Continuous stepping device for screw plate of filter

A filter and screw plate technology is applied in the field of filter screw plate continuous stepping devices, which can solve the problems of wasting manpower and material resources, increasing production costs of molds and equipment, and cumbersome production processes, and achieving a solution space. Limitation, reducing equipment production costs, saving production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

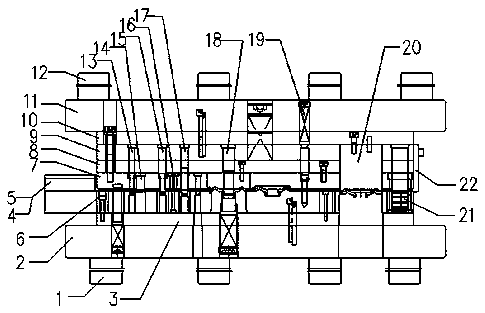

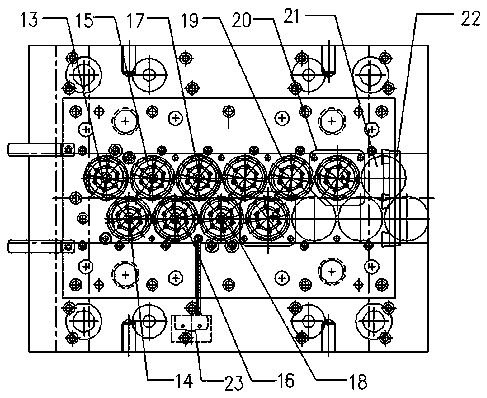

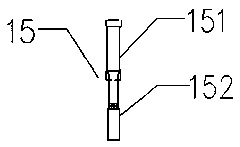

[0022] Such as Figure 1-2 As shown in , a filter screw plate continuous stepping device includes a frame, and the frame is sequentially provided with a lower pad iron 1, a lower template 2, a lower pad 3, a concave template 6, and a discharge plate from bottom to top. 7. Unloading back plate 8, fixed plate 9, upper backing plate 10, upper formwork 11, upper pad iron 12, a plate conveying device 24 is arranged between the concave formwork 6 and the unloading plate 7, and the plate conveying device 24 presses It is set to continuously convey plates between adjacent processes in a step-by-step manner. A guide block I4 and a guide block II5 are provided at the front end of the plate conveying device 24. Between the upper template 11 and the lower template 2 according to the corresponding process From left to right, there are φ6 punching assembly 13, φ13 forming die assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com