LED decorative light strip outer surface acrylic particle coating device

An acrylic and outer surface technology, which is applied in the field of acrylic particle coating device on the outer surface of LED decorative light strips, can solve problems such as uneven rubbing, weak particle bonding, and uneven bonding of particles on the surface of the light strip, so as to improve work efficiency. Efficiency, the effect of overcoming human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

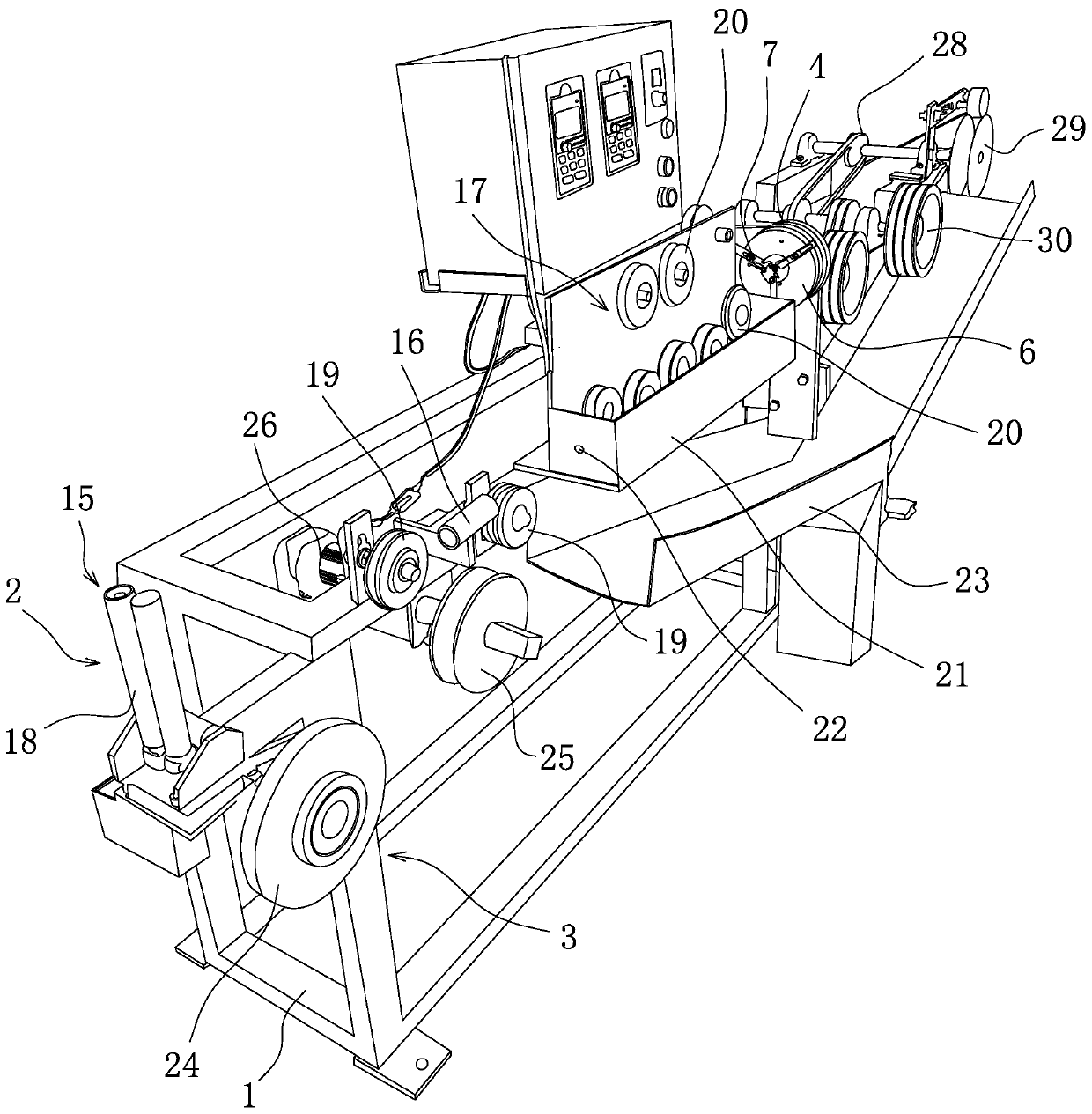

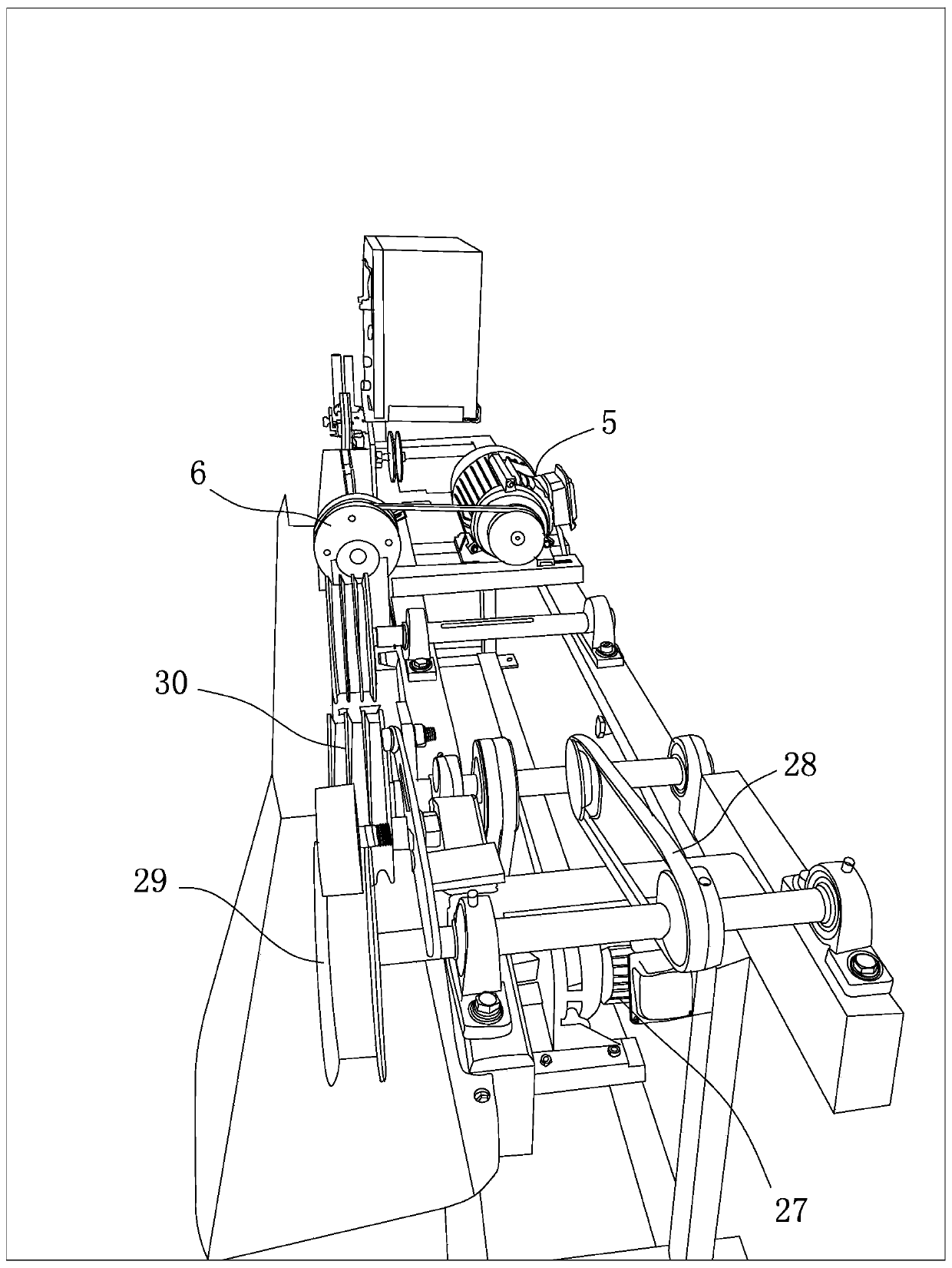

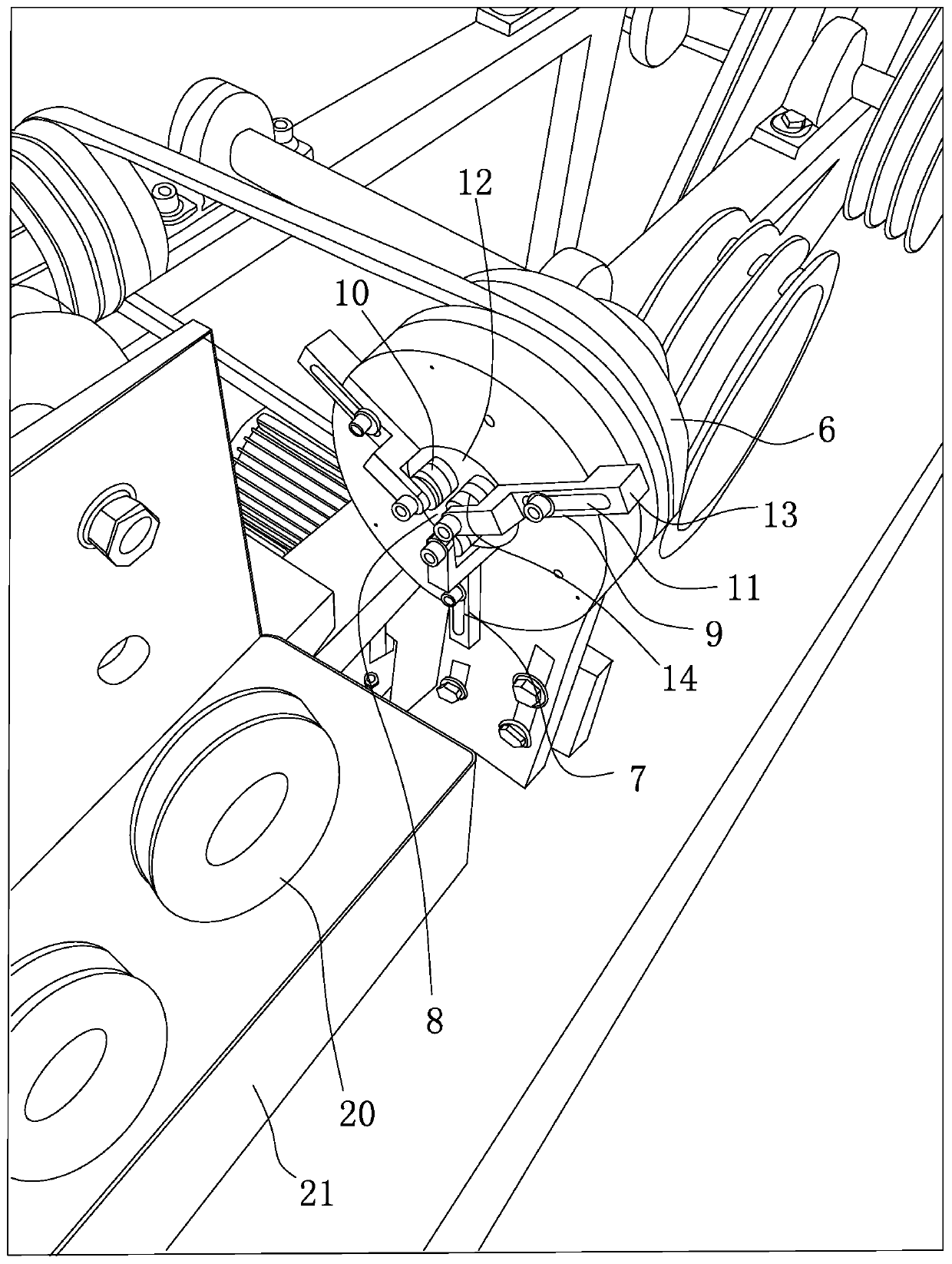

[0027] like Figure 1-3 As shown, a device for coating acrylic particles on the outer surface of an LED decorative light strip, including a frame 1, on which a light strip feeding mechanism 2 and a double-sided tape wrapping mechanism 3 are arranged, and the frame 1 is also provided with an acrylic particle coating mechanism 4. The acrylic particle coating mechanism 4 includes a coating motor 5 fixed on the frame 1, and a coating rotary table 6 connected to the coating motor 5. The coating A number of kneading components 7 that can rotate along the circumferential direction are detachably provided on the turntable 6, and a kneading channel 8 for the light strip to penetrate is formed between the several kneading components 7. When the light strip penetrates into the kneading channel 8 , the rubbing component 7 forms a contact fit with the outer surface of the lamp strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com