Automatic laser auxiliary heat stripping type insulated cable stripper

A laser-assisted, insulated cable technology, applied in cable installation, cable installation devices, equipment for dismantling/armored cables, etc. Efficiency and project progress, simple and convenient operation steps, and the effect of improving work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

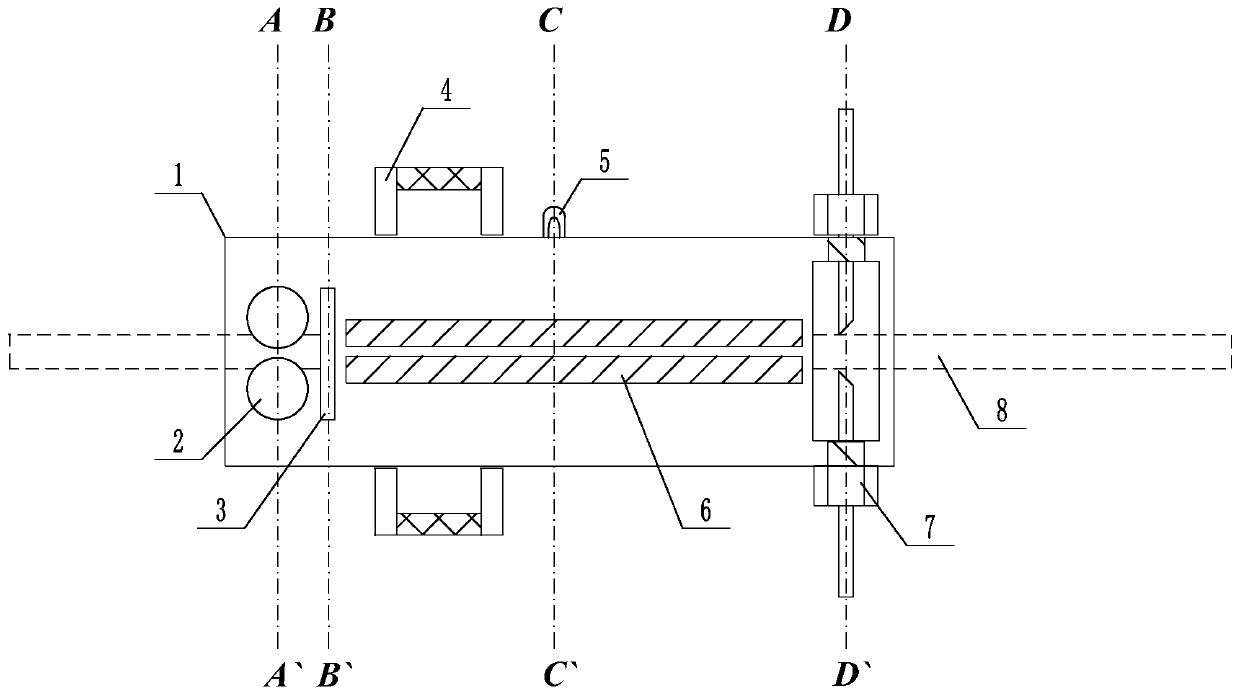

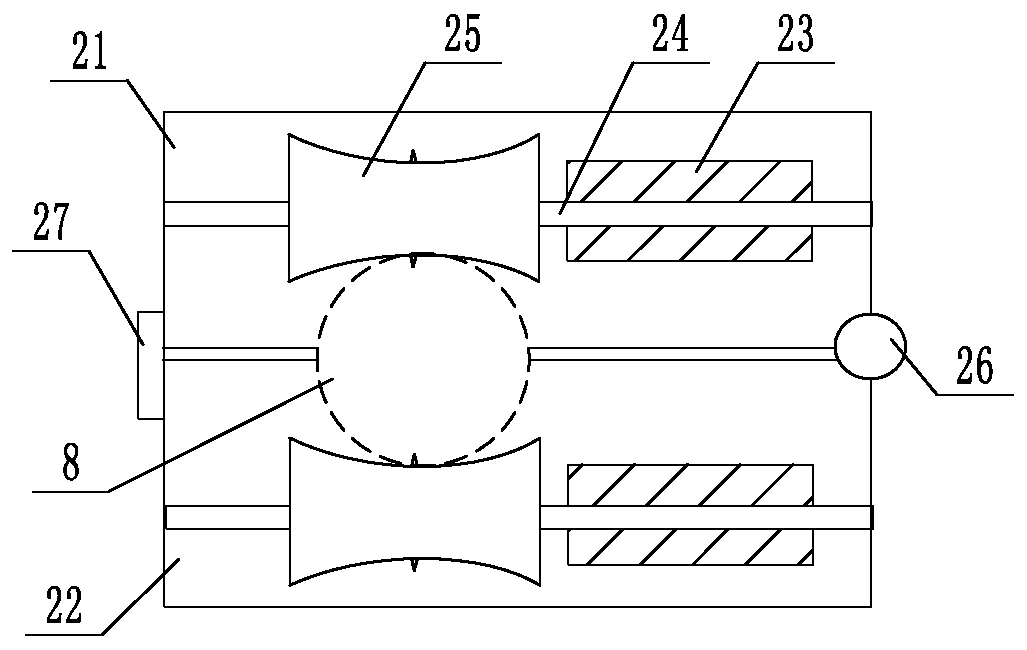

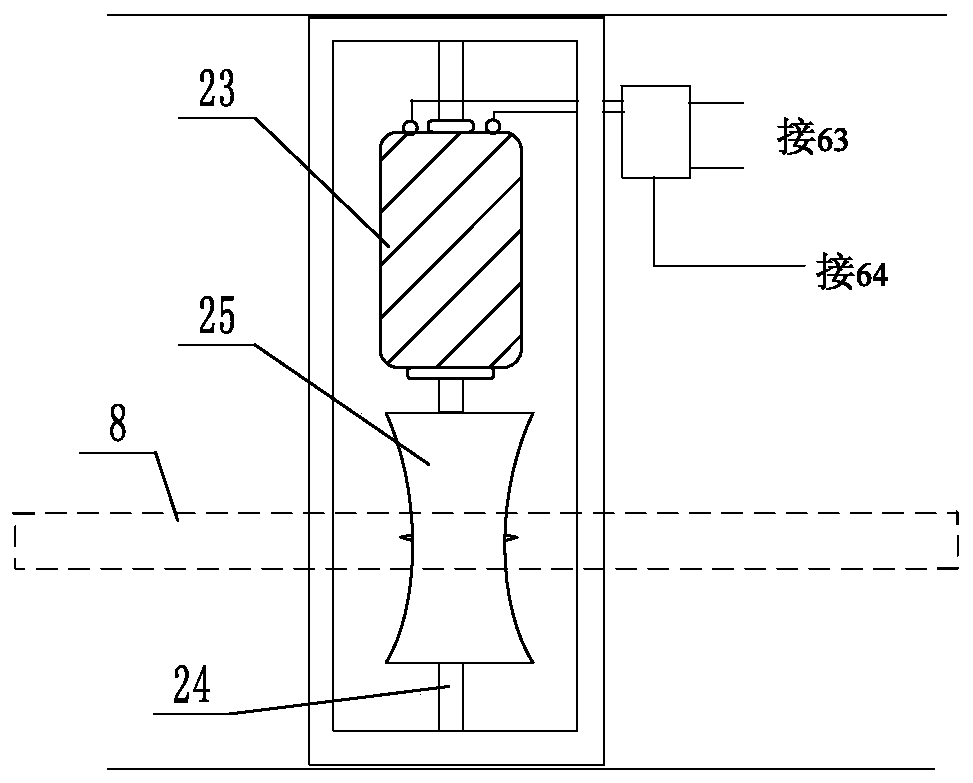

[0037] like Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a fully automatic laser-assisted thermal stripping insulation cable stripper, and the structure of the cable stripper is shown in the accompanying drawings. In the implementation of the present invention, the cable insulating protective layer is firstly treated with an ultraviolet laser to make part of the surface aging and deformed, and then the cable insulating protective layer is heated and softened by a temperature-controlled heating electrode, and then the softening layer is softened by using a blade and a cable traction motor. The final cable protective layer is stripped to achieve safe, efficient and automatic cable protective layer stripping. See the following description for details: the cable stripper includes a cable stripper box 1, and a cable pulling module 2, a laser pretreatment module 3, a heating module 6 and a stripping module 7 are installed in the cable stripper box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com