Aluminum composite plate

An aluminum composite panel and a composite panel technology, applied in the field of composite panels, can solve the problems of poor fire resistance, high cost of aluminum veneer, low yield of finished products, etc., and achieve the effects of good fire resistance, simple molding, and reduced quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

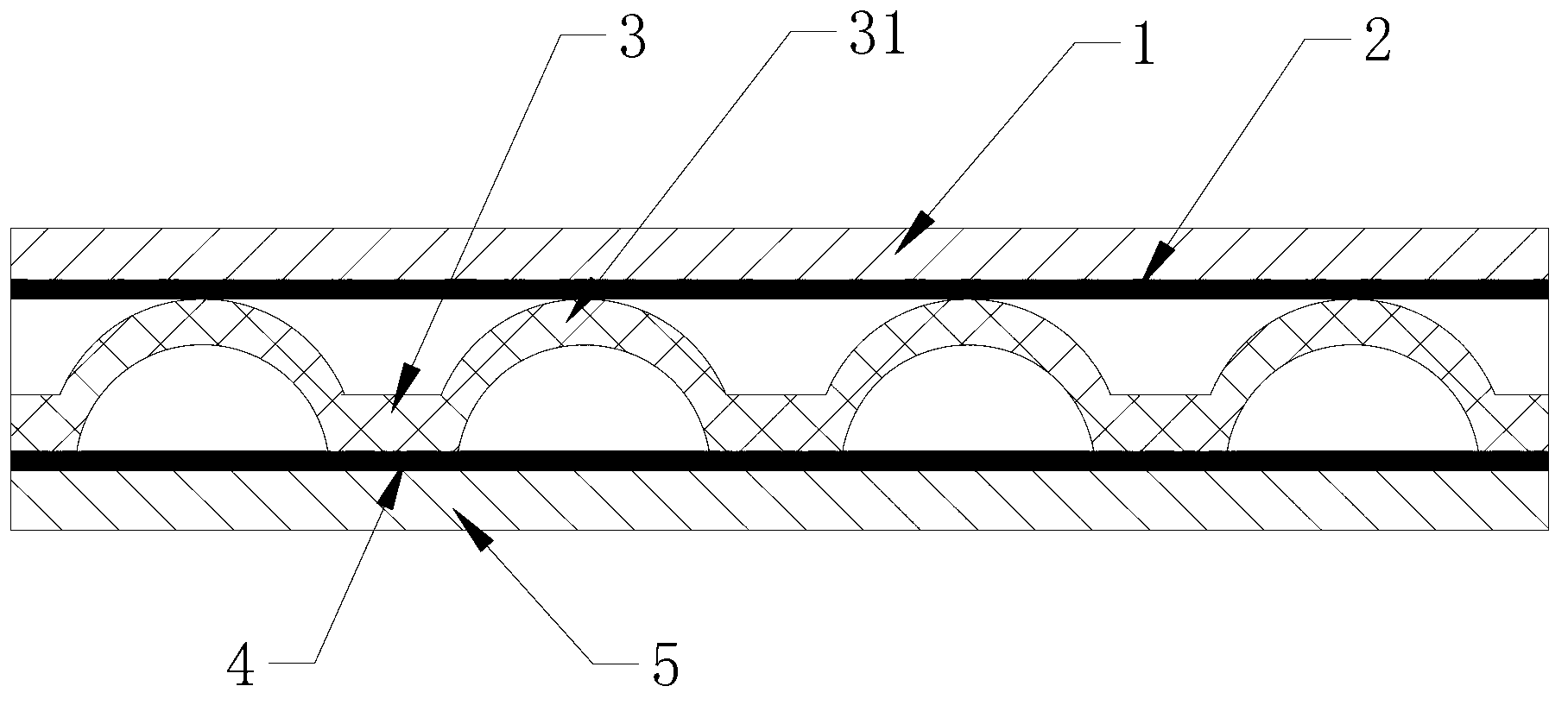

[0022] Such as figure 1 As shown, an aluminum composite panel comprises a core panel 3, a bottom panel 5 and a surface panel 1 adhered to both sides of the core panel 3, and the core panel 3, the bottom panel 5 and the surface panel 1 are all made of aluminum , preferably made of aluminum, several first protrusions 31 are evenly pressed on the core plate 3, and the protrusion height and protrusion direction of the first protrusions 31 are the same, and the bottom plate 5 and the surface plate 1 are glued together The layers are bonded to the core board 3 . Wherein, the surface board 1 is bonded with the first protrusion 31 of the core board 3 through the adhesive layer one 2, and the bottom board 5 is bonded with the board surface of the core board 3 through the adhesive layer two, and the first protrusion 31 It is a spherical protrusion, and of course it can also be in other shapes, such as an ellipsoidal protrusion or a prismatic protrusion. The prism shape may be a triang...

Embodiment 2

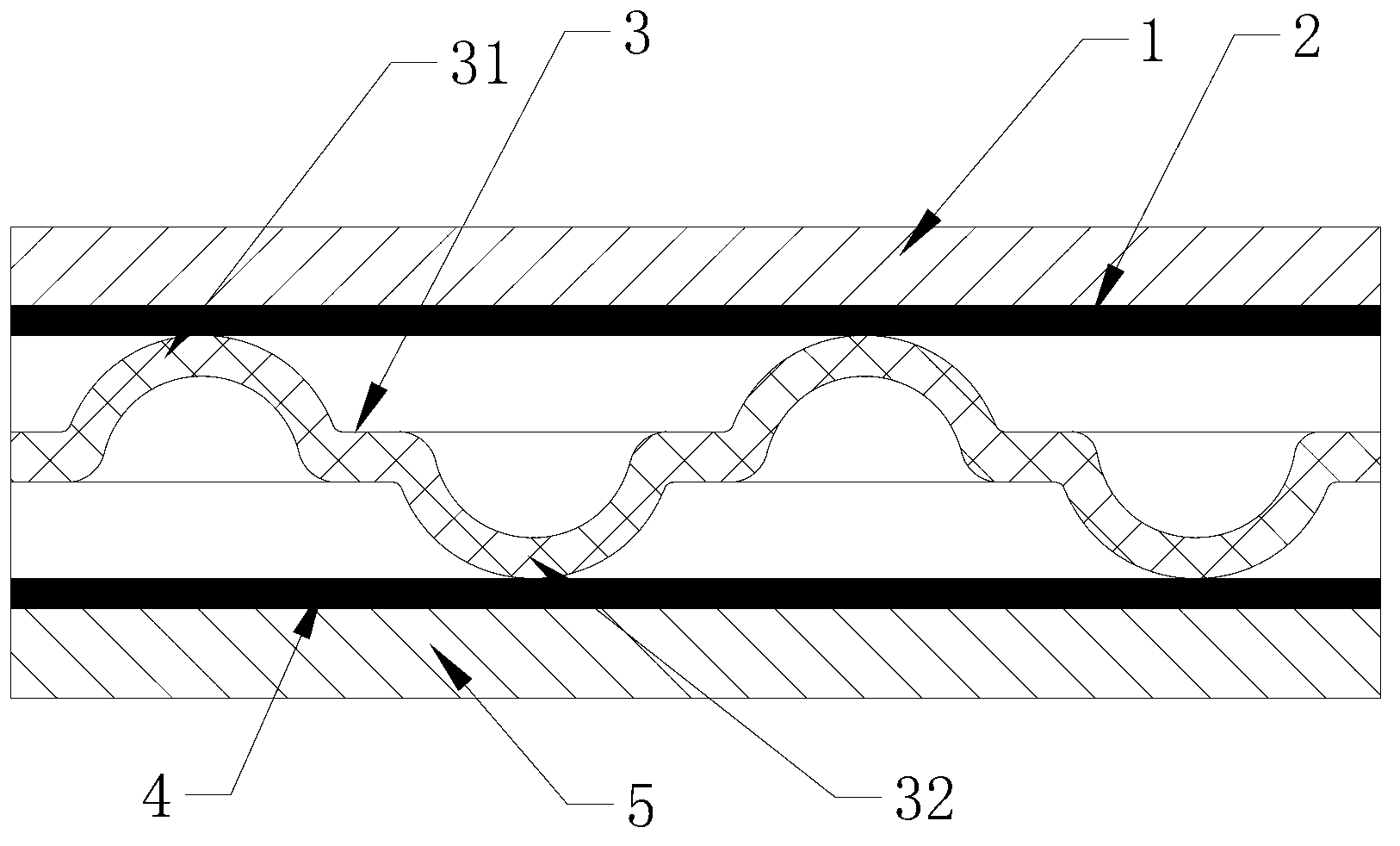

[0024] The structure of this embodiment is basically the same as that of Embodiment 1, except that the core board 3 also includes a plurality of second protrusions 32 with the same height, and the protrusion direction of the second protrusions 32 is the same as that of the first protrusions 31. The direction of the protrusion is opposite, and the first protrusion 31 and the second protrusion 32 are evenly staggered and arranged at intervals. The uniform staggered arrangement mentioned here means that the position of each first protrusion 31 is between the second protrusions 32 , and the position of each second protrusion 32 is between the first protrusions 31 . The first protrusion 31 and the second protrusion 32 have the same shape and are also spherical protrusions.

[0025] Wherein, the surface plate 1 is a color-coated aluminum plate, and the color-coated aluminum plate refers to a layer of protective film bonded on the surface plate 1 . The adhesive layer is a hot-melt a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com