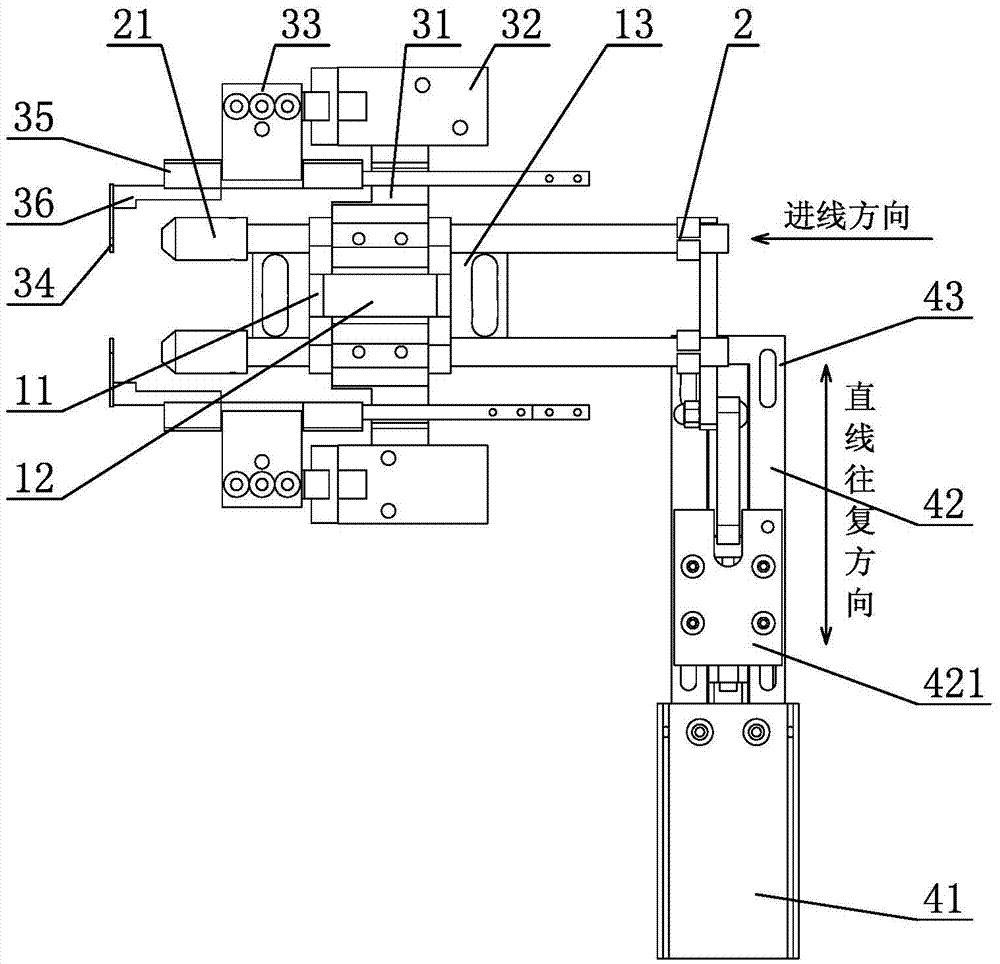

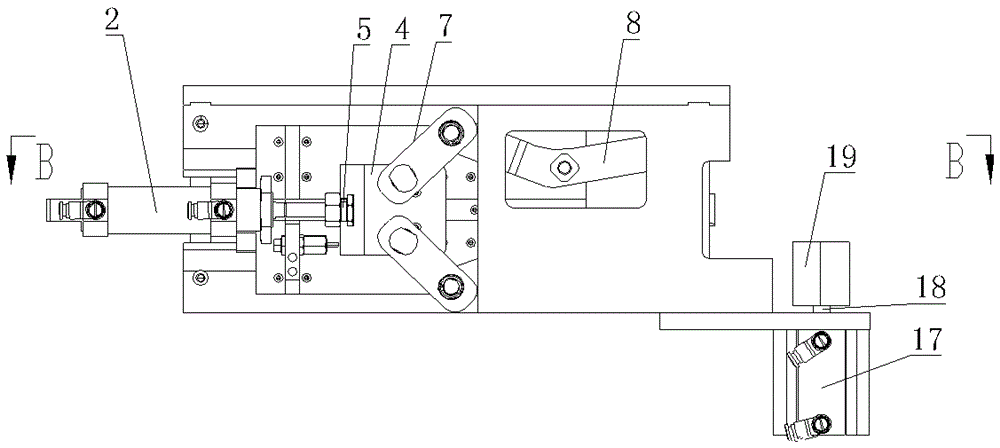

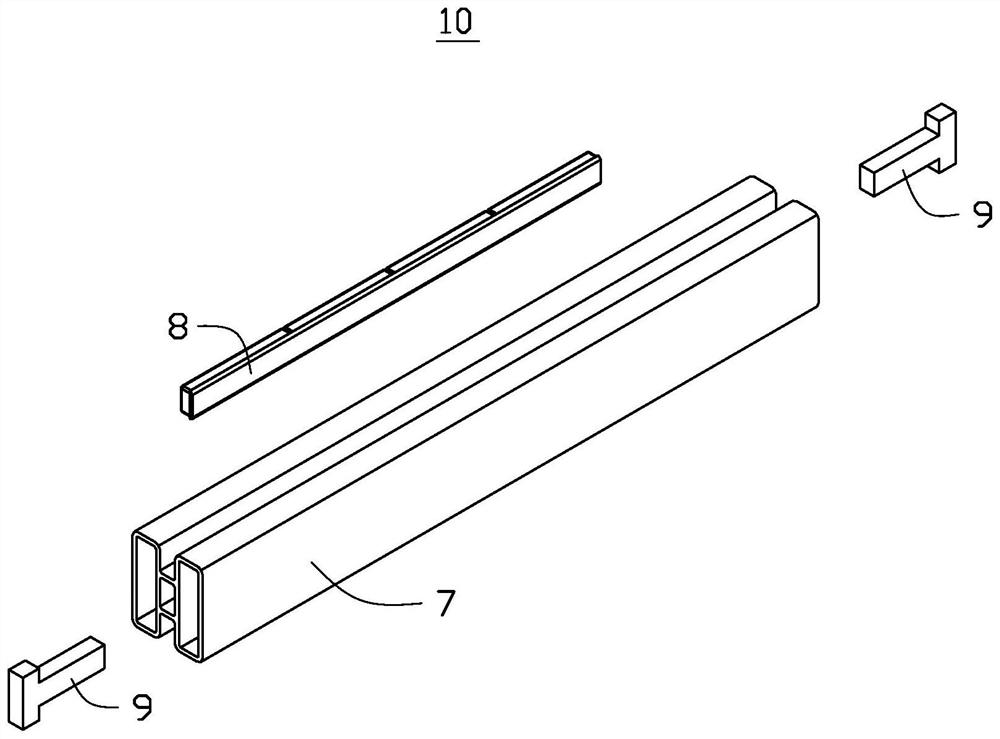

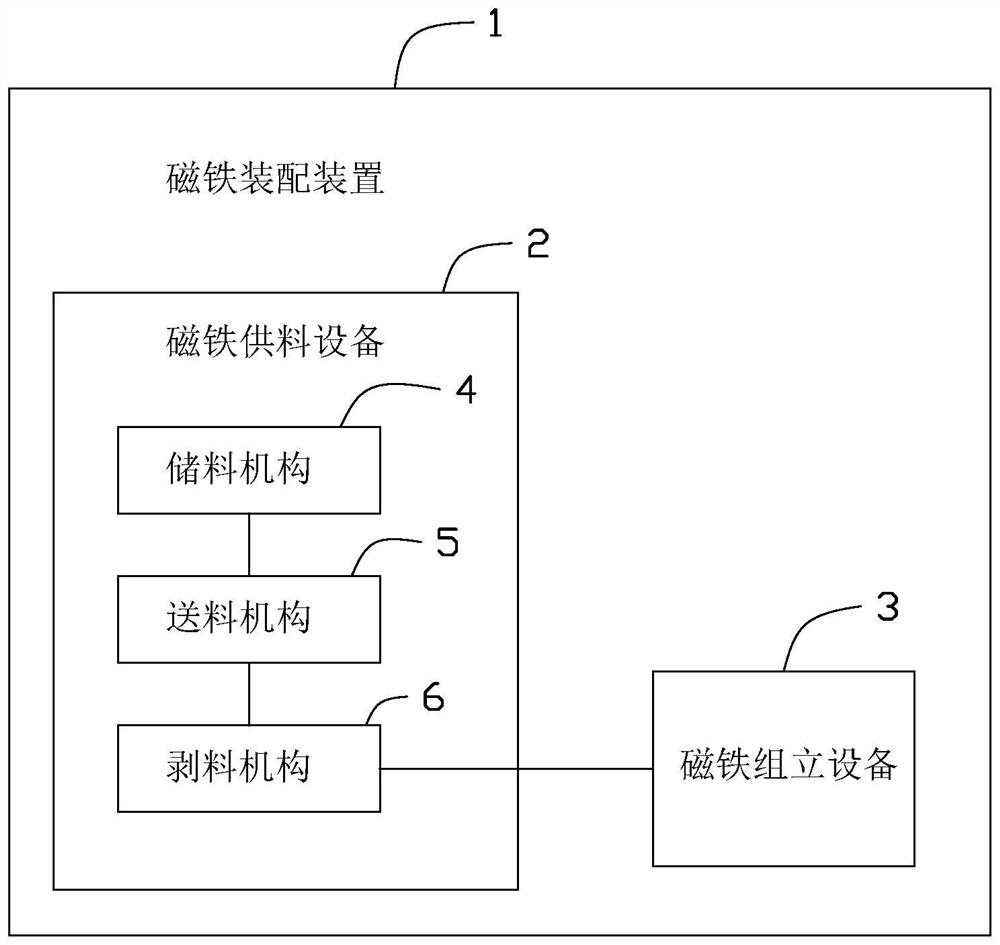

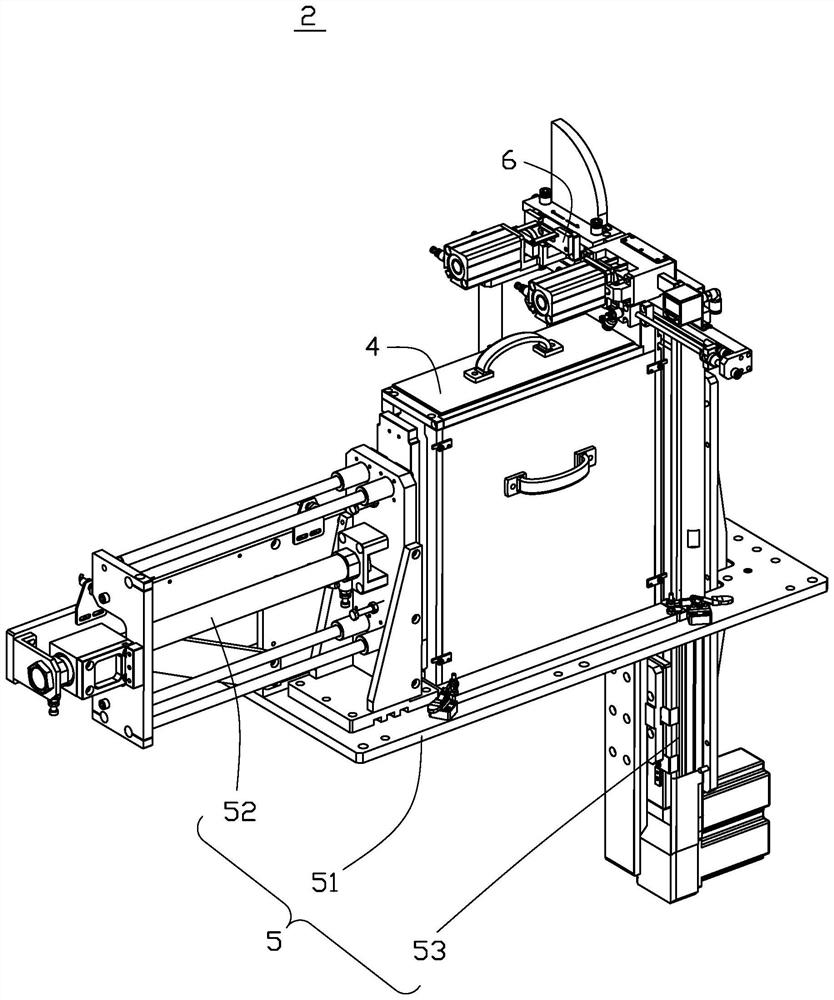

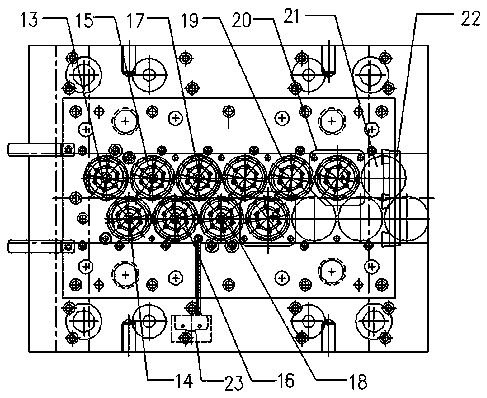

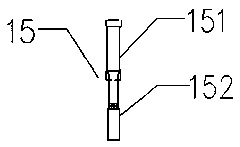

Magnet assembling device and magnet supplying equipment and material stripping mechanism thereof

ActiveCN111689210ARealize automatic strippingReduce labor costsMetal working apparatusConveyor partsEngineeringMechanical engineering

The invention provides a material stripping mechanism. The mechanism comprises a main body, a material pushing module, a material stripping module, a material blowing module, a discharging module anda discharging shade. The main body comprises a feeding part, a discharging part, a material guiding part and a material stripping part. The feeding part is arranged on the discharging part and is positioned on the lower part of the discharging part. The material guiding part and the material stripping part are respectively arranged at two opposite ends of the feeding part, and the material stripping part is in butt joint with the discharging part at the same time. The feeding part is used for receiving incoming materials. The material pushing module is used for pushing the incoming materials received by the feeding part to the material stripping part. The material stripping module is used for unplugging two rubber plugs of the incoming materials in the material stripping part and pushing amaterial box with the two rubber plugs unplugged together with small magnet pieces in the material box to the material blowing module. The material blowing module is used for blowing the small magnetpieces out of the material box and into the discharging part, and blowing an empty material box to the discharging shade. The discharging module is used for pushing the small magnet pieces out of thedischarging part. A material stripping mechanism can realize automatic stripping of the small magnet pieces. The invention further provides magnet supplying equipment and a magnet assembling device.

Owner:HONGFUJIN PRECISION ELECTRONICS ZHENGZHOU

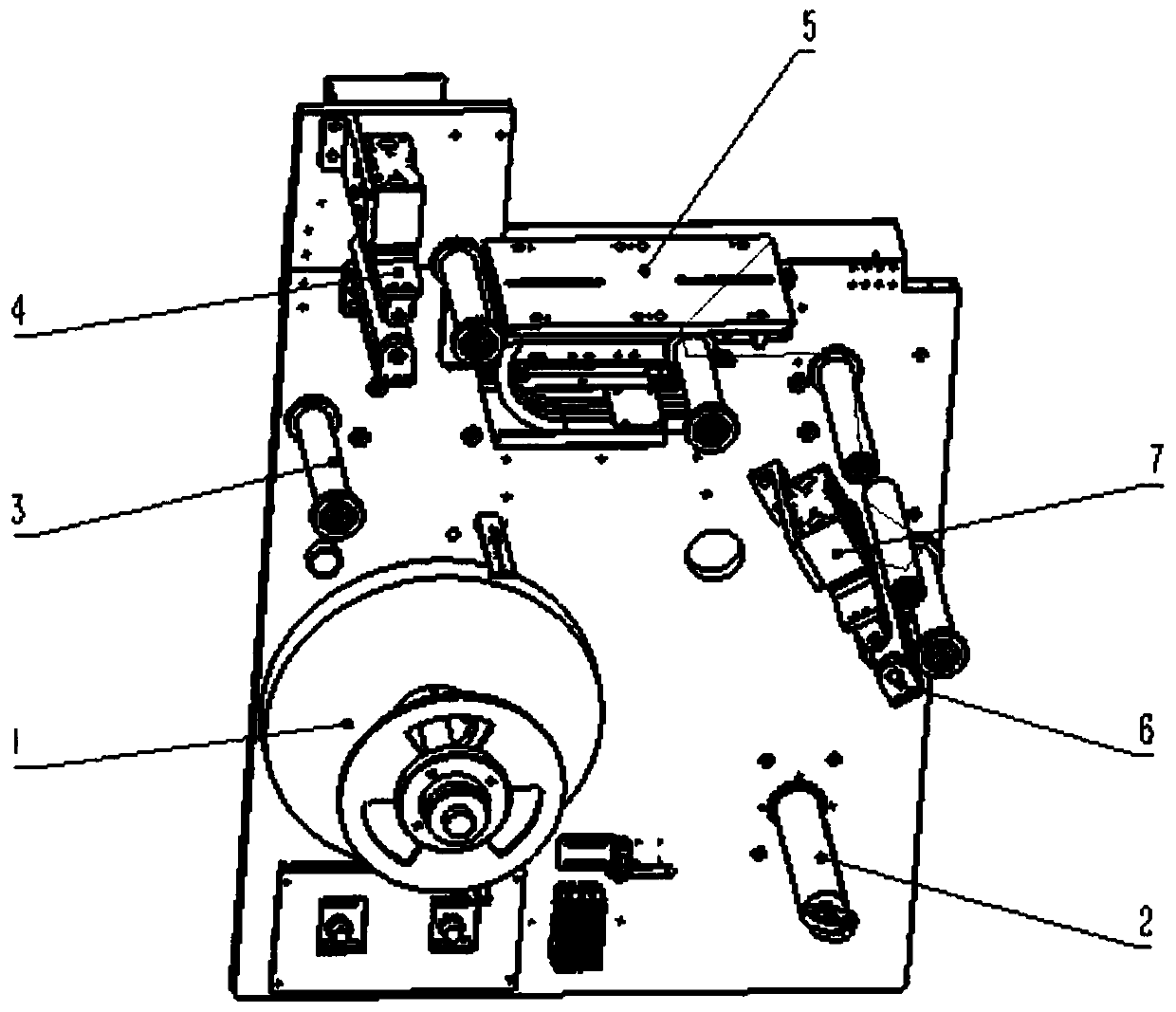

Vibrator tape pasting equipment

ActiveCN112092400AAutomatic strippingAchieve strippingLayered productsLaminationComposite materialManufacturing engineering

The invention relates to the field of tape pasting equipment, in particular to vibrator tape pasting equipment. The vibrator tape pasting equipment comprises an operation table, two supports, a back plate and a bottom frame, the supports and the bottom frame are fixed to the top of the operation table, and the bottom frame is located between the two supports. The problems that in the prior art, vibration isolation is conducted by pasting a foam adhesive tape on a vibrator manually, adhesive tape raw materials comprise a protective film and the foam adhesive tape, the protective film needs to be stripped manually and then the foam adhesive tape needs to be taken out to be pasted, the manual adhesive tape stripping and pasting efficiency is low, the automation degree is low, and the adhesivetape stripping and pasting quality is difficult to control, in addition, the stripped protective film needs to be cleaned in time, existing vibrator tape pasting equipment is lack of a part for cleaning the stripped protective film in time, the steps of taking a tape sheet, pasting the film and then taking the tape sheet again need to be conducted in sequence in the using process of the whole tape pasting equipment, a new tape sheet cannot be taken while the film is pasted, and thus the efficiency of the whole operation step is greatly reduced can be solved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

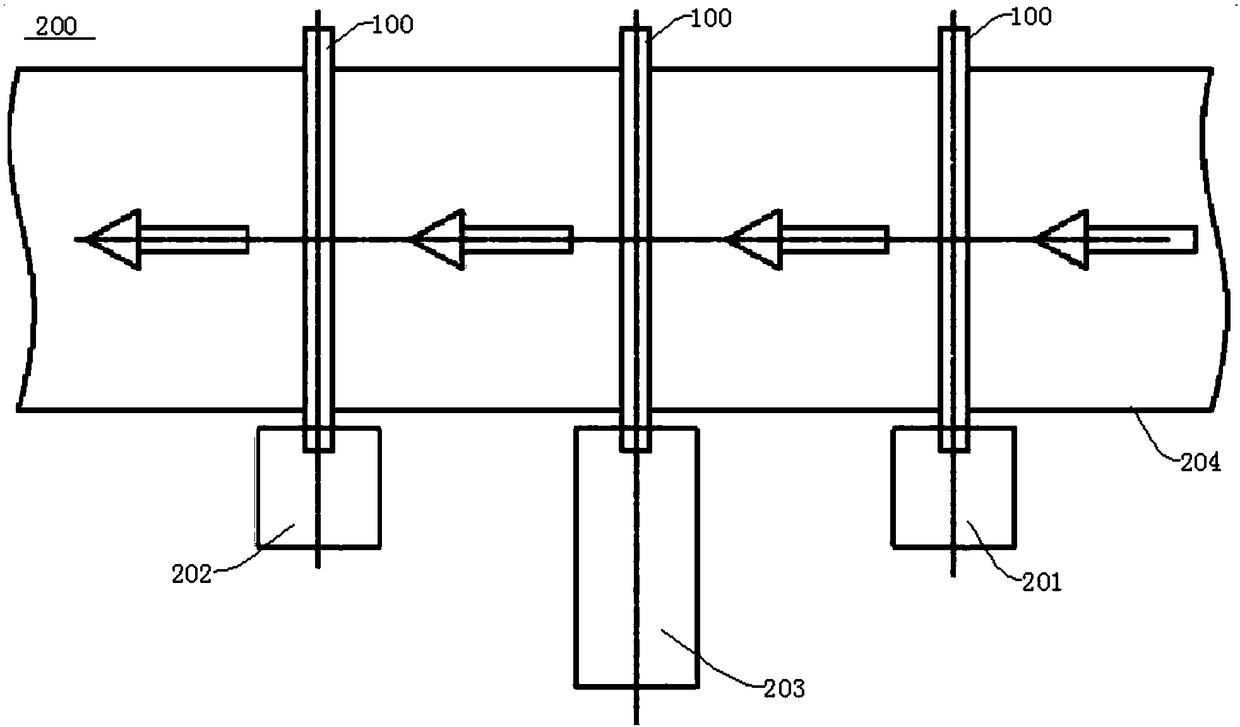

Continuous stepping device for screw plate of filter

InactiveCN105562515AEasy to moveSave production costShaping toolsPerforating toolsPunchingEngineering

The invention discloses a continuous stepping device for a screw plate of a filter. The continuous stepping device comprises a rack which is sequentially provided with lower pad iron, a lower die plate, a lower base plate, a concave die plate, a discharging plate, a discharging backing plate, a fixing plate, an upper base plate, an upper die plate and upper pad iron from bottom to top. A plate conveying device is arranged between the concave die plate and the discharging plate. A first material guiding block and a second material guiding block are arranged at the front end of the plate conveying device. A phi 6 punching assembly, a phi 13 forming die assembly, a phi 8.05 punching assembly, a budding die assembly, a phi 9 punching assembly, a forming die assembly, a blanking die assembly, an inner guide sleeve assembly and a cutting assembly are sequentially arranged between the upper die plate and the lower die plate from left to right according to the corresponding processes. Compared with the prior art, the continuous stepping device for the screw plate of the filter has the following advantages that relevant machining modules for manufacturing the screw plate are equipped on one device, by combining the stepping conveying device, material movement of the screw plate is achieved according to the set step pitch, and therefore automatic machining is completed, the production cost and the maintenance cost are reduced, production benefits of enterprises are increased, and popularizing is convenient.

Owner:BENGBU CITY MINGWEI FILTER CO LTD

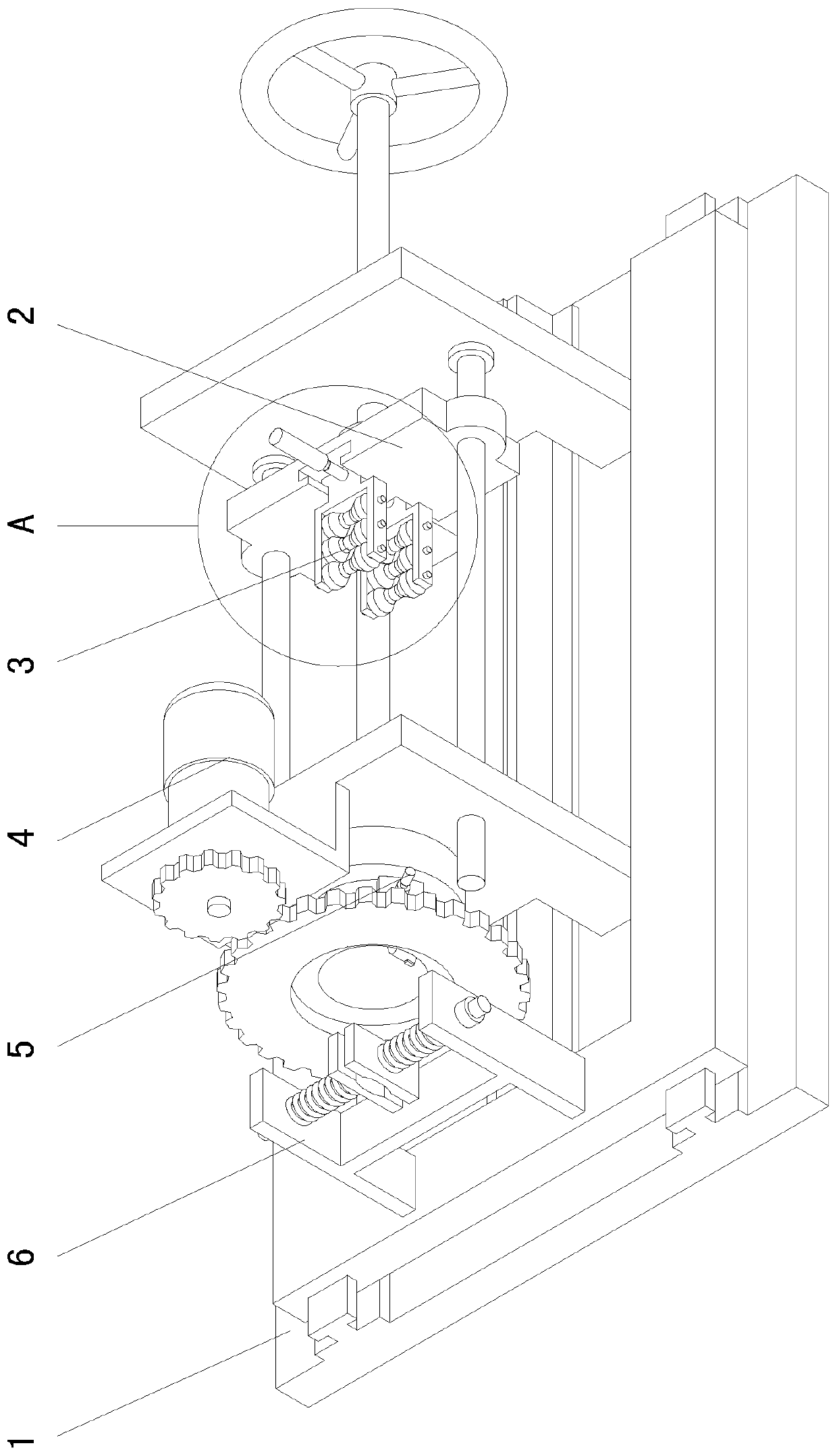

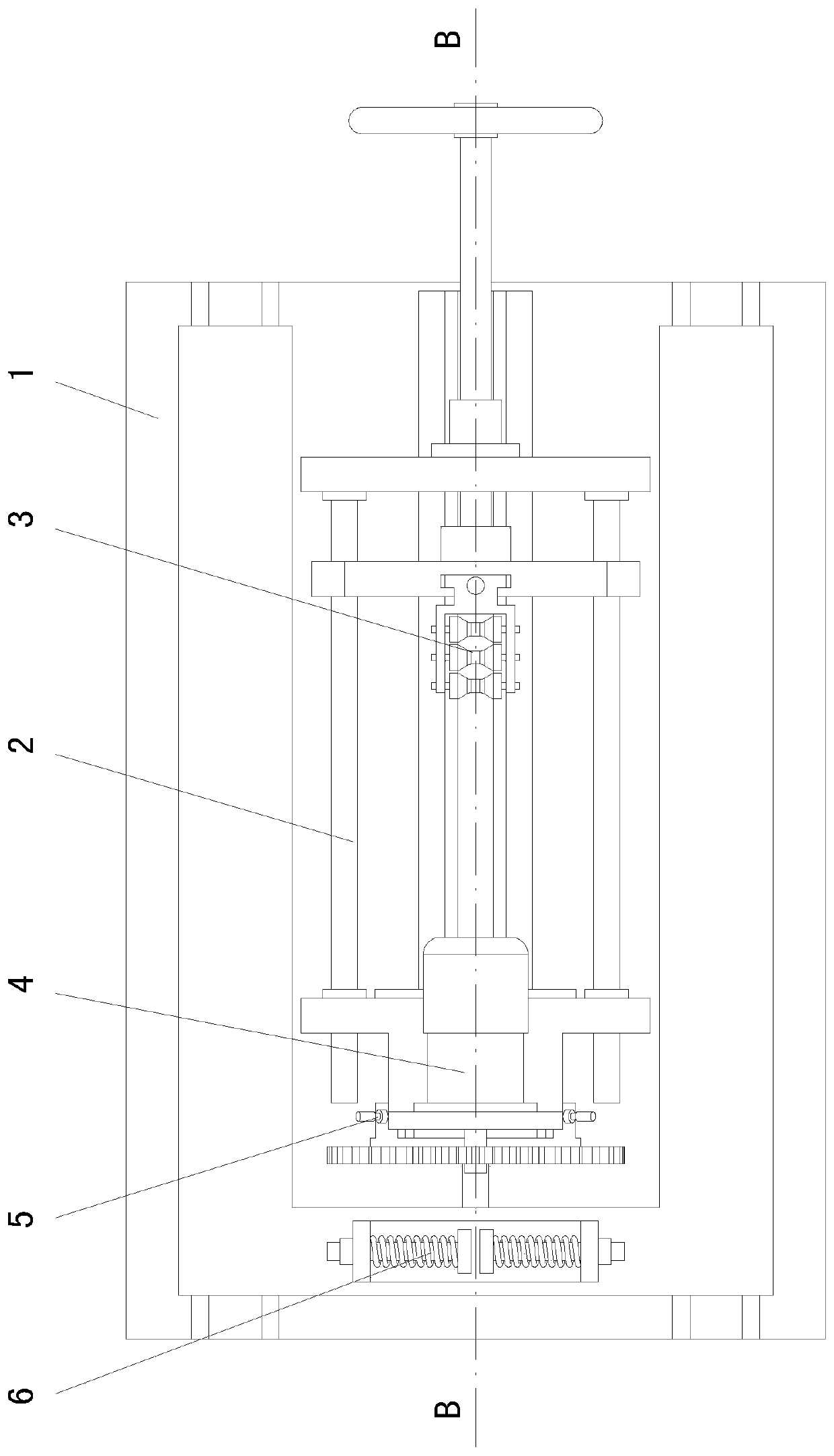

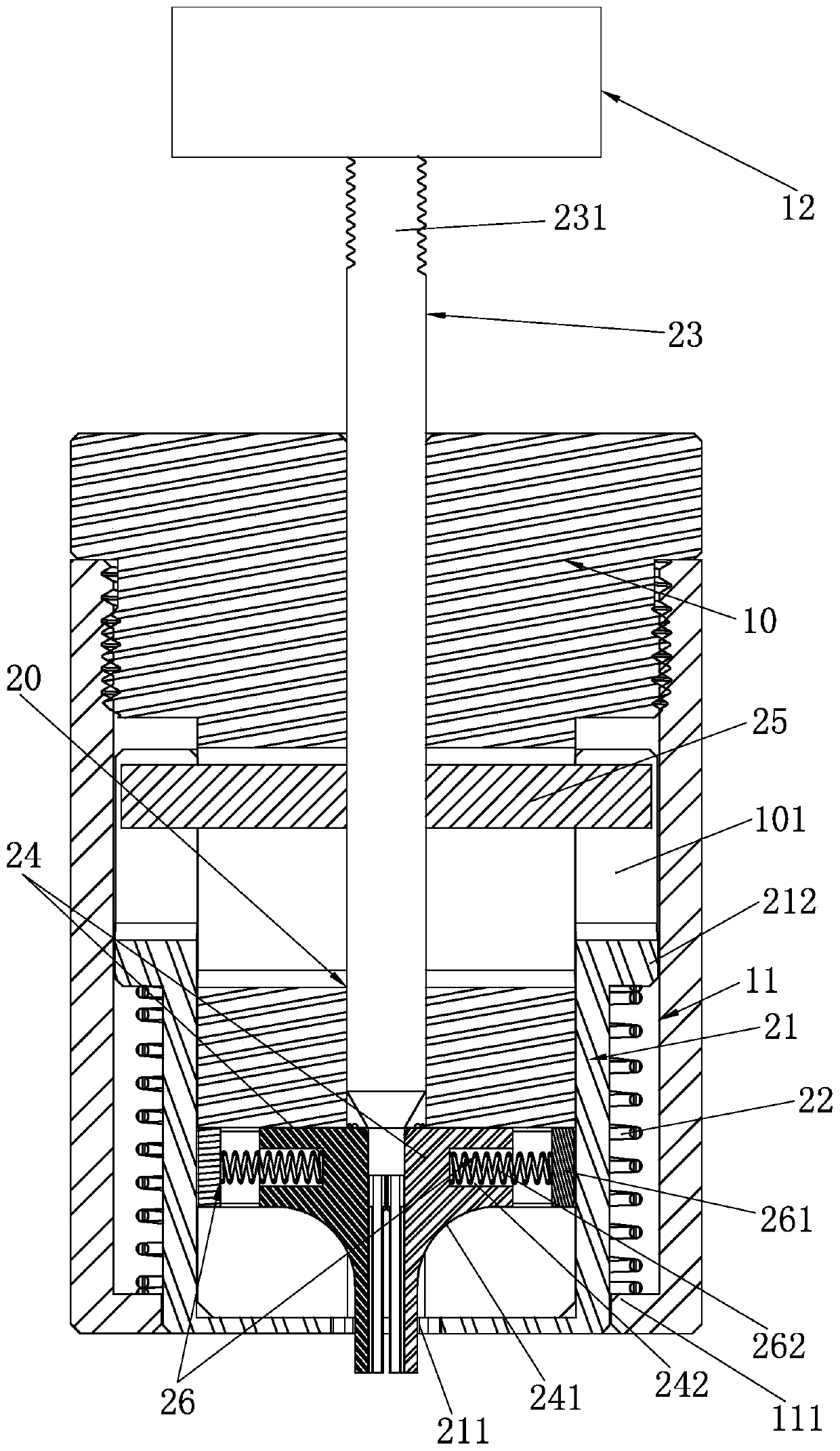

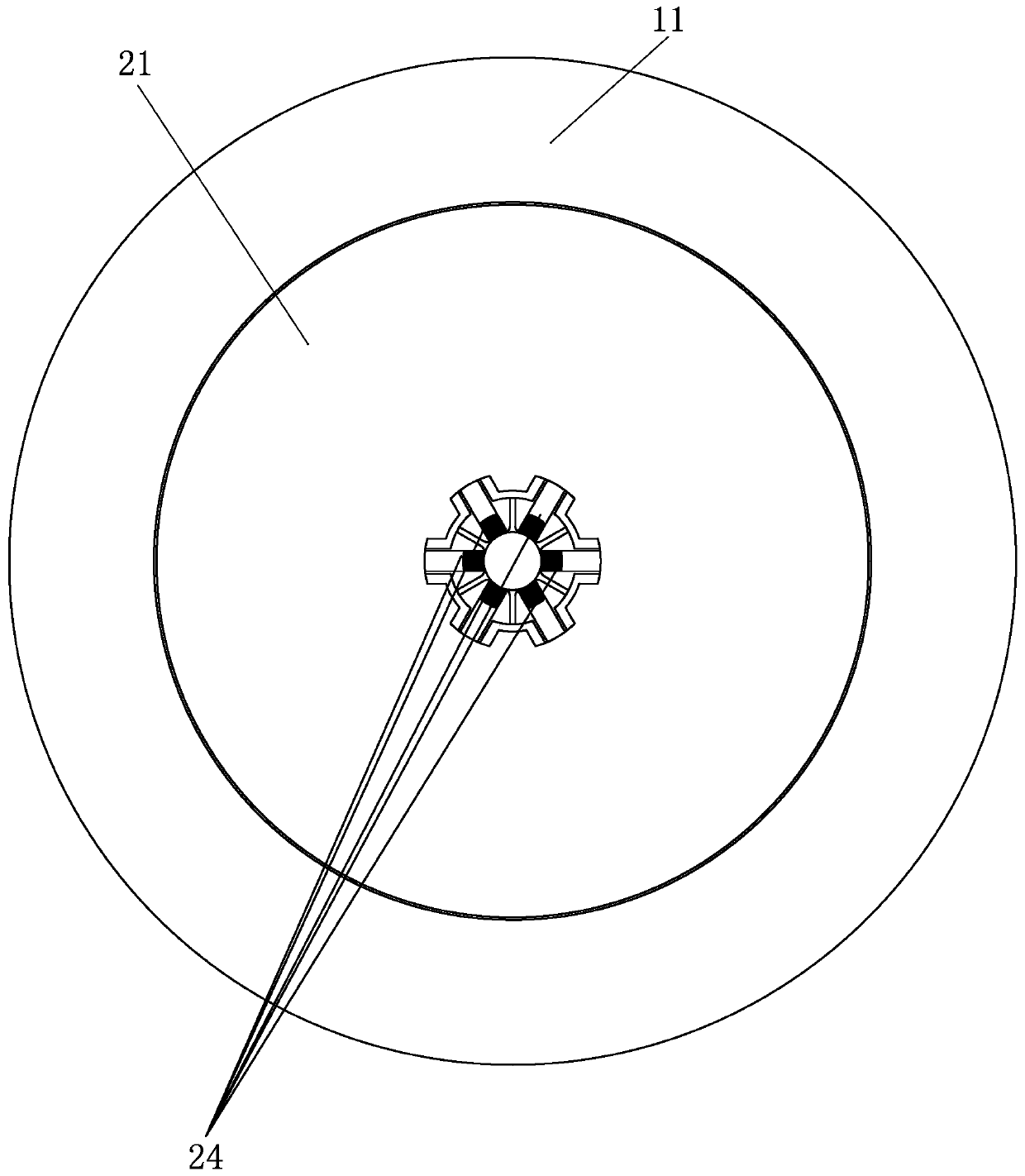

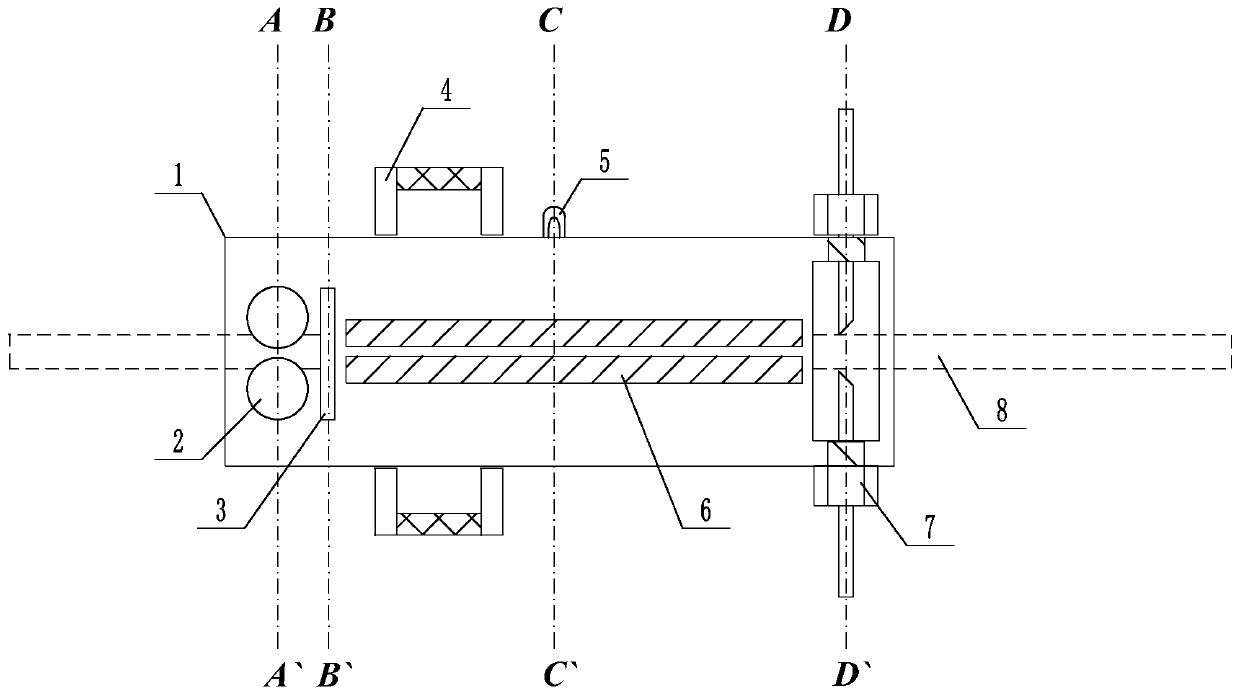

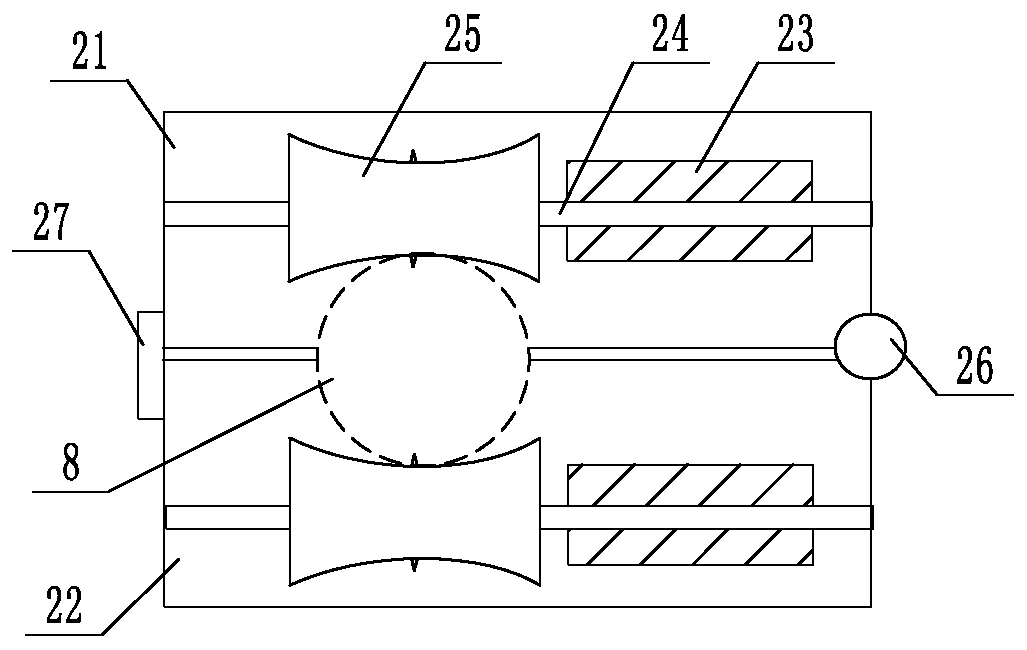

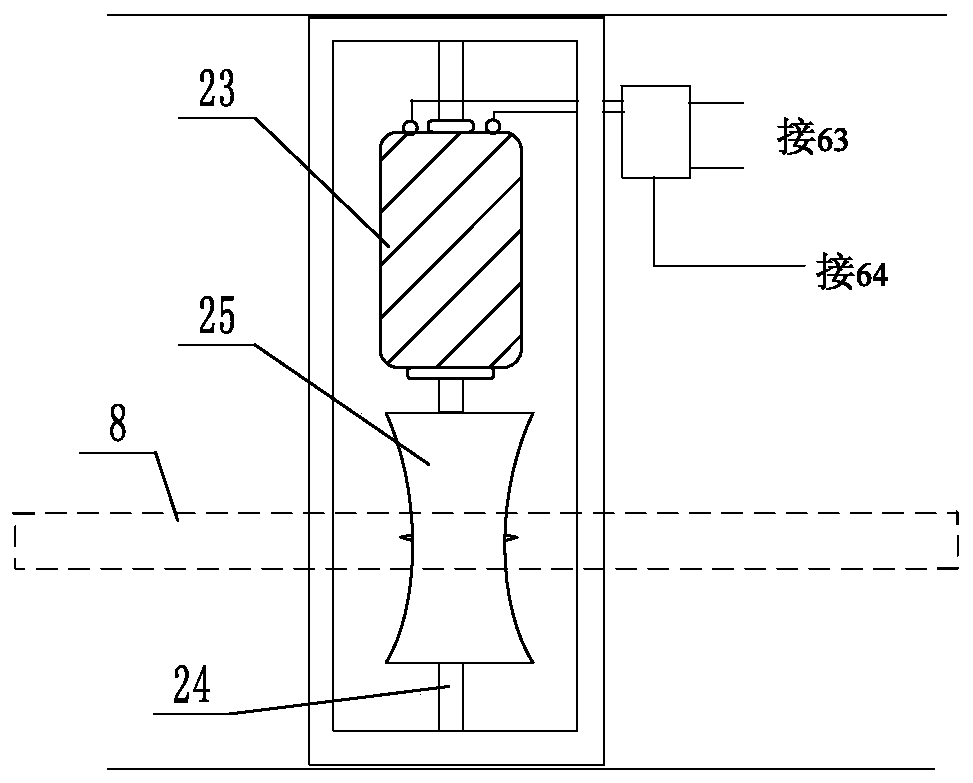

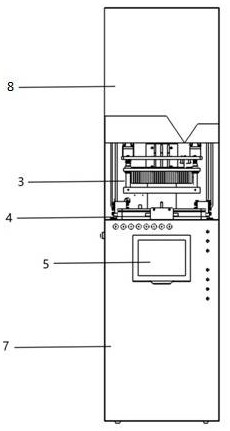

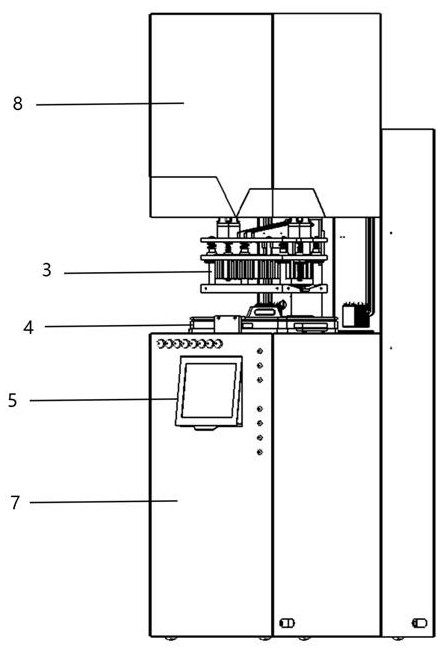

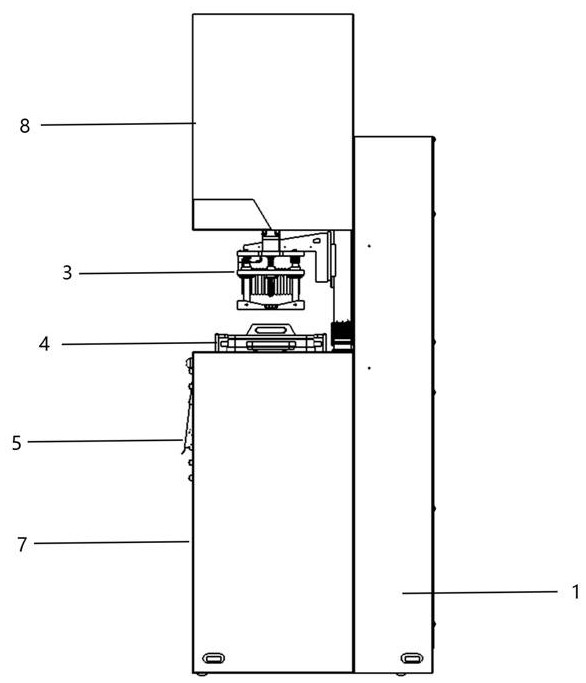

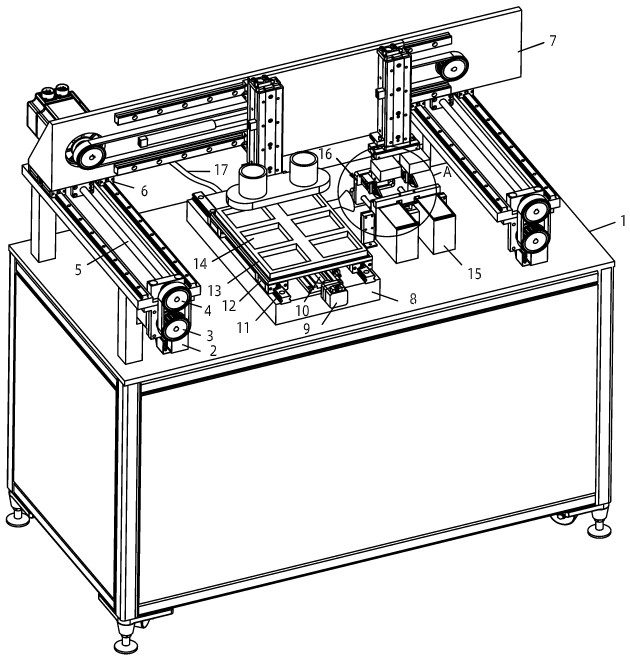

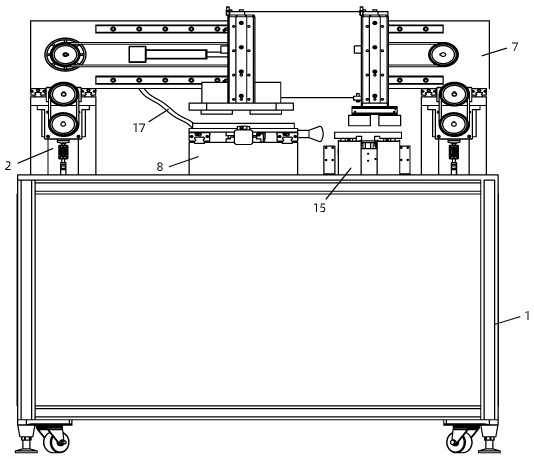

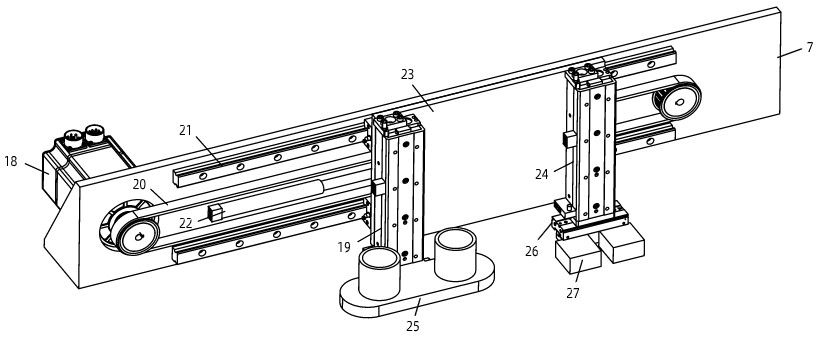

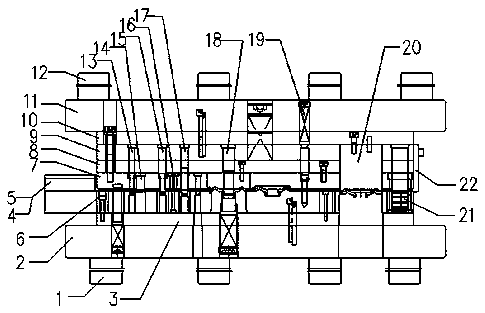

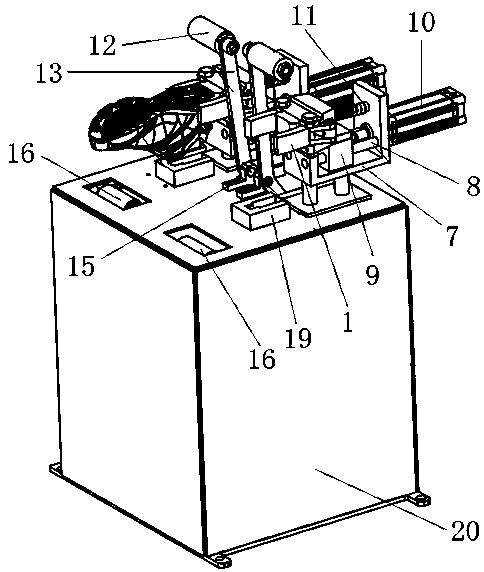

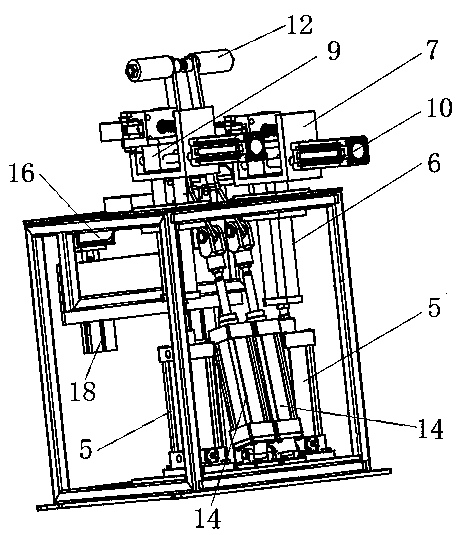

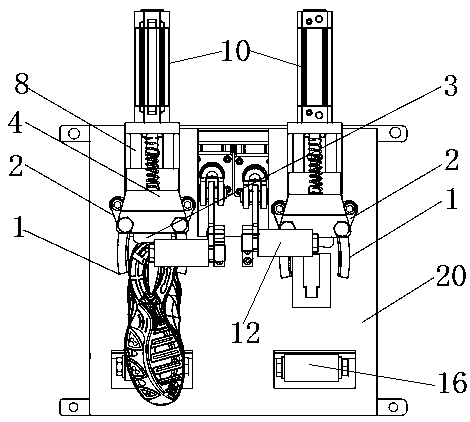

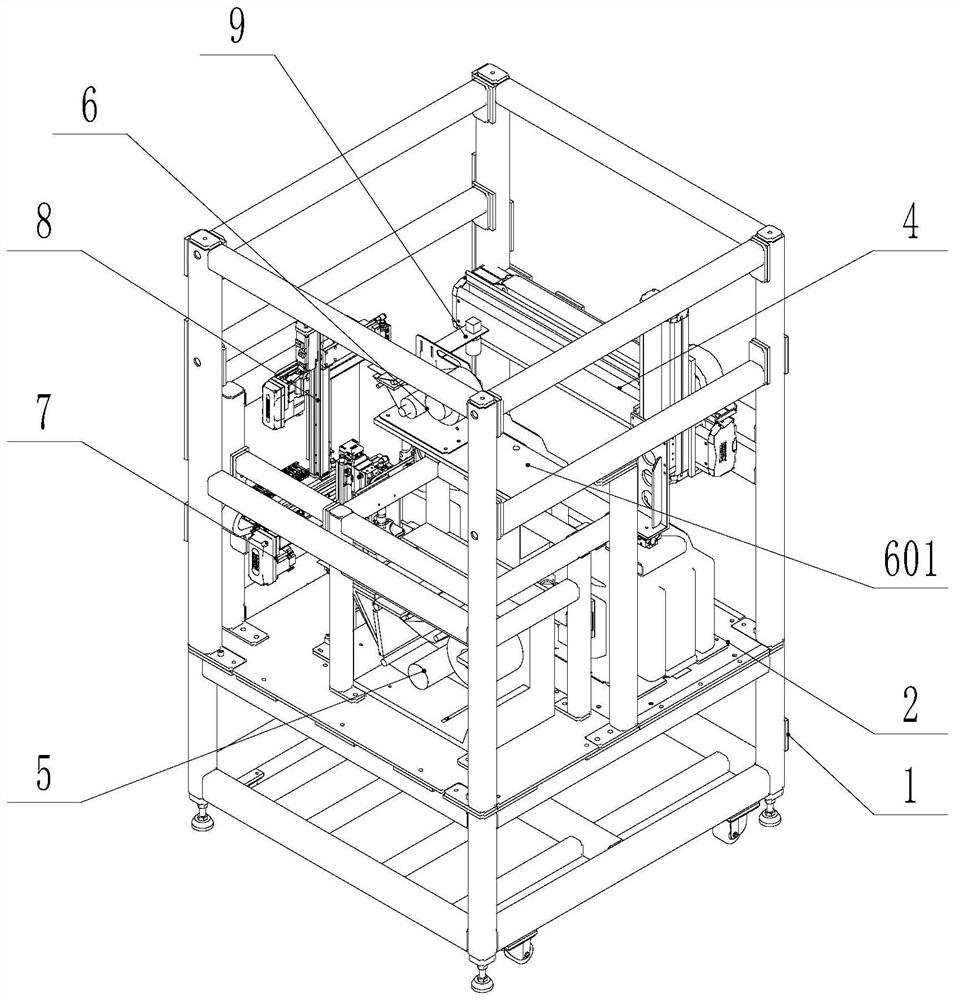

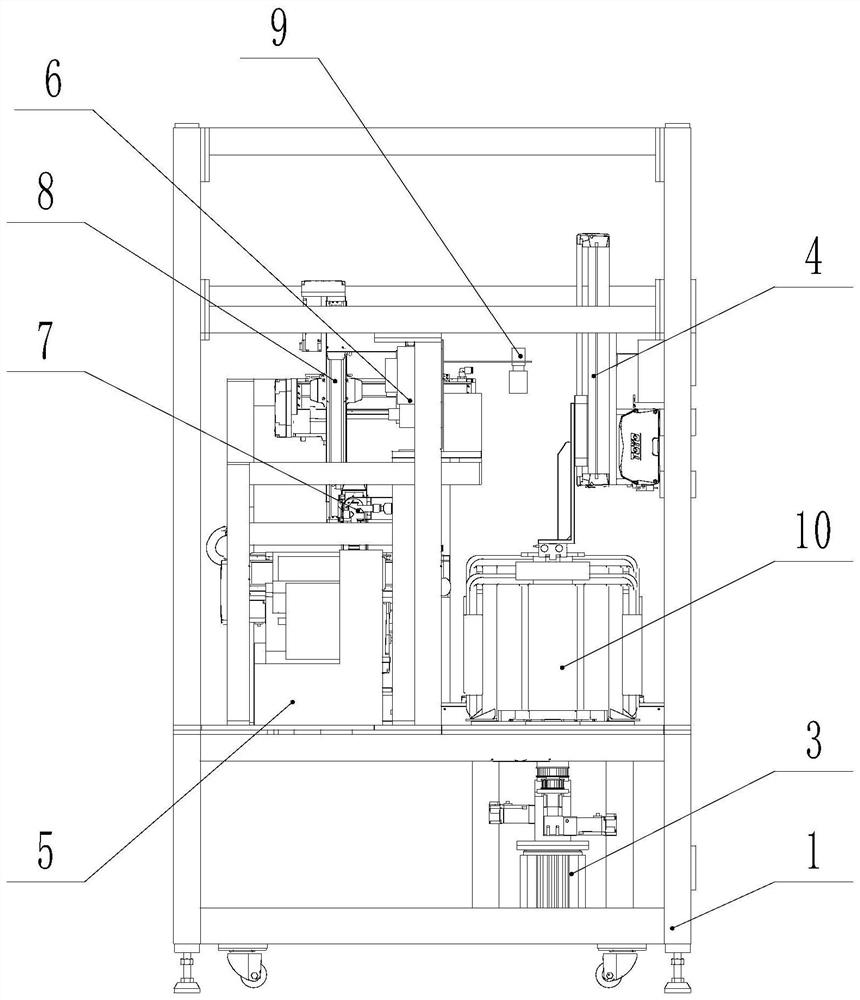

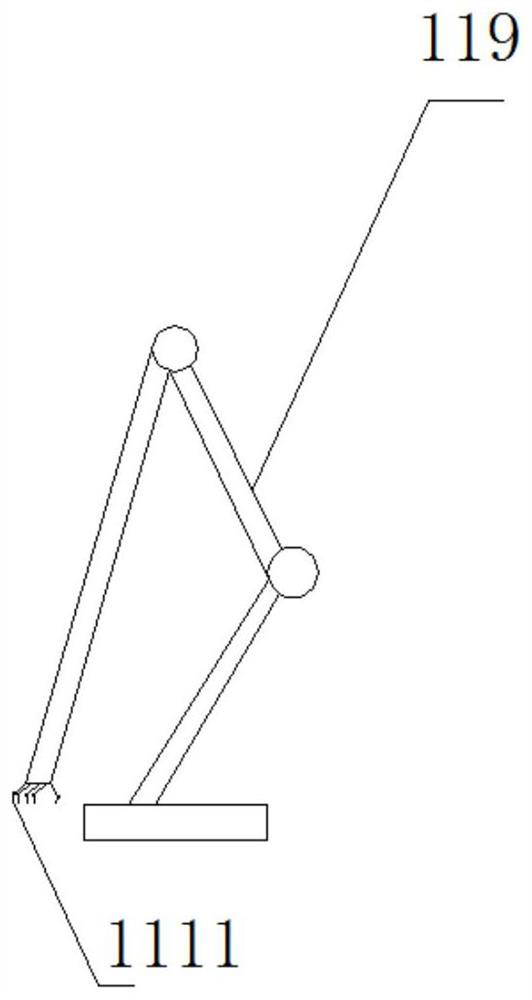

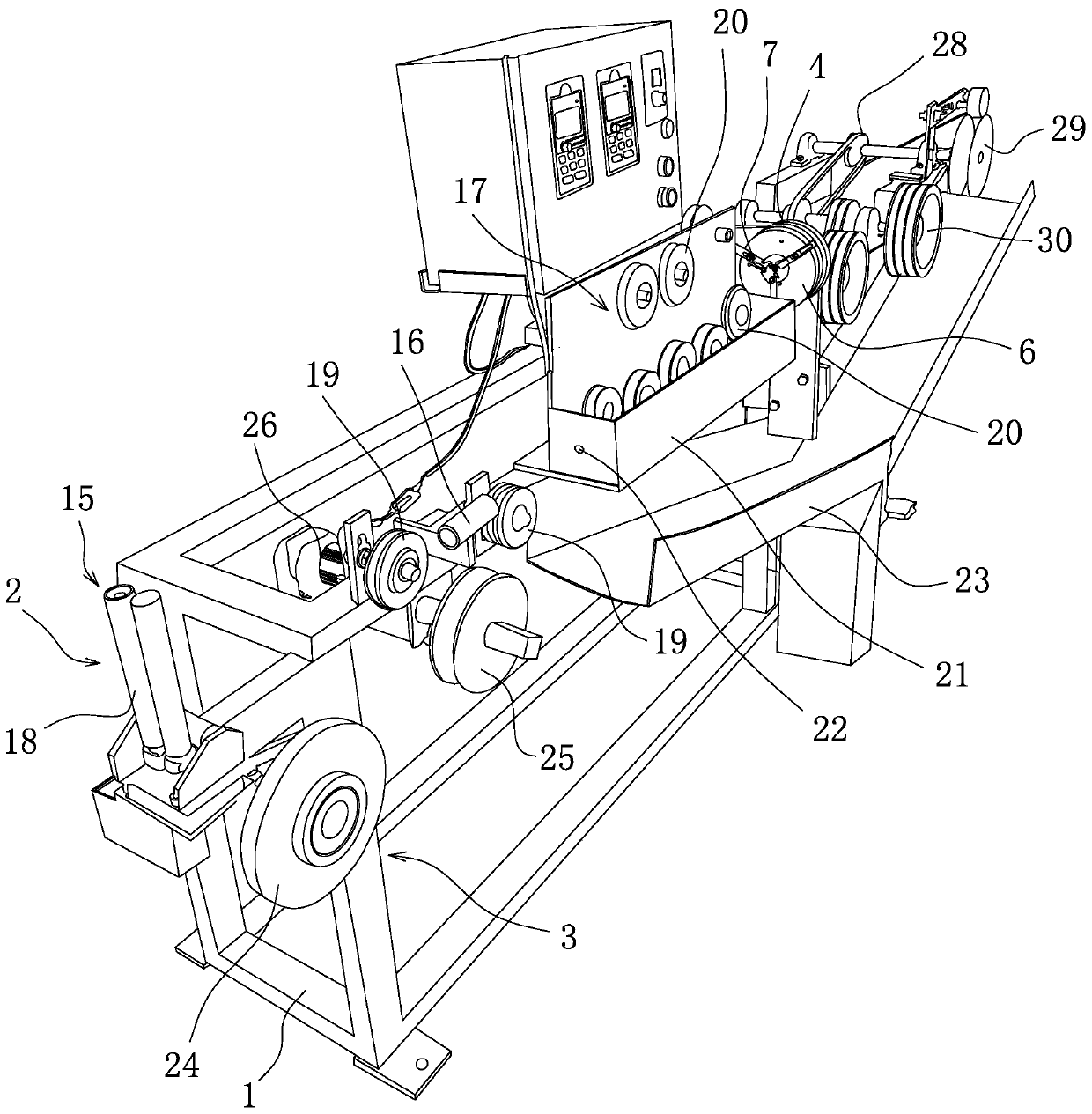

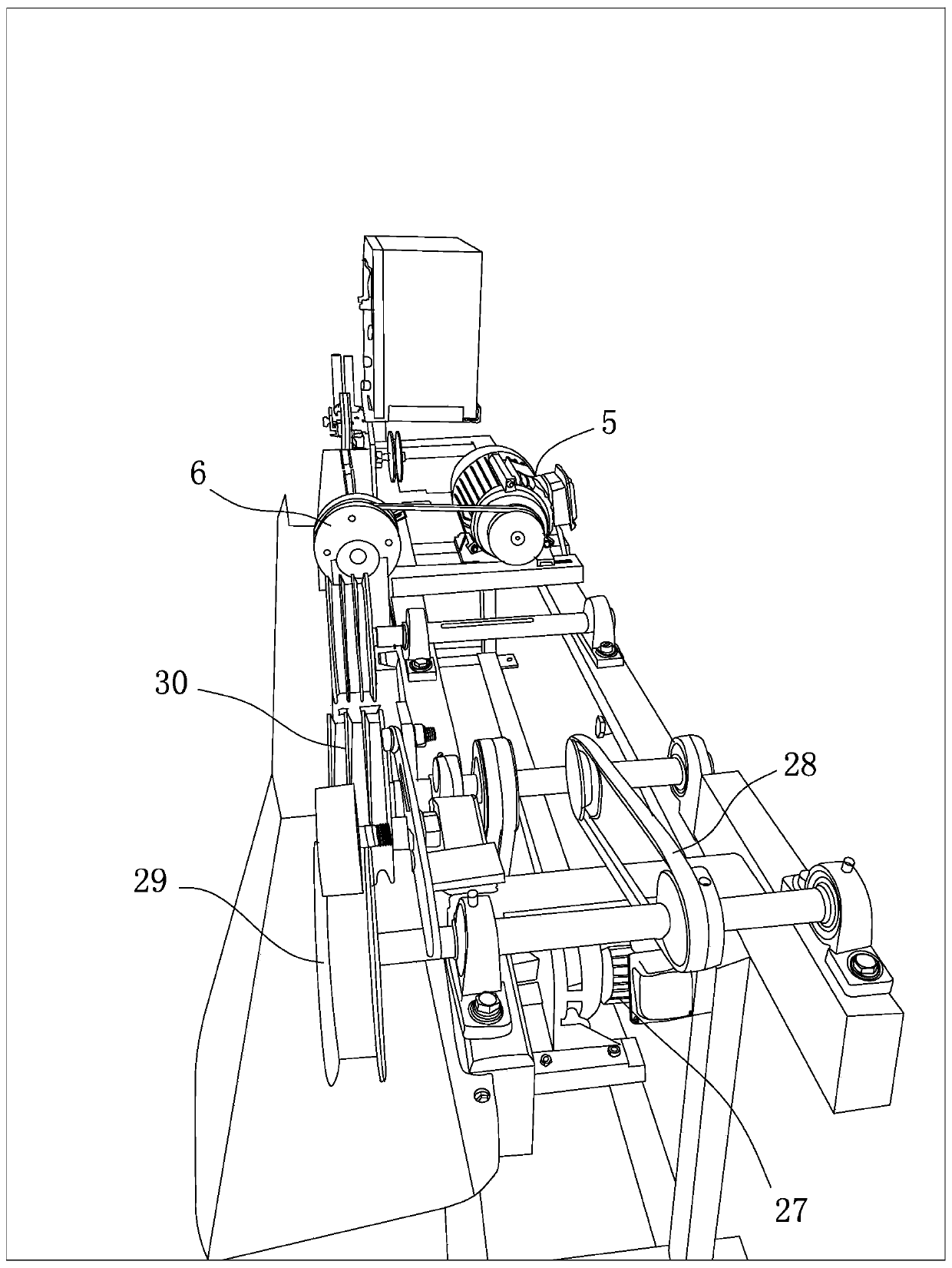

Full-function and automatic last removing machine

ActiveCN110495680ARealize stripping workRealize double-station automatic strippingLastingEngineering

The invention discloses a full-function and automatic last removing machine and belongs to the field of shoemaking processing. The full-function and automatic last removing machine comprises a rack, alast fixed seat arranged on the upper end surface of a top cover of the rack and a last removing machine arranged on the rack and used for removing the last, and the last removing machine further comprises a jacking roller mechanism and a pressing roller mechanism, wherein the jacking roller mechanism is capable of ascending and descending, is located at a position right below a vamp and is capable of jacking a molded shoe, and the pressing roller mechanism is capable of swinging and pressing the molded shoe. According to the full-function and automatic last removing machine in the invention,the last removing work of three types of lasts of a common last, a C-shaped last and a V-shaped last can be realized, double-station automatic last removal can be realized, the usability is high, andthe problems of manpower consumption, low efficiency, poor adaptability and the like of the existing last removing machine are effectively solved.

Owner:YANSHAN UNIV

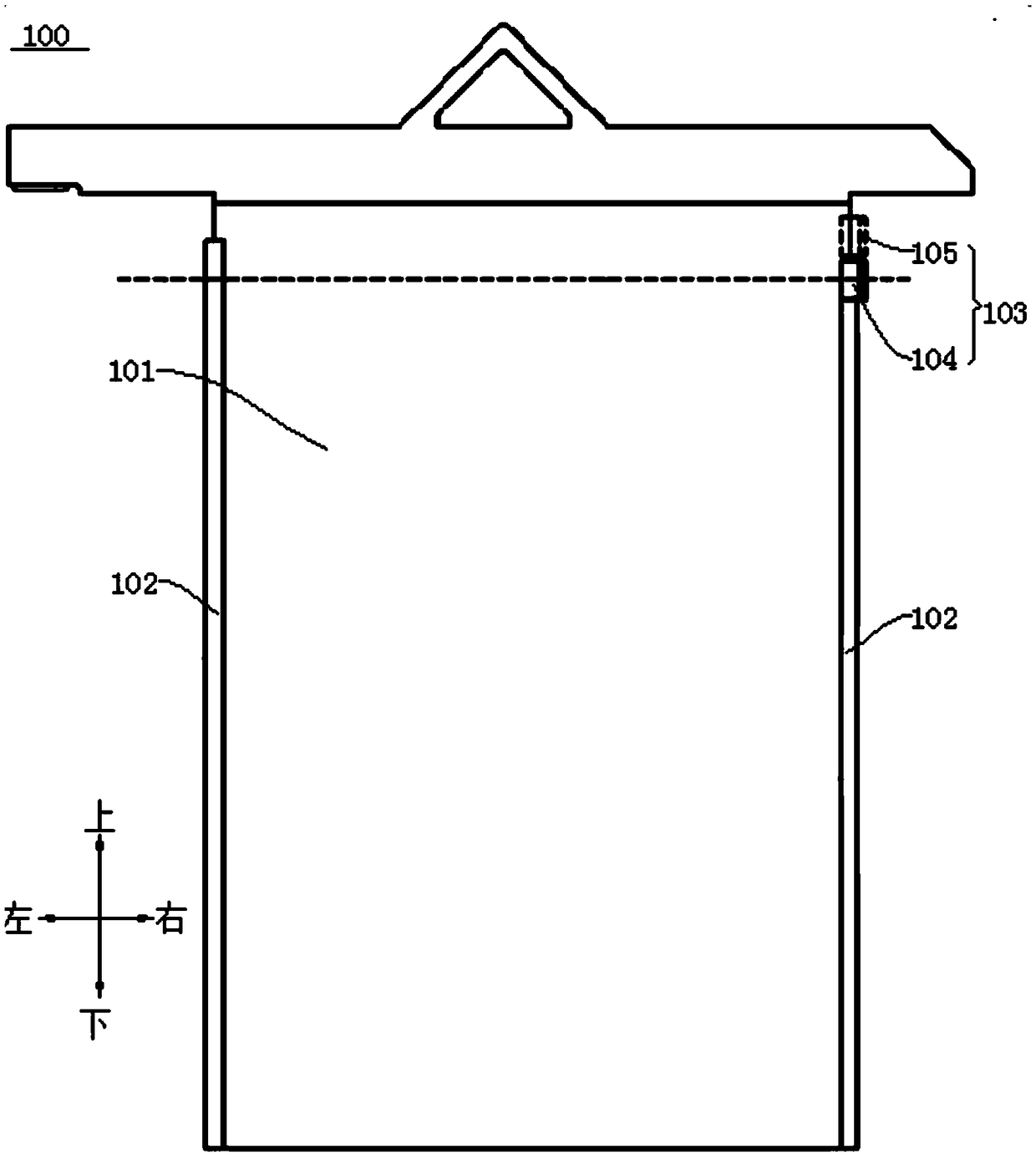

Labeling device of FOSB packaging assembly line

PendingCN112498884AHigh degree of automationImprove labeling efficiencyPackaging machinesLabelling machinesClip devicePackaging Case

The invention discloses a labeling device of an FOSB packaging assembly line. The labeling device comprises an integral rack, a feeding platform, a rotary lifting translation conveyor belt, a top clamping device, an ID label marking and stripping device, a warning label stripping device, an ID label pasting device, a warning label pasting device and a shooting device, wherein the feeding platformand the rotary lifting translation conveying belt are both fixed on the integral rack, the feeding platform is arranged at the inlet end of the rotary lifting translation conveying belt, the top clamping device is fixed above the feeding platform and the rotary lifting translation conveying belt, and the ID label marking and stripping device, the warning label stripping device, the warning label pasting device and the ID label pasting device are mounted on the side, the same as the rotary lifting translation conveying belt, of the integral rack. The labeling device can automatically complete labeling work of wafer packaging boxes, and has high degree of automation, less manpower consumption and high labeling efficiency.

Owner:无锡迪渊特科技有限公司

Automatic ultra-thin and easy-to-wrinkle CU foil stripping technology

InactiveCN110254873ARealize automatic strippingImprove efficiencyBinding material removalWrinkle skinForeign matter

Owner:SHENZHEN JIYIN TECH

Electrolytic metal layer pre-stripping system, pre-stripping method and stripping system

ActiveCN109423667ARealize automatic strippingEasy to peelPhotography auxillary processesElectrolysis componentsMetalCathode

The invention discloses an electrolytic metal layer pre-stripping system, a pre-stripping method and a stripping system. An electrolytic cathode assembly comprises a cathode plate, edge cover strips and an insulating clamp. The insulating clamp is movably sealed and clamped on the cathode plate between the first position and the second position. The pre-stripping system includes a first shifting device for moving the insulating clamp from the first position to the second position; a second shifting device used for moving the insulating clamp from the second position to the first position; a pre-stripping device used for forming a pre-stripping opening between an electrolytic metal layer and the cathode plate, with the first shifting device, the second shifting device and the pre-strippingdevice being spaced apart; and a driving device capable of driving the cathode plate to move among the first shifting device, the pre-stripping device and the second shifting device. According to thepre-stripping system, automatic electrolytic metal layer pre-stripping can be achieved and the pre-stripping efficiency is high.

Owner:JIANGXI NERIN EQUIP

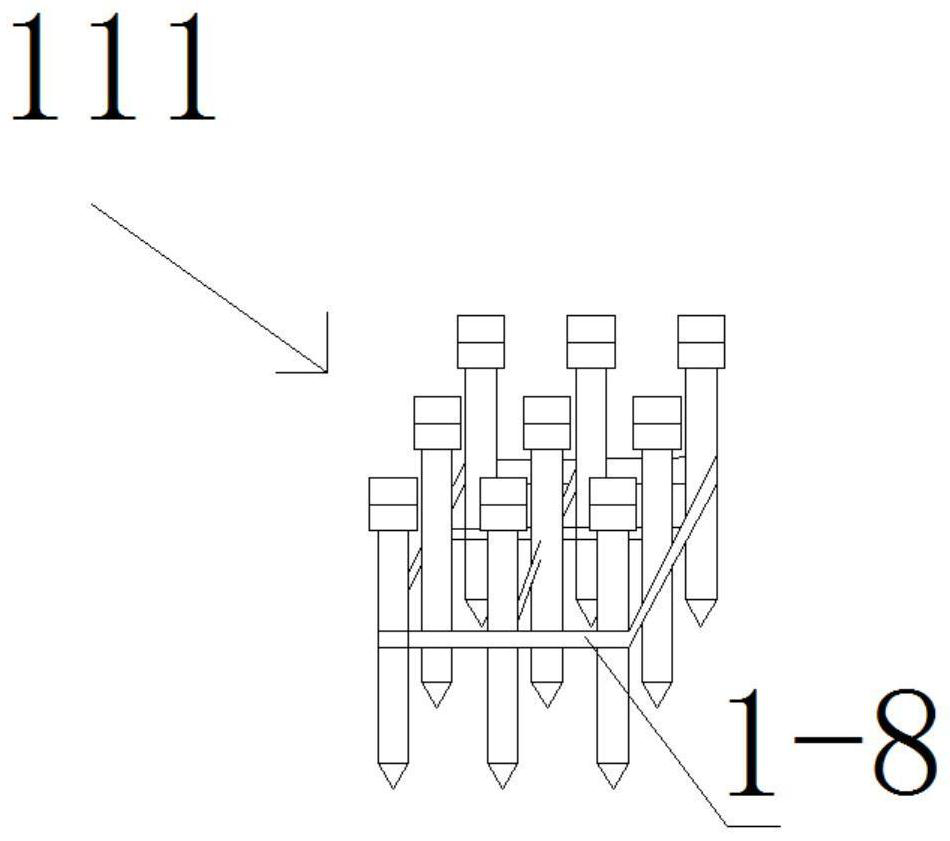

Vehicle-mounted automatic soil sampling device

PendingCN111076970AReal-timeRealize remote transmissionWithdrawing sample devicesSatellite radio beaconingSoil scienceIn vehicle

The invention relates to a vehicle-mounted automatic soil sampling device. The device comprises a GPS positioner, a supporting frame, a vehicle-mounted connecting device, a power controller, a supportejector rod, a support, a hydraulic pump, a power source, a lifting driving device, a soil stripper and a soil sampling drill. A bottom groove extends out of a car hopper, the soil sampling drill islifted by the lifting driving device, the lifting driver drives the soil sampling drill to collect a soil sample in a target area, and when the soil sampling drill reaches the soil sampling depth, thesoil sampling drill is lifted to a fixed position, the soil stripper strips soil, thus completing the soil sampling operation. According to the method, the land parcel in the soil sampling area can be put on line, the position coordinates of the soil sampling point can be planned in advance according to the shape of the land parcel, a soil sample of the planning point can be collected according to the GPS positioning function, and the coordinate points can be recorded on line.

Owner:SINOCHEM AGRI HLDG

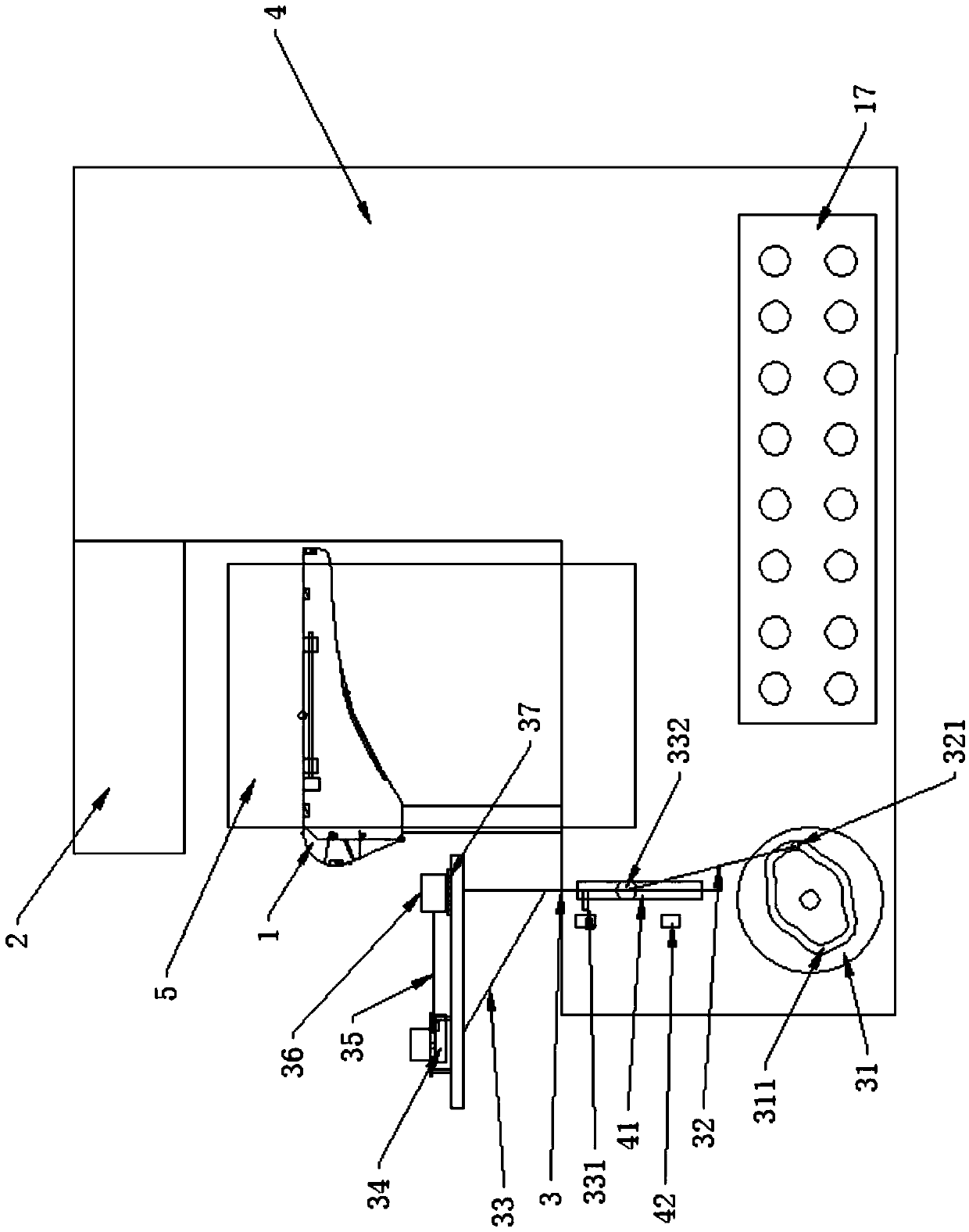

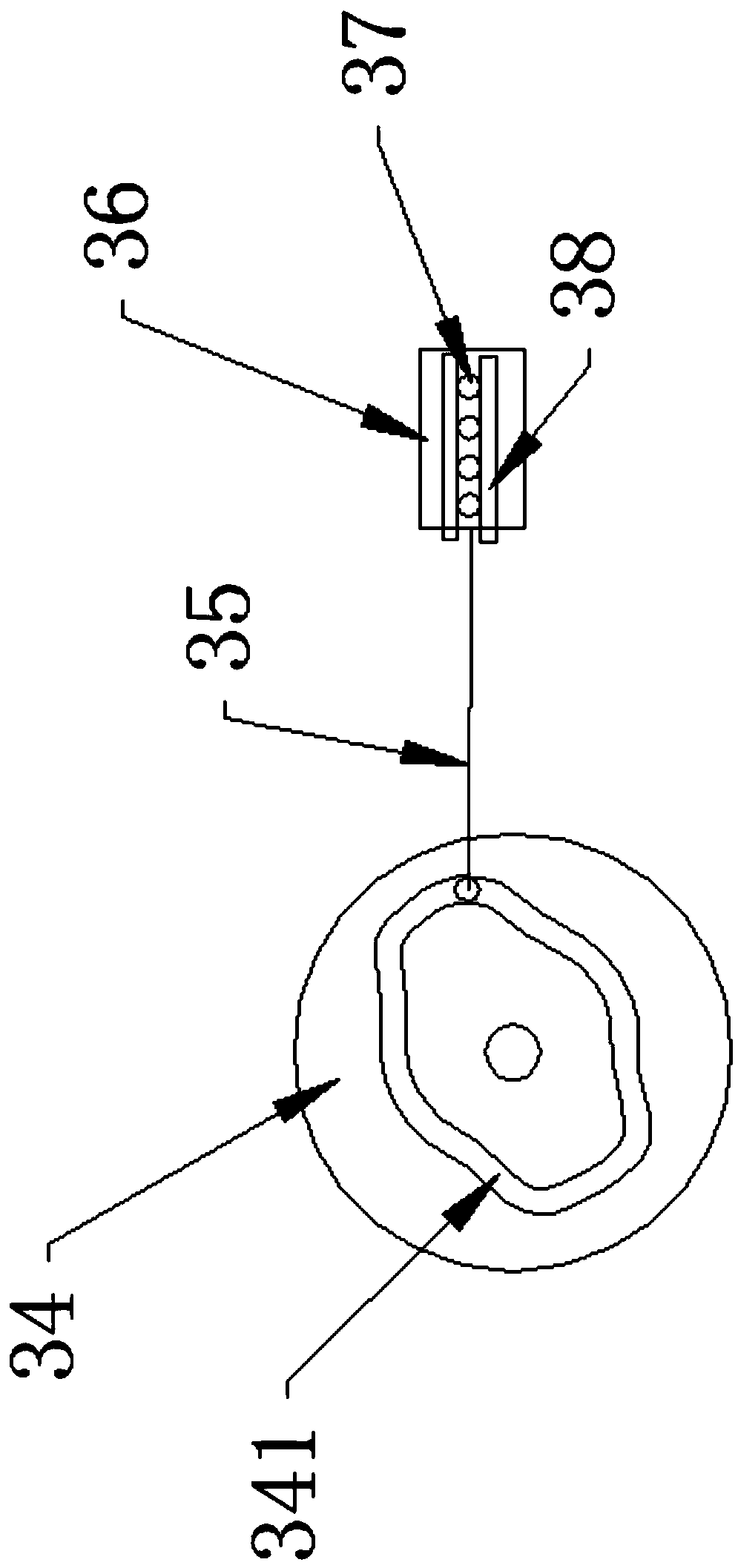

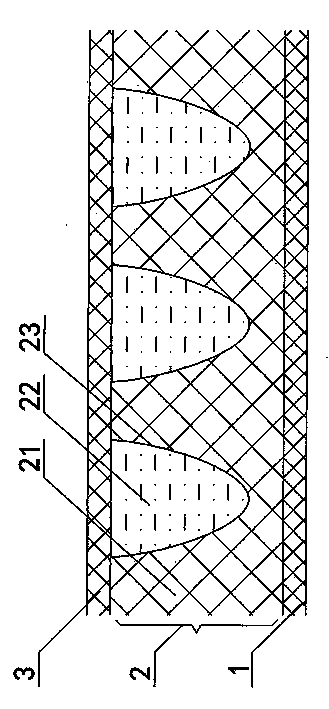

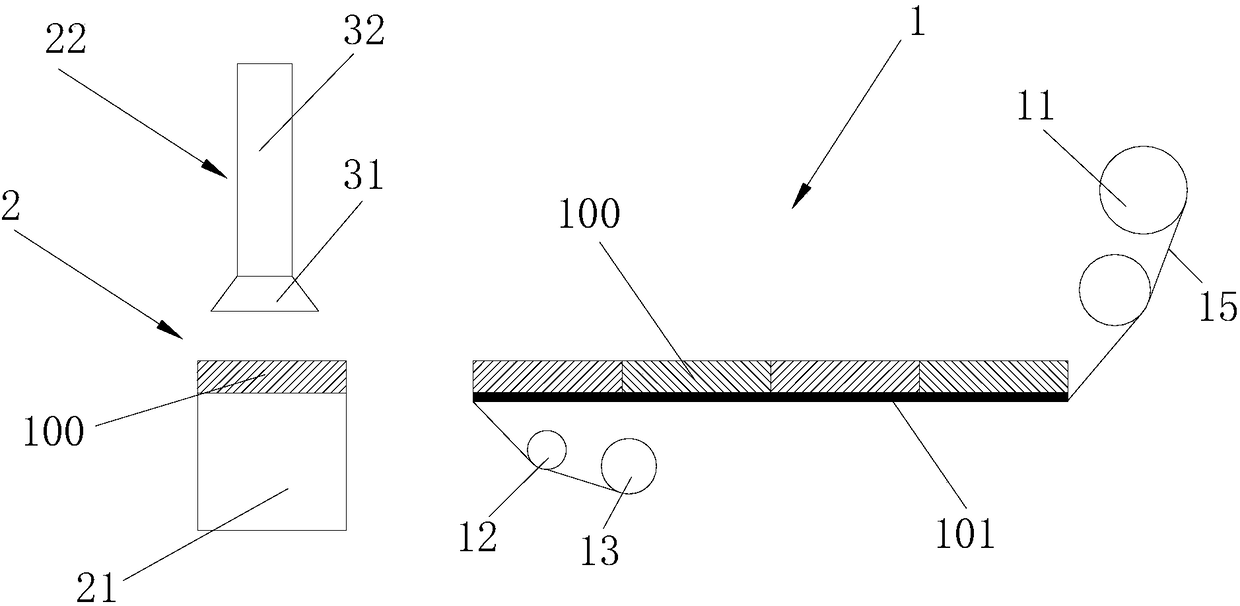

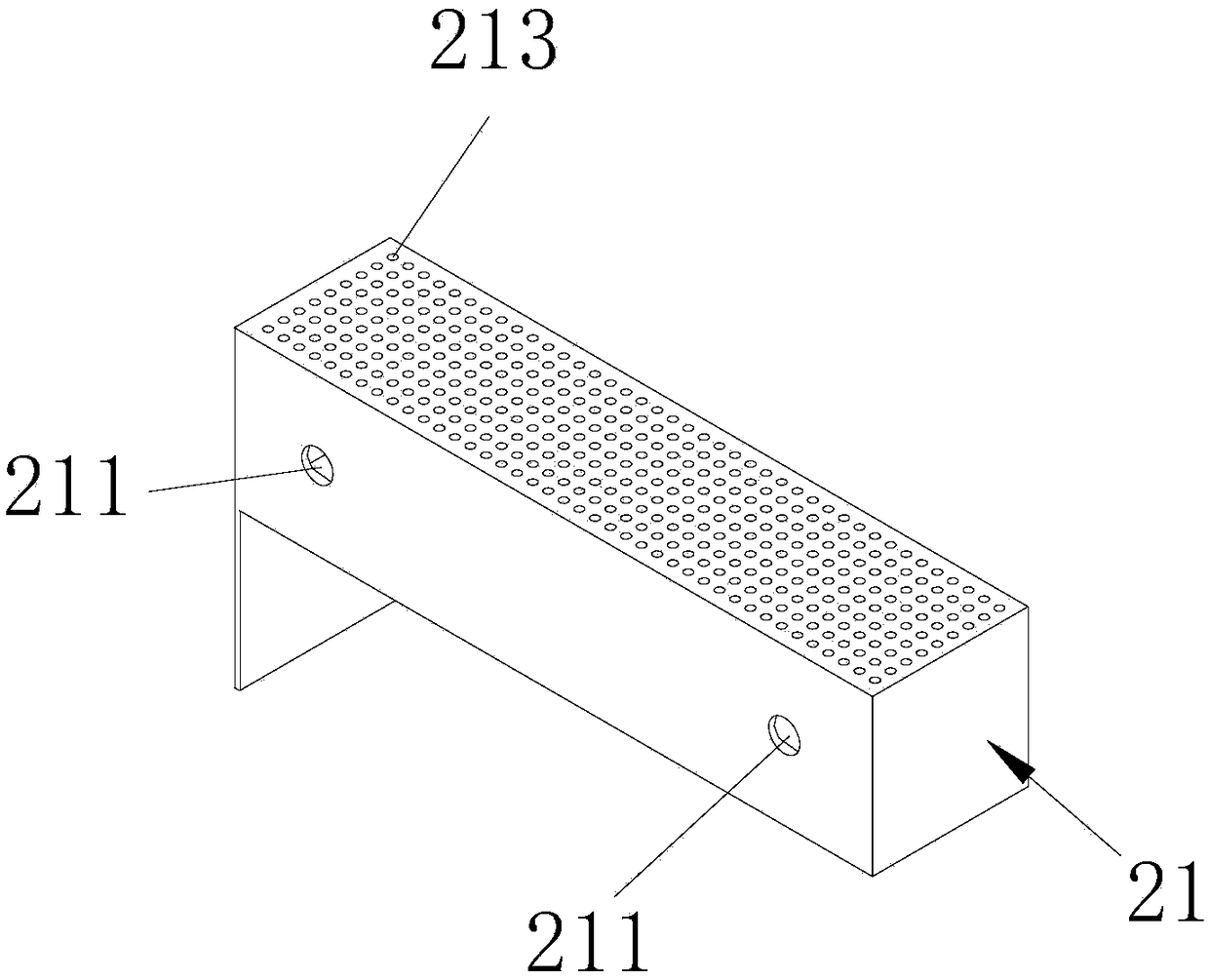

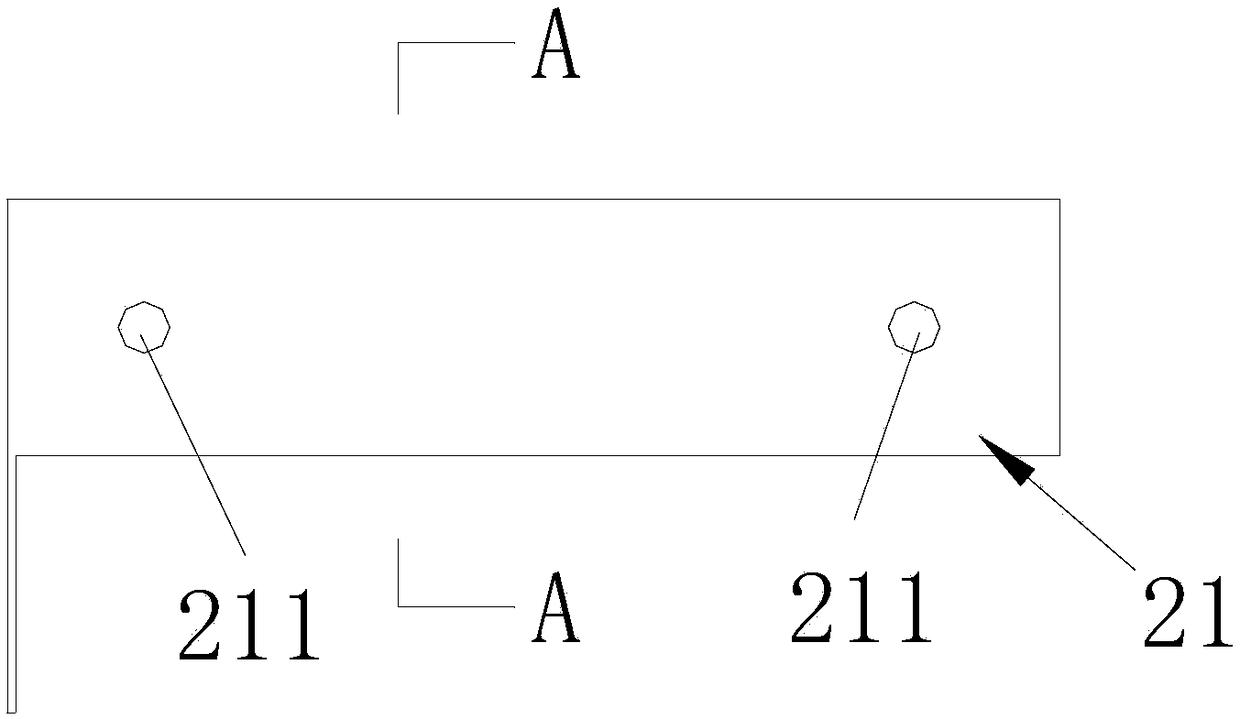

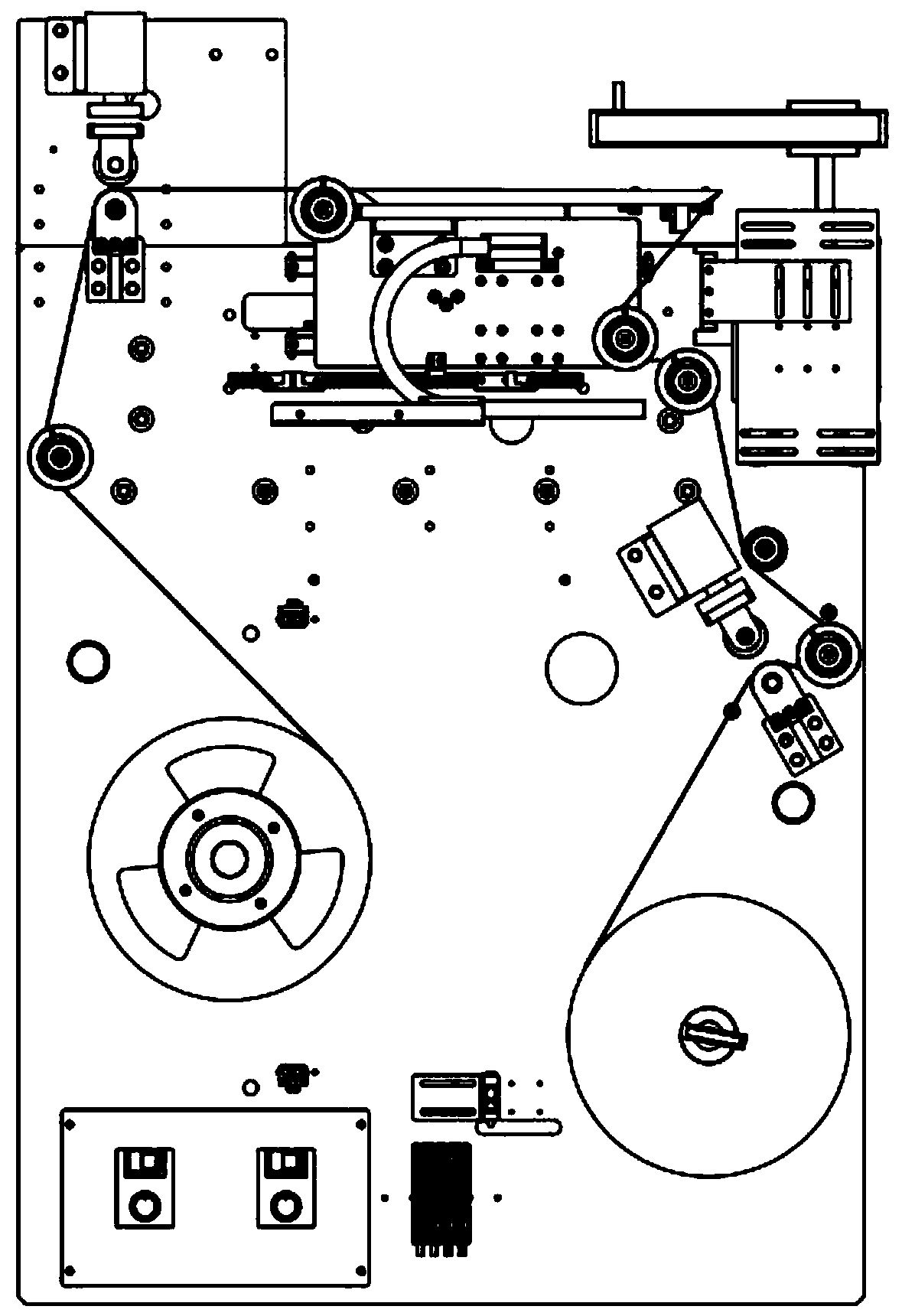

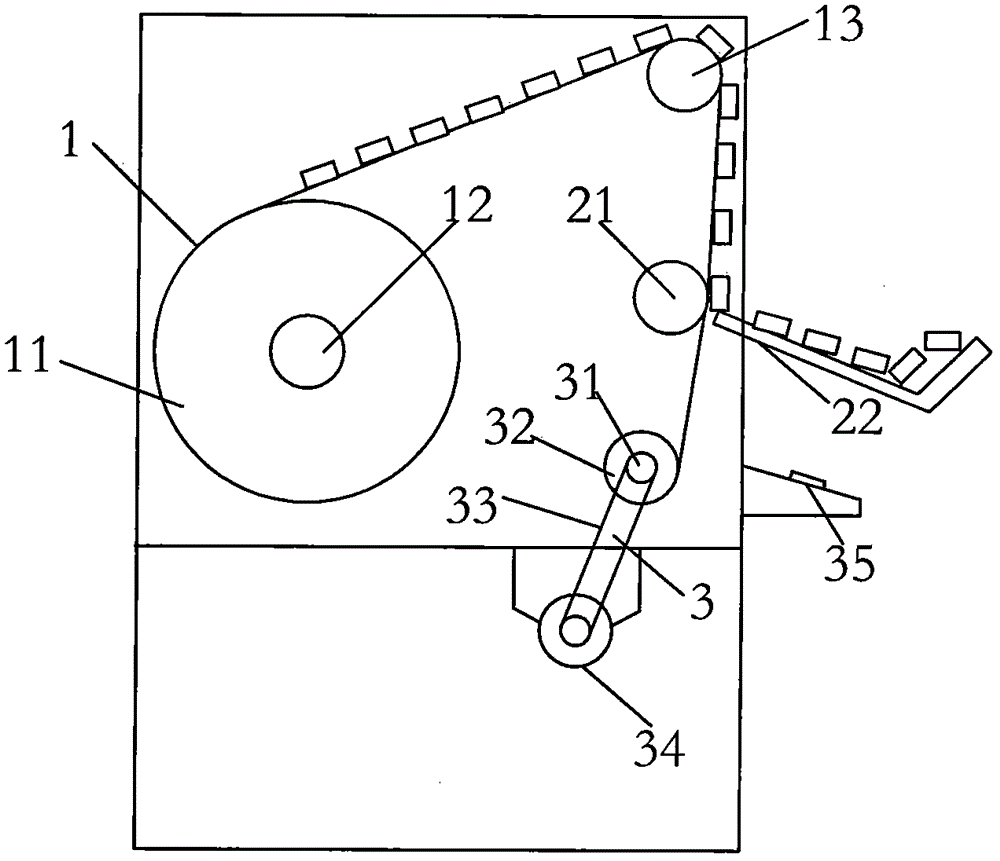

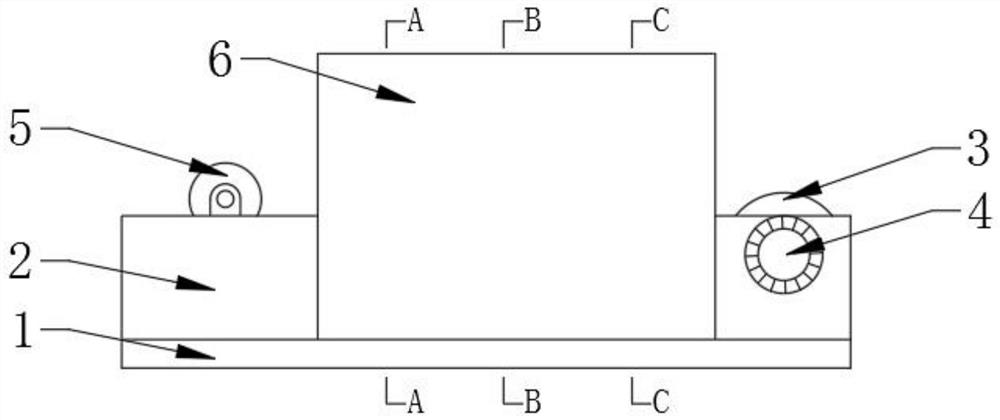

Intelligent material rolling device

InactiveCN105882108ARealize automatic strippingReduce labor costsLamination ancillary operationsLaminationEngineeringMaxillary gingiva

The invention relates to the field of automation production and discloses an intelligent material rolling device. The device comprises a discharging mechanism (1), a peeling mechanism (2) and a material collecting mechanism (3) which are mounted on a rack, wherein the discharging mechanism (1) is used for fixing a discharging barrel (11) of a material roll, the discharging barrel (11) is connected to the rack through a discharging cross shaft (12), and the material roll is mainly composed of release paper and a to-be-peeled gum sponge attached to the release paper; the peeling mechanism (2) comprises a peeling shaft (21) and a sliding-off plate (22), and a gap is reserved between the peeling shaft (21) and the sliding-off plate (22), wherein the gap is large enough to allow the release paper to go through but cannot allow the to-be-peeled gum sponge to go through; the material collecting mechanism (3) comprises a material collecting shaft (31) which can rotate around the axis of the material collecting shaft (31), the material collecting shaft (31) is provided with a material collecting barrel (32) which is used for collecting the release paper output from the peeling mechanism (2), the material collecting shaft (31) is in transmission connection with a driving device, and the driving device is connected with a control unit at a minimum. By means of the intelligent material rolling device, the gum sponge can be peeled from the release paper automatically, labor cost is saved, and production efficiency is improved.

Owner:ANHUI HONGSHI AUTOMATION EQUIP CO LTD

Automatic detection, automatic dispensing and automatic sorting device for LED lamp beads arranged in array mode

ActiveCN114833031AAvoid secondary repair useRealize automatic strippingLiquid surface applicatorsCoatingsComputer hardwareControl system

The invention relates to an automatic detection, automatic dispensing and automatic sorting device for LED lamp beads arranged in an array, which comprises a chip detection device for detecting whether each chip in the LED lamp beads arranged in the array works normally or not and a dispensing device for dispensing the chips in the LED lamp beads arranged in the array, the dispensing device comprises a plurality of dispensing machines arranged in an array, and the chip detection device is used for detecting whether each chip in the LED lamp beads arranged in the array works normally or not. Each dispensing machine corresponds to one LED lamp bead needing to be dispensed, the chip detection equipment transmits a working state detection result of each chip in the LED lamp beads which are arranged in an array to the control system, and the control system recognizes the chips which work abnormally and coordinate information corresponding to the chips; the system controls the electric valve of the dispensing machine corresponding to the coordinates of the chip to be closed so as to stop dispensing on the abnormally working chip, the system further comprises a sorting device electrically connected with the control system, and the control system subsequently controls the sorting device to remove the abnormally working chip. The device can save fluorescent powder, glue and manpower.

Owner:深圳市华笙光电子有限公司

Cable internal metal stripping device in electric power engineering field

ActiveCN113328389AEasy to cutAchieve reductionApparatus for removing/armouring cablesElectronic waste recyclingMetal stripsEngineering

The invention discloses a cable internal metal stripping device in the electric power engineering field in the technical field of cable internal metal stripping. According to the cable internal metal stripping device, first cutters are uniformly and fixedly arranged on the inner wall of a protection box, adjusting screw rods are assembled on the front side and the rear side of a fixing plate in a threaded connection mode, a cutter head is fixedly assembled on a fixing disc through fixing bolts, second cutters are evenly and fixedly arranged on the inner wall of the cutter disc, guide rods are fixedly arranged at the bottom parts of the two sets of fixing discs, a fixing base connected to the outer walls of the guide rods in a sleeving mode is fixedly arranged at the top part of the base, fixing cylinders are fixedly arranged at the front end and the rear end of a limiting plate correspondingly, and the output ends of the four sets of electric telescopic rods penetrate through the fixing cylinders and then are fixedly provided with clamping plates matched with the fixing cylinders. Therefore, insulation materials can be cut in the horizontal direction and the circumferential direction, insulation material blocks on the outer wall of a cable can be extruded and removed, metal in the cable can be automatically stripped, manual operation is not needed, and the automation degree is high.

Owner:昭通浩鑫工程有限公司

LED decorative light strip outer surface acrylic particle coating device

The invention belongs to the technical field of LED decorative light strip production, and relates to an LED decorative light strip outer surface acrylic particle coating device. The coating device includes a machine frame. The machine frame is provided with a light strip feeding mechanism and a double-side adhesive tape coating mechanism, the machine frame is further provided with an acrylic particle coating mechanism, the acrylic particle coating mechanism includes a coating motor fixed to the machine frame and a coating rotary disc connected with the coating motor, the coating rotary disc is detachably provided with a plurality of rubbing components capable of rotating in the circumferential direction, rubbing channels are formed between the rubbing components, thus light strips can penetrate through the rubbing channels, and when the light strips penetrate through the rubbing channels, contact matching of the rubbing components and the outer surfaces of the light strips is formed.According to the LED decorative light strip outer surface acrylic particle coating device, the defect of many personal errors of manual operation is overcome, and the work efficiency is improved.

Owner:TAIZHOU CITY DADI LIGHT DECORATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com